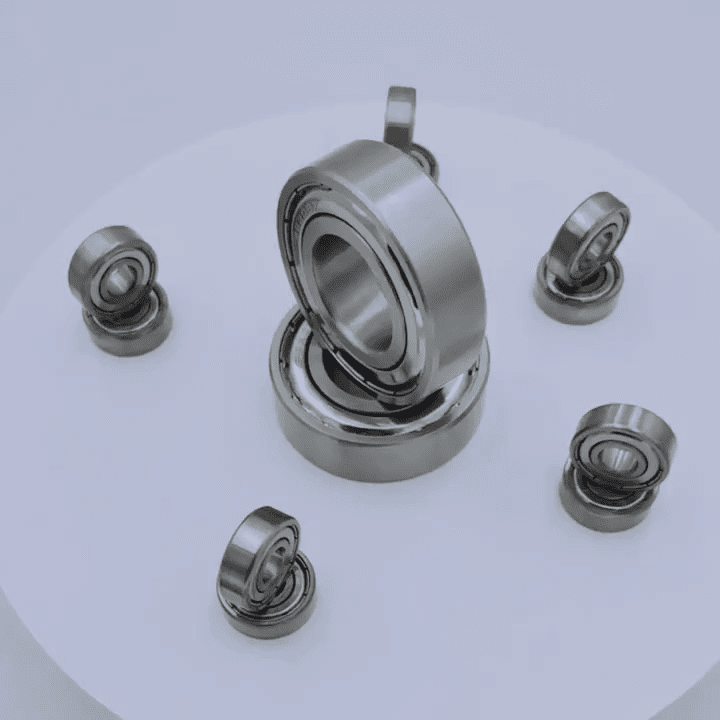

NSK B10-50D 10mm x 27mm x 11mm Sealed Alternator Ball Bearing

Brand Name: NTN NSK

Outside Diameter:27 mm

-

Customization: Customized logo(Min. Order: 100 Pieces)

Customized packaging(Min. Order: 100 Pieces)

NSK B10-50D 10mm x 27mm x 11mm Sealed Alternator Ball Bearing

NSK B10-50D is a deep groove ball bearing, which is inherently suitable for high-speed applications, including automotive alternators. Alternators operate at very high RPMs, and deep groove ball bearings are designed to handle these speeds efficiently with low friction. The sealed versions (like B10-50D-2RS) are particularly good as they retain lubrication and keep contaminants out, both crucial for high-speed, long-life operation in an alternator.

|

Bearing No.

|

Boundary Dimensions (mm)

