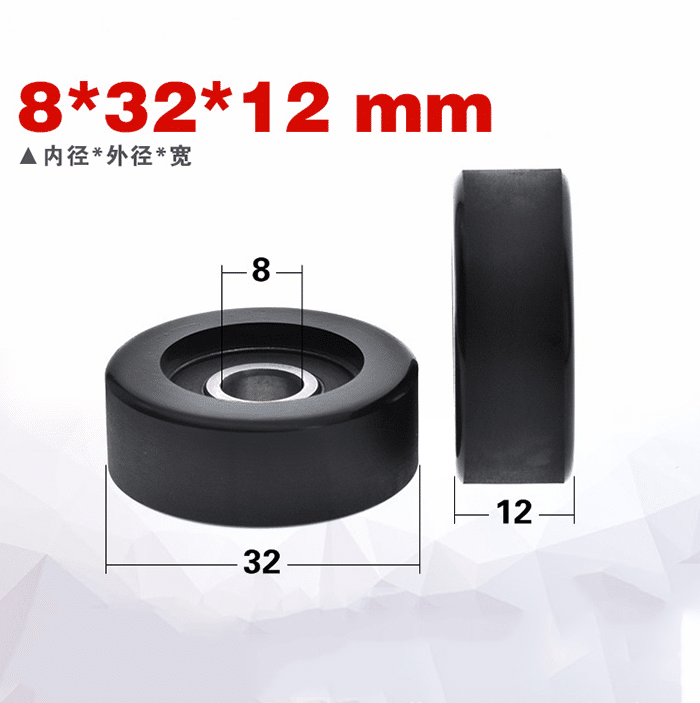

1) Plastic bearings are lubricated material as a whole, long life;

2) plastic bearings are not occur in rusting and corrosion, and metal bearings can not be used in chemical liquid ;

3) The plastic bearing quality lighter than metal, which is more suitable for modern lightweight design trends ;

suitable for mass production ;

5) plastic bearing no noise during operation, has a shock-absorbing function;

6) plastic sliding bearings suitable for high temperature work -200 to +250 degrees;