TFL Insulated Bearings

Introduction: TFL Insulated Bearings – The Future of Motor Protection

Bearing galvanic corrosion occurs on the surface of the bearing due to the presence of shaft currents during the motor’s operation. The generation of shaft current is mainly due to voltage fluctuation and electromagnetic interference at the frequency converter’s output, which causes the bearings to be subjected to high-frequency voltage, thus triggering galvanic corrosion. Insulated bearings, as a special type of bearing, play an irreplaceable role in the protection of motors because of their good insulating properties and are increasingly important in modern industrial applications. TFL insulated bearings, as a product in the field of insulated bearings, are widely used in many industries, such as electric power, petrochemical industry, mining and so on, by virtue of their unique performance and technical advantages.

TFL Insulated Bearings, Inc.

TFL Insulated Bearings has always focused on the research and development of today’s most advanced insulated bearing technology to improve the quality and performance of bearings continuously. We have been in the bearing industry for 10 years and have been engaged in the international trade, import, and export of bearings for more than 8 years. China Bearing Suppliers and China Bearing Manufacturers are also very numerous worldwide. We produce Insulated Bearings with low noise, low vibration, high rotational accuracy and good sealing performance. Our Insulated Bearing products are also available in sizes from 1mm to 200mm and in a wide range of models that suit different industry sectors. Among many Chinese bearing manufacturers, we have also won the trust and favor of many customers with our technical strength, flexibility, innovation and continuous research and development.

TFL Insulated Bearings Catalog

TFL Insulated Bearing Co., Ltd. is an ISO-certified manufacturer of insulated bearings in China. We have a competitive price advantage, sufficient stock of 1 million insulated bearings and can deliver them quickly within 7 days. Agent brands include SKF, KOYO, NTN and so on. We can supply various types of insulation bearings, including ball bearings, angular contact bearings, spherical roller bearings, cylindrical roller bearings, needle roller bearings, tapered roller bearings, precision bearings, bushings, thrust bearings, linear bearings, single and double row bearings, inch bearings.

Customer reviews for TFL Bearings

I just wanted to say thank you for your professional salesman and the excellent customer service he provided for us at ModernMushroom Farms. Since I have been working with TFL Bearings, Eugene has always answered my requests quickly, and we love the prices he offers. Thanks! —Elton Don Elton Don

My name is Tim, and I am from Somalia. This is my fourth year with TFL Bearing, and so far, I am number one in bearing sales in our local area. Thank you for your supply, especially OEM-bearing products; the market is very popular in Somalia; thank you …… –Russel Drou Russel Drou (Architect)

TFL Insulated Bearing Warranty

TFL Insulated Bearings is determined to resist counterfeiting and remain truthful and transparent. We only work with the leading original manufacturers in the bearing field. We respect every penny of our customers’ money and will do our best to serve them and save every penny. Providing the same product at the best price is the long-term motivation and driving force behind our business growth.

Core Technology of TFL Insulated Bearings

Insulated bearings prevent the passage of electric current and have their own insulating properties. TFL insulated bearings are based on this and are treated with specific materials and processes to achieve higher insulating properties and a wider range of applications. It can not only meet the basic performance requirements of bearings (such as pressure, speed, durability, etc.) but also effectively isolate external current interference to ensure the safety and reliability of equipment.

