Bearing Grease: Lithium vs. Synthetic – A 2026 Technical Comparison

Key Takeaways

- Lithium Grease (Standard/Complex): The industrial workhorse. Ideal for General Purpose (GP) applications such as standard electric motors and conveyors. It is optimized for stable environments where operating temperatures remain below 120°C.

- Synthetic Grease: A high-performance specialist designed for Extreme Pressure (EP) environments and temperatures exceeding 150°C. It is mandatory for precision instrumentation requiring low starting torque in cryogenic conditions.

- ROI Factor: While synthetic lubricants require a 3x to 5x higher initial investment, they deliver a 400% extension in maintenance intervals, significantly lowering the Total Cost of Ownership (TCO) for critical assets.

Simply put: General Lithium Grease is the industry standard for moderate conditions, while Synthetic Hydrocarbon Grease is engineered for performance in extreme environments. Use the tool below to see which one matches your needs.

🌡️ Select Your Operating Temperature

Click on the temperature range below to see our recommendation.

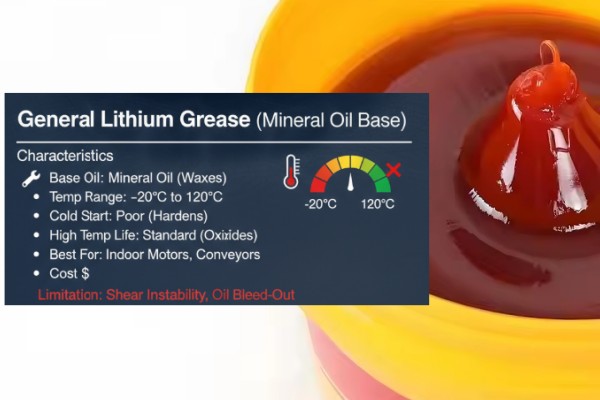

1. General Lithium Grease (Mineral Oil Base)

This is the most widely used lubricant in the industry, typically formulated with a Mineral Oil base and a lithium soap thickener.

- Advantages: Cost-effective, good water resistance, and sufficient mechanical stability. It is the ideal choice for standard electric motors, fans, and pumps operating in controlled temperatures (-20°C to 120°C). For TFL general-purpose bearings operating in standard electric motors, conveyors, and other General Purpose (GP) applications, lithium grease is the ideal choice.

- Primary Limitation: Temperature Sensitivity. Mineral-based lubricants are highly sensitive to thermal fluctuations. At temperatures below -20°C, the natural paraffinic wax molecules inherent in mineral oil begin to crystallize. This crystallization process causes the grease to harden rapidly, resulting in excessive starting torque that can lead to motor overload, bearing skidding, or cage fracture. Conversely, exceeding 120°C accelerates mineral oil oxidation, leading to a total loss of lubricating film integrity.

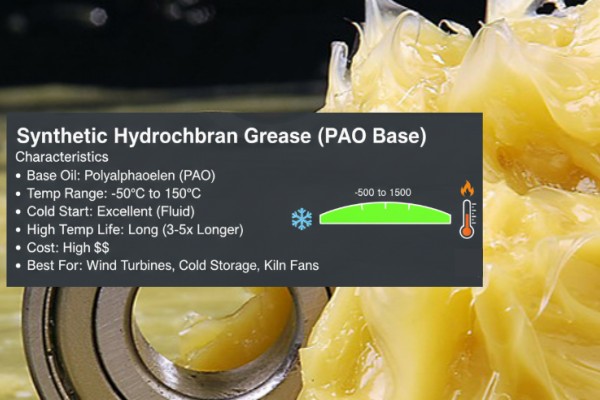

2. Synthetic Hydrocarbon Grease (PAO Base)

These are typically formulated with Polyalphaolefin (PAO) synthetic base oils. They are the standard recommendation for harsh operating conditions.

