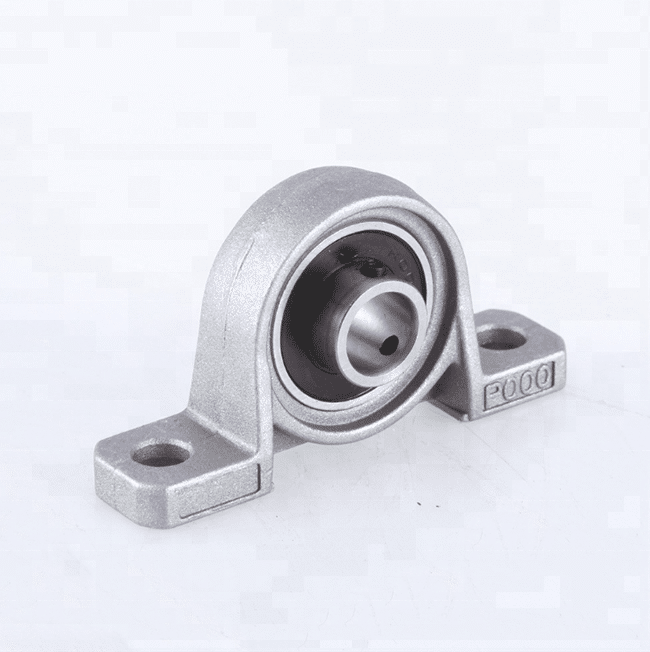

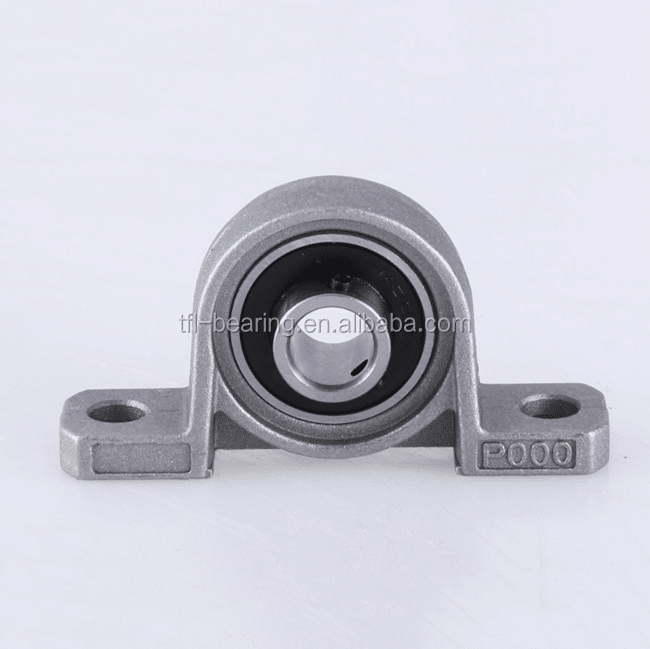

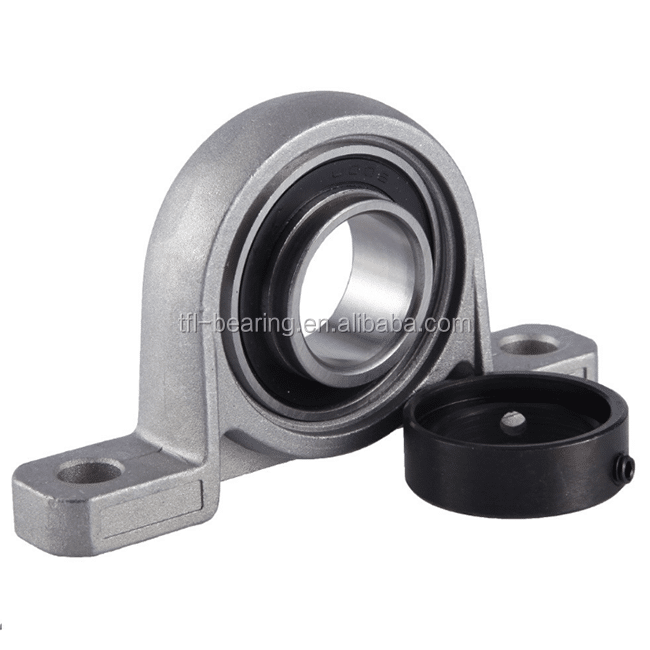

Anti Strong Corrosion Zinc Alloy Pillow Block Bearing Housing KP004

-

Lead Time–If you finish the payment today, your order will ship out within the delivery date.

