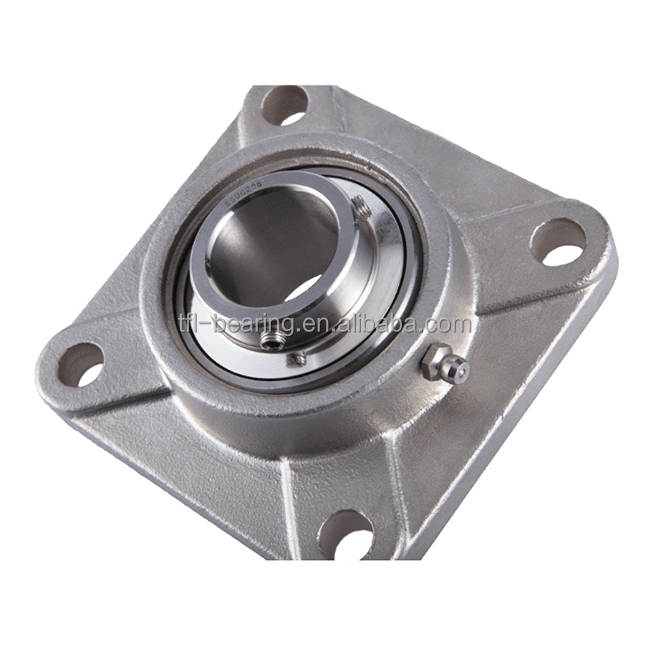

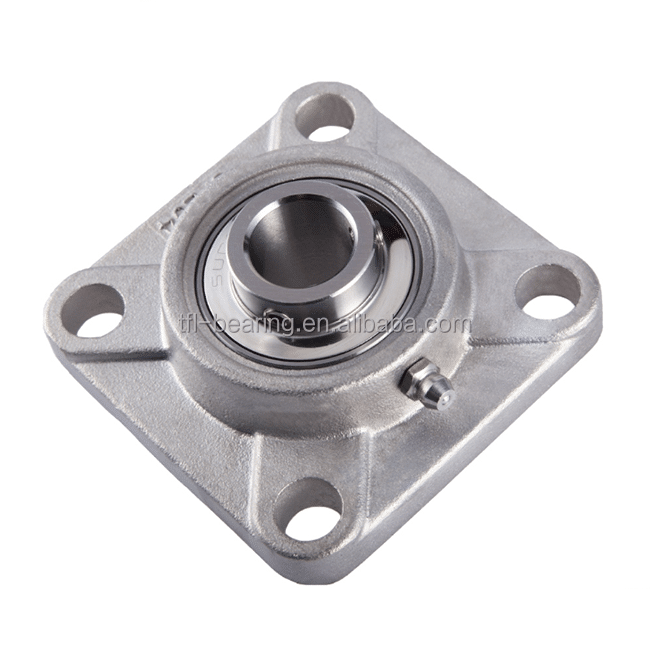

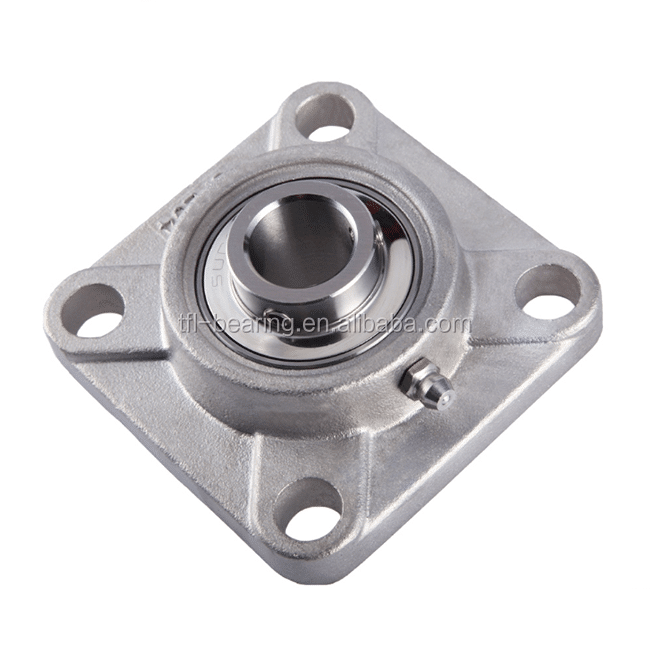

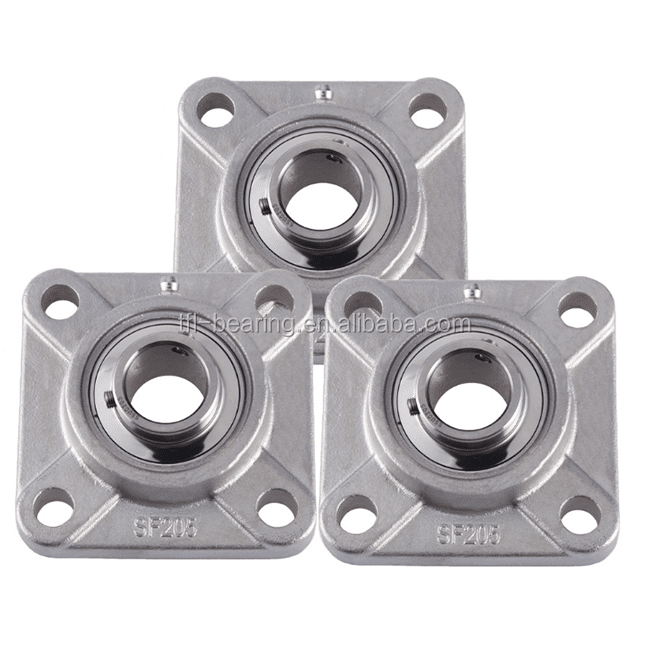

Stainless Steel SUCF210 Pillow Block Bearing Unit SF210 Housing

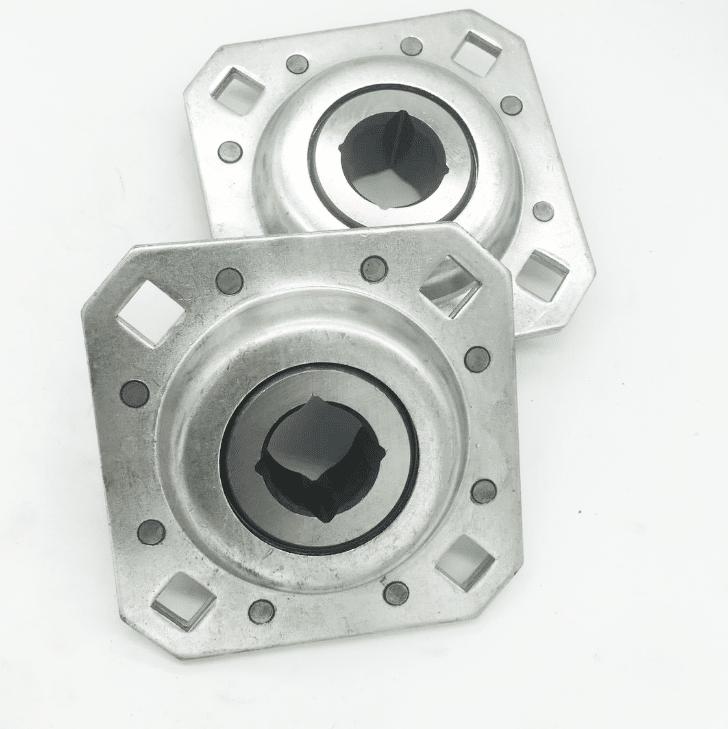

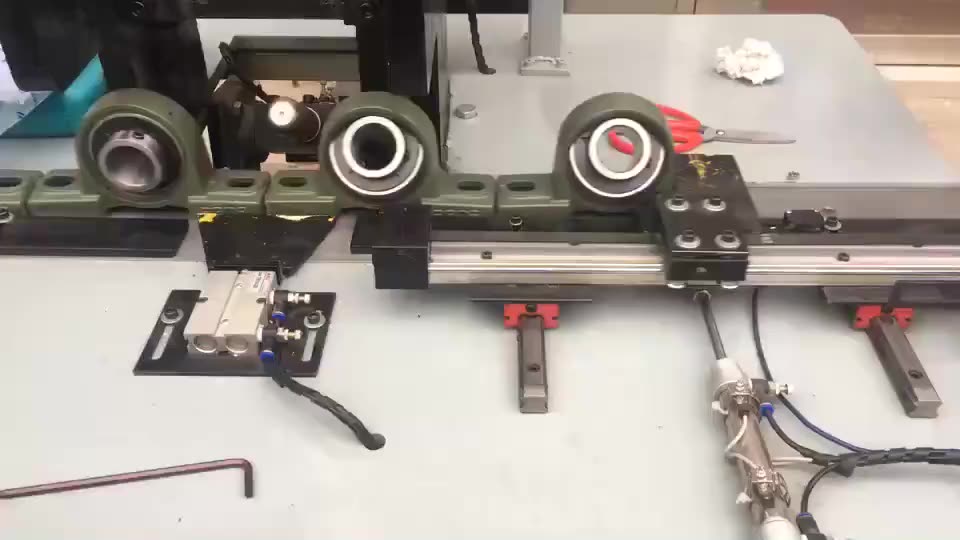

A pillow block, also known as a Plummer block or bearing housing, is a mounted or roller bearing used to provide support for a rotating shaft with the mounting surface on a parallel