- Advantages:

- Wide Temperature Range: Unlike mineral oil, PAO bases are chemically synthesized to be wax-free. This uniform molecular structure ensures the lubricant maintains excellent fluidity from -50°C to 150°C. Synthetic grease is essential for TFL high-performance bearings operating in Extreme Pressure (EP) environments, temperatures > 150°C, or precision instrumentation requiring low starting torque.

- Extended Lifespan: Its stable molecular structure offers 3-5 times the oxidation resistance of mineral oils, drastically extending relubrication intervals.

- Energy Efficiency: significantly lower starting torque in cold weather reduces energy consumption during startup.

- Considerations: The initial cost is typically 3-5 times higher than standard grease. Compatibility with certain older seal materials should be verified prior to application.

3. Key Parameters Comparison

| Feature | General Lithium Grease (Mineral) | Synthetic Hydrocarbon Grease (PAO) |

|---|---|---|

| Base Oil Type | Mineral Oil | Synthetic Hydrocarbon (PAO) |

| Temp Range | -20°C ~ 120°C | -50°C ~ 150°C |

| Cold Start | Poor (Hardens/Waxy) | Excellent (Fluid) |

| High Temp Life | Standard | Long (3x longer) |

| Cost | Low ($) | High ($$$) |

| Best For | Indoor pumps, standard motors | Cold storage, Outdoor mining, Wind turbines |

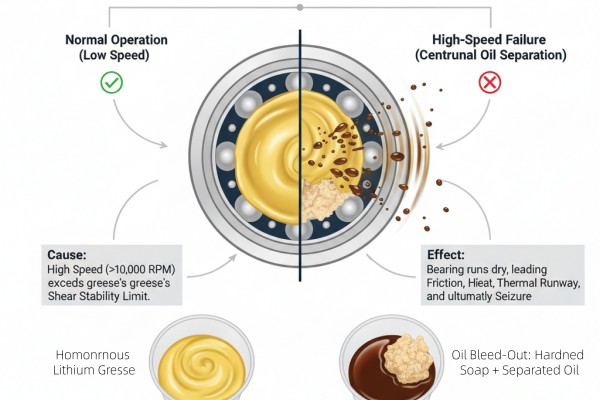

Engineer’s Field Note (2026 Update): Preventing Oil Bleed-Out

In high-speed spindle applications (>10,000 RPM), we frequently observe “Centrifugal Oil Separation”. This is not a seal failure; it is a grease failure.

When standard Lithium grease exceeds its Shear Stability limit (ASTM D217), the thickener matrix collapses, releasing the base oil. The bearing then runs dry, leading to rapid Thermal Runaway and eventual seizure (welding of rolling elements to raceways).

Prevention Strategy: For applications exceeding 120°C or high DN values, TFL recommends upgrading to a Synthetic Fluorocarbon or Polyurea-thickened grease. These maintain structural integrity under high shear forces, preventing the “souping” effect seen in degraded lithium greases. Do not mix greases. Mixing Lithium and Synthetic bases often causes immediate hardening or liquefaction due to chemical incompatibility.

Selection Recommendation

- If your equipment uses standard industrial bearings and operates in a controlled indoor environment (e.g., a heated factory) with standard loads, lithium grease is sufficient..

- For TFL special condition bearings operating in freezing outdoor conditions (e.g., mining, wind energy) or high-heat zones, upgrading to synthetic hydrocarbon grease is mandatory to protect these bearings.

Technical Risks of Grease Incompatibility

Incompatibility between different base oils is a primary cause of lubrication failure. Mixing standard Lithium mineral grease with Synthetic PAO grease often leads to a collapse of the thickener matrix. This chemical reaction typically results in:

- Loss of Consistency: The grease may liquefy and leak from the bearing (oil bleed-out).

- Oxidative Hardening: The mixture transforms into a solid residue, increasing starting torque and leading to potential cage fracture.

Recommendation: TFL recommends a complete system purge and cleaning of all rolling elements before transitioning to a synthetic lubricant to ensure chemical integrity.

