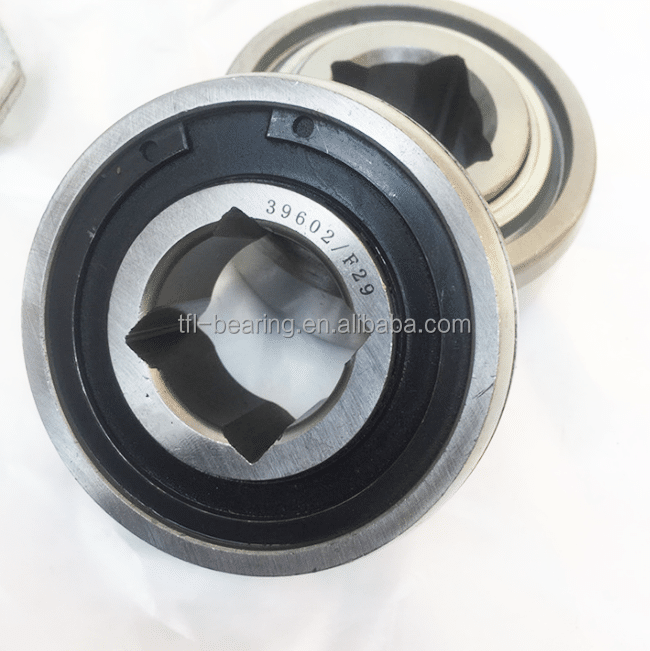

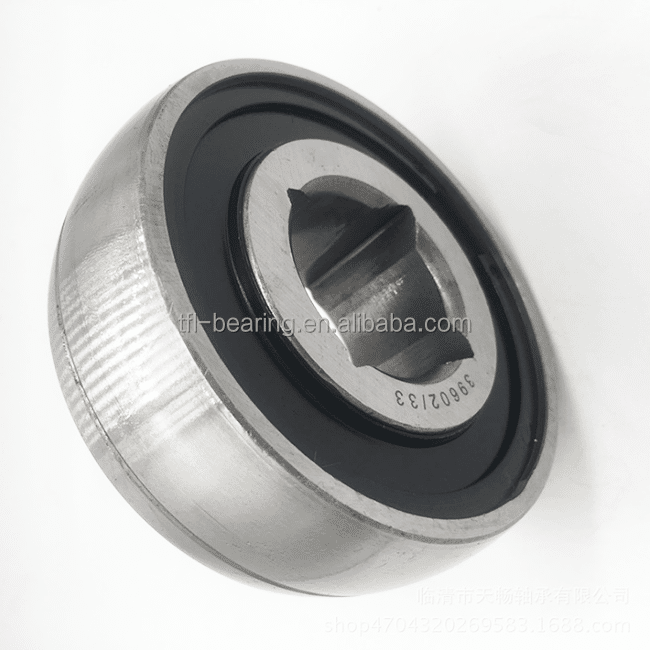

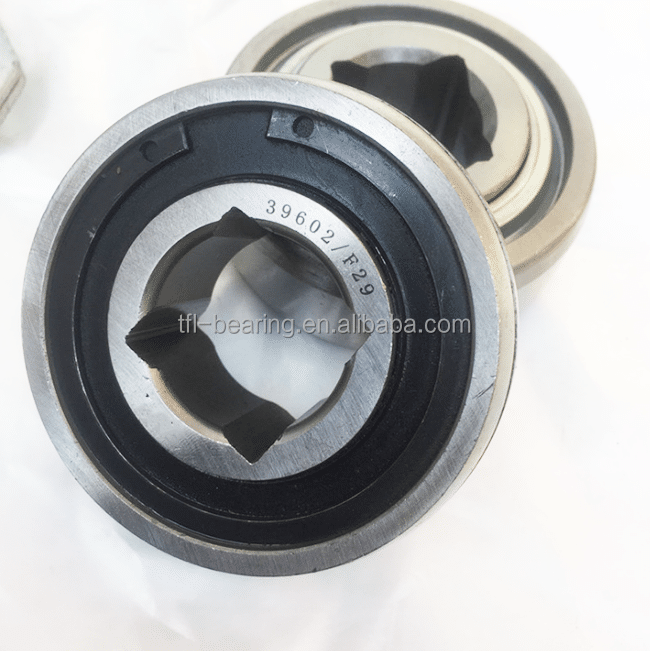

koyo square hole Agricultural Bearing 39602 / F29 39602 / F33 39602 / F41

- Samples:

-

TFL or OEM , 100 – 1500 mm

$6.52/Piece | 1 Piece (Min. Order) |

- Lead Time

If you finish the payment today, your order will ship out within the delivery date.

:

-

Quantity(Pieces) 1 – 2000 >2000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 10 Pieces)Customized packaging(Min. Order: 10 Pieces)

More

|

item

|

value

|

|

Type

|

BALL

|

|

Structure

|

Deep Groove

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Construction works, Energy & Mining

|

|

Bore Size

|

33.3mm – 1000mm

|

|

Model Number

|

39602/F33

|

|

Precision Rating

|

P0 P6 P5 P4 P2

|

|

Seals Type

|

OPEN ZZ 2RS RS

|

|

Number of Row

|

DOUBLE ROW

|

|

Place of Origin

|

China

|

|

Shandong

|

|

|

Material

|

Chrome steel

|

|

Precision Rating

|

P6 P5 P4

|

|

Package

|

Standard

|

|

Size

|

33.3*100*33.3mm

|

|

Operating characteristics(OC)

|

high speed

|

|

Standard

|

ISO9001:2000

|

|

Market:

|

Global

|

|

Service

|

OEM Customized Services

|

|

Hardness

|

60-64

|

|

Related Model

|

39602/F33

|

Frequently Asked Questions

How do Koyo square hole bearings improve agricultural machinery performance?

Koyo square bore bearings improve agricultural machinery performance by providing safe and efficient load distribution, reducing component wear and ensuring smooth operation even in adverse conditions. Their design allows for better alignment and reduced slip, which improves machinery reliability and efficiency.

What are the benefits of using Koyo square hole agricultural bearings?

The benefits of using Koyo square bore agricultural bearings include increased durability, enhanced load carrying capacity and improved alignment, resulting in reduced maintenance and downtime. These bearings are designed to withstand the harsh agricultural environment, ensuring long-lasting performance and reliability.

How to install Koyo 39602 square hole agricultural bearings in farm equipment?

To install a Koyo 39602 square bore agricultural bearing in farm equipment, thoroughly clean the bearing and bearing housing. Align the square bore of the bearing with the square shaft of the equipment. Gently press or tap the bearing to ensure it is evenly and firmly seated. Apply an appropriate lubricant to minimize friction and wear.