NTN Insulated Bearings

Introduction

NTN Corporation was founded in 1918 and is headquartered in Nishi-ku, Osaka, Japan. The company is one of the world’s leading manufacturers of comprehensive precision machinery for a wide range of industries, including automotive, construction machinery, wind power, aircraft, space, trains, etc. NTN has accumulated decades of experience in the development of high-value-added functional modules and system products through the integration of proprietary materials, engineering design, computer control technology, and bearing technology. NTN Insulated Bearings are bearings with insulating properties and are typically used in applications where electrical isolation is required to prevent current from being conducted through the bearing to other components. NTN-insulated bearings ensure electrical isolation by applying an insulating treatment to some or all of the bearing surfaces.

What are NTN Insulated Bearings?

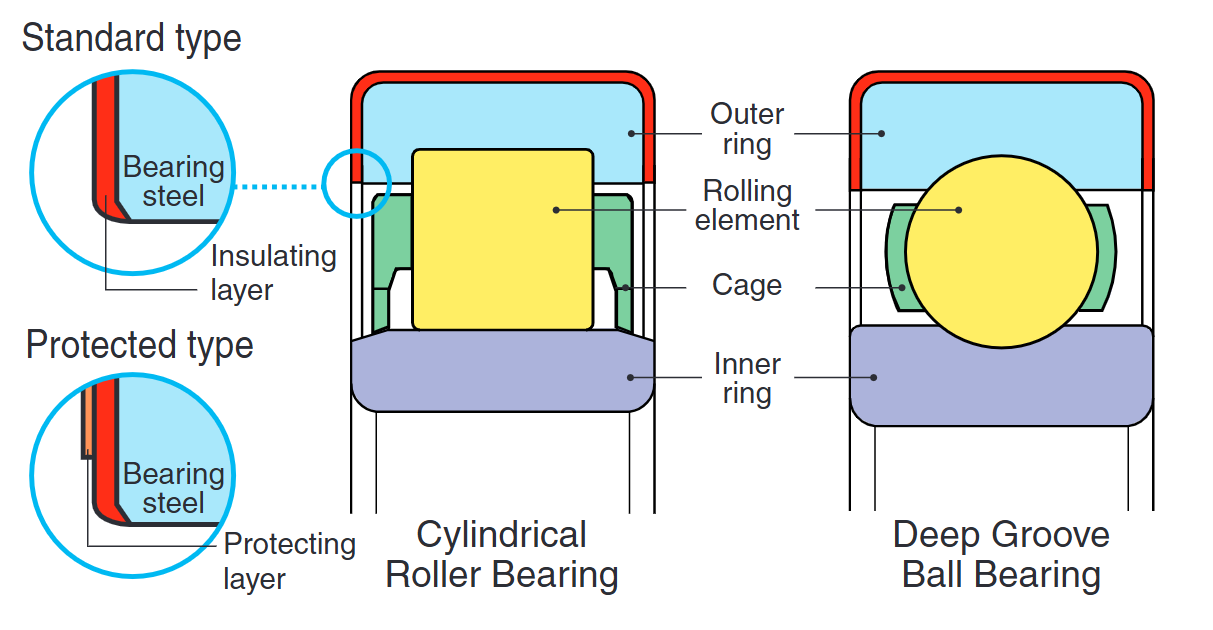

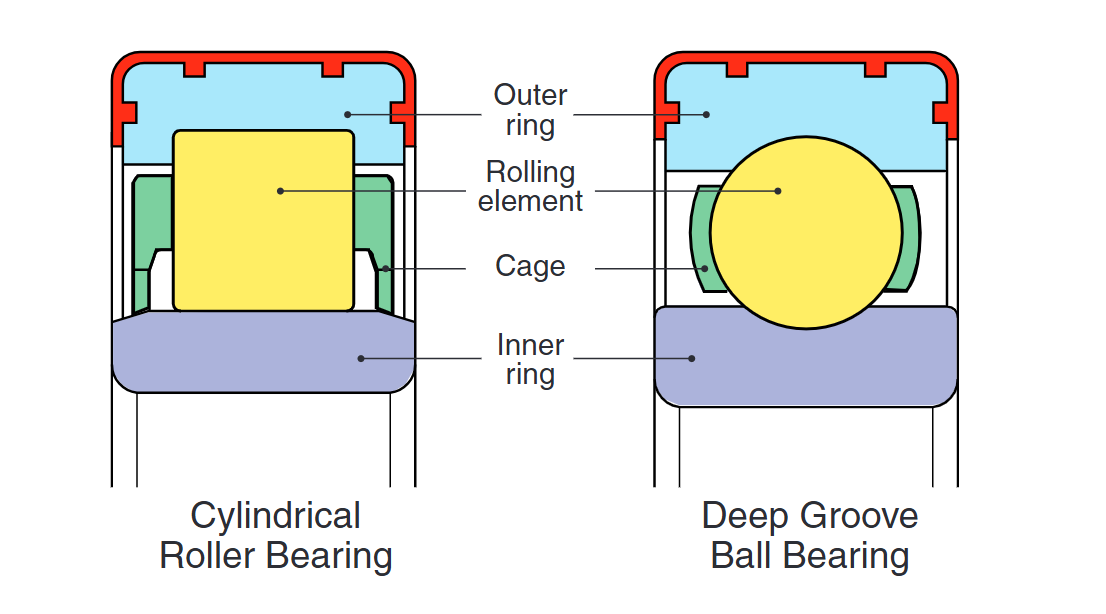