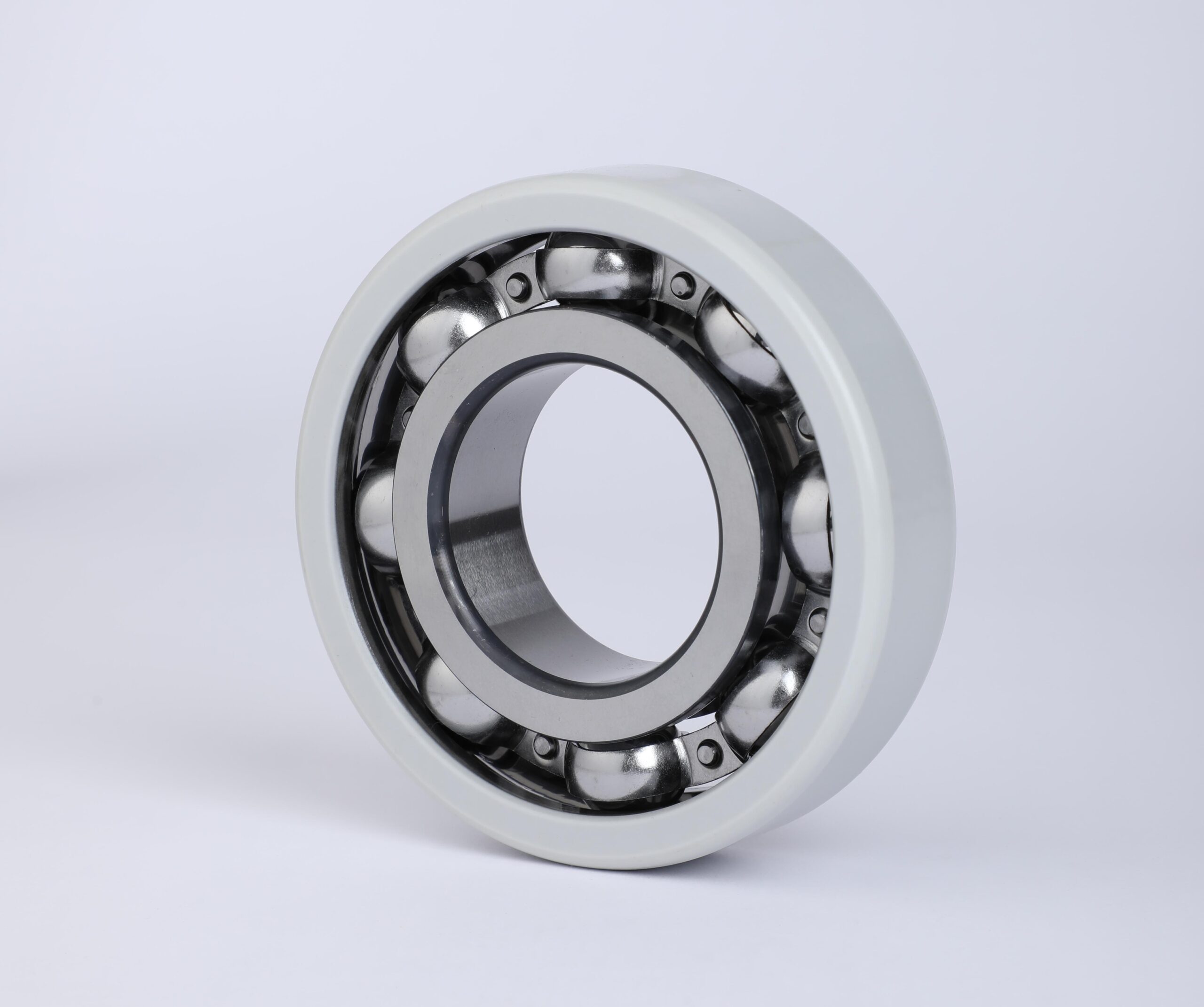

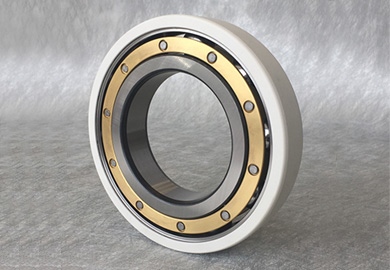

TFL Ceramic Coating Technology: Key to Insulation Performance

Ceramic coating is a general term for a class of inorganic non-metallic coatings whose constituent materials include a variety of ceramic materials such as oxides, carbides and nitrides. Common oxide ceramic coating materials include Al₂O₃, TiO₂, ZrO₂, etc.; carbide ceramics are mainly SiC, WC, etc.; nitride ceramics including Si₃N₄, TiN, etc. These materials are used to form one or more layers of coatings on the surface of metals or other substrates through specific process methods, such as fusion burning, spraying, vapor phase deposition, etc., to give the substrate new properties.

Hybrid Ceramic Design: Balancing Insulation and Durability

Advantages of TFL hybrid ceramic bearings:

- Insulation: the highest level of current throughput protection

- Higher speed suitability: lower centrifugal force due to lighter-weight rolling elements

- Lightweight: Silicon nitride is 60% lighter than conventional rolling element steel.