line with the axis of the shaft. Housing material for a pillow block bearing is typically made of or pressed steel. TR Pillow block bearings are extensively used in conveyor systems such as. Most pillow block bearings are self-lubricating.

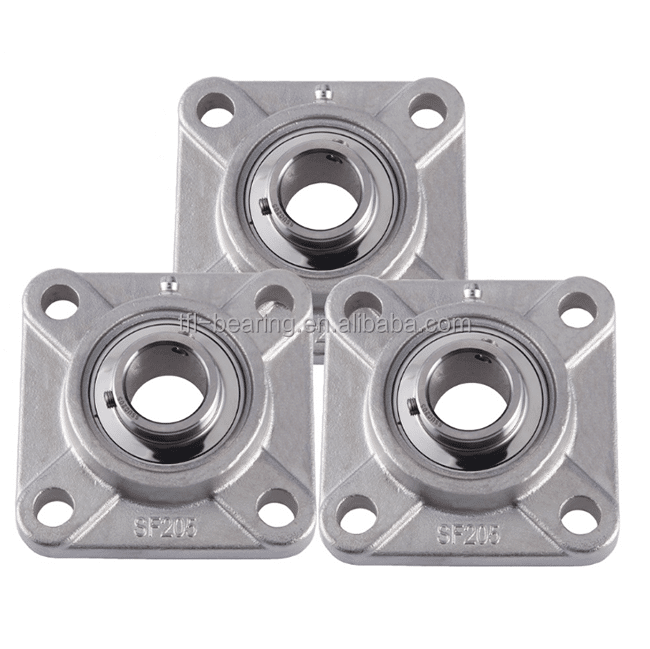

TFL Pillow block bearings are widely used in various kinds of industries and machines such as car wash equipment, construction machinery, fans, HVAC, food processing, metal working machinery, textile machinery, paper making & paper converting equipment & woodworking machinery.

TFL Pillow block bearings are mounted type bearings available in flanged & upright styles in different inch & metric sizes. TR Pillow block bearings are designed to support shafts. Features include mounting surfaces parallel to shaft axes & elongated bolt holes in bases or feet of units for adjustment & mounting of pillow block bearing. TR Pillow block bearings are available in bore sizes ranging from 1/2 in. To 10 in.

