Cylindrical Roller Bearing Installation Guide

Contents

hide

Introduction

Want your cylindrical roller bearings to last a long time and run smoothly? Then proper installation is key. Ask yourself, do you want to avoid costly premature failures? Of course, you do!

Whether you’re new to this or a seasoned pro, following the right steps is nothing to it. This guide gives you simple and practical suggestions for both press fits and shrink fits. You’ll quickly find out how to avoid common mistakes and keep your bearings in top condition.

Don’t rush; take your time and you’ll have those bearings running like new in no time.

Understanding Cylindrical Roller Bearings

Cylindrical roller bearings are a type of rolling-element bearing that uses cylinders instead of spheres to maintain the separation between the moving parts. They are typically used in high-load applications and are designed for both radial and axial loads.

What Are Cylindrical Roller Bearings?

Cylindrical roller bearings are designed with rollers in a cylindrical shape. These bearings have high load-carrying capacity, which makes them ideal for heavy-duty applications like industrial machines, automotive parts, and even aerospace equipment.

Benefits of Cylindrical Roller Bearings

Cylindrical roller bearings offer better load distribution, longer service life, and higher performance compared to other bearing types. They are especially useful in applications with high radial loads.

Common Applications of Cylindrical Roller Bearings

These bearings are used in applications like electric motors, gearboxes, pumps, and conveyor systems. They are great for conditions where strength and durability are important.

Preparing for Cylindrical Roller Bearing Installation

Before putting in cylindrical roller bearings, you need to make sure that everything is in great shape. This part talks about the steps that need to be taken to get ready for the installation so that it goes smoothly.

Ensuring Cleanliness of Bearings and Tools

Keep things clean. Bearings can be damaged by dirt, grease, and other contaminants, so make sure that all tools, work areas, and bearings are clean.

Checking for Surface Damage on Bearings

For used bearings, check for burrs, scratches, or cracks. For new bearings, verify that they match the required specifications and are free of defects.

Verifying Proper Fit and Dimensions

Confirm that the bearing dimensions match the application requirements. Check radial and axial play, ensuring the correct fit with the shaft and housing.

Press Fits Method of Cylindrical Roller Bearing

Press Fits is suitable for small bearings with loose fits. Here’s how to do it correctly to avoid damaging the bearing.

Using a Sleeve and Hammer for Installation

A sleeve and hammer method can be used for small bearings, applying gentle and even force on the bearing ring to avoid tilting or misalignment.

Ensuring Even Pressure Distribution

When applying pressure, it is important to do so uniformly across the bearing’s outer ring. This prevents damage and ensures a smooth fit.

Checking for Correct Alignment

Always ensure that the bearing is aligned straight during installation. Misalignment could result in bearing failure or reduced lifespan.

Shrink Fits Method of Cylindrical Roller Bearing

For larger cylindrical roller bearings, a shrink fit may be required to achieve the necessary fit. This section explains how to apply this method safely.

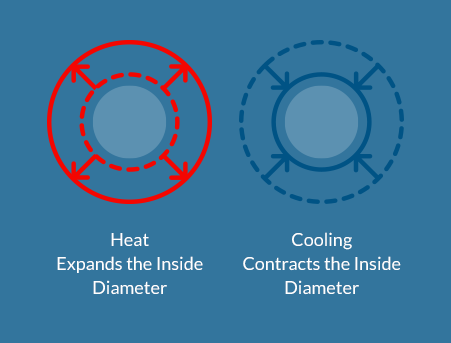

Heating the Bearing and Housing

Heat the bearing and housing evenly to expand them for easier installation. The recommended temperature should not exceed 120°C for open bearings.

(Reference: 2. Mounting | NSK Global)

The Importance of Uniform Heating

Ensure the heat is evenly distributed to avoid thermal stress. Overheating can result in bearing damage or material changes.

Correct Temperature for Bearings with Seals

If you don’t want to damage the seals or oils inside bearings with seals, the temperature should not go above 80°C.

Post-installation Checks and Maintenance of Cylindrical Roller Bearing

After installation, performing the necessary checks ensures the bearing operates correctly and prevents premature failure.

Verifying Proper Lubrication

Lubricate the bearing as per the manufacturer’s instructions. Proper lubrication reduces wear and prevents overheating.

Ensuring Smooth Operation

Check for smooth rotation and ensure there’s no unusual noise or vibration. These could be signs of improper installation.

Regular Maintenance to Extend Bearing Life

Set up a regular maintenance schedule to inspect bearings for wear and replace them when necessary.

Troubleshooting Common Installation Issues of Cylindrical Roller Bearing

Sometimes, issues arise during installation. Here’s how to troubleshoot and solve common problems.

Bearing Misalignment During Installation

If the bearing is misaligned, it can lead to uneven load distribution. Use proper installation tools to keep the bearing aligned.

Damage During Press Fits

Bearing damage can happen when assembly is done in cold weather because of uneven pressure. When you use the sleeve and hammer method, be careful and make sure the surface of the tool is smooth.

Overheating During Shrink Fits

If the bearing seals get too hot, they can break or the material can change. Always keep an eye on the temperature and make sure it’s heating evenly.

Conclusion

Do you want your cylindrical roller bearings to last a long time and work well? Then proper installation and maintenance are key – it’s really nothing to it!

Whether you go with press fits or shrink fits, sticking to the right steps means your bearings will run smoothly, saving you from downtime and costly repairs. It’s that simple!

Looking for more info or top-notch cylindrical roller bearings? Pop over to TFL Bearings today and get expert advice and support. You’ll quickly find everything you need.

Related Questions

How do I install cylindrical roller bearings properly?

Follow the manufacturer’s instructions, choose the right installation method, and ensure cleanliness and alignment during installation.

What is the difference between press fits and shrink fit installation?

The press fit method is used for small bearings with loose fits, while shrink fit method is for larger bearings that require expansion through heating.

How often should I lubricate cylindrical roller bearings?

Bearings should be lubricated regularly according to the manufacturer’s specifications to prevent wear and ensure smooth operation.

Can improper installation damage cylindrical roller bearings?

Yes, misalignment or uneven pressure during installation can lead to bearing damage or premature failure.

How long do cylindrical roller bearings last with proper maintenance?

With proper installation, lubrication, and maintenance, cylindrical roller bearings can last many years, often over 10 years in some applications.