SKF Explorer deep groove ball bearings

Better performing, longer-lasting, smoother running.

Failure of critical process machinery is expensive. It can result in costs of up to thousands of dollars per hour in lost production. Downtime doesn’t just hurt the companies that depend on these machines; it also impacts the companies that manufacture them. OEMs selling failure-prone machines risk damaging their

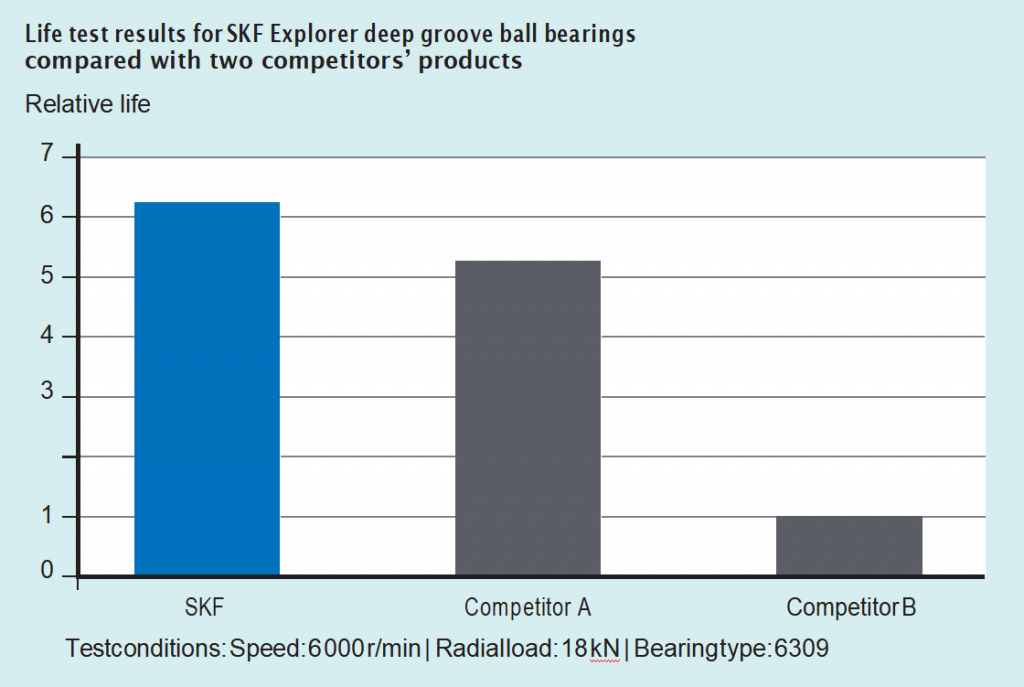

reputations and losing business to competitors. Yet this can be avoided. A more robust bearing can improve service life and have more extended trouble-free machine operation with lower operating costs. Life test results below confirm the superior behavior of SKF Explorer deep groove ball bearings compared to two competitors’ solutions.

The SKF Explorer deep groove ball bearing ticks all the boxes. This is the range that delivers the performance levels that reduce downtime. The content that’s been manufactured to world-class specifications. The field that’s capable and versatile enough to answer “yes,” no matter how much you ask of it.