|

||||

|

d

|

D

|

B

|

|||

|

B8-74D

|

8

|

22

|

11

|

||

|

B8-79D

|

8

|

23

|

11

|

||

|

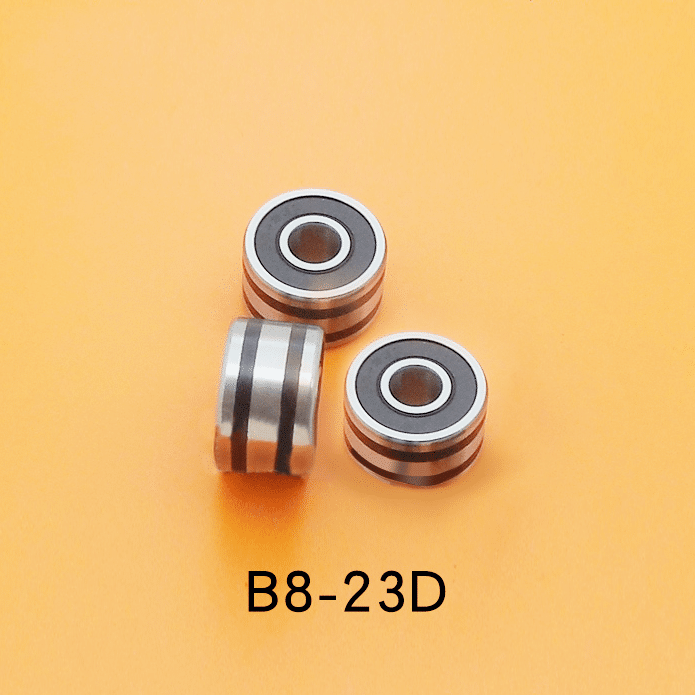

B8-23D*

|

8

|

23

|

14

|

||

|

B8-85D

|

8

|

23

|

14

|

||

|

B10-46D

|

10

|

23

|

11

|

||

|

6000-TT*

|

10

|

26

|

8

|

||

|

62000

|

10

|

26

|

10

|

||

|

B10-50D

|

10

|

27

|

11

|

||

|

B10-27D*

|

10

|

27

|

14

|

||

|

62200

|

10

|

30

|

14

|

||

|

W6200

|

10

|

30

|

14.3

|

||

|

63001

|

12

|

28

|

12

|

||

|

62201

|

12

|

32

|

14

|

||

|

949100-2140

|

12

|

35

|

18

|

||

|

949100-3660

|

15

|

32

|

11

|

||

|

6202-TT*

|

15

|

35

|

11

|

||

|

B15-69

|

15

|

35

|

13

|

||

|

949100-2790

|

15

|

35

|

13

|

||

|

62202

|

15

|

35

|

14

|

||

|

949100-3460

|

15

|

38

|

19

|

||

|

62302

|

15

|

42

|

17

|

||

|

949100-3190

|

15

|

43

|

13

|

||

|

949100-3360

|

15

|

46

|

14

|

||

|

B15-86D

|

15

|

47

|

14

|

||

|

B15-83D

|

15

|

47

|

18

|

||

|

949100-3820

|

15

|

52

|

16

|

||

|

62203

|

17

|

40

|

16

|

||

|

W6203

|

17

|

40

|

17.5

|

||

|

6203-TT*

|

17

|

40

|

12

|

||

|

B17-107D

|

17

|

47

|

18

|

||

|

62303

|

17

|

47

|

19

|

||

|

B17-47D

|

17

|

47

|

24

|

||

|

949100-3330

|

17

|

52

|

16

|

||

|

B17-99D

|

17

|

52

|

17

|

||

|

B17-116D

|

17

|

52

|

18

|

||

|

62304(17)

|

17

|

52

|

21

|

||

|

6904DW

|

18.8

|

37

|

9

|

||

|

62204

|

20

|

47

|

18

|

||

|

62304(20)

