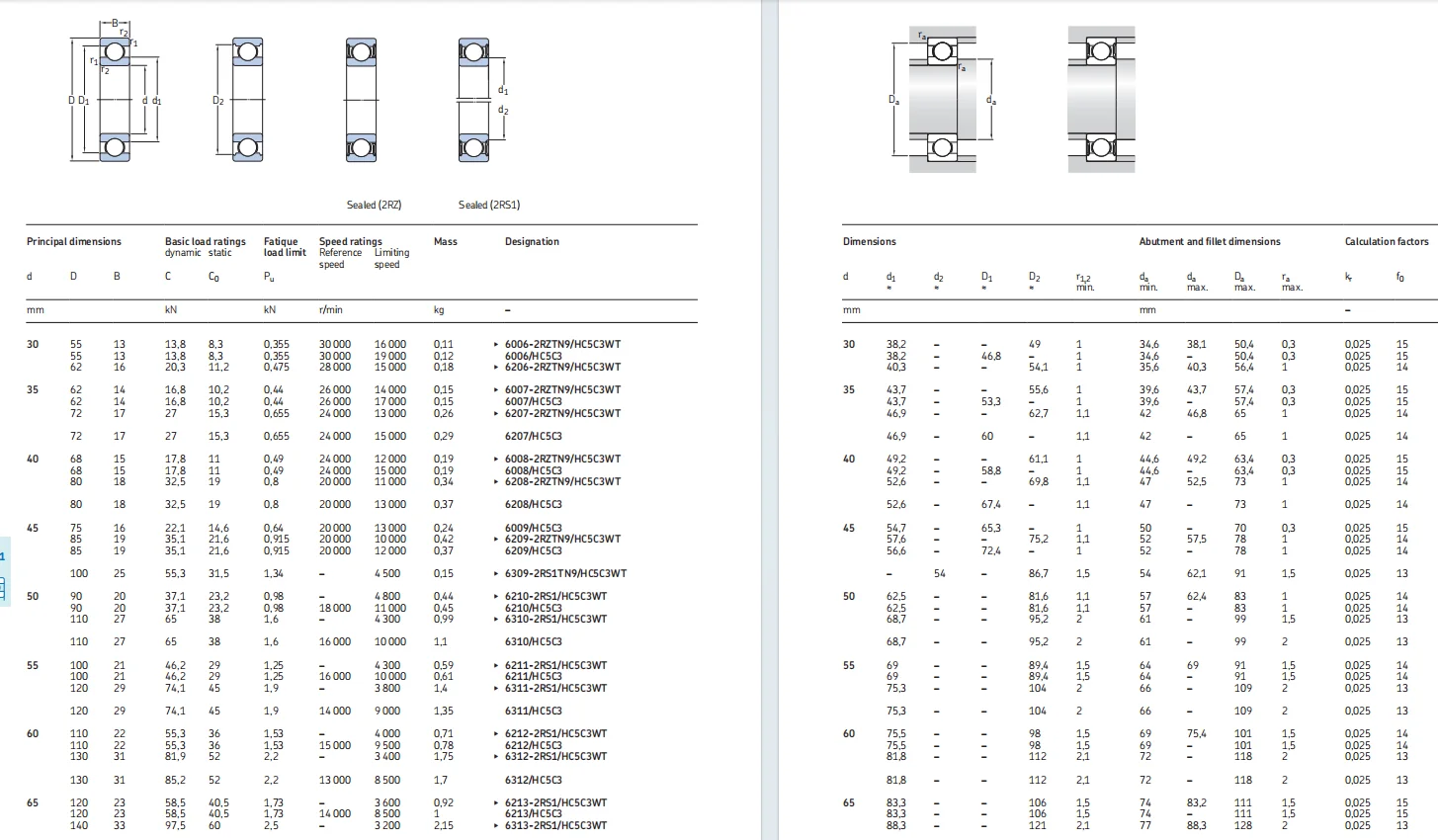

6310/HC5C3 Deep Groove Ball Bearing 6310-HC5C3 50x110x27mm Hybrid Bearing 6310 HC5C3 Ceramic Ball Bearing

Key attributes

Industry-specific attributes

Applicable Industries

Manufacturing Plant, Machinery Repair Shops, Retail, Other

Bore Size

30 – 65 mm

Precision Rating

P6

Number of Row

Single row

Other attributes

Place of Origin

China

Type

BALL

Structure

Deep Groove

Model Number

6310/HC5C3

Seals Type

Open

Model name

Hybrid deep groove ball bearing

Material

chrome steel (GCR-15)

