Taper Roller Excavator Bearing 36990/20 Ll735449/10 L540049/10 Ll639249/10 Lm739749 L540048/10

Bore Size: 177.8 mm

Outside Diameter: 215.9 mm

-

Customization:

-

Customized logo(Min. Order: 1 Pieces)Customized packaging(Min. Order: 1 Pieces)

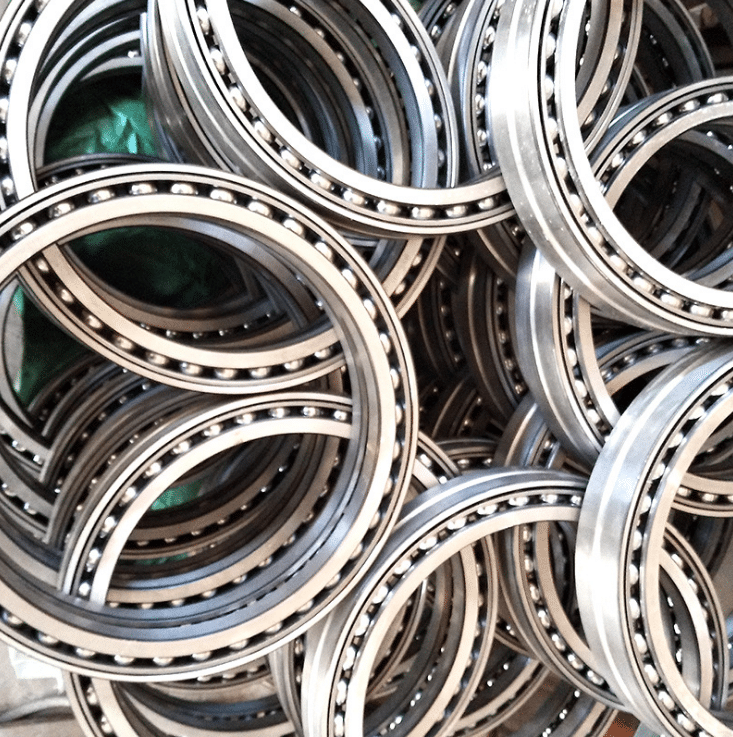

Taper Roller Excavator Bearing 36990/20 Ll735449/10 L540049/10 L540049/10 L639249 Ll639249/10 Lm739749 L540048/10

Excavator bearing are widely used in excavator. Mainly used for KOBELCO excavator, KOMATSU excavator, CATERPILLAR excavator, KATO excavator, HITACHI excavator, DAEWOO excavator, HYUNDAI excavator, Volvo excavator, etc.

Application:

Excavator specialized angular ball bearing are used for the application of excavator machinery. This kind of angular contact ball bearing has big contact angle(40 degree), so can under take big axial load, and aslo axial radial allied load. Moreover it cancarry heavier load capacity than the same size bearings because it has more balls inside. It is widely used for all imported exavator.

|

Bearing No.

|

ID(mm)

|

OD(mm)

|

H(mm)