Application Scenarios: Where to Deploy

Lithium Grease (The Cost-Effective Standard)

Best for non-critical, moderate-speed equipment where relubrication is frequent and accessible.

-

Conveyor Bearings: Standard speeds, ambient temperatures.

-

Agricultural Hub Bearings: High dust, moderate load, frequent washdowns (requires Lithium Complex with tacky additives).

-

Electric Motor Bearings: Frame sizes <250, operating indoors.

Synthetic Grease (The Performance Critical)

Mandatory for “Fill-for-Life” bearings or inaccessible machinery.

-

Wind Turbine Main Shaft Bearings: Extreme load, oscillating movement, impossible to re-grease manually.

-

Robotic Bearings: Requires low starting torque at varying temperatures.

-

High-Temperature Kiln Fan Bearings: Ambient heat causes mineral oil to carbonize; Synthetic resists high-temp oxidation.

-

Food Processing Machinery Bearings: H1 Food Grade synthetics prevent contamination while resisting aggressive washdown chemicals.

Buying Guide: Optimizing Your Sourcing

Many buyers default to “General Purpose” grease to save 15% on unit cost, only to face premature bearing replacement.

The TFL Factory Advantage: As a specialized bearing manufacturer, we don’t just sell bearings; we also customize tribology solutions (lubrication science) for your specific load profile.

-

Custom Fill Rates: Standard bearings are filled 25-30%. TFL can adjust fill rates (15% for high speed, 50% for low speed/high contaminant) at the factory level.

-

Verified Formulations: Verified Formulations: We can provide lubricant formulations from reputable brands like Kyodo Yushi, Klüber, and Shell upon request, ensuring optimal protection for your bearings and compliance with your specific OEM maintenance manuals.

-

Seal Integrity: We pair synthetic greases with compatible seal materials (e.g., FKM/Viton for high temp) to prevent seal shrinkage or swelling, thereby extending bearing lifespan.

Cost-Effective Strategy: Use Lithium Complex for 80% of your plant’s standard machinery. Reserve Synthetic for the “Critical 20%”—assets where downtime costs exceed $1,000/hour.

Ready to choose the best TFL bearings and lubrication solution for your machinery? Contact TFL Engineering now for 2026 technical datasheets and a competitive quote within 24 hours.

-

Phone/WhatsApp: +86 15806631151

-

Email: info@tflbearing.com

-

Request a Quote: 【Click Here】

Frequently Asked Questions (FAQ)

Q: What is the main difference between Lithium Grease and Synthetic Hydrocarbon Grease?

A: The primary difference lies in the base oil. Standard General Lithium Grease uses mineral oil, which contains natural waxes that harden in the cold. Synthetic Hydrocarbon Grease (often PAO-based) uses chemically engineered synthetic oil that maintains excellent fluidity and structural stability even in extreme temperatures ranging from -50°C to 150°C.

Q: Why does standard Lithium Grease fail in cold weather?

A: Standard Lithium Grease fails because the wax molecules in its mineral base oil crystallize when temperatures drop below -20°C. This turns the grease into a hard, sludge-like substance, causing a drastic increase in starting torque. This can lead to motor overload, bearing skidding, or even cage fracture during startup.

Q: Can I mix Synthetic Grease with the old Lithium Grease in my bearings?

A: Generally, No. While some thickeners might be compatible, mixing mineral oil with synthetic oil can lead to unpredictable changes in viscosity and additive performance. We strongly recommend completely purging the old grease or cleaning the bearing before switching to a new Synthetic Hydrocarbon Grease to ensure maximum performance.

Q: Is Synthetic Grease worth the higher cost?

A: Yes, especially for outdoor or critical equipment. While Synthetic Grease costs 3-8 times more than standard lithium grease, it lasts 3-5 times longer and prevents expensive failures (like bearing replacement and unplanned downtime). For equipment operating below -20°C, it is an essential investment, not an optional cost.