-

Quantity(Pieces) 1 – 2000 >2000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 100 Pieces)Customized packaging(Min. Order: 100 Pieces)

Anti-Strong Corrosion Zinc Alloy Pillow Block Bearing Housing KP004

Zinc alloy pillow block bearing Description

A small Zinc pillow block bearing is a new type of bearing, to join other elements for zinc-based alloy bearing. Often alloy elements are aluminum, copper, magnesium, cadmium, lead, titanium, etc. Zinc base alloy low melting point, good liquidity, easy fusion welding, brazing and plastic processing, in the atmosphere corrosion, deformed material easy to recycle and remelt; But has low creep strength, and is prone to natural aging changes in size. The melting method, die casting and pressure processing timber. The manufacturing process can be divided into cast zinc-base alloy and deformation of zinc-base alloy.

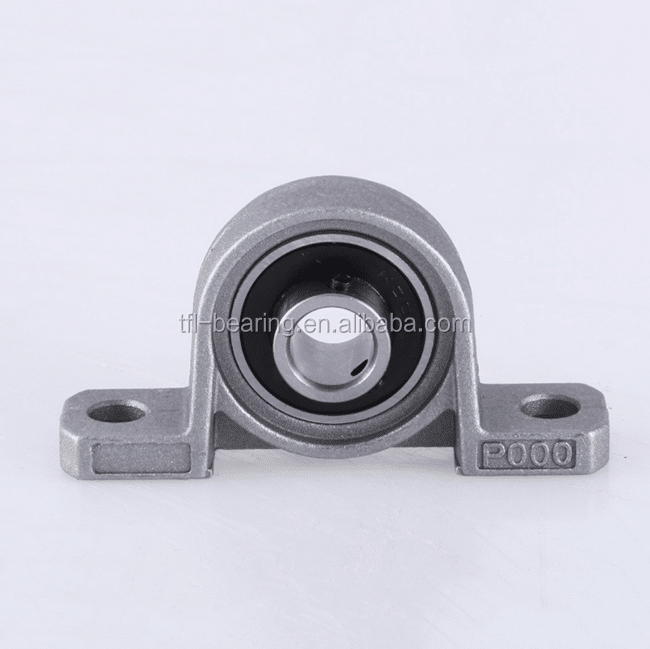

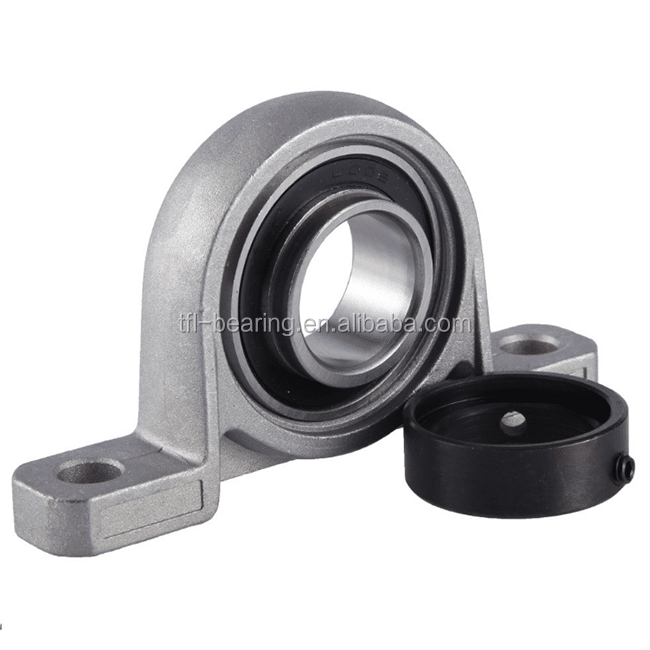

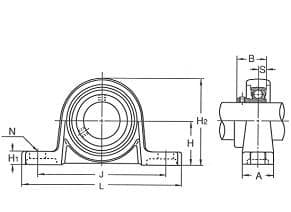

| earing Unit NO. | Shaft Dia d |

Dimensions(mm) | Bolt Used | Bearing No. | Housing No. | Weight (kg) |

||||||||

| (mm) | h | a | e | b | s | g | w | Bi | n | (mm) | ||||

| KP000 | 10 | 18 | 67 | 53 | 16 | 7 | 6 | 35 | 14 | 4 | M6 | K000 | P000 | 0.17 |

| KP001 | 12 | 19 | 71 | 56 | 16 | 7 | 6 | 38 | 14.5 | 4 | M6 | K001 | P001 | 0.2 |

| KP002 | 15 | 22 | 80 | 63 | 16 | 7 | 7 | 43 | 16.5 | 4.5 | M6 | K002 | P002 | 0.28 |

| KP003 | 17 | 24 | 85 | 67 | 18 | 7 | 7 | 47 | 17.5 | 5 | M6 | K003 | P003 | 0.35 |