More reliable and more versatile and more versatile

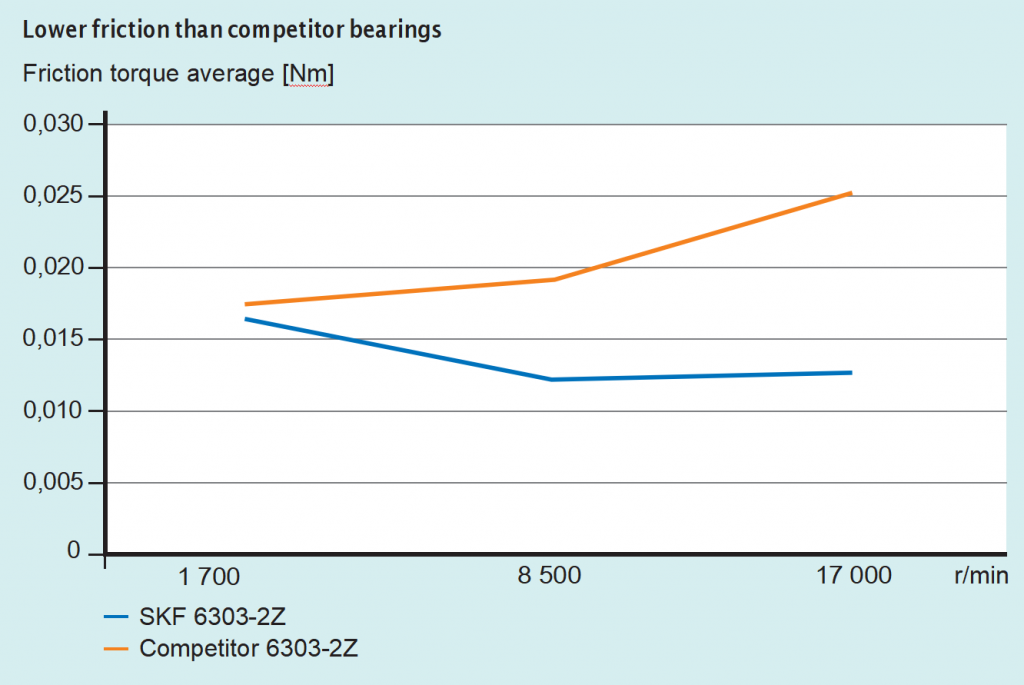

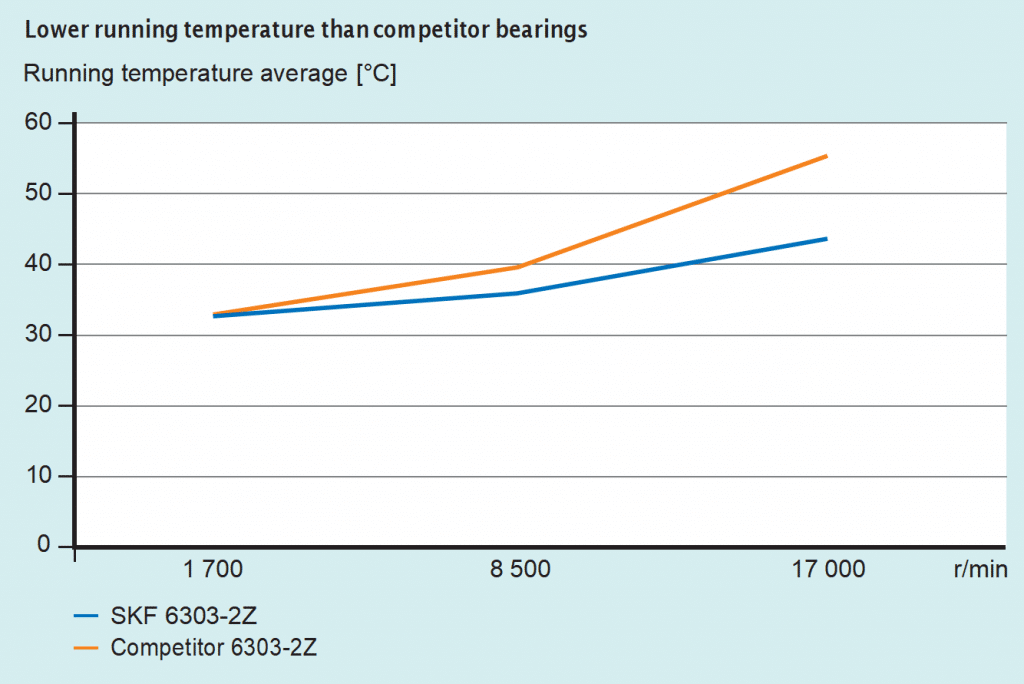

SKF Explorer deep groove ball bearings lead the way to performance. They run more smoothly, quietly, at cooler temperatures, and longer than standard deep groove ball bearings.