NTN insulated bearings are bearings with insulating properties, which are usually ensured by a special process of coating the outer or inner ring of the bearing with a layer of insulating material, or whose rolling elements are made of ceramics. The name and designation of insulated bearings adopt the international bearing designation; the outer ring insulated bearing designation is VL0241, and the inner ring insulated bearing designation is VL2071.

NTN MEGAOHM Series: Epitome of Excellence

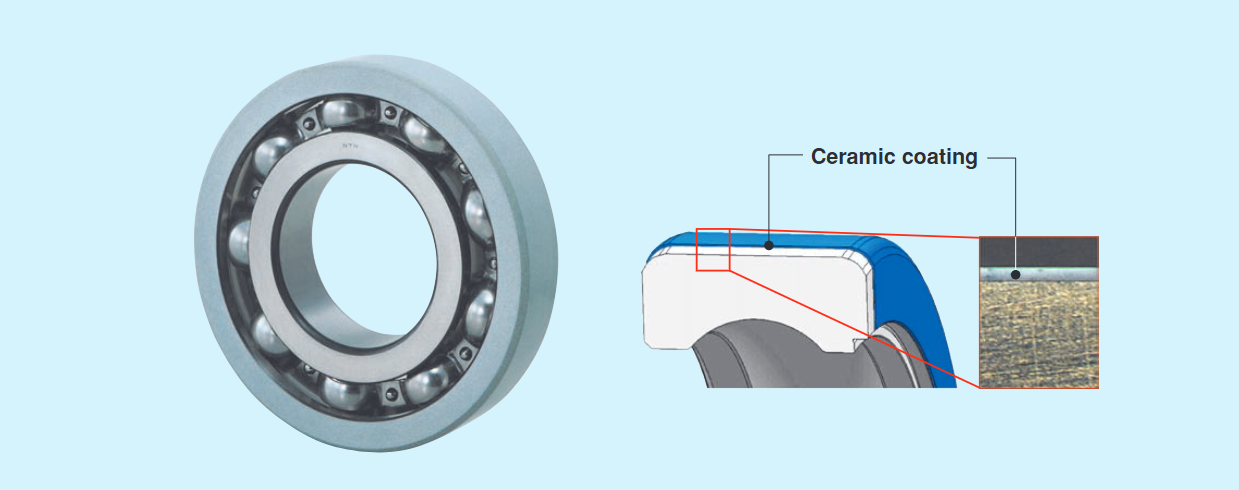

Bearings used in electrical equipment, such as motors and generators, often suffer from electrical pitting due to current leakage.NTN’s MEGAOHMS Insulated Bearing series is designed to counteract electrical pitting. These bearings are available in both ceramic and resin types for a variety of applications.NTN’s MEGAOHMS insulated bearings are bearings with high insulating properties and are mainly used in applications where electrical isolation is required. With a 50-200μm thick ceramic coating on the bearing surface, the bearings are able to withstand electrical pitting at 1000V and are suitable for high voltage motors and large motors, such as those over 400KW.