rolling element material

Si3N4

Service

OEM Service& Good service

Type

ball bearing

Quality standard

ISO 9001:2008 approved

Feature

Long Life .durable

Stock

yes

MOQ

2 Pcs

technical support

yes

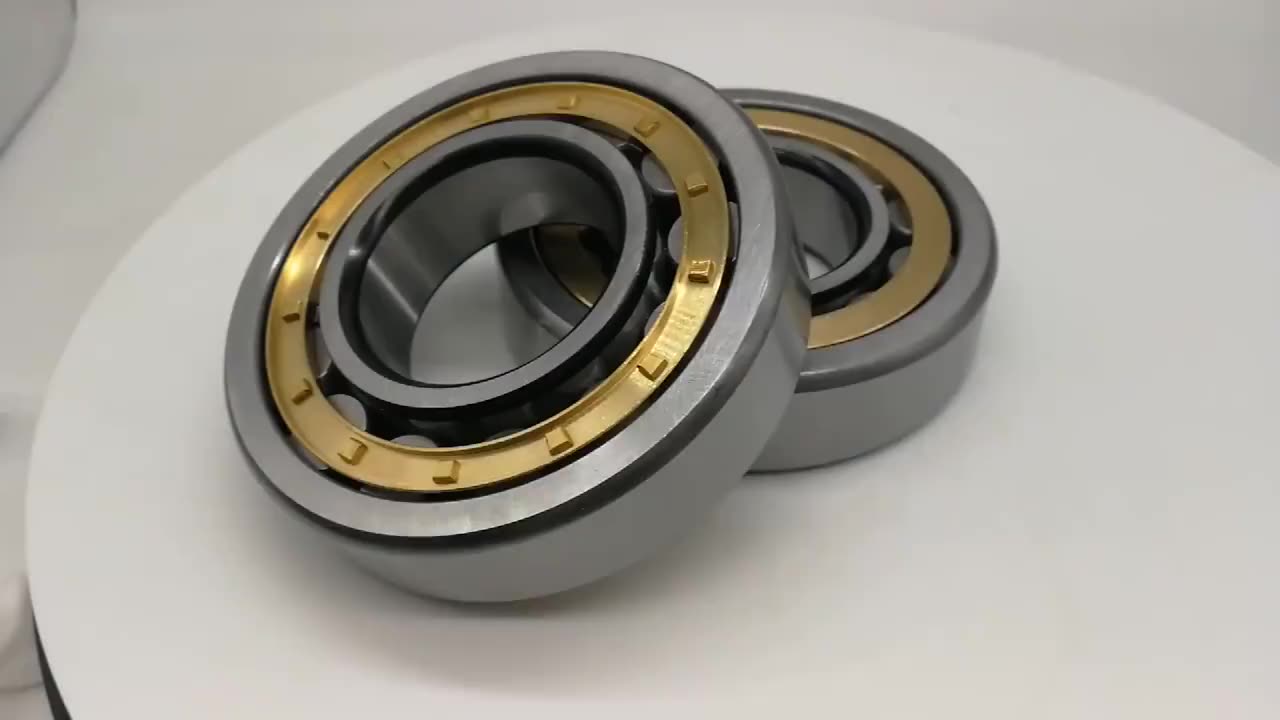

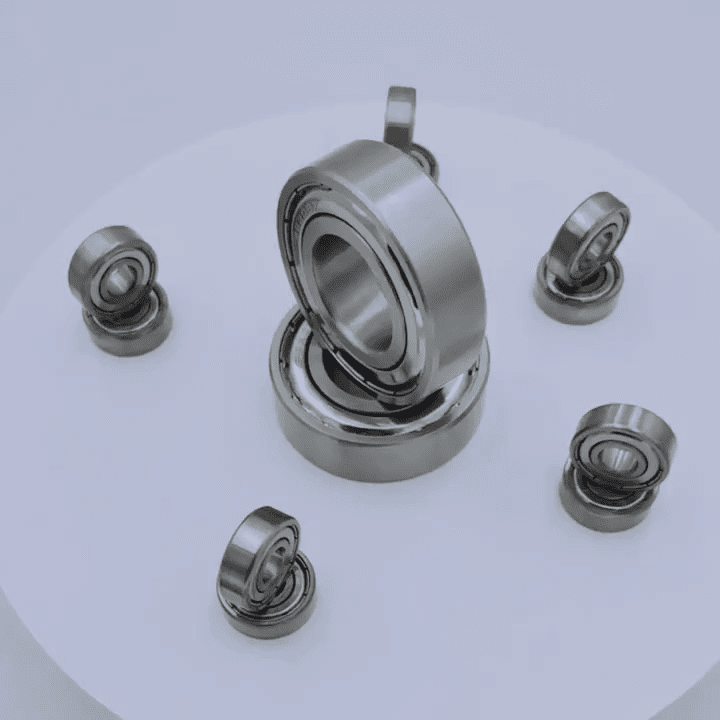

Hybrid ceramic deep groove ball bearings

Hybrid ceramic single row deep groove ball bearings are composed of inner and outer rings made of bearing steel and rolling elements made of bearing grade silicon nitride (Si3N4), enabling the bearings to achieve electrical insulation. Deep groove ball bearings are the most commonly used type of bearing, especially in motors. Silicon nitride rolling elements not only prevent bearings from being damaged by current, but also enhance the performance of bearings, extend their service life, improve rotational speed capability, enhance wear resistance and bearing stiffness, reduce the risk of adhesive wear or pseudo Bush indentation, and have lower sensitivity to temperature changes compared to steel rolling element bearings of the same size. This feature makes it suitable for use in harsh working conditions and polluted environments.1. Prevent shaft from being damaged by overcurrent

2. Especially suitable for harsh conditions and polluted environments

3. Typical advantages of single row deep groove ball bearings

Hybrid ceramic single row deep groove ball bearings are composed of inner and outer rings made of bearing steel and rolling elements made of bearing grade silicon nitride (Si3N4), enabling the bearings to achieve electrical insulation. Deep groove ball bearings are the most commonly used type of bearing, especially in motors. Silicon nitride rolling elements not only prevent bearings from being damaged by current, but also enhance the performance of bearings, extend their service life, improve rotational speed capability, enhance wear resistance and bearing stiffness, reduce the risk of adhesive wear or pseudo Bush indentation, and have lower sensitivity to temperature changes compared to steel rolling element bearings of the same size. This feature makes it suitable for use in harsh working conditions and polluted environments.1. Prevent shaft from being damaged by overcurrent

2. Especially suitable for harsh conditions and polluted environments

3. Typical advantages of single row deep groove ball bearings