|

20

|

52

|

21

|

||

|

62322

|

20

|

56

|

21

|

||

|

62205

|

25

|

52

|

18

|

||

|

W6205

|

25

|

52

|

20.6

|

||

|

B25-147

|

25

|

62

|

19

|

||

|

62305

|

25

|

62

|

24

|

||

|

W6305

|

25

|

62

|

25.4

|

||

|

62206

|

30

|

62

|

20

|

||

|

W6306

|

30

|

72

|

30.2

|

||

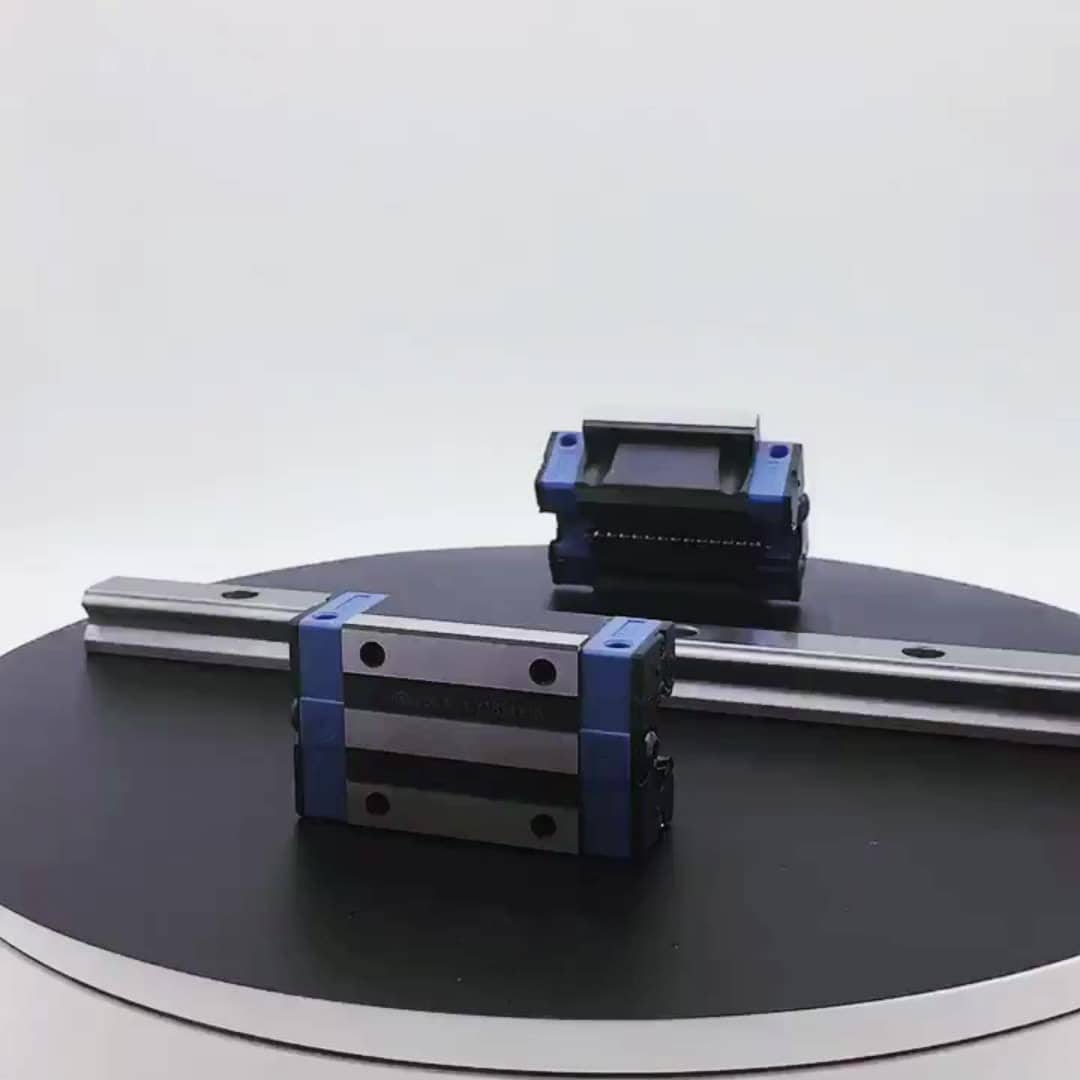

is a professional bearing manufacturer and dealer in china.We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.We have our own brand “TFL” and applied ISO9001:2000 certificate for certification authority.We attend international bearing fairs, put in many B2B website and achieve many customers all over the world also bulid up good reputation from our customers.

