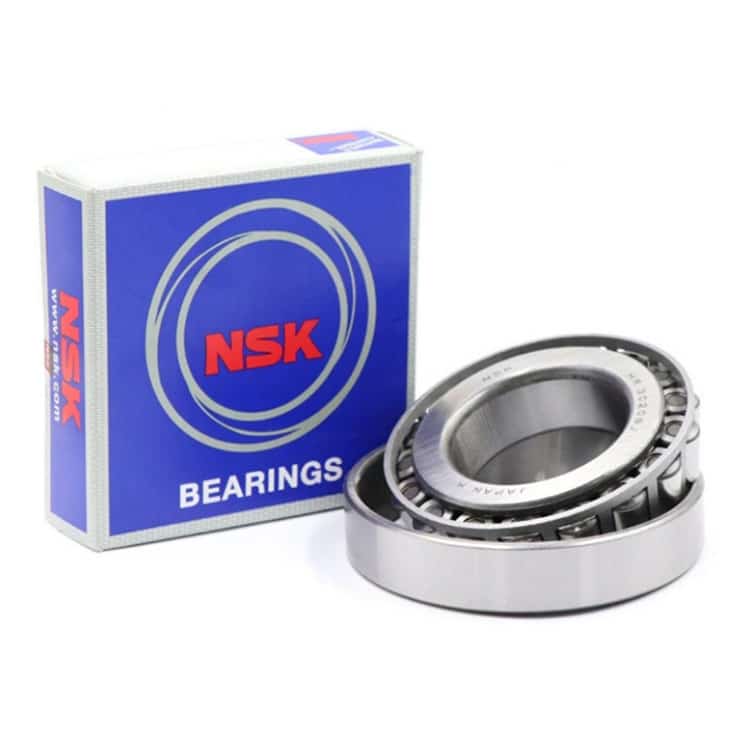

NTN 30311 original forklift bearing 55*120*31.5mm tapered roller bearings

- Samples:

-

55mm , 120mm$3.80/Piece | 1 Piece (Min. Order) |

- Lead TimeIf you finish the payment today, your order will ship out within the delivery date.:

Quantity(Pieces) 1 - 1000 >1000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

More

Alibaba.com Freight | Compare Rates | Learn more

Alibaba.com Freight | Compare Rates | Learn more

Tapered roller bearing

Tapered roller bearings are separable bearings. Both the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of rows installed. Single row tapered roller bearings can bear radial load and single direction axial load. When the bearing bears radial load, it will produce an axial component force, so when it needs another bearing that can bear the axial force in the opposite direction to balance it. It is widely used in industries such as automobiles, rolling mills, mining, metallurgy, and plastic machinery.

The single row tapered roller bearing has an outer ring, its inner ring and a set of tapered rollers are an inner ring assembly enclosed by a basket-shaped cage. The outer ring can be separated from the inner ring assembly. According to the ISO tapered roller bearing external dimension standard, any standard type of tapered roller bearing outer ring or inner ring assembly should be able to achieve internationality with the same type of outer ring or inner ring assembly exchange. That is to say, in addition to the external dimensions and tolerances of the outer ring of the same model, which must comply with the requirements of ISO492 (GB307), the cone angle and component cone diameter of the inner ring component must also comply with the relevant regulations for interchange.

Generally, the tapered angle of the outer ring raceway of a single-row tapered roller bearing is 10°~19° before it can bear the combined action of axial load and radial load at the same time. The larger the cone angle, the greater the ability to withstand axial load. Bearings with large taper angle, add B to the rear code, and the taper angle is between 25°~29°, which can bear larger axial load. In addition, single-row tapered roller bearings can adjust the size of the clearance during installation.

The outer ring (or inner ring) of a double-row tapered roller bearing is a whole. The small end faces of the two inner rings (or outer rings) are similar, with a spacer in the middle. The clearance is adjusted by the thickness of the spacer. The thickness of the spacer can also be used to adjust the pre-interference of the double-row tapered roller bearing.