- Longer life: Longer bearing life, longer relubrication intervals

- Reduced friction: reduces frictional heat, especially at high speeds

- Higher stiffness: less deformation in the rolling contact area

- Reduces the risk of poor lubrication at high speeds and rapid acceleration or when the lubricant film is inadequate

- Interchangeable sizes, no additional tools required

Characterization of ceramic rolling elements: 1. Electrically isolating 2. Low friction coefficient 3. Corrosion resistant 4. Higher modulus of elasticity

Optimized Dielectric Strength: Ensuring Long-term Reliable Operation

The optimized dielectric strength of insulated bearings is mainly reflected in the thickness of their insulating layer and the choice of material.

The thickness of the insulation layer: Insulated bearings are usually coated with a 50-200μm thick ceramic coating on the bearing surface, and this thickness can resist the electric jumping fire generated by 1000V voltage. Thicker coatings can withstand higher voltages, such as high voltage discharges above 1000V.

Selection of insulating materials: Insulated bearings usually use oxide ceramics as insulating materials, which have good insulating properties and corrosion resistance. In addition, the design of insulated bearings needs to consider factors such as bond strength, working heat influence, and sealing technology to ensure the coating’s durability and insulating properties.

Application Areas of TFL Insulated Bearings

The main application areas for insulated bearings include the power industry, railroad facilities, industrial pumps, high-speed spindles and the electric vehicle industry.

Electric Vehicles: Enhancing Powertrain Efficiency

In electric vehicle motors, insulated bearings can effectively reduce the motor’s insulation loss and failure rate. When the electric vehicle drive motor is running, due to the unbalance of the internal windings, there is a potential difference between the stator and rotor, and the current will flow through the bearings, causing galvanic corrosion. The use of insulated bearings can block the current and prevent galvanic corrosion from occurring. Also, insulated bearings can withstand high temperatures and pressures, reducing motor vibration, wear and tear and lowering the failure rate.

Wind Power Generation: Tackling Harsh Environment Challenges

In the field of wind turbines, the insulated bearing is one of the important parts, mainly used in the transmission system of the motor, which can effectively resist the high voltage current and large shock load generated in the work of the wind turbine and also reduce the vibration and noise generated by the bearing in the wind. The high-quality characteristics of insulated bearings can keep the wind turbine in efficient working condition; if there are no insulated bearings, the wind turbine may be shut down due to electrical problems during the operation.

Industrial Pumps and Motors: Improving Reliability and Lifespan

Insulated bearings are also widely used in the construction machinery industry, such as excavators, loaders, road rollers, and other mechanical equipment, due to the construction machinery working in a lot of dust, mud, water, and other harsh environments. If you do not use insulated bearings, they may enter the work into the water or the mud, contaminating it and resulting in reduced bearing life, efficiency, and other issues. Using insulated bearings can help achieve high efficiency in mechanical equipment in harsh environments.

High-speed Spindles: Reliable Partner for Precision Machining

In high-speed spindles, the application scenarios for insulated bearings mainly include electric motors and generators, especially inverter motors. Since inverter motors generate shaft voltage during operation, if left unchecked, this can lead to galvanic corrosion of the bearing raceways and rolling element surfaces, affecting the bearings’ service life. Insulated bearings can effectively prevent this galvanic corrosion by blocking the current path, ensuring more reliable motor operation.

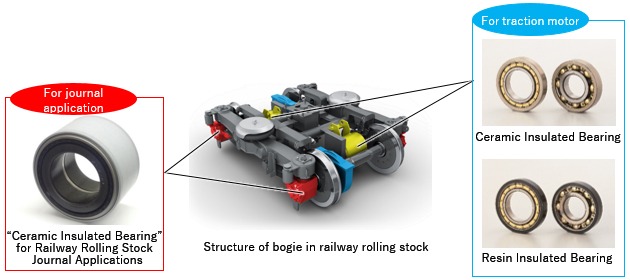

Railway Traction: Ensuring Reliability in Long-distance Transportation

In the railroad industry, insulated bearings are mainly used in equipment such as traction motors for internal combustion locomotives. These types of equipment usually need to withstand high power and high voltage electricity, and insulated bearings can effectively prevent the current from damaging the bearings, ensure the normal operation of the equipment, and prevent the current from affecting the lubricating grease and rolling body, thus improving the service life of the bearings. This is essential to ensure the safe and stable operation of railroad facilities.