Ceramic Coating Technology: The Core of Insulation

NTN ceramic coating technology mainly includes multi-arc ion plating technology and thermal spraying technology.

- Multi-arc ion plating technology

The multi-arc ion plating technique is a method to prepare (Ti, Al)N coatings on Ti(C, N)-based metal-ceramic substrates. This technique systematically investigates the relationship between the composition, organization, and properties of Ti(C, N)–based metal-ceramics by experimental means such as scanning electron microscopy (SEM) and X-ray energy spectroscopy (EDS). It was found that when the C content was 0.7 wt%, better microstructure and higher mechanical properties could be obtained; when the Mo addition was 16 wt%, the flexural strength and hardness of Ti(C, N)-based cermet could reach up to 1930 Mpa and 89.5 HRA, respectively.

- Thermal Spraying Technology

Thermal spray technology uses a concentrated heat source to melt a raw material and accelerate the spraying of molten particles onto the surface of a substrate. Thermal spray processes are often categorized according to the type of energy source used to melt the feedstock and include flame spraying, arc wire spraying, supersonic flame spraying, explosive spraying, and atmospheric plasma spraying. Thermal spray technology is used in a wide variety of applications, such as aircraft engines, gas turbines, and solid oxide fuel cells.

Insulation-coated bearings” for e-Axle

NTN Corporation (hereinafter referred to as NTN) has developed an electro-corrosion-resistant “Insulation Coated Bearing” for the electric vehicle (EV) and hybrid electric vehicle (HEV) triple power system (e-Axle). In order to prevent the passage of electric current inside the bearing, an insulating film is coated on the outer diameter and end face of the outer ring of the bearing, which can withstand voltages of 100V or more, and has excellent insulating characteristics, which is a good response to the market trend toward higher voltages in new energy vehicles.

NTN MEGAOHM Insulated Bearing

NTN’s MEGAOHMS insulated bearings are bearings with high insulating properties and are mainly used in applications where electrical isolation is required.

Advantages of MEGAOHM insulated bearings

MEGAOHM series insulated bearings offer the following unique advantages:

- Exhibits insulation resistance of at least 100 MΩ at 500 VDC.

- With a variety of insulation layer materials, high voltage resistance and shock resistance, can meet different user requirements.

- Conforms to ISO 492, DIN 620 and JIS 1514.

- Available in aperture sizes from 50 to 160 mm.

Specification of MEGAOHM insulated bearings

| 7MC | 7MC2 | 7MC3 | 7MP | 7MP2 | |

|---|---|---|---|---|---|

| High voltage resistance | 5kV | 3kV | 3kV | 5kV | 5kV |

- Ceramic insulated bearings: 7MC3-6330M2C3

| 7MC3 | 6 | 3 | 30 | M2 | C3 |

|---|---|---|---|---|---|

| 7MC: Protected ceramic layer type with high voltage resistance 7MC2: Protected ceramic layer type 7MC3: Standard type | Bearing type | Dimension series | Bore diameter | Cage | Clearance |

- Resin Insulated Bearings:7MP-NU214L1BC4P6

| 7MP | NU | 2 | 14 | L1B | C4 | P6 |

|---|---|---|---|---|---|---|

| 7MP: Standard resin type 7MP2: Heat-dissipating and creep-resistant resin type | Bearing type | Dimension series | Bore diameter | Cage | Clearance | Tolerance |

Performance of MEGAOHM insulated bearings

The various features of the insulated bearings MEGAOHMTM Series are summarized below. Choose the configuration that best suits your application.

