Seals Type:

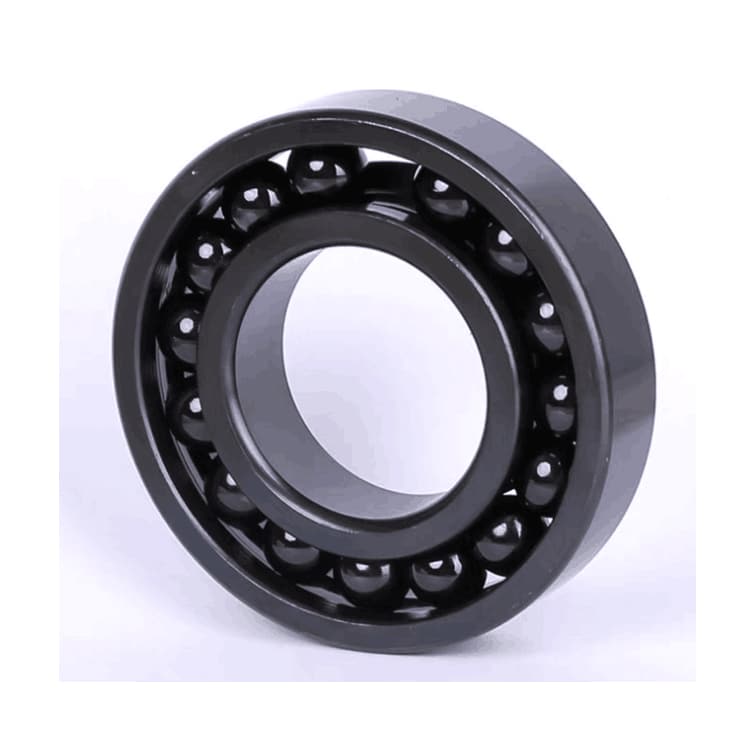

NSK 970213 970214 970215 970216 High Temperature Deep Groove Ball Bearing

Brand Name: TFL or OEM

Outside Diameter: 120 mm

Samples: NSK 970213 970214 970215 970216 High Temperature Deep Groove Ball Bearing

$3.20/Piece | 1 Piece (Min. Order) |

-

Lead Time–If you finish the payment today, your order will ship out within the delivery date.

-

Quantity(Pieces) 1 – 2000 >2000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 500 Pieces)Customized packaging(Min. Order: 500 Pieces)

NSK 970213 970214 970215 970216 High Temperature Deep Groove Ball Bearing

The deep groove ball bearing of deep groove ball bearings is made up of an outer ring, an inner ring, a set of steel balls and a group of retaining structures. There are two types of deep groove ball bearings, single and double row, deep groove ball structure is also divided into two kinds of sealing and opening, the open type is the bearing without sealing structure, sealed type deep groove ball is divided into dust proof seal and oil proof seal. The material of the dust-proof sealing cover is steel stamping, and it only plays a simple way to prevent dust from entering the bearing raceway. The oil proof type is the contact type oil seal, which can effectively prevent the grease overflow in the bearing.

High temperature bearings are widely used in high temperature operation machinery such as metallurgy, kiln, glass, blast furnace, painting equipment, etc.

2Z , 2RS , 2RZ , ZZ , N , NR , any more

|

Model

|

970203

|

|||

|

MASS

|

3

|

kg

|

||

|

Size

|

||||

|

d

|

65

|

mm

|

||

|

D

|

120

|

mm

|

||

|

B

|

23

|

mm

|

||

is a professional bearing manufacturer and dealer in china.We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.We have our own brand “TFL” and applied ISO9001:2000 certificate for certification authority.We attend international bearing fairs, put in many B2B website and achieve many customers all over the world also bulid up good reputation from our customers.