SKF-specified steel has a higher fatigue resistance. And with the capacity to handle greater loads, SKF offers you a high-performing solution that is available as a catalog offering and versatile enough to be used in many different applications.

Performance fine-tuned for your application.

Beyond our catalog offering, SKF Explorer deep groove ball bearings are a great choice when you need a specific type of performance in your application. Take into account all of our different seals, greases, and other customizable features, and you will find that there are more than 10 000 possible variants involving our product. This brings you as close as possible to the exact performance mix that you need in your application, whatever it may be.

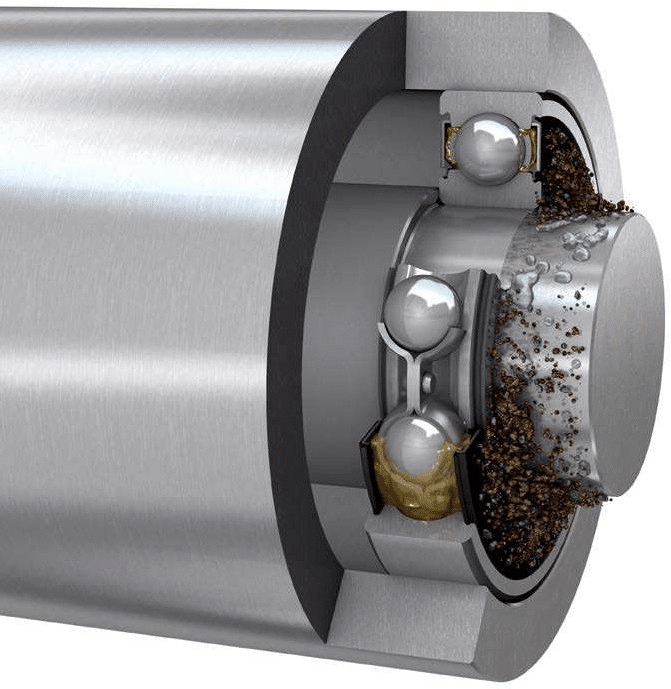

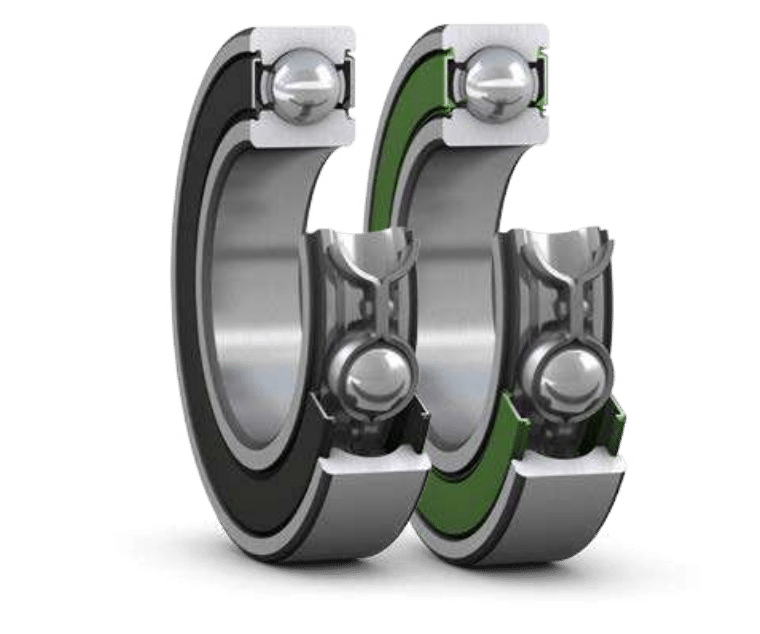

Robust seals for longer service life

Ball-bearing seals are a critical factor in durability. That’s why we have extended the range of sizes available with our unique RSH seals, which reduce maintenance costs and help your machine run longer. They are designed to provide excellent sealing efficiency, improved grease retention, and exclusion of water and contaminants.