Performance Advantages of TFL Insulated Bearings

The good performance of TFL-insulated bearings is mainly shown in more advantages, such as excellent load capacity, excellent temperature resistance, low noise operation, and long service life. These characteristics greatly improve the reliability of the equipment.

Excellent insulation properties: Improved equipment reliability

Insulated bearings can isolate the current and avoid the effect of the current on the bearings, protect the safe operation of the equipment, ensure the equipment works for a long time and stably, and greatly improve the reliability of the equipment. The coating of insulated bearings has good insulating properties, which can avoid the galvanic corrosion effect of induced current on bearings and protect the bearings from galvanic corrosion damage, thus prolonging the service life of bearings. Some of the insulated bearings use ceramic rolling bodies made of Si3N4 material, which have excellent wear resistance and low requirements for lubrication, especially suitable for high-speed, low-friction and low-temperature operation.

Excellent Temperature Resistance: Adapting to Extreme Environments

In terms of high-temperature resistance, the insulated bearings are made to cool and solidify rapidly when the molten particles are sprayed on the surface of the rings through special process parameters so that the surface of the bearings is always maintained at about 100 degrees Celsius, eliminating the effects of high temperature on the bearings. This high-temperature resistance makes the insulated bearings able to work stably in high-temperature environments, which is suitable for high voltage large motors, motors powered by variable frequency power supply, electric vehicles, traction motors of railroad locomotives, wind power generators and other special working conditions.

Low Noise Operation: Enhancing Equipment Comfort

Insulated bearings have excellent quiet performance through optimized design and precision manufacturing. This design can significantly reduce bearing noise at high speeds and improve the smoothness and comfort of equipment operation. In addition, the damping effect of grease is also an important factor in reducing bearing noise. The grease has a damping effect, which can attenuate the vibration of the bearing, thus reducing noise generation.

Extended Service Life: Reducing Maintenance Costs

The special material and manufacturing process of insulated bearings gives them better performance of high-temperature and corrosion resistance, which can operate normally even in harsh environments and effectively extend the service life of the equipment. Insulated bearings can reduce the number of equipment failures and repairs, reduce downtime and repair costs due to bearing damage, and further reduce overall maintenance costs.

High Energy Efficiency Design: Ideal Choice for Energy Saving and Environmental Protection

The high-efficiency design of insulated bearings really helps to save energy and protect the environment. Insulated bearings can effectively prevent current from passing through them, avoiding damage to the equipment due to current erosion. Thus, insulated bearings can reduce maintenance costs and energy consumption. Using insulated bearings can reduce the equipment’s energy consumption and waste, aligning with energy-saving and emission-reduction requirements.

Selecting and Maintaining TFL Insulated Bearings

Choosing the right insulated bearings is crucial to protect our equipment and increase productivity. Similarly, proper maintenance of insulated bearings is also an important precaution to increase the life of the bearings and prolong their life.

Choosing the Right TFL Bearing Model for Your Application

You can refer to the following points for choosing the right TFL insulated bearings:

- Insulation performance: the most important feature of insulated bearings is their insulation performance, including insulation resistance and withstand voltage and other parameters. TFL insulated bearings usually use a plasma spraying process. The inner or outer ring, sprayed with a layer of about 100 μm thick insulating coating, can withstand at least 1000V voltage to prevent the current on the bearings of the galvanic corrosion effect.

- Size and Accuracy: Insulated bearings’ Different sizes and accuracies must be selected depending on the application scenario.TFL insulated bearings are available in a range of sizes, including:

Deep groove ball bearings: inner diameter 40mm~140mm, outer diameter 80mm~300mm, width 18mm~62mm.

Angular contact ball bearings: inner diameter 40mm~140mm, outer diameter 80mm~300mm.

- Load carrying capacity and life: TFL insulated bearings have a long life because they are not subject to damage caused by overcurrent and have high operational reliability.

Installation Considerations: Ensuring Optimal Performance

Caveats:

1, Do not use a hammer to hit the bearing surface when installing it directly

2, Do not use the surface defective insulation bearings

3, Clean the bearing chamber and bearings, which shall not be adhered to the conductive body

4, Choose the appropriate shoulder to prevent the current from the side of the bearing from flowing through the bearing

5, The bearing chamber should be poured at least 0.5MM deep slope 10-15 ° angle

6, For DC motors, during the resistance test, they need to be grounded to the shaft

Daily Maintenance Tips: Extending Service Life

Routine maintenance of TFL insulated bearings:

- Lubrication: For lubrication of TFL insulated bearings, the following methods can be used:

- High-pressure oil pump lubrication: Lubricant is injected into the bearings through nozzles and is suitable for high-speed bearings.