| Ceramic | Resin | Ceramic Rolling Element (reference) | |

|---|---|---|---|

| Insulation performance | Excellent | Excellent | Excellent |

| Creep resistance | Excellent | Normal | Excellent |

| Heat dissipation | Excellent | Normal | Excellent |

| Shock immunity | Normal | Normal | Excellent |

| Price | Normal | Excellent | Poor |

Features of MEGAOHM insulated bearings

Key features of MEGAOHMS insulated bearings include:

- High insulation performance: the bearing surface has a layer of 50-200μm thick ceramic coating, which is able to withstand the electric jump fire under 1000V voltage, and is suitable for high-voltage motors and large motors, such as motors over 400KW.

- Wide range of applications: applicable to motors and generators, especially inverter motors, it can effectively prevent the impact of shaft current on the motor and improve the operational stability and life of the motor.

NTN’s New Development – Insulation Coated Bearings

In recent years, various industries have been promoting decarbonization and emission reduction, so the automotive market is also accelerating the development and popularization of environmentally friendly models led by EVs and HEVs. These vehicles, which use electric motors as their main power source, are equipped with a triboelectric system (e-Axle) that combines an electric motor, an inverter, and a gearbox. e-Axle is driven by electric power, but when an electric current passes through the inside of the bearings, sparks are generated, which leads to corrosion and spalling of the metal tissues. overcoming galvanic corrosion due to leakage currents is a problem for bearings used in triboelectric systems.

Advantages of Insulation Coated Bearings

- Electrical corrosion resistance: By coating the outer diameter and end face of the outer ring of the bearing with an insulating coating, the electric current passing through the inside of the bearing is weakened, making it insulating enough to withstand voltages of 100V or more. The voltage that bearings for motors can withstand is generally less than 10% of the battery voltage, so even if the battery voltage increases to 800V in the future, the bearings will be able to adapt.

- Heat dissipation: Since the thickness of the coating takes into account both galvanic corrosion resistance and heat dissipation, it has the same heat dissipation as the uncoated standard product.

- Wear resistance: Insulating film has a low coefficient of friction and good wear resistance, which can reduce the total wear between the outer ring O.D. and the inner wall of the bearing box by 88% compared with the standard product without coating. Even if the fixed outer ring creeps and slips, the coating thickness required for insulation can be maintained.

Handling Precautions

- To avoid accidents or malfunctions due to damage to the insulating bearings, carefully observe the following.

- Do not drop the insulated bearings or hit them directly with a hammer during installation.

- Do not use insulated bearings with visible surface defects or abnormal appearance.

- Connecting electrical conductors to insulated bearings reduces the insulation resistance of the bearings.