|

Unit NO. |

DiSensions |

Bolt Size SS inch |

Weight(kg) |

||||||||||

|

d |

a |

e |

i |

g |

i |

s |

z |

t |

B |

n |

|||

|

SUCF201 |

12 |

86 |

64 |

25.5 |

12 |

25.5 |

12 |

33.3 |

37.5 |

31 |

12.7 |

M10 |

0.6 |

|

SUCF202 |

15 |

86 |

64 |

25.5 |

12 |

25.5 |

12 |

33.3 |

37.5 |

31 |

12.7 |

M10 |

0.59 |

|

SUCF203 |

17 |

86 |

64 |

25.5 |

12 |

25.5 |

12 |

33.3 |

37.5 |

31 |

12.7 |

M10 |

0.58 |

|

SUCF204 |

20 |

86 |

64 |

25.5 |

12 |

25.5 |

12 |

33.3 |

37.5 |

31 |

12.7 |

M10 |

0.56 |

|

SUCF205 |

25 |

95 |

70 |

27 |

14 |

27 |

12 |

35.8 |

40 |

34.1 |

14.3 |

M10 |

0.8 |

|

SUCF206 |

30 |

108 |

83 |

31 |

14 |

31 |

12 |

40.2 |

44.5 |

38.1 |

15.9 |

M10 |

1.12 |

|

SUCF207 |

35 |

117 |

92 |

34 |

16 |

34 |

14 |

44.4 |

48.5 |

42.9 |

17.5 |

M12 |

1.46 |

|

SUCF208 |

40 |

130 |

102 |

36 |

16 |

36 |

16 |

51.2 |