We are continuously improving the SKF Explorer deep groove ball bearing – RSH seals included. The seals have optimized vent holes for larger bearing sizes, eliminating the risk of a vacuum effect caused by low internal pressure – and do so without compromising sealing efficiency. We also redesigned the seal groove of the outer ring of the bearing to improve the seal’s performance. Both of these developments contribute to longer service life.

Manufacturing precision

SKF Explorer deep groove ball bearings are produced to ISO class 6 tolerances – which is better than the ISO Normal tolerances – contributing to a consistent outcome when mounting in the application. They also achieve a lower total run-out, minimizing vibration and heat generation.

Tried, tested, and trusted around the world

SKF Explorer deep groove ball bearings are our most widely used bearing type in the industry today. Compatible with a wide range of machinery, they are available in many variants and sizes. Each is made with high-quality steel for robustness and offers superior performance in demanding applications – for example; there are high loads, high rotation speeds, or polluted environments.

Customization options

Here are some of the features that we can customize to help you get the very best out of your bearing in your application:

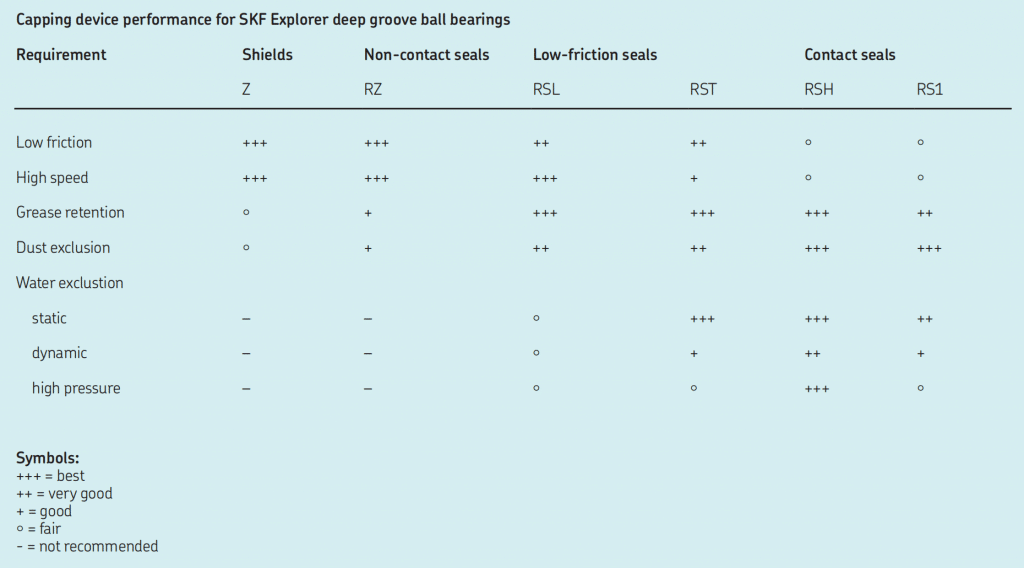

More options for enhanced seal efficiency

The proper protection means you can extend bearing life with better performance in friction, speed, grease retention, dust exclusion, and water exclusion. The SKF Explorer deep groove ball bearing offers a wide range of sealing options, including RSH, metallic shields, contact seals such as RS1, and the low-friction RST. These can help you achieve the specific per for-mance you need in your application.