|

|

T2ED045-1

|

45

|

95

|

36

|

|

4T-T2ED045

|

45

|

95

|

37

|

|

4T-T7FC055ST

|

55

|

115

|

34

|

|

T7FC060

|

60

|

125

|

37

|

|

T7FC060

|

60

|

125

|

37

|

|

4T-T7FC065ST

|

65

|

130

|

37

|

|

4T-T7FC060

|

65

|

130

|

37

|

|

10BA14

|

105

|

145

|

20

|

|

CR2256

|

110

|

150

|

20.5

|

|

BD110-1

|

110

|

140

|

28

|

|

BA115-1

|

115

|

145

|

15

|

|

120BA16

|

120

|

165

|

22

|

|

561904P6X

|

120

|

170

|

27

|

|

120BA16

|

120

|

165

|

22

|

|

HS05154

|

126

|

154

|

14

|

|

HS05154

|

126

|

154

|

14

|

|

LL225749/10

|

127

|

165.985

|

18.3

|

|

BD130-1SA

|

130

|

166

|

34

|

|

BD130-16

|

130

|

166

|

40

|

|

DE2622

|

130

|

166

|

34

|

|

BD130-1

|

130

|

166

|

34.7

|

|

BD130-16

|

130

|

166

|

41

|

|

L327249/10

|

133.35

|

177.008

|

25.4

|

|

BA135-6

|

135

|

170

|

20

|

|

SF2812PX1

|

140

|

175

|

17.5

|

|

140BA180

|

140

|

180

|

22

|

|

SF2812VPX1

|

140

|

175

|

17.5

|

|

BD140-1

|

140

|

180

|

38

|

|

SF2907VPX1

|

143

|

175

|

16

|

|

SF2912VPX1

|

145

|

200

|

27.5

|

|

BA152-2036

|

150

|

203

|

26

|

|

151BA179

|

151

|

179

|

14

|

|

BA152-2306

|

152

|

230

|

26

|

|

BD155-6A

|

155

|

198

|

47

|

|

BD155-1

|

155

|

198

|

47

|

|

SF3227PX1

|

160

|

200

|

20

|

|

SF3235PX1

|

160

|

200

|

20

|

|

SF3215

|

160

|

200

|

28

|

|

SF3227VPX1

|

160

|

200

|

10

|

|

BA160

|

160

|

210

|

24

|

|

BD155-5A

|

165

|

210

|

54

|

|

BA16519A

|

165

|

203

|

19

|

|

BA165-203

|

165

|

203

|

17.5

|

|

BD165-6A

|

165

|

210

|

52

|

|

BA168-1

|

168

|

205

|

20

|

|

SF3417VPX1

|

168

|

205

|

19

|

|

36990/20

|

177.8

|

227.012

|

30.165

|

|

LL735449/10

|

177.8

|

215.9

|

20.6

|

|

180BA-2256

|

180

|

225

|

22

|

|

BA180-4WSA

|

180

|

250

|

33

|

|

180BN19

|

180

|

250

|

33

|

|

SF3607PX1

|

180

|

225

|

15

|

|

BA180-4WSA

|

180

|

250

|

33

|

|

SF3607VPX1

|

180

|

225

|

21

|

|

180BA-2256

|

180

|

225

|

21.5

|

|

180BN19W

|

180

|

250

|

33

|

|

184BA-2251

|

184

|

226

|

21

|

|

184BA-2251

|

184

|

226

|

21.5

|

|

BD185-6A

|

185

|

232

|

31

|

|

BA195-3A

|

195

|

280

|

36.5

|

|

BA195-3A

|

195

|

280

|

36

|

|

LL639249/10

|

196.85

|

241.3

|

23.812

|

|

L540049/10

|

196.85

|

254

|

28.575

|

|

LM739749

|

196.85

|

257.175

|

39.688

|

|

R196Z-4

|

196.85

|

241.3

|

23.812

|

|

R196Z-4

|

196.85

|

241.3

|

23.8

|

|

L639249

|

196.85

|

241.3

|

23.8

|

|

L540049/10

|

196.85

|

254

|

28.5

|

|

BA200-10

|

200

|

280

|

38

|

|

200BA27V-2

|

200

|

270

|

33

|

|

SF4007PX1

|

200

|

250

|

25

|

|

SF4019PX1

|

200

|

260

|

30

|

|

L540048/10

|

200

|

254

|

28.575

|

|

BA200-7B

|

200

|

250

|

25

|

|

BA200-10

|

200

|

280

|

38

|

|

200BA27V

|

200

|

272

|

33

|

|

BA200-6A

|

200

|

250

|

24

|

|

BD200-6A

|

200

|

255

|

32

|

|

SF4007VX1

|

200

|

250

|

25

|

|

BA205-1A

|

205

|

295

|

40

|

|

BA205-1

|

205

|

295

|

40

|

|

AC423040-1

|

210

|

300

|

40

|

|

210BA29V

|

210

|

295

|

35

|

|

AC423040

|

210

|

300

|

40

|

|

210BA29V

|

210

|

295

|

35

|

|

SF4224PX1

|

210

|

280

|

35

|

|

BA220-6SA

|

220

|

276

|

26

|

|

BA220-6WSA

|

220

|

276

|

26

|

|

B-SF4454PX1

|

220

|

295

|

33

|

|

B-SF4444PX1

|

220

|

295

|

33

|

|

CR4411PX1

|

220

|

290

|

32

|

|

BN220-1

|

220

|

280

|

28

|

|

BA220-6WSA

|

220

|

276

|

26

|

|

CR4411

|

220

|

290

|

33.5

|

|

BA220-1

|

220

|

280

|

28

|

|

SF4444VPX1

|

220

|

295

|

33

|

|

B-SF4454VPX1

|

220

|

295

|

33

|

|

SF4411VPX1

|

220

|

290

|

32.5

|

|

BA222-1WSA

|

222

|

273

|

26

|

|

BA222-1WSA

|

222

|

273

|

26

|

|

AC4531

|

225

|

315

|

36

|

|

BA4531

|

225

|

315

|

40

|

|

AC4531

|

225

|

315

|

40

|

|

544090/116

|

228.6

|

295.275

|

33.338

|

|

544090/544

|

228.6

|

295.275

|

33.3

|

|

AC463240

|

230

|

320

|

40

|

|

AC4615

|

230

|

300

|

35

|

|

AC4629

|

230

|

290

|

27

|

|

AC4631

|

230

|

310

|

40

|

|

AC4630

|

230

|

300

|

35

|

|

BA230-7T12SA

|

230

|

300

|

35

|

|

230BA27V2

|

230

|

300

|

35

|

|

BA230-7T12SA

|

230

|

300

|

35

|

|

BA120-7

|

230

|

300

|

35

|

|

AC463240

|

230

|

320

|

40

|

|

AC4629

|

230

|

290

|

