Bearing Vibration Analysis Guide: Detecting Issues in Cylindrical Roller Bearings

Introduction

Vibration analysis is the industry standard for predicting bearing failure. By measuring vibration frequencies, maintenance teams can identify specific defects—such as inner race spalling or cage damage—weeks before the machine actually breaks down.

In this guide, we will explore the principles of analysis, vibration limits, and how to interpret data specifically for cylindrical roller bearings.

What is Vibration Analysis and How Does It Work?

The Basics of Vibration Analysis for Cylindrical Roller Bearings

Instead of waiting for a loud noise or a seized shaft (reactive maintenance), vibration analysis allows for predictive maintenance—fixing issues only when necessary.

Key Sources of Vibration in Cylindrical Roller Bearings

-

Roller & Raceway Defects: Spalling or pitting on the contact surfaces creates high-frequency impacts.

-

Improper Lubrication: Insufficient grease causes metal-to-metal contact, generating “hash” or high-frequency noise in the spectrum.

-

Misalignment: If the bearing housing isn’t perfectly aligned with the shaft, it generates distinct vibration at 1x or 2x the running speed.

-

Assembly Errors: Forcing a bearing onto a shaft can deform the rings, leading to uneven operation.

How Vibration Analysis Works for Cylindrical Roller Bearings

-

Normal Vibrations: A smooth, steady hum indicates healthy cylindrical roller bearings.

-

Abnormal Vibrations: Jerky spikes or uneven rhythms suggest problems such as bearing wear, misalignment, or lubrication issues.

Tools You’ll Need for Vibration Analysis of Cylindrical Roller Bearings

-

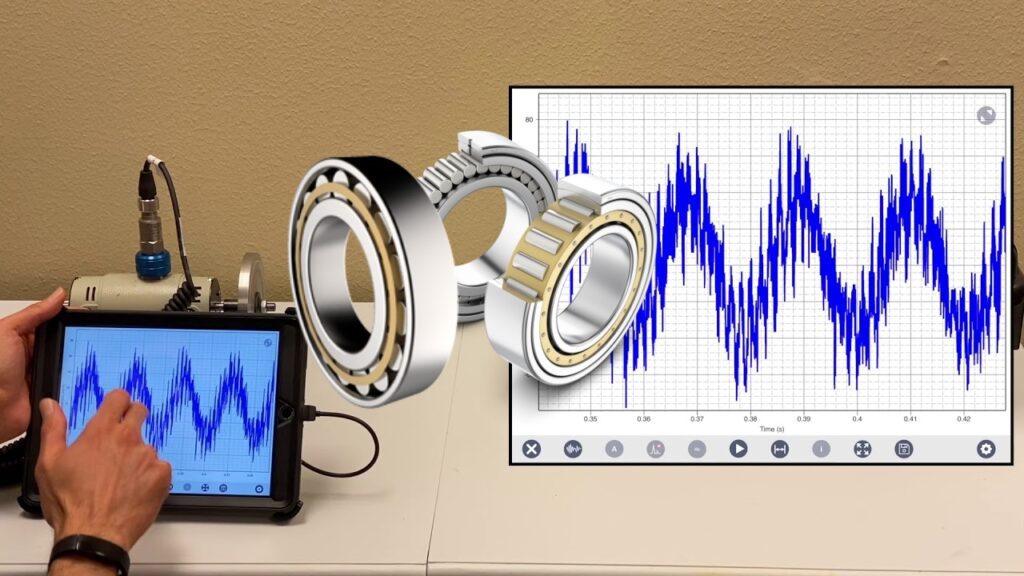

Accelerometers (Sensors): These measure the G-force of the vibration. For rolling element bearings, ensure your sensor has a high-frequency response range.

-

Data Collector/Analyzer: Software that converts the raw signal into a waveform or FFT spectrum (Fast Fourier Transform).

-

Mounting Method: Pro Tip: Avoid hand-held probes if possible. Use a magnetic mount or stud mount for more accurate, repeatable data.

Essential Tools for Analyzing Cylindrical Roller Bearings

-

Sensors: Sensors are essential for vibration research. These devices attach to the machine with cylindrical roller bearings and work like mics to catch vibrations. They sense even the small changes in vibrations, which makes them crucial for finding problems early.

-

Software: After the sensors gather vibration data, special software turns it into simple plots and charts. You can use free or low-cost apps like SpectraQuest or smartphone tools to examine data and spot issues in cylindrical roller bearings.

-

Your Senses: While technology plays a significant role, don’t underestimate the power of your own senses. For example:

-

Hearing: A grinding or rumbling noise often indicates a failing cylindrical roller bearing.

-

Touch: Excess heat around the bearing housing can signal friction or lubrication issues.

-

Standard Vibration Limits (ISO 10816 Reference)

Many engineers ask: “What is an acceptable vibration level?” While specific limits depend on machine class, here is a general reference for vibration velocity (RMS):

| Condition | Vibration Velocity (mm/s) | Action |

|---|---|---|

| Good | 0 - 1.12 | None |

| Satisfactory | 1.12 - 2.80 | Monitor |

| Unsatisfactory | 2.80 - 7.10 | Plan Maintenance |

| Unacceptable | > 7.10 | Stop & Check |

Note: These values are general references for medium-sized machines. Always consult your bearing manufacturer’s specifications.

How to Read Vibration Data for Cylindrical Roller Bearings

-

Compare to Baseline: Every machine has a “normal” vibration level, known as the baseline. If your readings show vibrations 20% or more above this baseline, it’s time to investigate further. For cylindrical roller bearings, even small deviations can indicate early signs of wear or misalignment.

-

Look for Patterns: Vibration graphs often reveal specific patterns that point to particular issues:

-

High-frequency spikes: These sharp peaks might show issues such as cracked rollers, not enough grease, or surface damage in cylindrical roller bearings.

