How to Choose the Perfect Cylindrical Roller Bearings for Your Needs

Introduction

Choosing the right cylindrical roller bearing may seem like a specialized task, but it’s easier than it sounds once you know the essential factors to consider.

Here, I’ve compiled a simple guide to help you select the perfect cylindrical roller bearing that fits your needs.

Step 1: Understand Your Application for Cylindrical Roller Bearings

Before you purchase, it’s important to ask yourself: What is the bearing going to be used for?

-

High-load applications: Are you working with equipment that needs to bear heavy radial loads, such as motors, gearboxes, or turbines? Cylindrical roller bearings are specifically designed to handle high radial loads, making them ideal for these heavy-duty tasks.

-

Limited space or compact designs: If space is tight, cylindrical roller bearings are often an excellent choice due to their compact size and high load capacity.

-

Speed and precision: Are you dealing with machinery that requires high rotational speeds or precision performance, like in precision tools or pumps? Some cylindrical roller bearings are designed for such tasks with reduced friction and heat generation.

Once you understand your specific application, you’ll be in a better position to determine which type of cylindrical roller bearing best suits your needs.

Step 2: Key Features of Cylindrical Roller Bearings

Why opt for cylindrical roller bearings? Here are some important benefits:

-

High Load Capacity: These bearings are designed to handle large radial loads, making them perfect for high-pressure applications.

-

Excellent Performance in Harsh Conditions: Cylindrical roller bearings are made to perform well under extreme conditions, such as high temperatures or heavy-duty vibrations.

-

Low Maintenance: With fewer moving parts and a durable design, cylindrical roller bearings often require less maintenance, saving you time and effort in the long run.

-

Versatility: Available in various configurations, cylindrical roller bearings can be adapted for different types of machinery, such as those requiring non-separable or separable designs.

Step 3: Check Cylindrical Roller Bearings Configuration

Cylindrical roller bearings come in different designs, each with unique features suited for different applications. Understanding these configurations can help you make the right choice:

Single-row cylindrical roller bearings

These are ideal for applications where space is limited and moderate radial load capacity is required. They are widely used in electric motors, fans, and other smaller machinery.

Double-row cylindrical roller bearings

These bearings provide higher load capacity and are suited for heavy-duty applications, like industrial gearboxes and steel mill machinery.