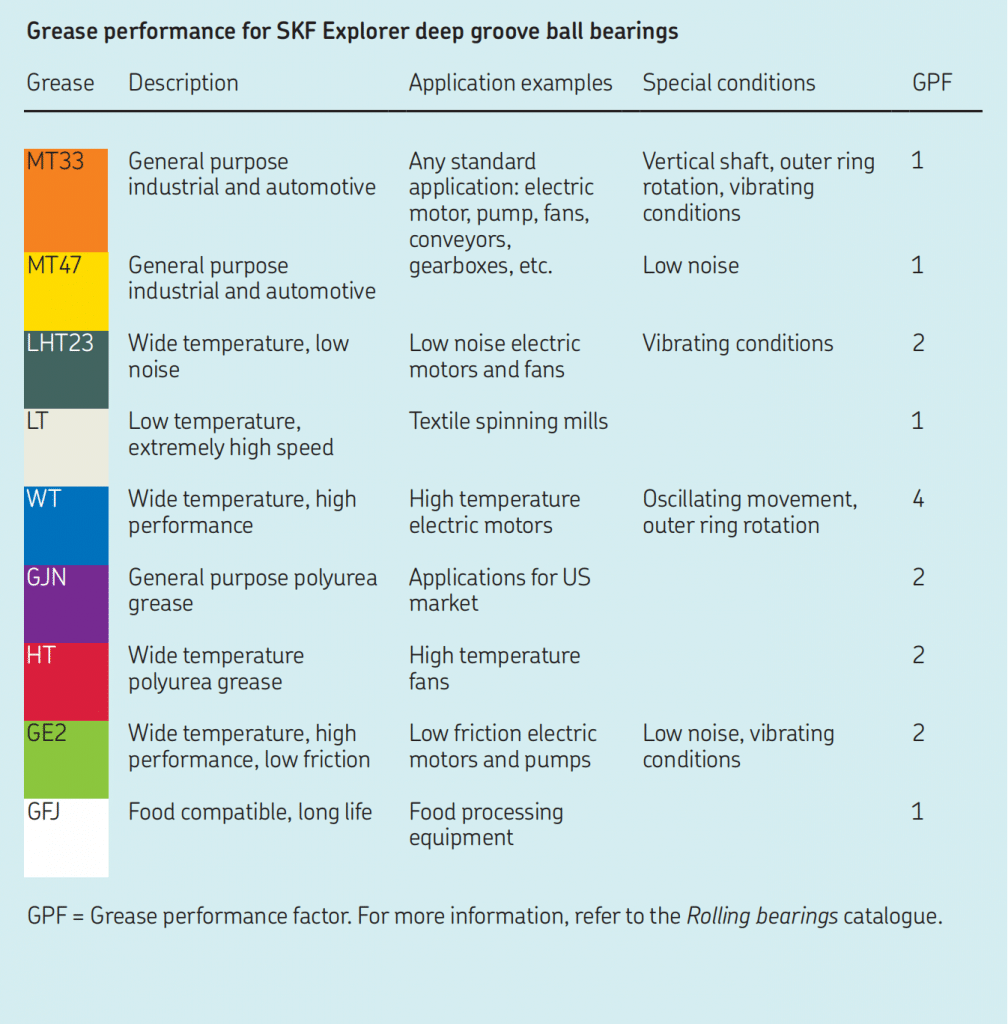

Optimized lubricant options

The lubrication requirements of an SKF Explorer deep groove ball bearing can vary depending on the application and its operating conditions. The catalog offer is available with a multi-purpose grease suitable for a wide range of conditions. This lubricant is just one option in a wide range of bearing greases available to meet different performance needs, including application-specific fats such as food-grade grease and alternative lubricants such as Solid Oil.

