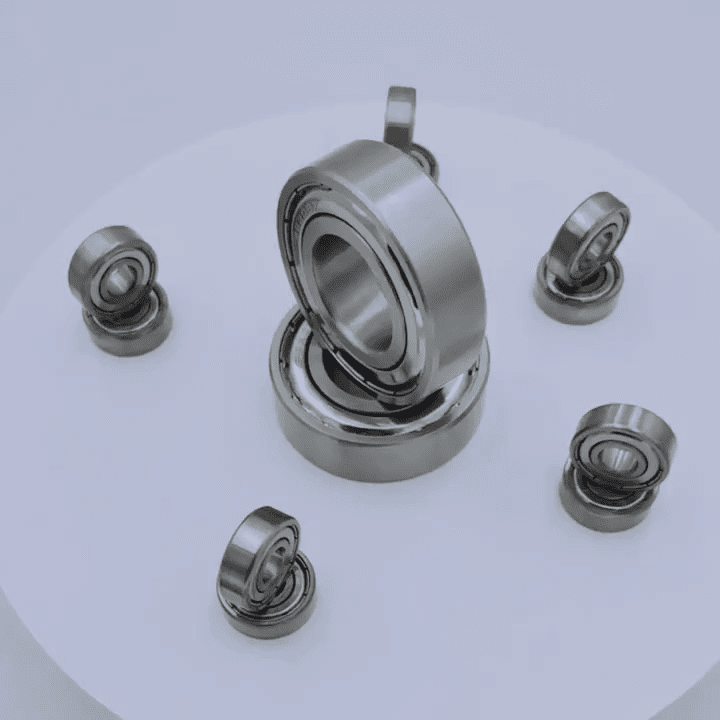

anti-rust Stainless steel bearing SS626ZZ S626-2RS R-1960ZZ B626ZZ S626Z 6*19*6mm

Brand Name: TFL or OEM

-

Customized logo(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

|

item

|

value

|

|

Type

|

BALL

|

|

Structure

|

Deep Groove

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Retail, Construction works , Energy & Mining

|

|

Bore Size

|

6mm – 1000mm

|

|

Model Number

|

S626-2RS

|

|

Precision Rating

|

P0 P6 P5 P4 P2

|

|

Seals Type

|

OPEN ZZ 2RS RS

|

|

Number of Row

|

Single Row

|

|

Place of Origin

|

China

|

|

Shandong

|

|

|

Material

|

stainless steel

|

|

Precision Rating

|

P6 P5 P4

|

|

Package

|

Standard

|

|

Size

|

6*19*6mm

|

|

Operating characteristics(OC)

|

high speed

|

|

Standard

|

ISO3547

|

|

Market:

|

Global

|

|

Service

|

OEM Customized Services

|

|

Hardness

|

60-64

|

|

Related Model

|

S626-2RS

|

Shandong Tefule Bearing Co.,Ltd

is a professional bearing manufacturer and dealer in China. We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

FAQ1: How does stainless steel prevent bearing rust and corrosion?

Stainless steel prevents rust and corrosion primarily through the formation of a passive chromium oxide layer on its surface. Here’s a more detailed explanation:

Chromium Content: Stainless steel contains a minimum of 10.5% chromium. For bearing grades like AISI 440C, the chromium content is typically 16-18%.

Passive Layer Formation: When chromium is exposed to oxygen (either in the air or water), it rapidly reacts to form a very thin, stable, and invisible layer of chromium oxide (Cr2O3) on the surface. This layer is called the “passive layer” or “passive film.”

Protective Barrier: This passive layer acts as an extremely effective barrier that prevents further oxidation (rusting) of the iron atoms within the steel. It essentially seals the surface from the corrosive environment.

Self-Healing: A remarkable property of this passive layer is its self-healing capability. If the surface is scratched or damaged, exposing fresh metal to oxygen, the chromium reacts almost instantaneously to reform the passive layer, maintaining its protective integrity.

Corrosion Resistance: This passive layer is highly resistant to many corrosive agents, including water, humidity, and mild acids/alkalis. The higher the chromium content (and sometimes other alloying elements like molybdenum), the more robust and resistant the passive layer becomes to more aggressive environments.

Chromium Content: Stainless steel contains a minimum of 10.5% chromium. For bearing grades like AISI 440C, the chromium content is typically 16-18%.

Passive Layer Formation: When chromium is exposed to oxygen (either in the air or water), it rapidly reacts to form a very thin, stable, and invisible layer of chromium oxide (Cr2O3) on the surface. This layer is called the “passive layer” or “passive film.”

Protective Barrier: This passive layer acts as an extremely effective barrier that prevents further oxidation (rusting) of the iron atoms within the steel. It essentially seals the surface from the corrosive environment.

Self-Healing: A remarkable property of this passive layer is its self-healing capability. If the surface is scratched or damaged, exposing fresh metal to oxygen, the chromium reacts almost instantaneously to reform the passive layer, maintaining its protective integrity.

Corrosion Resistance: This passive layer is highly resistant to many corrosive agents, including water, humidity, and mild acids/alkalis. The higher the chromium content (and sometimes other alloying elements like molybdenum), the more robust and resistant the passive layer becomes to more aggressive environments.

FAQ2: Difference between SS626ZZ and 626ZZ chrome steel bearings?

The key difference between SS626ZZ and 626ZZ (without the ‘S’ or ‘SS’ prefix) lies solely in the material composition of their rings and rolling elements, which then dictates their performance characteristics.

SS626ZZ is for applications where corrosion resistance and hygiene are critical, even if it means a slight compromise in load capacity and higher cost.

626ZZ is the standard workhorse bearing for general applications where high load capacity, durability, and cost-effectiveness are priorities, and the environment is dry and non-corrosive.

SS626ZZ is for applications where corrosion resistance and hygiene are critical, even if it means a slight compromise in load capacity and higher cost.

626ZZ is the standard workhorse bearing for general applications where high load capacity, durability, and cost-effectiveness are priorities, and the environment is dry and non-corrosive.