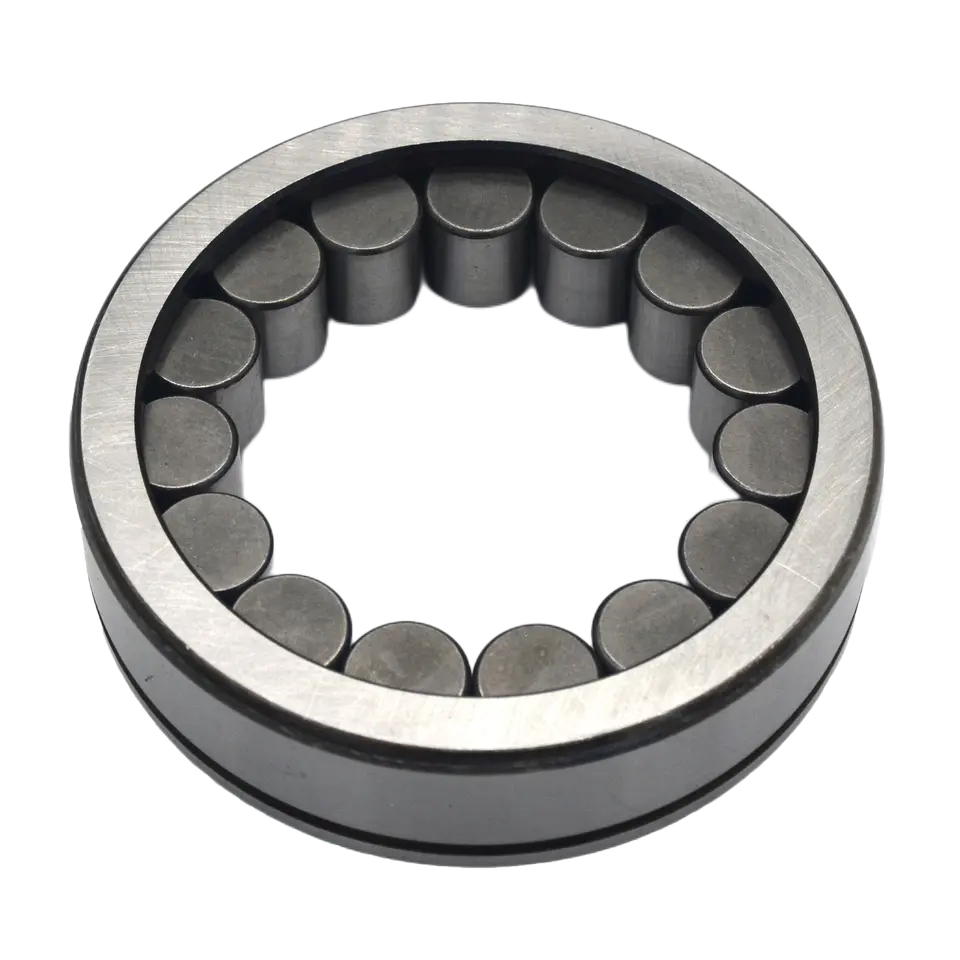

Full complement cylindrical roller bearings

With no cage and an increased number of rollers, these bearings offer higher radial load capacity and are ideal for situations where high load demands and low speeds are prevalent.

Split cylindrical roller bearings

Designed for easy installation and maintenance, these bearings can be split into two parts, allowing for quick assembly or disassembly, especially in large equipment where space is tight or bearings are hard to access.

Eccentric cylindrical roller bearings

Featuring a unique design with an eccentric sleeve, these bearings are useful in applications requiring precise adjustment or alignment, such as in automotive or construction machinery.

Each of these bearing configurations is tailored to meet specific operational needs, ensuring that you can select the optimal bearing for your application.

Step 4: Assess Cylindrical Roller Bearings Material and Coating Options

The material and coating of cylindrical roller bearings can significantly affect their performance, especially in extreme environments:

Steel cylindrical roller bearings

The most common material used, offering excellent load capacity and durability. However, they are prone to corrosion in moist or harsh conditions.

Stainless steel cylindrical roller bearings

These are a better choice for corrosive environments, offering enhanced resistance to rust and corrosion.

Ceramic cylindrical roller bearings

Made from materials like silicon nitride (Si3N4) or zirconia (ZrO2), ceramic cylindrical roller bearings offer higher speed capabilities, increased stiffness, and superior wear and corrosion resistance. They are ideal for high-precision applications, such as CNC spindles or environments with extreme wear conditions.

(Reference: Temperature-dependent Mechanical and Oxidation Behavior of in Situ Formed ZrN/ZrO2-containing Si3N4-based Composite by Liu et al., 2023)

Choosing the right material and coating can extend the service life of the bearing, especially in challenging operating environments.

Step 5: Select A Trusted Supplier for Cylindrical Roller Bearings

Just like any other important equipment, the quality of your cylindrical roller bearing is crucial for your machinery’s performance. When choosing a supplier, here are some factors to consider:

-

Reputation: Has the supplier been trusted by others in your industry? Customer reviews and testimonials are a good way to gauge the quality of the product and service.

-

Price vs. Quality: While it’s tempting to go for the cheapest option, keep in mind that durability and performance matter. Choose a supplier that offers the best balance of price and quality.

-

After-Sales Support: Does the supplier offer technical assistance and guidance? Can they help with installation or troubleshooting if you encounter issues with the bearing?

Conclusion

Cylindrical roller bearings are ideal for equipment that needs high-load capacity and consistent performance, whether it’s used in motors, turbines, or conveyors.

Choosing the right bearing ensures that your equipment runs smoothly, reduces downtime, and saves on future maintenance costs.

I hope this guide has been helpful! If you have any questions or need further assistance, feel free to reach out. Let’s find the perfect cylindrical roller bearing for your needs!