55.5 |

49.2 |

19 |

M14 |

1.84 |

|

SUCF209 |

45 |

137 |

105 |

38 |

18 |

38 |

16 |

52.2 |

56.5 |

49.2 |

19 |

M14 |

2.15 |

|

SUCF210 |

50 |

143 |

111 |

40 |

18 |

40 |

16 |

54.6 |

59.5 |

51.6 |

19 |

M14 |

2.42 |

|

SUCF211 |

55 |

162 |

130 |

43 |

20 |

43 |

19 |

58.4 |

63 |

55.6 |

22.2 |

M16 |

3.31 |

|

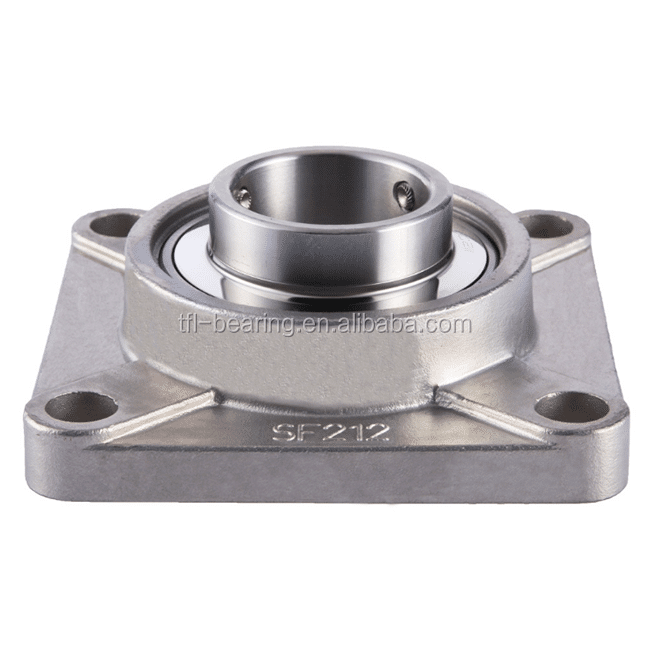

SUCF212 |

60 |

175 |

143 |

48 |

20 |

48 |

19 |

68.7 |

73.5 |

65.1 |

25.4 |

M16 |

4.28 |

|

SUCF213 |

65 |

187 |

149 |

50 |

22 |

50 |

19 |

69.7 |

74.5 |

65.1 |

25.4 |

M16 |

4.99 |

|

SUCF214 |

70 |

193 |

152 |

54 |

22 |

54 |

19 |

75.4 |

81.5 |

74.6 |

30.2 |

M16 |

5.85 |

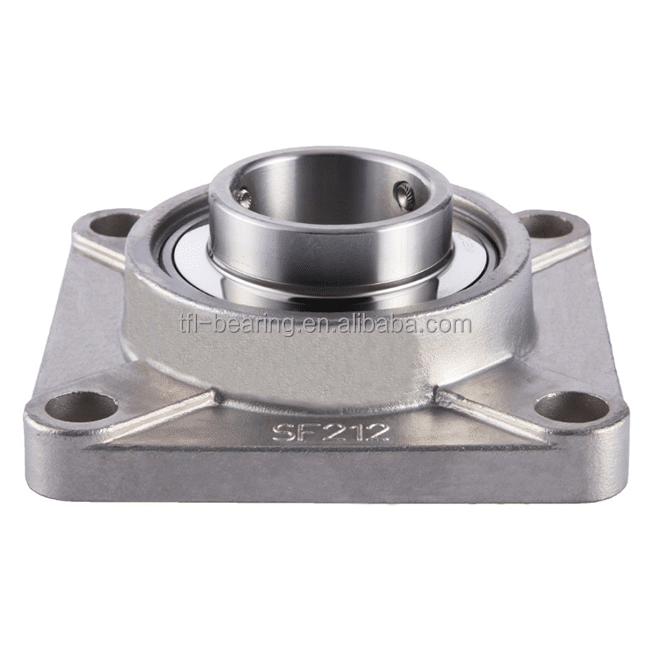

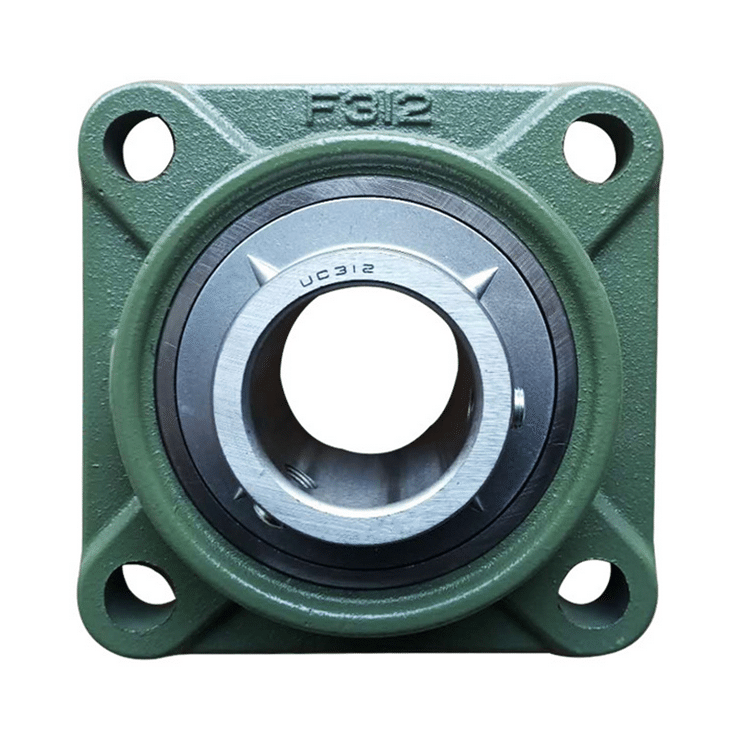

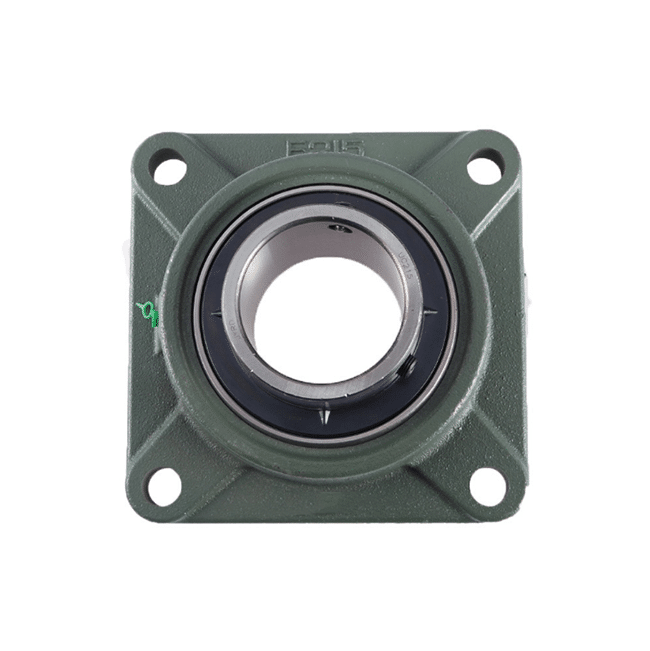

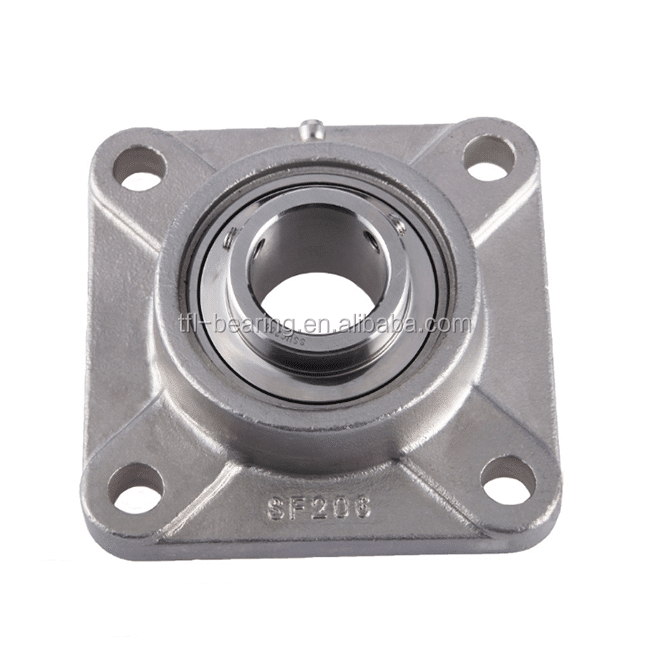

FAQ1: Difference between SUCF210 and UCF210 bearings?

