22232 Double Row Spherical Roller Bearing For Water Pump

- $66.66/Piece | 1 Piece (Min. Order) |

Lead Time–If you finish the payment today, your order will ship out within the delivery date.

-

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

22232 Double Row Spherical Roller Bearing For Water Pump

There are two rows of symmetrical spherical rollers, the outer ring has a common spherical raceway, and the inner ring has two raceways inclined at the same angle to the axis of the bearing. It has good self-aligning performance. When the shaft is bent or installed out of center, the bearing can still be used normally at the same time. The alignment varies with the bearing size series. Generally, the allowable alignment angle is 1~2.5 degrees. This type of bearing has a large load capacity, and the bearing can withstand radial load. The double-acting axial load has good impact resistance. Generally speaking, the allowable working speed of spherical roller bearings is low.

|

Boundary dimensions

(mm)

|

Load ratings

(KN)

|

Limiting speeds

(r/min)

|

Mass

(kg)

|

Bearing NO.

|

||||||||

|

d

|

D

|

B

|

Cr

|

Cor

|

Grease

|

oil

|

||||||

|

160

|

290

|

80

|

1150

|

1400

|

2600

|

1900

|

23.3

|

22232

|

||||

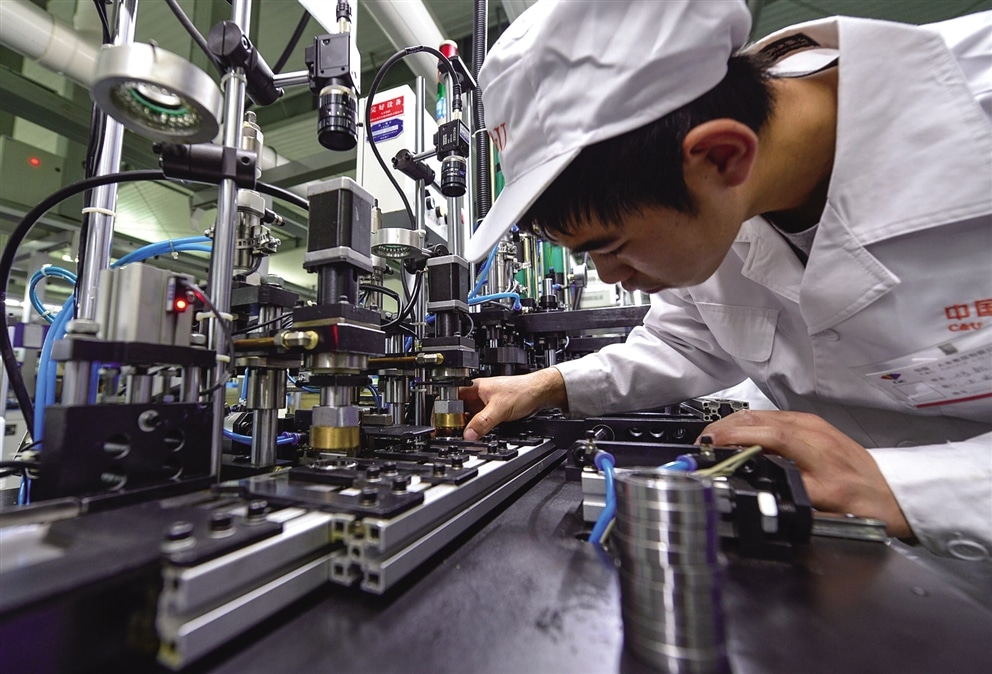

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

FAQ1: What are the advantages of 22232 spherical roller bearings?

The 22232 spherical roller bearing (and spherical roller bearings in general) offers several significant advantages, making it ideal for demanding applications:

High Load Capacity: They are designed to handle extremely heavy radial loads and moderate axial loads in both directions. The large number of barrels (rollers) and their optimal contact angle distribute the load effectively.

Self-Aligning Capability: This is their most distinctive advantage. Spherical roller bearings can accommodate considerable angular misalignment between the shaft and the housing bore (typically up to 0.5 to 2 degrees, depending on the series). This is crucial in applications where shaft deflection, mounting errors, or housing deformation might occur.

Robustness: They are very robust and less sensitive to shock loads and vibrations compared to other bearing types.

Long Service Life: When properly selected, installed, and lubricated, their high load capacity and self-aligning features contribute to a long and reliable operating life.

FAQ2: What lubrication suits spherical roller bearings in wet conditions?

High-Quality Lithium Complex Greases: These are very common and effective. Look for greases formulated with:

Excellent Water Resistance: They should resist being washed out by water and maintain their consistency.

Good Corrosion Protection: Contain rust and corrosion inhibitors to protect the bearing surfaces.

Good Adhesion: They should stick well to the bearing surfaces, even in the presence of water.

EP (Extreme Pressure) Additives: If heavy loads are also present.

Polyurea Greases: These greases offer exceptional water resistance, corrosion protection, and high-temperature stability, making them an excellent choice for demanding wet environments.

Calcium Sulfonate Greases: Known for their superior water resistance and inherent anti-corrosion and extreme pressure properties, they are often used in marine and very wet industrial applications.

Synthetic Greases: While more expensive, synthetic base oils can offer superior performance over a wider temperature range and enhanced water resistance compared to mineral oil-based greases.

Crucially, in wet conditions, proper sealing is paramount. Even the best grease won’t fully compensate for water entering the bearing cavity. Consider upgraded seals like labyrinth seals, V-rings, or specialized contact seals.