-

Uneven waves: Irregular vibration patterns often suggest misaligned bearings or uneven load distribution.

-

-

Act Fast: Early detection is key. Small changes in vibration patterns today can escalate into major failures tomorrow. By addressing issues promptly, you can extend the lifespan of your cylindrical roller bearings and avoid costly downtime.

Benefits of Vibration Analysis for Cylindrical Roller Bearings

Early Detection of Bearing Wear or Damage

-

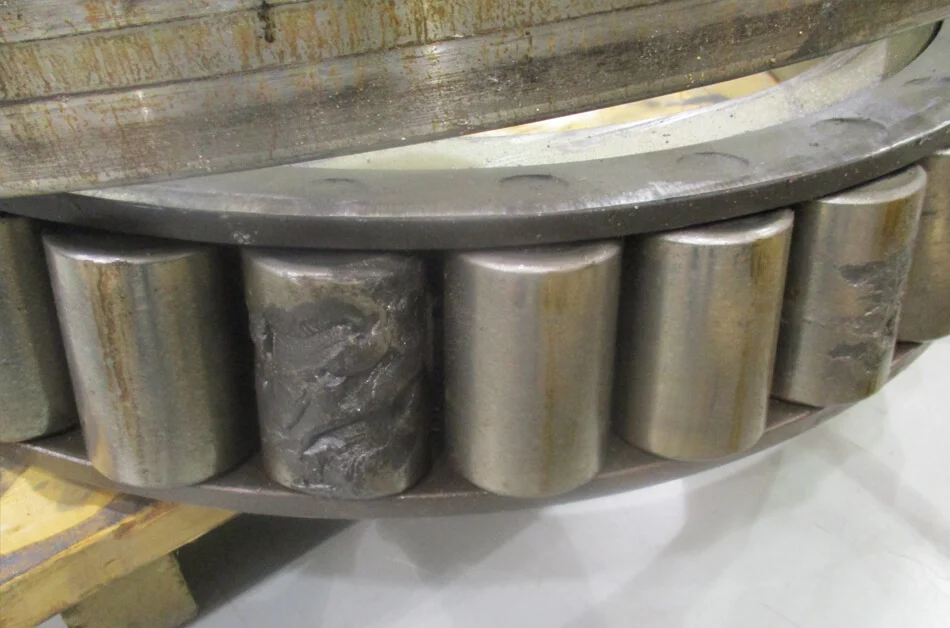

A small crack in a roller might only cost $20 to fix if caught early.

-

If ignored, that crack could shatter the bearing, costing $500+ and halting production.

Reducing Unplanned Downtime

-

Schedule repairs during slow periods.

-

Avoid “surprise” breakdowns that stop your work.

Saving Money on Repairs

-

Less damage to nearby parts (like shafts or housings).

-

No rush fees for emergency repairs.

Common Problems Detected in Cylindrical Roller Bearings

Misalignment Issues

-

Faster wear on rollers and raceways.

-

Extra stress on the machine’s frame.

Lubrication Failures

-

High-pitched squealing noises.

-

Overheated bearings (use a thermal gun to check).

Bearing Fatigue or Cracks

-

Noticing changes in vibration “harmonics” (like a guitar string going out of tune).

-

Alerting you to replace the bearing before it fails catastrophically.

How to Perform Vibration Analysis on Cylindrical Roller Bearings

Step-by-Step Setup for Vibration Testing

-

Preparation: Clean the mounting surface. Dirt or rust dampens the vibration signal.

-

Sensor Placement: Place the sensor as close to the load zone of the cylindrical roller bearing as possible.

-

Radial: Primary measurement direction.

-

Axial: Useful for checking misalignment.

-

-

Data Collection: Run the machine at a steady speed and record the spectrum.

-

Analysis: Look for peaks at specific “fault frequencies” (BPFO, BPFI) which indicate outer or inner race defects.

Best Practices for Accurate Data

-

Test regularly: Check bearings every 3–6 months (or more for heavy-use machines).

-

Record baseline data: Know what “normal” looks like for your equipment.

-

Check multiple points: Test different spots on the machine to rule out other issues.

Interpreting Vibration Patterns

-

Low-frequency vibrations: Often mean looseness or misalignment.

-

High-frequency spikes: Likely cracks or lubrication problems.

-

Side note: If you’re unsure, compare your data to online guides or ask a specialist.

Best Practices for Maintaining Cylindrical Roller Bearings

Regular Inspection Schedules

-

Monthly: Quick visual checks for rust, leaks, or loose parts.

-

Quarterly: Basic vibration tests and grease top-ups.

-

Yearly: Deep inspections (disassemble bearings if needed).

Combine Vibration Analysis with Other Checks

-

Temperature checks: Use a thermal gun to spot overheating.

-

Sound checks: Listen for grinding or rattling noises.

-

Visual checks: Look for cracked seals or grease leaks.

Common Problems & Solutions

-

High-Frequency Noise: Usually indicates lubrication failure. Check your grease quality and quantity immediately.

-

Low-Frequency Spikes: Often points to unbalance or looseness in the mounting, rather than the bearing itself.

-

Temperature Rise: If vibration is high AND the bearing housing is hot, the bearing is likely in the final stages of failure.

Conclusion

Detecting issues early through bearing vibration analysis saves time, money, and stress. It transforms maintenance from a guessing game into a precise science.

However, analysis is only useful if you start with high-quality components.

Need Durable Replacements?

At TFL Bearing, we engineer precision [Cylindrical Roller Bearings] designed to withstand heavy loads and rigorous operation.

-

[Browse Our Catalog]

-

[Contact Our Engineers] for advice on vibration troubleshooting.