- Circulating oil lubrication: An oil pump transmits the filtered oil to the bearing interior, where the lubricant is then filtered and cooled for use. This system is suitable for bearings with high rotational speeds. Oil bath lubrication: A portion of the bearing is immersed in an oil bath, and the lubricant is carried up by the rotating bearing parts and flows back into the oil bath.

- Cleaning and inspection: When dismantling a bearing for inspection, first record its appearance by taking photographs, confirming the amount of remaining lubricant, and sampling the lubricant.

- When cleaning the bearings, remove the grease or adhesive with rough washing, then carefully clean with fine washing, using neutral water-free diesel oil or kerosene as the cleaning agent. Immediately after cleaning, apply antirust oil or antirust grease on the bearings.

Following these steps, TFL insulated bearings can be effectively selected and maintained to ensure their long-term stable operation.

Performance monitoring: Timely identification of potential problems

Insulated bearings are tested for.

- Appearance inspection is the most basic test method; you need to check whether the bearing’s surface is flat, with no cracks, rust, damage, etc., to ensure that it has no obvious quality problems.

- Insulation performance testing is one of the important parts of insulation bearing testing, which requires the use of equipment such as multimeters or insulation resistance testers to test the insulation resistance value of insulation bearings. Generally speaking, the insulation resistance should be above 100MΩ. Otherwise, the bearing needs to be replaced.

- Noise testing is a method of detecting whether the bearing sealing cover and bearing cap are complete and whether the sealing is good. It requires the use of equipment such as a sound level meter to measure the amount of noise when the bearing is running. If the noise is too loud, it is necessary to check whether the bearing sealing cover and bearing cap are loose or damaged.

- Lubrication testing is a method for detecting bearing lubrication. You need to check the bearings’ oil level and quality, whether the oil filling port is normal, whether the lubricant meets the requirements and other conditions. If the bearing is found to be poorly lubricated, it is necessary to add lubricant or replace it in time.

Conclusion

As industrial technology advances and equipment requirements for reliability increase, the range of applications for insulated bearings will continue to expand. In the future, TFL insulated bearings will continue to innovate in materials, processes and technologies to meet higher standards of insulation requirements and a wider range of application scenarios. In conclusion, TFL insulated bearings, as an important industrial component, play an important role in guaranteeing the safe operation of motors and other equipment, prolonging the service life of the equipment and improving its reliability. With the continuous development of technology and application expansion, the market prospect of TFL-insulated bearings will be broader.

Frequently Asked Questions

- What are TFL insulated bearings used for?

TFL insulated bearings are mainly used in the power industry, railroad industry, machinery and metallurgy industry, mining machinery industry, petrochemical industry, and other major machinery and equipment industries.

- How do TFL insulated bearings perform in high temperatures?

Insulated bearings’ performance at high temperatures largely depends on their material properties and design. Insulated bearings are electrically insulated using a ceramic coating on the bearing surface, which usually has high thermal stability and high temperature resistance. The thickness of the ceramic coating is generally between 50-200 μm, capable of resisting electrical jump fires at a voltage of 1,000 V. Thicker coatings can resist even higher voltages.

- What is the lifespan of TFL insulated bearings?

The service life of insulated bearings is usually between 10,000 and 25,000 hours. The main factors affecting the service life of insulated bearings include the operating environment, load, and rotational speed. If properly used and maintained, the life of an insulated bearing can be significantly extended.

- Can I use TFL insulated bearings in outdoor applications?

TFL insulated bearings are perfectly suited for use in outdoor applications. Insulated bearings, as a special bearing type, have excellent insulating properties that prevent damage caused by the passage of electric current through the bearing and are adapted to harsh environments. Therefore, they are widely used in various industrial environments, including outdoor environments with high temperatures, humidity and corrosive environments.

- How can I contact TFL for purchases?

Come to TFL to buy insulated bearings; you can call the phone, send an email, or visit our official website or Alibaba shopping site for consultation.

Call Us: 0086 15806631151

Email Us: info@tflbearing.com / candice004@foxmail.com