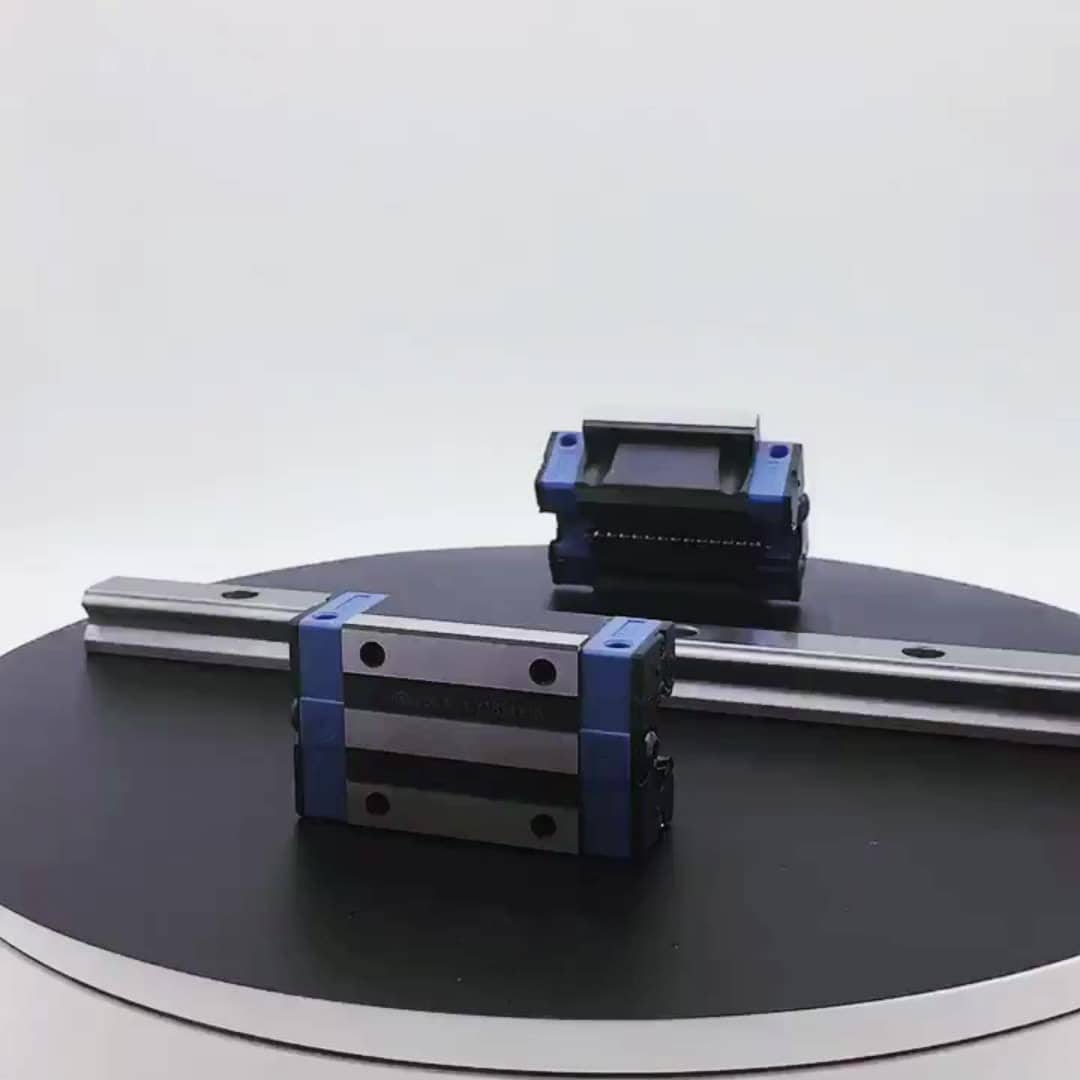

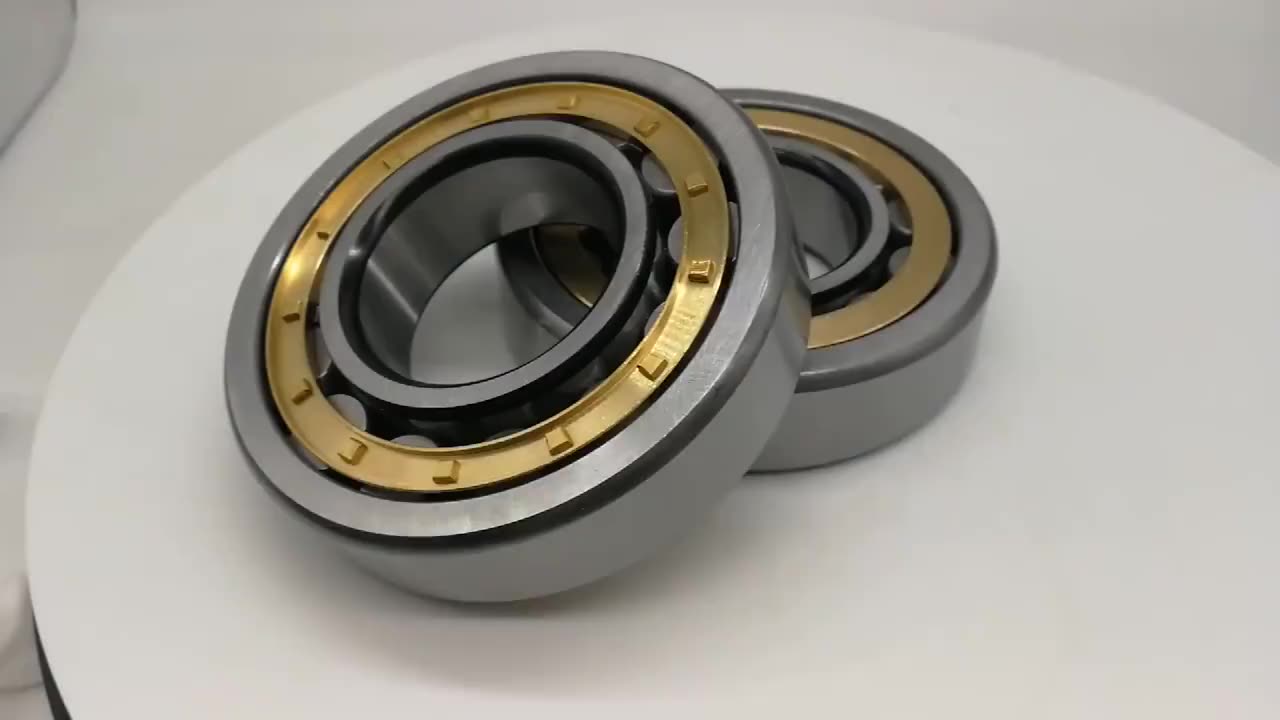

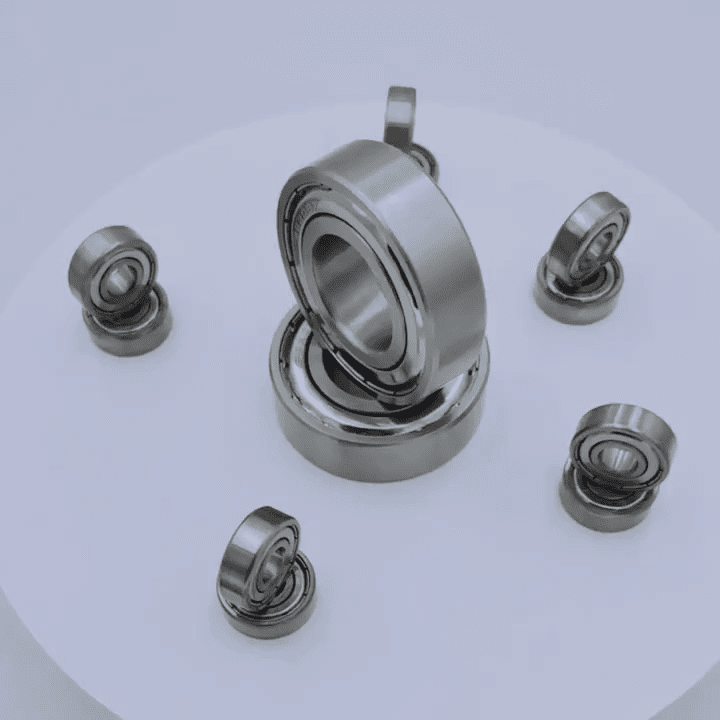

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

FAQ1: What makes NSK 970213–970216 bearings heat resistant?

NSK bearings in the high-temperature series (like 970213–970216) are heat resistant due to three main factors:

Specialized Heat-Treated Steel: The bearing rings and rolling elements are made from materials (often high-carbon chromium steel) that have been specially heat-stabilized. This prevents the steel from changing its shape or hardness when exposed to high temperatures for long periods.

Internal Clearance: They feature a higher internal clearance (looseness) than standard bearings. This is necessary because the components will expand when heated, and the extra space prevents the bearing from seizing.

High-Temperature Lubricant: They are pre-filled with high-performance grease designed specifically to withstand high temperatures without breaking down, drying out, or leaking.

Specialized Heat-Treated Steel: The bearing rings and rolling elements are made from materials (often high-carbon chromium steel) that have been specially heat-stabilized. This prevents the steel from changing its shape or hardness when exposed to high temperatures for long periods.

Internal Clearance: They feature a higher internal clearance (looseness) than standard bearings. This is necessary because the components will expand when heated, and the extra space prevents the bearing from seizing.

High-Temperature Lubricant: They are pre-filled with high-performance grease designed specifically to withstand high temperatures without breaking down, drying out, or leaking.

FAQ2: Which lubricants are used in high-temperature bearings?

The lubricants used in high-temperature bearings are typically:

Fluorinated Greases (PFPE): These synthetic greases offer the best performance at very high temperatures, sometimes exceeding 250℃ to 300℃. They are chemically stable and have low volatility.

Silicon-Based Greases: Used for temperatures up to around 200 ℃.

Inorganic Thickeners: Special thickeners (like polyurea or clay) are used in the grease instead of typical soap-based thickeners, as they maintain their structure better under heat.

Fluorinated Greases (PFPE): These synthetic greases offer the best performance at very high temperatures, sometimes exceeding 250℃ to 300℃. They are chemically stable and have low volatility.

Silicon-Based Greases: Used for temperatures up to around 200 ℃.

Inorganic Thickeners: Special thickeners (like polyurea or clay) are used in the grease instead of typical soap-based thickeners, as they maintain their structure better under heat.