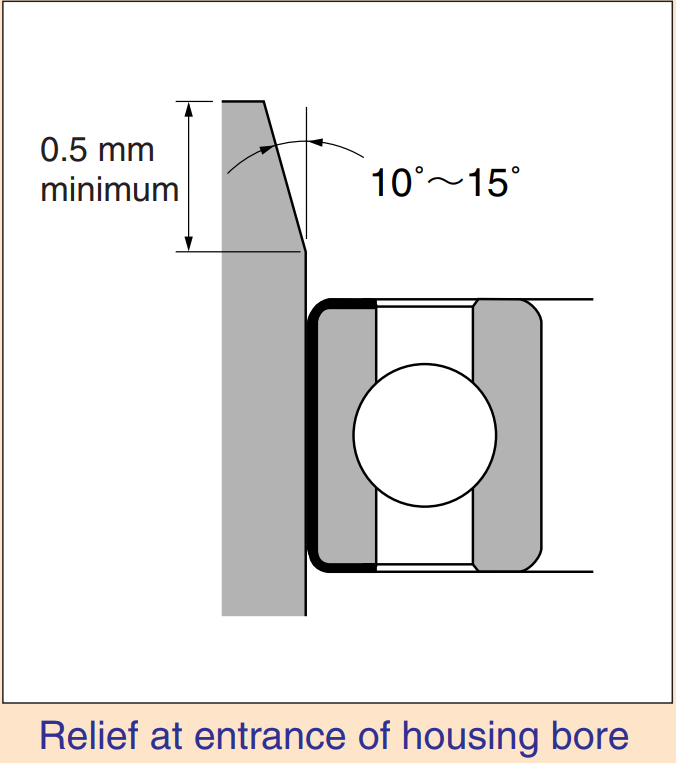

- To prevent current from flowing out of the side of the bearing, strictly observe the mounting dimensions given in the dimension table for the required shoulder height.

- Providing approximately 15° backspacing at the housing entrance will facilitate assembly.

- For DC motors, such as those used in railroad vehicles, the shaft is grounded during the withstand voltage test.

Excessive shock can damage the insulation and may result in electrical pitting. Electrical pitting can, in turn, damage the bearing, resulting in abnormal bearing performance and possible incorrect operation or malfunction.

Electrical Resistance Measurement: Ensuring Optimal Insulation

The resistance measurement method of NTN insulated bearings mainly includes the following steps and tools:

Use of Insulation Resistance Measuring Instruments: NTN insulated bearings are usually measured using specialized insulation resistance measuring instruments. These instruments are designed with a surface film contact body, usually made of conductive rubber and other conductive polymer materials, to ensure good contact with the insulating surface film of the outer ring of the bearing so as to accurately measure the insulation resistance value.

Measurement steps:

- Covered metal tape conductive medium: Measurement is carried out with a metal tape conductive medium (e.g. copper tape, aluminum foil, etc.) wrapped around the outside of the bearing. This method is more common in bearing manufacturing enterprises, but due to the poor metal conductive medium and insulation coating contact, the test results may not be accurate.

- Measurement by pressing into the housing: Measurement is made by pressing the insulated bearing into the housing. This method is more common in the use of units, but due to the press-fitting may cause damage to the appearance of the bearing, is not suitable for the full inspection of the manufacturer.

Applications of NTN Insulated Bearings

NTN insulated bearings have a wide range of applications, such as electric vehicle fields, wind turbine generators, high-speed railroads, industrial motors and so on.

Innovation in Electric Vehicles

NTN-insulated coated bearings are widely used in applications requiring high voltage tolerance and good heat dissipation performance, such as the e-Axle system for electric vehicles. In electric vehicles, motor bearings need to withstand high voltages and frequent current changes. Insulation-coated bearings can effectively prevent galvanic corrosion and improve the system’s reliability and service life.