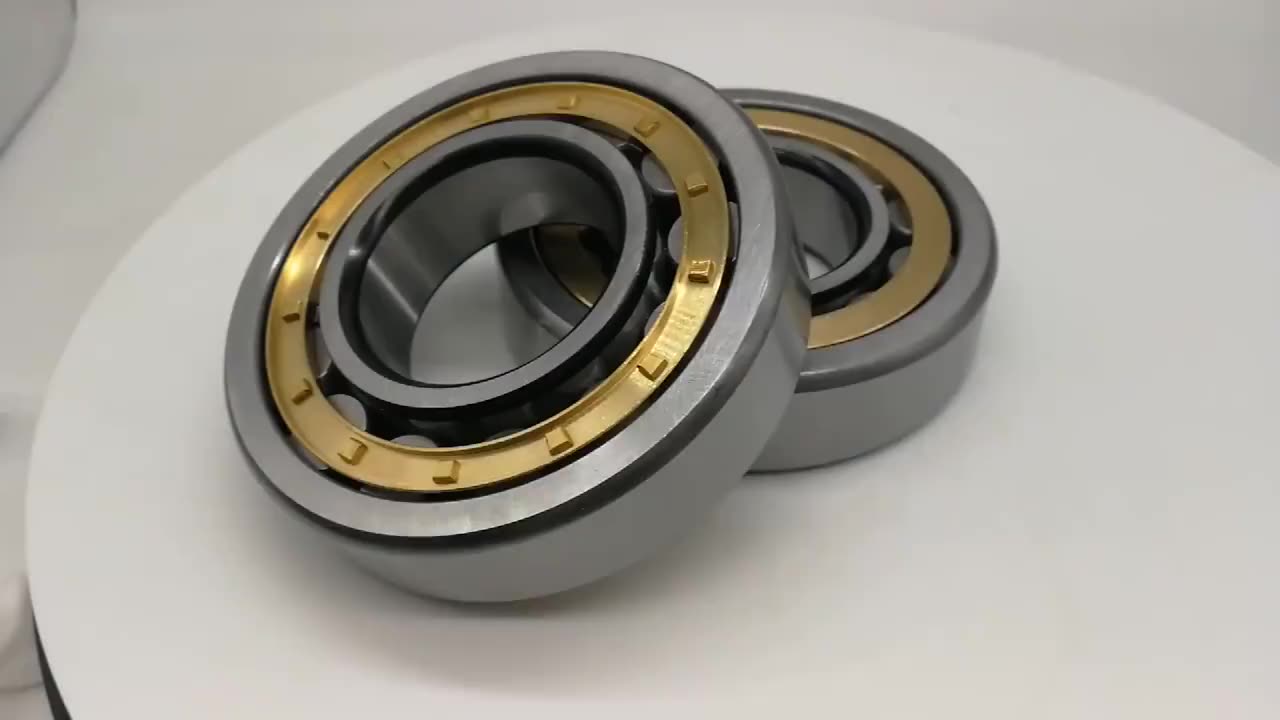

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

FAQ: What’s the difference between sealed alternator bearings and open alternator bearings?

The main difference lies in their protection and maintenance requirements:

1. Open Bearings: No seals or shields; The internal rolling elements (balls and raceways) are exposed to the environment.

Requires external lubrication: They need to be regularly lubricated, often by the machine’s central lubrication system or manual regreasing.

Pros: Lower friction (no seal drag), lower initial cost.

Cons: Highly susceptible to contamination (dust, dirt, moisture), requiring very clean operating environments. Prone to premature failure in dirty conditions.

Use in alternators: Rarely used in modern automotive alternators unless the alternator design specifically provides an oil bath or very clean environment, which is uncommon.

2. Sealed Bearings (2RS/UU – rubber seals, or ZZ – metal shields):

Built-in seals/shields: These are integrated into the bearing design to protect the internal components.

2RS/UU (Rubber Seals): Have rubber or synthetic seals that make contact with the inner ring. Offer excellent protection against dust, dirt, and moisture, and retain grease very well. Slightly higher friction due to contact.

ZZ (Metal Shields): Have non-contact metal shields that sit in a groove. Offer good protection against larger particles and dust, but are less effective against fine dust or liquids than rubber seals. Lower friction than rubber seals.

Pre-lubricated for life: Typically filled with high-quality grease at the factory and designed to be maintenance-free for their service life.

Pros: Excellent protection against contamination, long service life in harsh environments, reduced maintenance.

Cons: Higher initial cost, slightly higher friction (for contact seals), potential for heat build-up in extremely high-speed applications if lubrication is inadequate or seals create too much drag.

Use in alternators: This is the standard type for modern automotive alternators due to the dusty, hot, and sometimes wet conditions they operate in. The sealed design ensures the internal components are protected and properly lubricated for the life of the bearing.

1. Open Bearings: No seals or shields; The internal rolling elements (balls and raceways) are exposed to the environment.

Requires external lubrication: They need to be regularly lubricated, often by the machine’s central lubrication system or manual regreasing.

Pros: Lower friction (no seal drag), lower initial cost.

Cons: Highly susceptible to contamination (dust, dirt, moisture), requiring very clean operating environments. Prone to premature failure in dirty conditions.

Use in alternators: Rarely used in modern automotive alternators unless the alternator design specifically provides an oil bath or very clean environment, which is uncommon.

2. Sealed Bearings (2RS/UU – rubber seals, or ZZ – metal shields):

Built-in seals/shields: These are integrated into the bearing design to protect the internal components.

2RS/UU (Rubber Seals): Have rubber or synthetic seals that make contact with the inner ring. Offer excellent protection against dust, dirt, and moisture, and retain grease very well. Slightly higher friction due to contact.

ZZ (Metal Shields): Have non-contact metal shields that sit in a groove. Offer good protection against larger particles and dust, but are less effective against fine dust or liquids than rubber seals. Lower friction than rubber seals.

Pre-lubricated for life: Typically filled with high-quality grease at the factory and designed to be maintenance-free for their service life.

Pros: Excellent protection against contamination, long service life in harsh environments, reduced maintenance.

Cons: Higher initial cost, slightly higher friction (for contact seals), potential for heat build-up in extremely high-speed applications if lubrication is inadequate or seals create too much drag.

Use in alternators: This is the standard type for modern automotive alternators due to the dusty, hot, and sometimes wet conditions they operate in. The sealed design ensures the internal components are protected and properly lubricated for the life of the bearing.