Four-row tapered roller bearings. The performance of this type of bearing is basically the same as that of double-row tapered roller bearings, but it bears greater radial load and lower limit speed than double-row tapered roller bearings. It is mainly used for heavy machinery, such as Rolling mills, etc.

Multi-sealed double and four-row tapered roller bearings, ZWZ provides long-life, multi-sealed double and four-row tapered roller bearings. Carry out a new and personalized design of the bearing, change the traditional design method of fully sealed bearing, and adopt a new type of sealing structure that combines sealing and dust prevention to improve the sealing effect and improve the sealing performance. Compared with open structure bearings, multi-sealed double and four-row tapered roller bearings have an increased life span of 20%-40%; lubricant consumption can be reduced by 80%.

Tapered roller bearings 30311 |

||

d |

55mm |

|

D |

120mm |

|

T |

31.5mm |

|

B |

29mm |

|

C |

25mm |

|

Weight |

1.63kg |

|

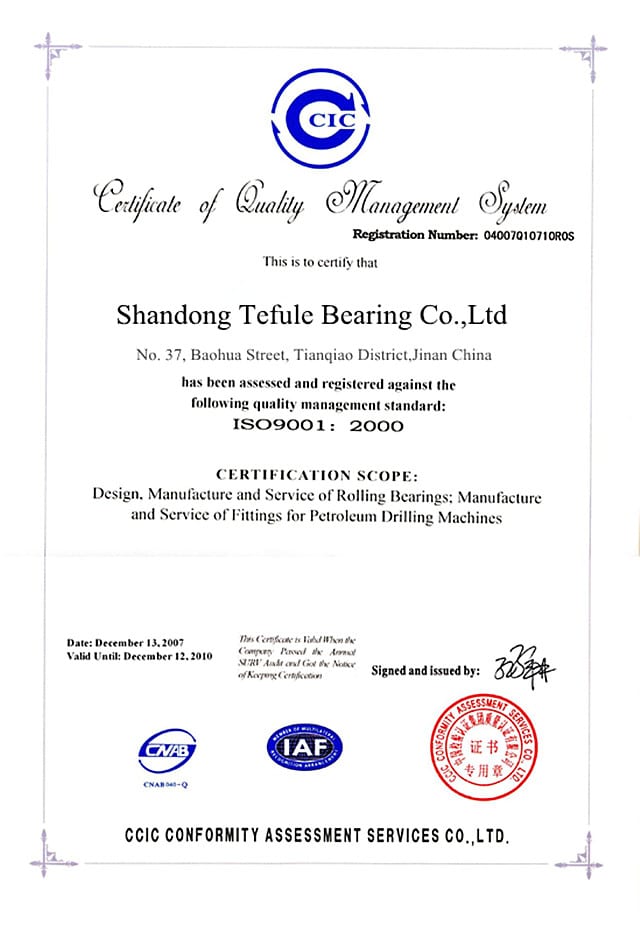

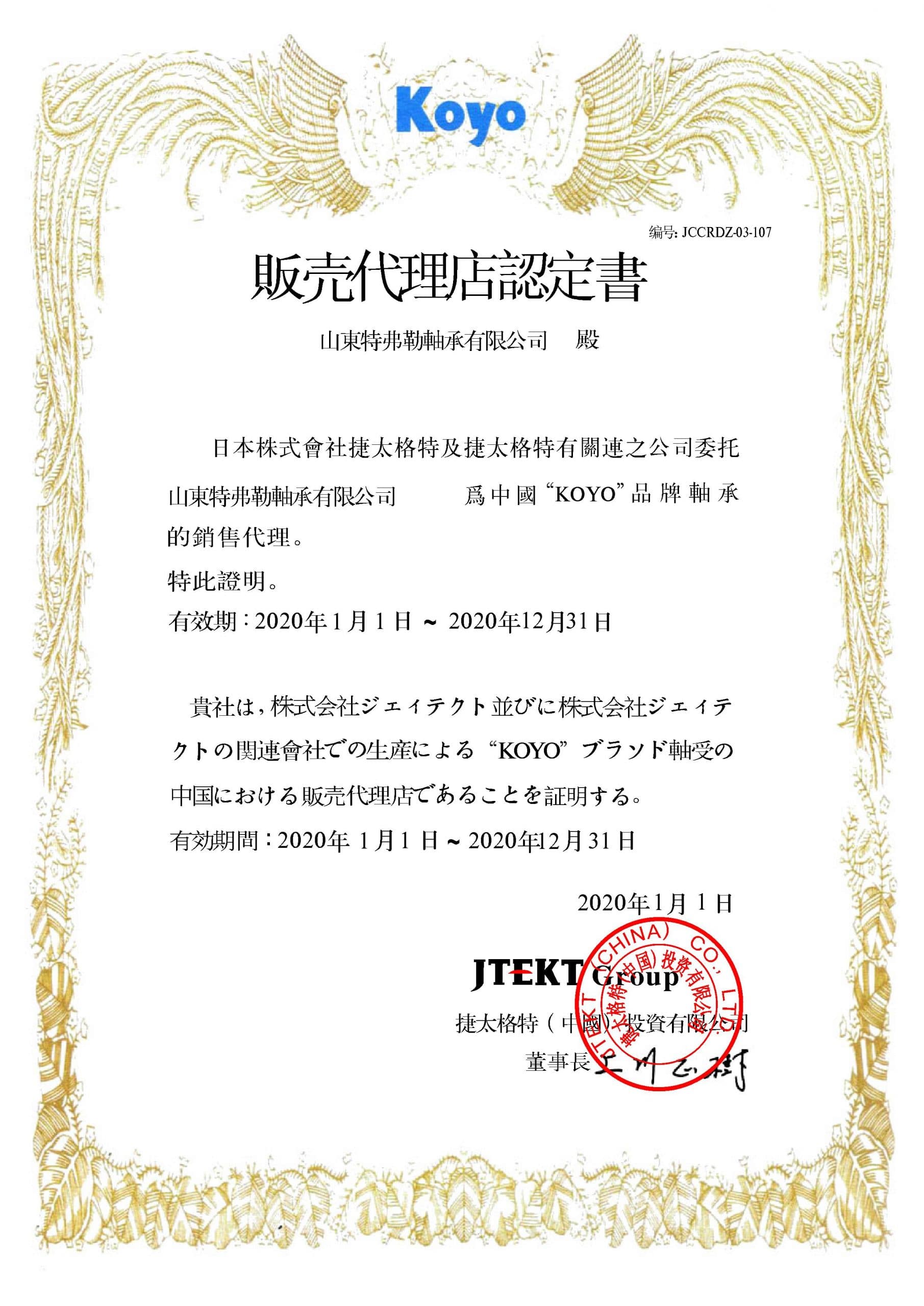

Shandong Tefule Bearing Co.,Ltd is a professional bearing manufacturer and dealer in china.We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.We have our own brand "TFL" and applied ISO9001:2000 certificate for certification authority.We attend international bearing fairs, put in many B2B website and achieve many customers all over the world also bulid up good reputation from our customers.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers' demands.

1. Who are we?

We are based in Shandong, China,sell to Mid East(30.00%),South Asia(20.00%),Northern Europe(15.00%),Africa(15.00%),Southeast

Asia(10.00%),Western Europe(10.00%),North America(10.00%).

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Ball Bearing,Roller Bearing,Wheel Bearing,Linear Bearing,Pillow Block Bearing

4. Why should you buy from us not from other suppliers?

Our company has gained rich experience: we know how to exactly handle every step of production.Our products possess the advantages of competitive price and good service.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash,Escrow;

We are based in Shandong, China,sell to Mid East(30.00%),South Asia(20.00%),Northern Europe(15.00%),Africa(15.00%),Southeast

Asia(10.00%),Western Europe(10.00%),North America(10.00%).