The main difference is the material used for the components:

UCF210: This is a standard square flanged unit. The housing (F210) is typically made of cast iron, and the insert bearing (UC210) is made of bearing steel (chrome steel). It’s designed for general industrial use.

SUCF210: This is the Stainless Steel version. The housing (SF210) is made of stainless steel, and the insert bearing (SUC210) is also made of stainless steel. This makes it corrosion-resistant and suitable for wash-down environments.

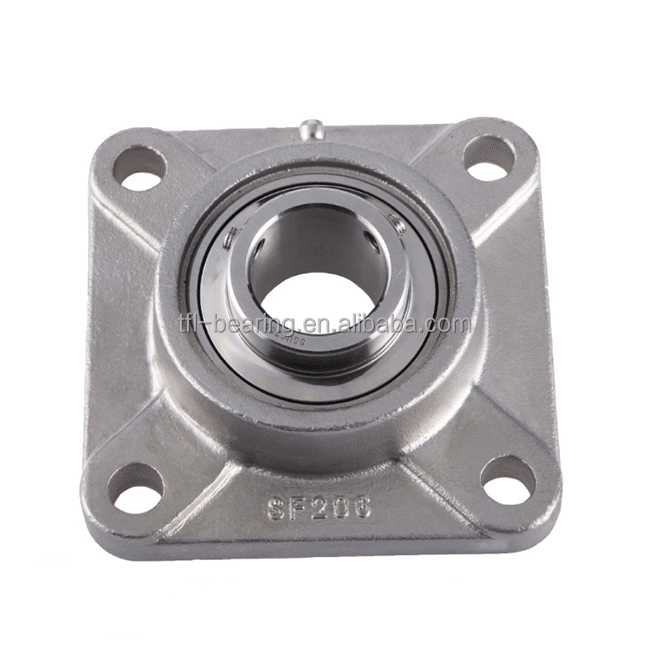

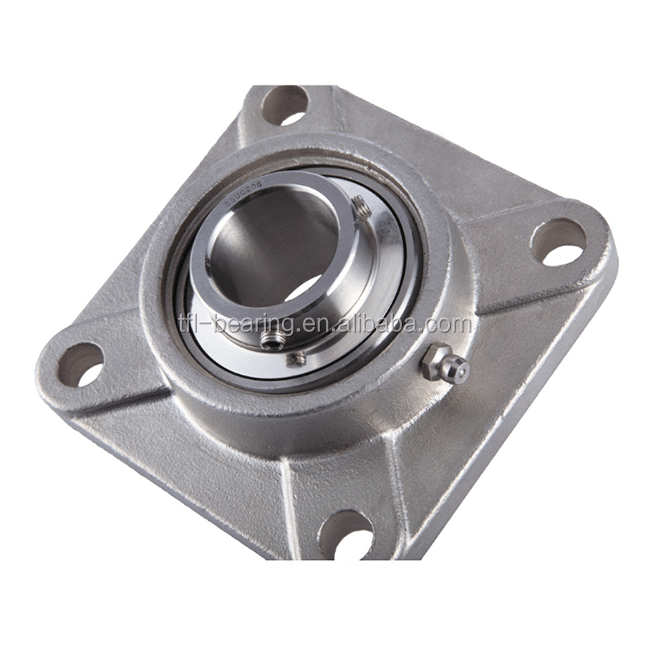

FAQ2: How does stainless steel prevent corrosion in bearings?

Stainless steel prevents corrosion through a natural process called passivation:

Stainless steel contains a minimum of 10.5% chromium.

When the steel is exposed to oxygen (in air or water), the chromium instantly reacts to form a very thin, invisible, non-reactive layer of chromium oxide on the surface.

This passive film acts as a stable, protective barrier that prevents oxygen and corrosive agents from reaching the iron in the steel, thereby stopping the formation of iron oxide, or rust.

If the surface is scratched, the layer can self-heal if it is re-exposed to oxygen.