27

|

|

AC4630

|

230

|

300

|

35

|

|

AC4631

|

230

|

310

|

39

|

|

BA230-7

|

230

|

300

|

35

|

|

BA230-2

|

230

|

320

|

40

|

|

BA230-3

|

230

|

300

|

35

|

|

SF4615VPX1

|

230

|

300

|

35

|

|

230BN30-2

|

230

|

300

|

33

|

|

SF4639PX1

|

230

|

300

|

34

|

|

544091/118

|

231.775

|

300.038

|

33.338

|

|

544090/544

|

231.775

|

300.038

|

33.3

|

|

BA240-3ASA

|

240

|

310

|

32

|

|

SF4815VPX1

|

240

|

310

|

34

|

|

SF4831PX1

|

240

|

310

|

33.4

|

|

SF4852PX1

|

240

|

310

|

33

|

|

SF4826PX1

|

240

|

310

|

33

|

|

SF4860PX1

|

240

|

320

|

38.6

|

|

BA240-3WSA

|

240

|

310

|

33

|

|

BA240-5

|

240

|

308

|

32

|

|

240BA35S1

|

240

|

320

|

38

|

|

SF5225VPX1

|

240

|

320

|

33

|

|

SF4903

|

245

|

305

|

31.5

|

|

BA246-2A

|

246

|

313

|

32

|

|

BA246-1SA

|

246

|

308

|

33

|

|

BA246-2A

|

246

|

313

|

32

|

|

AC5033

|

250

|

330

|

37

|

|

BA250-4A

|

250

|

330

|

37

|

|

BD155-4A

|

250

|

330

|

37

|

|

AC5033

|

250

|

330

|

38

|

|

BA250-4

|

250

|

330

|

38

|

|

BA257-1

|

257

|

315

|

30

|

|

AC523438-1

|

260

|

340

|

38

|

|

BA260-3A

|

260

|

340

|

38

|

|

BA260-4A

|

260

|

340

|

38

|

|

260BA355-2

|

260

|

355

|

44

|

|

SF5235

|

260

|

330

|

35

|

|

AC523438-1

|

260

|

340

|

38

|

|

BA260-3

|

260

|

340

|

38

|

|

BA260-4

|

260

|

340

|

38

|

|

BA260-6

|

260

|

340

|

36

|

|

BA270-3

|

270

|

350

|

39

|

|

BA280-2SA

|

280

|

370

|

40

|

|

AC563946AB

|

280

|

390

|

46

|

|

AC563946AB

|

280

|

390

|

46

|

|

BA280-2SA

|

280

|

370

|

40

|

|

AC5836

|

289

|

355

|

34

|

|

BA289-1A

|

289

|

255

|

34

|

|

AC5836

|

289

|

355

|

34

|

|

BA289-1

|

289

|

355

|

33

|

|

BA290-3A

|

290

|

380

|

42

|

|

BA290-3A

|

290

|

380

|

40

|

|

BA290-1SA

|

290

|

355

|

32.5

|

|

AC6037-1

|

300

|

370

|

34

|

|

BA300-5A

|

300

|

380

|

40

|

|

BA300-4WSA

|

300

|

395

|

52

|

|

SF6037-1

|

300

|

370

|

34

|

|

SF6015PX1

|

300

|

372

|

36

|

|

CR6016PX1

|

300

|

380

|

38

|

|

AC6037

|

300

|

370

|

33

|

|

BA300-4WSA

|

300

|

395

|

50

|

|

BA300-5

|

300

|

380

|

40

|

|

BA300-1WSA

|

300

|

390

|

40

|

|

MC6034

|

300

|

340

|

18

|

|

HS05383

|

320

|

383

|

30

|

|

SF6413PX3A

|

320

|

395

|

35

|

|

BA345-1

|

345

|

470

|

45

|

|

BA345-1

|

345

|

470

|

54

|

Shandong Tefule Bearing Co.,Ltd

is a professional bearing manufacturer and dealer in china.We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.We have our own brand “TFL” and applied ISO9001:2000 certificate for certification authority.We attend international bearing fairs, put in many B2B website and achieve many customers all over the world also bulid up good reputation from our customers.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

is a professional bearing manufacturer and dealer in china.We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.We have our own brand “TFL” and applied ISO9001:2000 certificate for certification authority.We attend international bearing fairs, put in many B2B website and achieve many customers all over the world also bulid up good reputation from our customers.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

FAQ: How to maintain excavator taper roller bearings?

Proper maintenance is critical for the long life of excavator bearings.

1. Grease: Use the correct type and amount of grease recommended by the manufacturer. EP (Extreme Pressure) grease is typically used for heavy-duty applications.

2. Frequency: Lubricate the bearings according to the excavator’s service manual. For excavator final drives and swing mechanisms, grease is typically applied daily or after every shift.

3. Check for Contamination: Inspect the seals and remove any dirt or debris that could contaminate the bearing.

4. Visual Inspection: Regularly check for signs of wear, rust, or damage.

1. Grease: Use the correct type and amount of grease recommended by the manufacturer. EP (Extreme Pressure) grease is typically used for heavy-duty applications.

2. Frequency: Lubricate the bearings according to the excavator’s service manual. For excavator final drives and swing mechanisms, grease is typically applied daily or after every shift.

3. Check for Contamination: Inspect the seals and remove any dirt or debris that could contaminate the bearing.

4. Visual Inspection: Regularly check for signs of wear, rust, or damage.