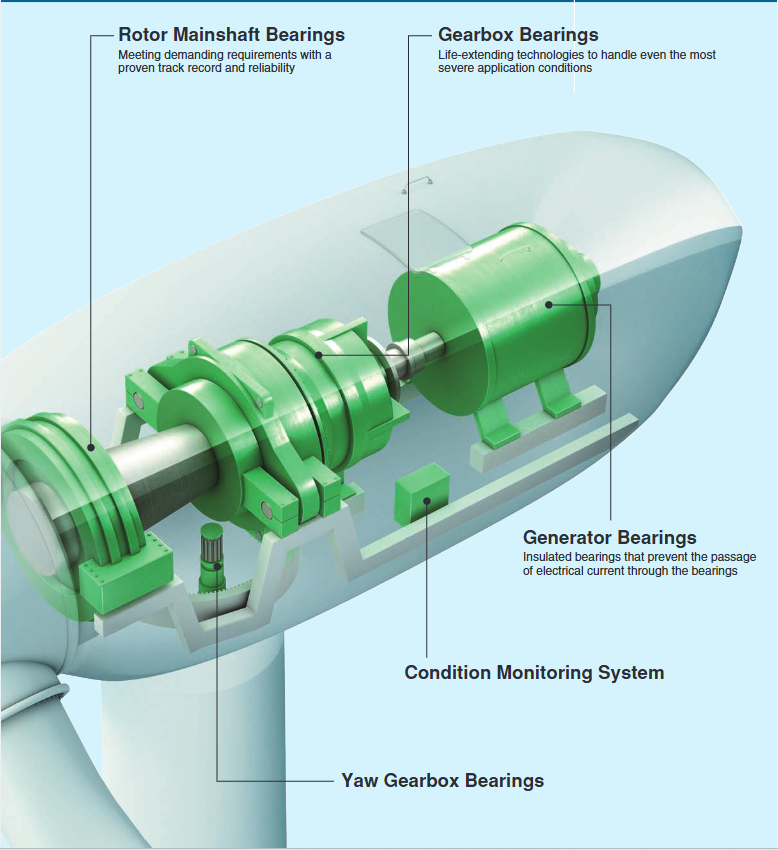

Reliable Choice for Wind Turbine Generators

Wind turbine technology continues to demand improved efficiency, reliability, and longer equipment life.NTN’s innovative bearing designs contribute to these improvements and to the use of wind technology for power generation.NTN products are manufactured with three concepts in mind: harmony with the natural environment, improved energy conservation, and contribution to the international community. Generator-insulated bearings prevent electric current from passing through the bearing. A ceramic coating on the outer surface of the bearing creates an insulating layer that prevents galvanic corrosion. (Insulation value at 500 V DC: 100 MΩ or higher; electrical breakdown power: 3 kV or higher) The dimensions and tolerances of the bearings are exactly the same as those of standard products (without insulation), so they can be easily machined.

Critical Components in High-Speed Railways

Railroad rolling stock is currently attracting attention as a low (CO2) emission mode of transportation. The electrification network of railroad rolling stock is expanding globally, and the number of hybrids combining internal combustion engines (diesel) with traction motors and batteries is increasing. The development of rail networks is also underway in urban areas of some emerging countries to reduce traffic congestion. In this context, there is an increasing need for further measures to prevent the electrical pitting of railroad rolling stock bearings. NTN offers the MEGAOHM™ series globally, which includes products developed to reduce maintenance costs for railroad rolling stock by preventing electrical pitting while contributing to the safety of equipment requiring electrical pitting measures.

Efficiency Boost in Industrial Electric Motors

With more than 75 years of experience in electric motors, NTN is one of only two bearing manufacturers to have received the prestigious global Deming Award for quality management and is committed to improving performance through an unrivaled dedication to quality.NTN offers world-class electric motor bearings that can be designed to meet the requirements of applications ranging from small applications to wind turbines to gearboxes and everything in between.NTN Each of NTN’s ball bearings meets motor quality standards to improve the overall performance of any system, making them one of the most trusted manufacturers of quality bearings.

Choosing the Right NTN Insulated Bearing

Choosing the right NTN insulated bearings starts with understanding your application needs based on current and voltage, load speed, material quality, etc.

Understanding Your Application Requirements

First of all, it is very important to clarify the usage scenario of the bearings. Insulated bearings are mainly used to avoid the occurrence of galvanic corrosion phenomenon and are suitable for equipment such as motors and generators. For example, insulated bearings can be applied to traction motors of railroad vehicles to guarantee the reliability of general-purpose motors, and they are also widely used in wind power generation systems to avoid accidents and malfunctions caused by bearing damage.

Current and voltage

Insulated bearings need to be able to resist certain voltages; usually, electrical jump fires are generated at a voltage of at least 1000VDC. In addition, insulated bearings need to be highly voltage and shock-resistant to meet the needs of different users.

Considering Load and Speed

Load is one of the important factors to consider when selecting a bearing. Different types of loads will have different effects on bearing selection:

- Static load: When the bearing is subjected to a large static load, it is necessary to choose bearings with high static load carrying capacity, such as roller bearings.

- Dynamic load: For bearings that require frequent rotation, bearings with a low coefficient of friction, such as ball bearings, should be selected to minimize energy loss and heat generation.

- Shock load: For equipment that may be subjected to shock load, bearings with good cushioning and vibration-damping properties should be selected to minimize damage to the bearings.

