Shandong Tefule Bearing Co., Ltd. is a company approved by the General Administration of Customs of China with import and export rights. Specializing in bearing trade at home and abroad, it is a large-scale industrial company integrating production and sales. Our bearing products have passed the ISO9001 quality system certification and ROHS lead-free certification. These products are widely used in the construction industry, railway industry, aerospace, agriculture, food industry, petroleum industry, cement industry, automobile industry, steel industry, mining, etc.

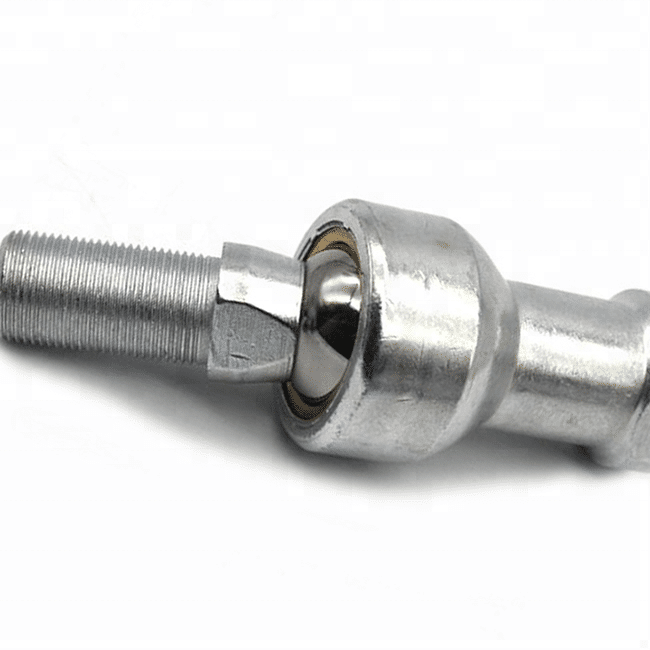

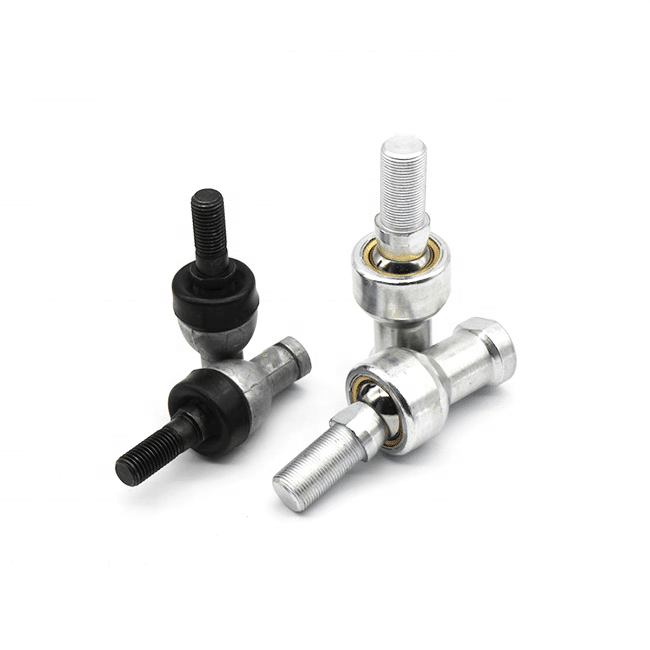

SQ…RS Series Winding Shape Ball Joint Rod End Bearing SQ22-RS

- Customization:

-

Customized logo(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

More

Rod end joint bearing vibration is very sensitive to the damage of rod end joint bearing, such as peeling, indentation, rust, crack, abrasion, etc. will be reflected in the rod end joint bearing vibration measurement, so by adopting special rod end joint bearing vibration The measuring device (frequency analyzer, etc.) can measure the magnitude of the vibration, and the specific abnormal situation cannot be inferred through the frequency division. The measured value is different due to the use conditions of the rod end joint bearing or the installation position of the sensor, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

Dimension(mm) |

Bearing Model |

weight(kg) |

||||

d |

D |

T |

||||

22 |

70 |

95 |

SQ22-RS |

0.713 |

||

No.1 We are large entity company.

No.2 International quality system certification

Shandong Tefule Bearing Co., Ltd. won the ISO9001-2015 quality management system certificate issued by the authoritative third-party certification company SGS certification body in 2015, and became a company in China that has obtained this authoritative certification.

A: Tube packing+carton+pallets

B: single box packing+carton+pallets

C:as customer's requirement

Shandong Tefule Bearing Co.,Ltd

is a professional bearing manufacturer and dealer in china.We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers' demands.

1. who are we?

We are based in Shandong, China,sell to Mid East(30.00%),South Asia(20.00%),Northern Europe(15.00%),Africa(15.00%),Southeast Asia(10.00%),Western Europe(10.00%),North America(10.00%).

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Ball Bearing,Roller Bearing,Wheel Bearing,Linear Bearing,Pillow Block Bearing

4. why should you buy from us not from other suppliers?

Our company has gained rich experience: we know how to exactly handle every step of production.

Our products possess the advantages of competitive price and good service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese

Rod end joint bearing vibration is very sensitive to the damage of rod end joint bearing, such as peeling, indentation, rust, crack, abrasion, etc. will be reflected in the rod end joint bearing vibration measurement, so by adopting special rod end joint bearing vibration The measuring device (frequency analyzer, etc.) can measure the magnitude of the vibration, and the specific abnormal situation cannot be inferred through the frequency division. The measured value is different due to the use conditions of the rod end joint bearing or the installation position of the sensor, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

Rod end joint bearing vibration is very sensitive to the damage of rod end joint bearing, such as peeling, indentation, rust, crack, abrasion, etc. will be reflected in the rod end joint bearing vibration measurement, so by adopting special rod end joint bearing vibration The measuring device (frequency analyzer, etc.) can measure the magnitude of the vibration, and the specific abnormal situation cannot be inferred through the frequency division. The measured value is different due to the use conditions of the rod end joint bearing or the installation position of the sensor, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

Rod end joint bearing vibration is very sensitive to the damage of rod end joint bearing, such as peeling, indentation, rust, crack, abrasion, etc. will be reflected in the rod end joint bearing vibration measurement, so by adopting special rod end joint bearing vibration The measuring device (frequency analyzer, etc.) can measure the magnitude of the vibration, and the specific abnormal situation cannot be inferred through the frequency division. The measured value is different due to the use conditions of the rod end joint bearing or the installation position of the sensor, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.