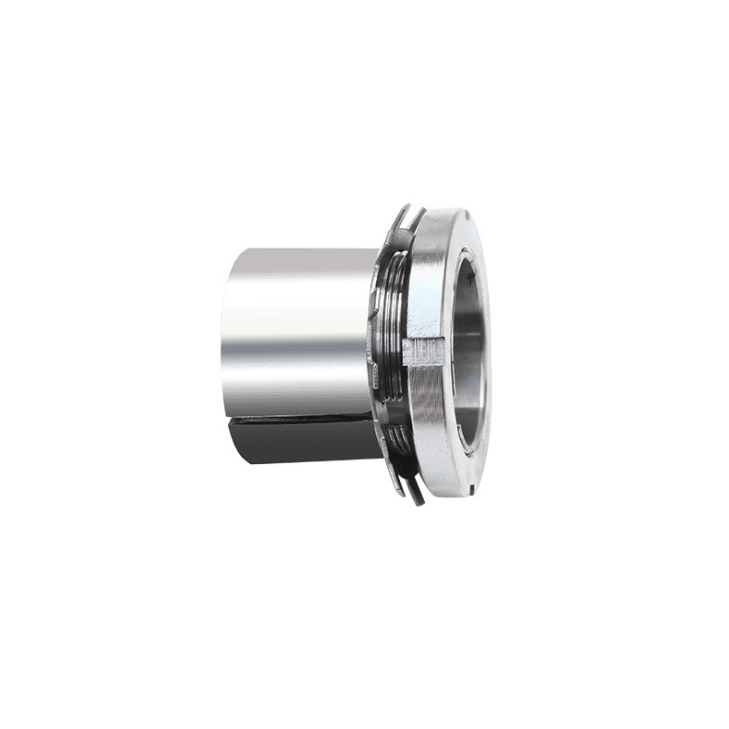

Bearing adapter sleeve H2307 2310 2313 2319 Self-aligning ball bearing Withdrawal sleeve Lock sleeve

-

Customization:

-

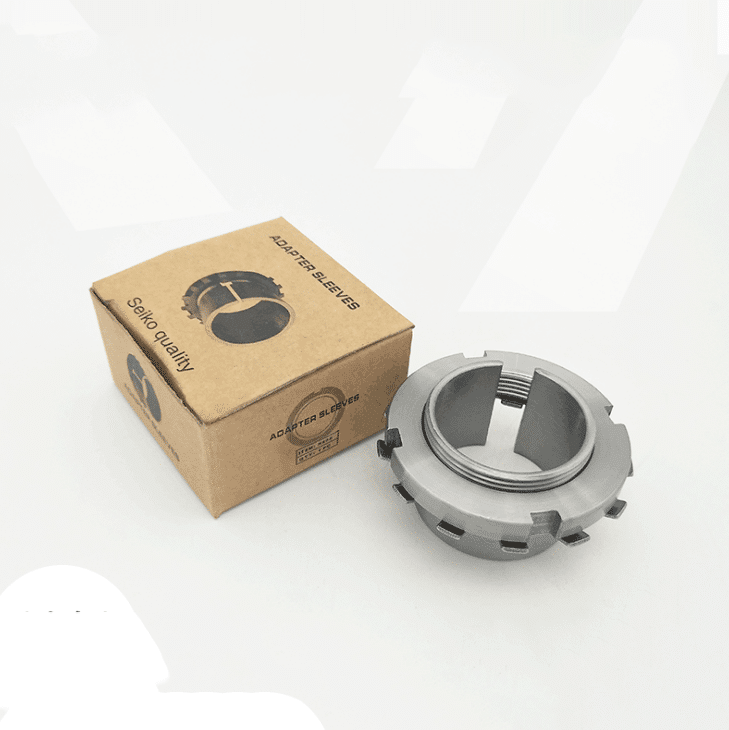

Customized logo(Min. Order: 10 Pieces)Customized packaging(Min. Order: 10 Pieces)

Bearing adapter sleeve H2307 2310 2313 2319 Self-aligning ball bearing Withdrawal sleeve Lock sleeve