| KP004 | 20 | 28 | 100 | 80 | 20 | 10 | 9 | 55 | 21 | 6 | M8 | K004 | P004 | 0.51 |

| KP005 | 25 | 32 | 112 | 90 | 20 | 10 | 10 | 62 | 22.5 | 6 | M8 | K005 | P005 | 0.66 |

| KP006 | 30 | 36 | 132 | 106 | 26 | 13 | 11 | 70 | 24.5 | 6.5 | M10 | K006 | P006 | 1.01 |

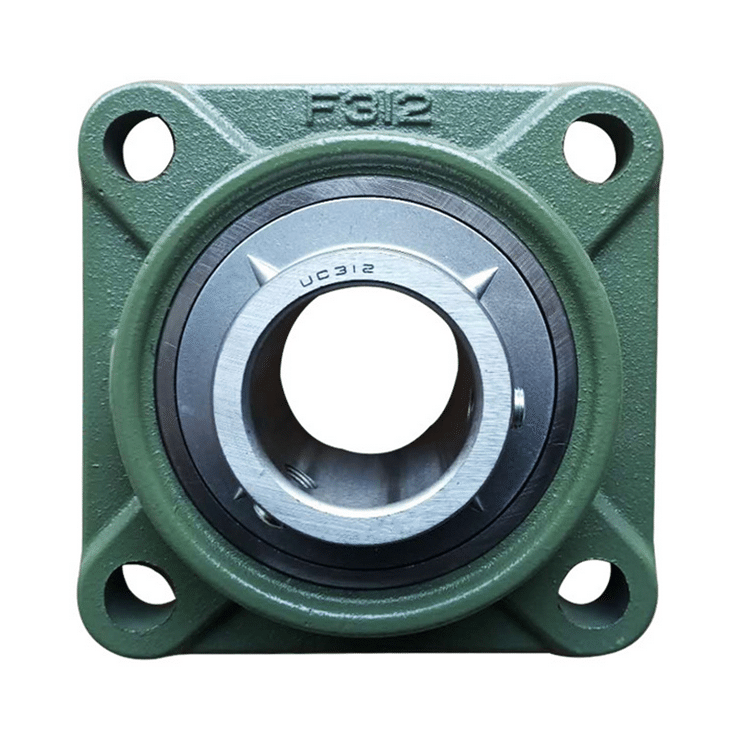

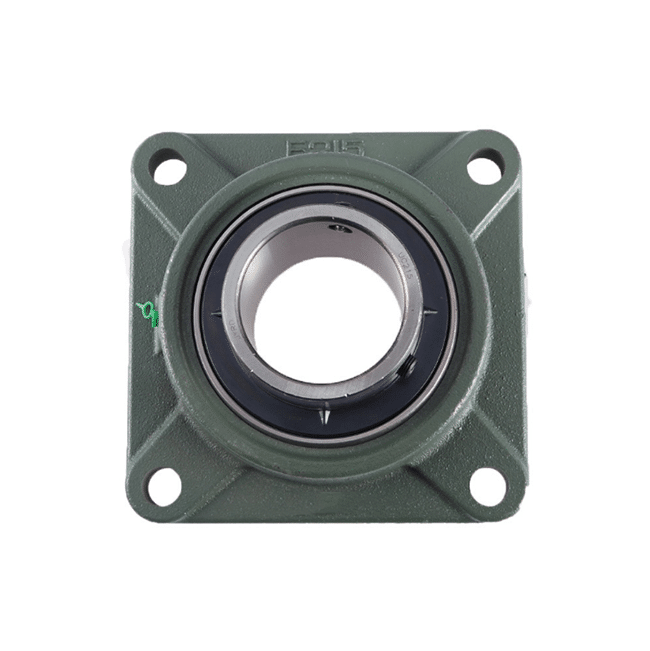

| Unit No. | Shaft d | Dimensions(mm) | Bolt Size mm | Bearing No. | Housing No. | Weight | |||||||||

| (mm) | H | J | A2 | A1 | A | N | L | s | Z | A3 | (kg) | ||||

| KFL000 | 10 | 60 | 45 | 6 | 6 | 12 | 7 | 36 | 4 | 16 | 20.3 | M6 | K000 | FL000 | 0.07 |

| KFL001 | 12 | 63 | 48 | 6 | 6 | 12 | 7 | 38 | 4 | 16.5 | 21 | M6 | K001 | FL001 | 0.08 |

| KFL002 | 15 | 67 | 53 | 6.5 | 6.5 | 13 | 7 | 42 | 4.5 | 18.5 | 23 | M6 | K002 | FL002 | 0.11 |

| KFL003 | 17 | 71 | 56 | 7 | 7 | 14 | 7 | 46 | 5 | 19.5 | 25 | M6 | K003 | FL003 | 0.14 |

| KFL004 | 20 | 90 | 71 | 8 | 8 | 16 | 10 | 55 | 6 | 23 | 28 | M8 | K004 | FL004 | 0.23 |

| KFL005 | 25 | 95 | 75 | 8 | 8 | 16 | 10 | 60 | 6 | 24.5 | 28.5 | M8 | K005 | FL005 | 0.27 |

| KFL006 | 30 | 112 | 85 | 9 | 9 | 18 | 13 | 70 | 6.5 | 27 | 30.5 | M10 | K006 | FL006 | 0.39 |

FAQ1: Zinc alloy bearings use new alloy materials. What are the differences from ordinary bearing steel?

High aluminum zinc-based alloy is a new alloy in the gravity casting zinc-based alloy series, represented by ZnAl27Cu2Mg, namely ZA27-2 and its derived high aluminum zinc-based alloy, which is used to manufacture various bearings, sleeves, slides, sliders, worm gears and transmission nuts and other anti-friction and wear-resistant parts.

Add other elements to make zinc-based alloys. Commonly added alloy elements include aluminum, copper, magnesium, cadmium, lead, titanium, etc. Zinc-based alloys have low melting points, good fluidity, easy to weld, braze and plastic processing, no corrosion in the atmosphere, and deformed materials are easy to recycle and remelt; but the creep strength is low and the size is easily changed due to natural aging. The smelting methods include die casting and pressure processing. According to the manufacturing process, it can be divided into cast zinc-based alloys and deformed zinc-based alloys.

FAQ2: Do zinc alloy bearings need to be lubricated?

A. Generally, VG680 dynamic viscosity lubricant is suitable for summer, and VG460 dynamic viscosity lubricant is suitable for winter. At the same time, environmental and regional differences should be considered during use, and attention should be paid to whether the thickness of the lubricating oil film meets the lubrication requirements.

B. Although high-aluminum zinc-based alloy bearings have lower requirements for lubricating oil than bronze sleeves, modern equipment requires large loads, high efficiency, and long life. Therefore, the lubrication concept should also be updated. In order to ensure safer operation of the machine, it is recommended to use high-quality lubricating oil containing extreme pressure and wear-resistant additives.