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Ball Bearing,Roller Bearing,Wheel Bearing,Linear Bearing,Pillow Block Bearing

4. Why should you buy from us not from other suppliers?

Our company has gained rich experience: we know how to exactly handle every step of production.Our products possess the advantages of competitive price and good service.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash,Escrow;

Tapered roller bearing

Tapered roller bearings are separable bearings. Both the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of rows installed. Single row tapered roller bearings can bear radial load and single direction axial load. When the bearing bears radial load, it will produce an axial component force, so when it needs another bearing that can bear the axial force in the opposite direction to balance it. It is widely used in industries such as automobiles, rolling mills, mining, metallurgy, and plastic machinery.

The single row tapered roller bearing has an outer ring, its inner ring and a set of tapered rollers are an inner ring assembly enclosed by a basket-shaped cage. The outer ring can be separated from the inner ring assembly. According to the ISO tapered roller bearing external dimension standard, any standard type of tapered roller bearing outer ring or inner ring assembly should be able to achieve internationality with the same type of outer ring or inner ring assembly exchange. That is to say, in addition to the external dimensions and tolerances of the outer ring of the same model, which must comply with the requirements of ISO492 (GB307), the cone angle and component cone diameter of the inner ring component must also comply with the relevant regulations for interchange.

Generally, the tapered angle of the outer ring raceway of a single-row tapered roller bearing is 10°~19° before it can bear the combined action of axial load and radial load at the same time. The larger the cone angle, the greater the ability to withstand axial load. Bearings with large taper angle, add B to the rear code, and the taper angle is between 25°~29°, which can bear larger axial load. In addition, single-row tapered roller bearings can adjust the size of the clearance during installation.

The outer ring (or inner ring) of a double-row tapered roller bearing is a whole. The small end faces of the two inner rings (or outer rings) are similar, with a spacer in the middle. The clearance is adjusted by the thickness of the spacer. The thickness of the spacer can also be used to adjust the pre-interference of the double-row tapered roller bearing.

Four-row tapered roller bearings. The performance of this type of bearing is basically the same as that of double-row tapered roller bearings, but it bears greater radial load and lower limit speed than double-row tapered roller bearings. It is mainly used for heavy machinery, such as Rolling mills, etc.

Multi-sealed double and four-row tapered roller bearings, ZWZ provides long-life, multi-sealed double and four-row tapered roller bearings. Carry out a new and personalized design of the bearing, change the traditional design method of fully sealed bearing, and adopt a new type of sealing structure that combines sealing and dust prevention to improve the sealing effect and improve the sealing performance. Compared with open structure bearings, multi-sealed double and four-row tapered roller bearings have an increased life span of 20%-40%; lubricant consumption can be reduced by 80%.

Tapered roller bearing

Tapered roller bearings are separable bearings. Both the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of rows installed. Single row tapered roller bearings can bear radial load and single direction axial load. When the bearing bears radial load, it will produce an axial component force, so when it needs another bearing that can bear the axial force in the opposite direction to balance it. It is widely used in industries such as automobiles, rolling mills, mining, metallurgy, and plastic machinery.

The single row tapered roller bearing has an outer ring, its inner ring and a set of tapered rollers are an inner ring assembly enclosed by a basket-shaped cage. The outer ring can be separated from the inner ring assembly. According to the ISO tapered roller bearing external dimension standard, any standard type of tapered roller bearing outer ring or inner ring assembly should be able to achieve internationality with the same type of outer ring or inner ring assembly exchange. That is to say, in addition to the external dimensions and tolerances of the outer ring of the same model, which must comply with the requirements of ISO492 (GB307), the cone angle and component cone diameter of the inner ring component must also comply with the relevant regulations for interchange.