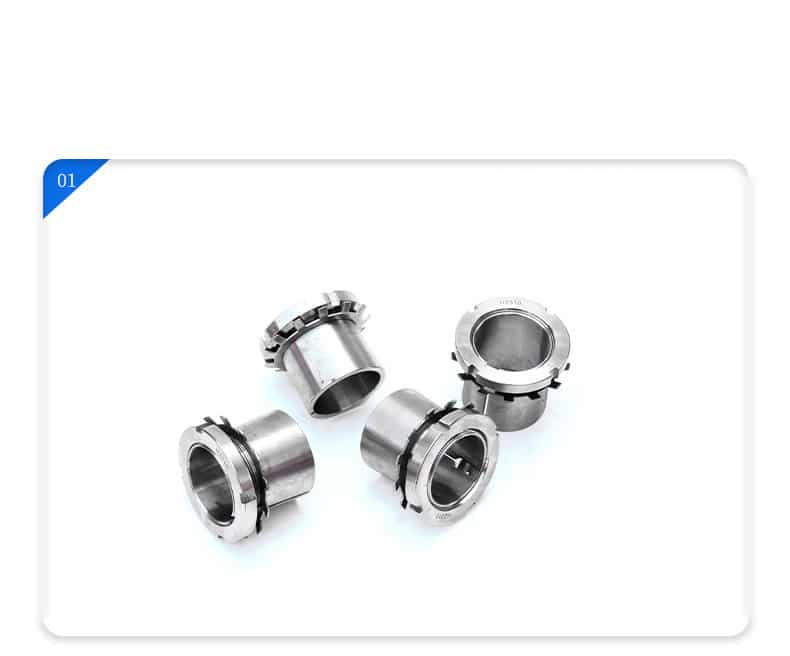

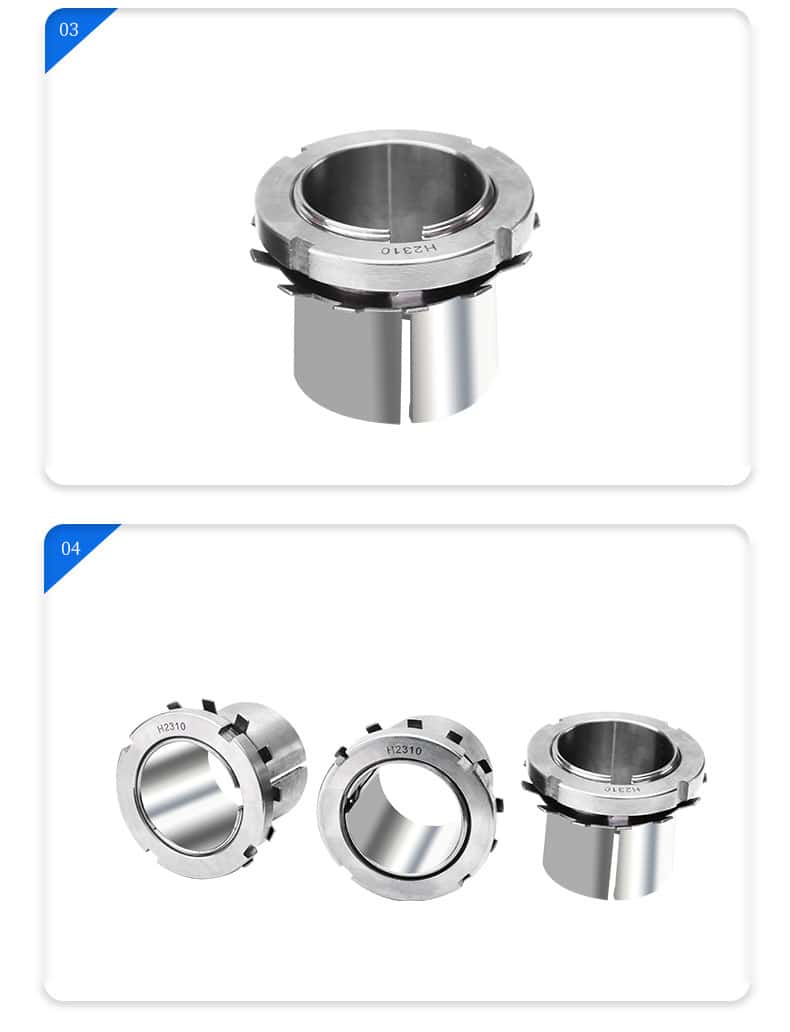

Adapter sleeves are the most commonly used components for locating bearings with a tapered bore onto a cylindrical seat as they can be used on plain shafts or stepped shafts.