The rotational speed of the bearing will also affect its selection:

- High-speed operation: For bearings that require high-speed operation, bearings with low coefficient of friction and good lubrication performance should be selected to ensure that the bearings can still maintain good operation at high speed.

- Low-speed operation: for low-speed operation of the equipment, one should choose good wear-resistant bearings to extend its service life.

Material and quality

Selection of high-quality materials and strict quality control are key to ensuring bearing performance.NTN bearings use high-quality materials such as high-carbon chromium bearing steel and ceramics, as well as various surface treatment techniques, such as quenching, carburizing, nitriding, etc., to improve the hardness and wear resistance of the bearing surface.

Maintenance and Care of NTN Insulated Bearings

NTN insulated bearings should also be cared for and maintained. Regular inspection, proper lubrication, and keeping a clean and suitable environment are all necessary.

Regular Inspection Procedures

In addition to routine maintenance, it is also necessary to carry out regular electrical performance testing to ensure that its insulation performance meets the design requirements. The inner and outer rings and rolling elements of the bearings also need to be checked regularly, measuring the relevant dimensions and observing the state of the rolling elements and cage to determine the wear and tear, if the wear and tear is serious, you need to replace the worn parts.

Proper Lubrication Methods

Adequate lubrication is critical to ensure smooth bearing operation. Appropriate amount of grease or oil should be injected into the bearings before commissioning, and their lubrication status should be checked regularly, and should be supplemented once insufficient oil is found.

Preventing Contamination and Damage

Install sealing rings or sealing plugs to prevent lubricant leakage and effectively block the intrusion of dust and moisture to ensure that the sealing of the bearing has a direct impact on its service life. We can also clean the bearings regularly by wiping them with a soft cloth or blowing with air pressure to remove surface dust. In order to ensure that the inside of the bearing is free of dust and impurities, it can also be deep cleaned with special cleaners.

Environmental Adaptation

Efforts are made to reduce load imbalance and transient shocks, prevent overloading of bearings, and safeguard their stable operation. Insulated bearings have certain requirements for ambient temperature and humidity. We need to ensure that their working environment meets the requirements to avoid performance degradation caused by environmental factors.

Conclusion

NTN insulated bearings are important in guaranteeing the reliability of motor operation and improving the system’s overall reliability through their excellent electrical insulation performance, wide range of applications, high-quality materials, and manufacturing process.TFL insulated bearings company has a long-term cooperation relationship with NTN and the professional leadership team and technical personnel to ensure high-quality insulated bearing products. If you are looking for affordable insulation bearings, come to TFL Insulation Bearing Company!

Frequently Asked Questions

- What are the benefits of NTN insulated bearings?

NTN insulated bearings can avoid galvanic corrosion, improve service life, high pressure and shock resistance, and are applicable to a variety of scenarios with considerable cost-effectiveness.

- How to maintain NTN insulated bearings for long-term use?

Through correct storage and handling, reasonable mounting and dismounting, proper lubrication, regular inspection and maintenance, attention to the working environment, as well as professional consultation and training and other measures, NTN insulated bearings can be effectively maintained to ensure their long-term use and reduce the occurrence of failures.

- What are the applications of NTN insulated bearings?

NTN insulated bearings are widely used in many fields, mainly in the electric power industry, railroad facilities, machinery and metallurgy industry, mining machinery industry and petrochemical industry.

- How do NTN insulated bearings prevent electrical erosion?

NTN-insulated bearings prevent electrical erosion by spraying an insulating coating on the bearing surface. Insulated bearings use a special spraying process. The outer surface of the bearing is sprayed with a high-quality coating, which has a strong bond with the substrate and good insulating properties and can effectively avoid the galvanic erosion of the bearing by induced currents.

- Are NTN insulated bearings suitable for high-voltage environments?

NTN insulated bearings are suitable for high-pressure environments. They can withstand voltages of up to 1,000 V DC by using a special coating process that sprays a 100-μm-thick overcoat on the surface of the outer or inner ring.