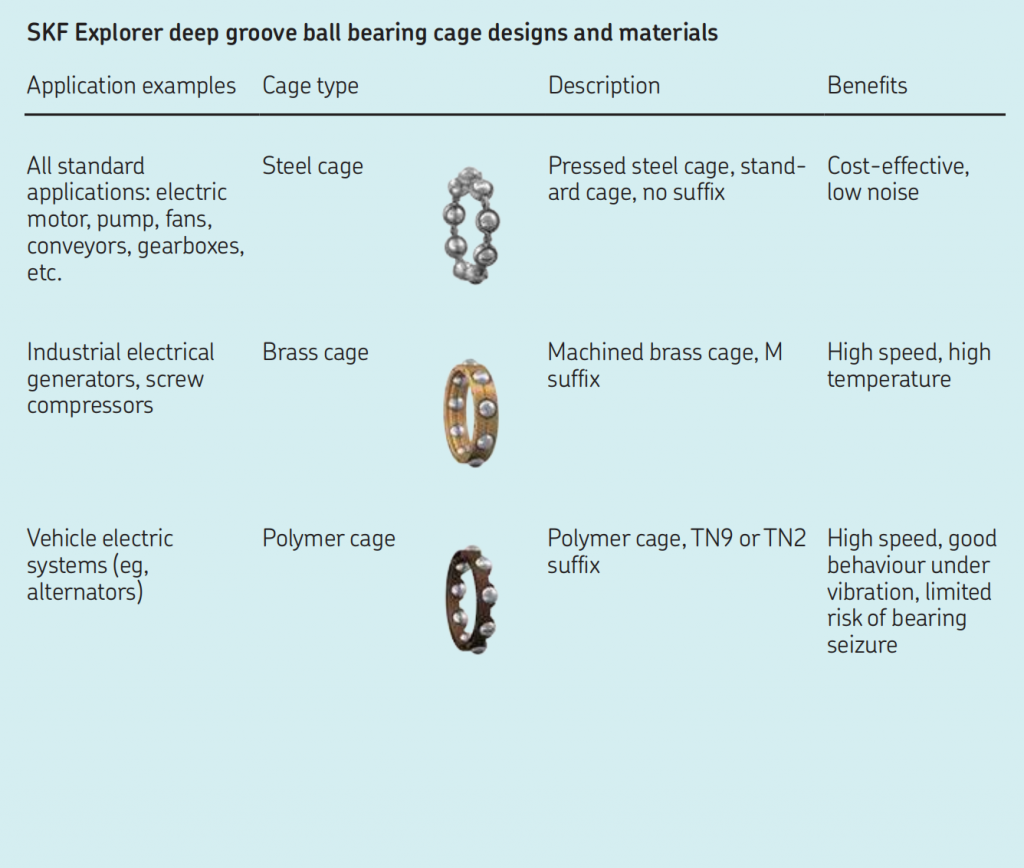

The right cage for your application

If you’re looking for exceptional performance in applications running at

high speeds, or with high acceleration or high ambient temperatures, choosing the right cage can make all the difference. The SKF Explorer deep groove ball bearing offers several cages alternatives that can help meet your specific requirements.

Heat stabilization

If the average operating temperatures of the application are higher than 120 °C, consider a bearing with a higher stabilization class to deliver an even longer service life, in addition to allowing for the appropriate selection of cage, lubrication, and sealing.

Upgrade to the ultimate all-rounder

For practically every application, the SKF Explorer deep groove ball bearing is the simple off-the-shelf solution that can deliver quieter, more excellent performance with lower friction and more extended service life. The SKF Explorer deep groove ball bearing is typically included in distributors’ bearing assortments, making it available worldwide.

• Easily interchangeable with original bearings

• Ready stock availability

Find a solution that’s up to your challenge

Whatever your specific performance requirements, the SKF Explorer deep

The groove ball bearing is ready to meet the challenge. More robust than standard deep groove ball bearings, it is highly customizable, with many different possible combinations of components. This allows you to find the optimum configuration to deliver the high performance you need – whether that’s exceptional durability, for example, or lower friction.

• Customizable performance

• 10 000 possible configurations

For more information, please visit skf.com and contact your local SKF representative.