They are easy to install and require no additional location on the shaft. When used on plain shafts, the bearing can be located at any position on the shaft. When used on stepped shafts together with an L-shaped spacer ring, the bearing can be accurately positioned axially, thereby facilitating bearing mounting and dismounting.

|

Principal dimensions

|

Adapter sleeve assembly

|

Included lock nut

|

Included locking device

|

||||||

|

d1[mm]

|

d[mm]

|

d3[mm]

|

B1[mm]

|

||||||

|

17

|

20

|

32

|

24

|

H 204

|

KM 4

|

MB 4

|

|||

|

17

|

20

|

32

|

28

|

H 304

|

KM 4

|

MB 4

|

|||

|

17

|

20

|

38

|

28

|

H 304 E

|

KMFE 4

|

||||

|

20

|

25

|

38

|

26

|

H 205

|

KM 5

|

MB 5

|

|||

|

20

|

25

|

38

|

29

|

H 305

|

KM 5

|

MB 5

|

|||

|

20

|

25

|

38

|

29

|

H 305 E

|

KMFE 5

|

||||

|

20

|

25

|

38

|

35

|

H 2305

|

KM 5

|

MB 5

|

|||

|

25

|

30

|

45

|

27

|

H 206

|

KM 6

|

MB 6

|

|||

|

25

|

30

|

45

|

31

|

H 306

|

KM 6

|

MB 6

|

|||

|

25

|

30

|

45

|

31

|

H 306 E

|

KMFE 6

|

||||

|

25

|

30

|

45

|

38

|

H 2306

|

KM 6

|

MB 6

|

|||

|

30

|

35

|

52

|

29

|

H 207

|

KM 7

|

MB 7

|

|||

|

30

|

35

|

52

|

35

|

H 307

|

KM 7

|

MB 7

|

|||

|

30

|

35

|

52

|

35

|

H 307 E

|

KMFE 7

|

||||

|

30

|

35

|

52

|

35

|

H 307 EL

|

KMFE 7 L

|

||||

|

30

|

35

|

52

|

43

|

H 2307

|

KM 7

|

MB 7

|

|||

|

35

|

40

|

58

|

31

|

H 208

|

KM 8

|

MB 8

|

|||

|

35

|

40

|

58

|

36

|

H 308

|

KM 8

|

MB 8

|

|||

|

35

|

40

|

58

|

36

|

H 308 E

|

KMFE 8

|

||||

|

35

|

40

|

58

|

46

|

H 2308

|

KM 8

|

MB 8

|

|||

|

35

|

40

|

58

|

46

|

H 2308 E

|

KMFE 8

|

||||

|

40

|

45

|

65

|

33

|

H 209

|

KM 9

|

MB 9

|

|||

|

40

|

45

|

65

|

39

|

H 309

|

KM 9

|

MB 9

|

|||

|

40

|

45

|

65

|

39

|

H 309 E

|

KMFE 9

|

||||

|

40

|

45

|

65

|

50

|

H 2309

|

KM 9

|

MB 9

|

|||

|

45

|

50

|

70

|

35

|

H 210

|

KM 10

|

MB 10

|

|||

|

45

|

50

|

70

|

42

|

H 310

|

KM 10

|

MB 10

|

|||

|

45

|

50

|

70

|

42

|

H 310 E

|

KMFE 10

|

||||

|

45

|

50

|

70

|

55

|

H 2310

|

KM 10

|

MB 10

|

|||

|

50

|

55

|

75

|

37

|

H 211

|

KM 11

|

MB 11

|

|||

is a professional bearing manufacturer and dealer in china.We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.We have our own brand “TFL” and applied ISO9001:2000 certificate for certification authority.We attend international bearing fairs, put in many B2B website and achieve many customers all over the world also bulid up good reputation from our customers.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

FAQ1: What is the difference between adapters and withdrawal sleeves?

The main difference is their function and installation method:

Adapter Sleeves (e.g., H series): Used to mount a tapered bore bearing (like a spherical roller bearing) onto a smooth cylindrical shaft. The bearing is pressed up the sleeve using a lock nut to secure it and set the internal clearance.

Withdrawal Sleeves (e.g., AH series): Used to mount a tapered bore bearing onto a stepped shaft (a shaft with a shoulder). They are specifically designed to help dismount the bearing from the shaft using a heavy-duty nut to pull the bearing off.

FAQ2:What materials are used in TFL adapter sleeves?

TFL (and other major brands) typically manufacture adapter sleeves from high-quality, low-carbon steel (often a grade like S45C or similar). This material is chosen for its:

Strength: To withstand the high forces of mounting and dismounting.

Machinability: To create the precise taper angle required for correct bearing seating.

Surface Finish: To ensure a smooth, secure fit between the sleeve and the shaft/bearing inner ring.