Generally, the tapered angle of the outer ring raceway of a single-row tapered roller bearing is 10°~19° before it can bear the combined action of axial load and radial load at the same time. The larger the cone angle, the greater the ability to withstand axial load. Bearings with large taper angle, add B to the rear code, and the taper angle is between 25°~29°, which can bear larger axial load. In addition, single-row tapered roller bearings can adjust the size of the clearance during installation.

The outer ring (or inner ring) of a double-row tapered roller bearing is a whole. The small end faces of the two inner rings (or outer rings) are similar, with a spacer in the middle. The clearance is adjusted by the thickness of the spacer. The thickness of the spacer can also be used to adjust the pre-interference of the double-row tapered roller bearing.

Four-row tapered roller bearings. The performance of this type of bearing is basically the same as that of double-row tapered roller bearings, but it bears greater radial load and lower limit speed than double-row tapered roller bearings. It is mainly used for heavy machinery, such as Rolling mills, etc.

Multi-sealed double and four-row tapered roller bearings, ZWZ provides long-life, multi-sealed double and four-row tapered roller bearings. Carry out a new and personalized design of the bearing, change the traditional design method of fully sealed bearing, and adopt a new type of sealing structure that combines sealing and dust prevention to improve the sealing effect and improve the sealing performance. Compared with open structure bearings, multi-sealed double and four-row tapered roller bearings have an increased life span of 20%-40%; lubricant consumption can be reduced by 80%.

Tapered roller bearing

Tapered roller bearings are separable bearings. Both the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of rows installed. Single row tapered roller bearings can bear radial load and single direction axial load. When the bearing bears radial load, it will produce an axial component force, so when it needs another bearing that can bear the axial force in the opposite direction to balance it. It is widely used in industries such as automobiles, rolling mills, mining, metallurgy, and plastic machinery.

The single row tapered roller bearing has an outer ring, its inner ring and a set of tapered rollers are an inner ring assembly enclosed by a basket-shaped cage. The outer ring can be separated from the inner ring assembly. According to the ISO tapered roller bearing external dimension standard, any standard type of tapered roller bearing outer ring or inner ring assembly should be able to achieve internationality with the same type of outer ring or inner ring assembly exchange. That is to say, in addition to the external dimensions and tolerances of the outer ring of the same model, which must comply with the requirements of ISO492 (GB307), the cone angle and component cone diameter of the inner ring component must also comply with the relevant regulations for interchange.

Generally, the tapered angle of the outer ring raceway of a single-row tapered roller bearing is 10°~19° before it can bear the combined action of axial load and radial load at the same time. The larger the cone angle, the greater the ability to withstand axial load. Bearings with large taper angle, add B to the rear code, and the taper angle is between 25°~29°, which can bear larger axial load. In addition, single-row tapered roller bearings can adjust the size of the clearance during installation.

The outer ring (or inner ring) of a double-row tapered roller bearing is a whole. The small end faces of the two inner rings (or outer rings) are similar, with a spacer in the middle. The clearance is adjusted by the thickness of the spacer. The thickness of the spacer can also be used to adjust the pre-interference of the double-row tapered roller bearing.

Four-row tapered roller bearings. The performance of this type of bearing is basically the same as that of double-row tapered roller bearings, but it bears greater radial load and lower limit speed than double-row tapered roller bearings. It is mainly used for heavy machinery, such as Rolling mills, etc.

Multi-sealed double and four-row tapered roller bearings, ZWZ provides long-life, multi-sealed double and four-row tapered roller bearings. Carry out a new and personalized design of the bearing, change the traditional design method of fully sealed bearing, and adopt a new type of sealing structure that combines sealing and dust prevention to improve the sealing effect and improve the sealing performance. Compared with open structure bearings, multi-sealed double and four-row tapered roller bearings have an increased life span of 20%-40%; lubricant consumption can be reduced by 80%.