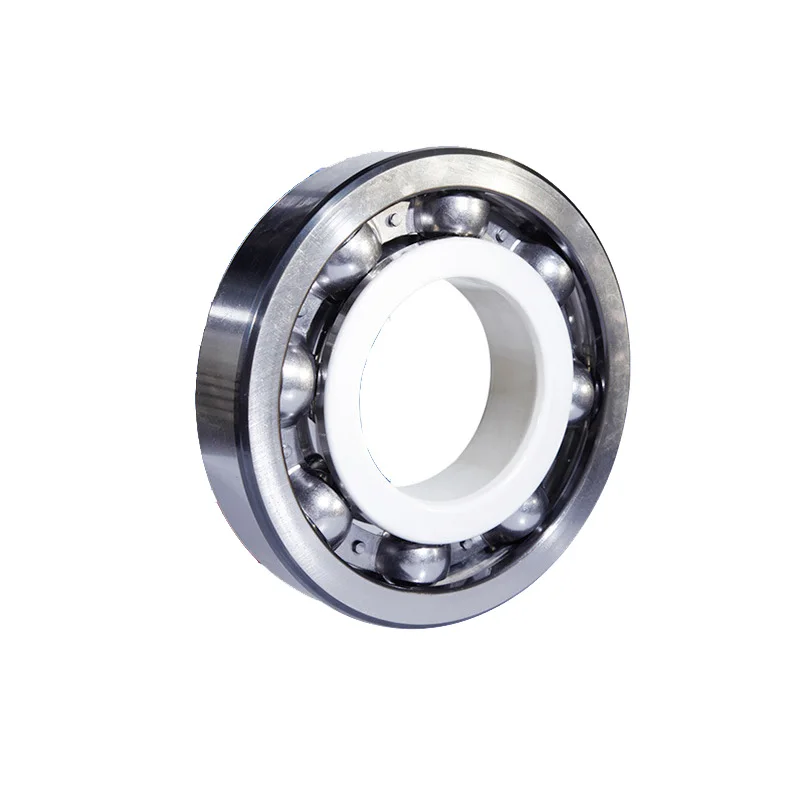

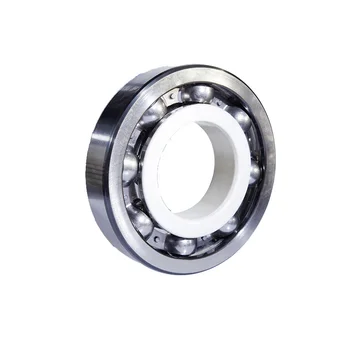

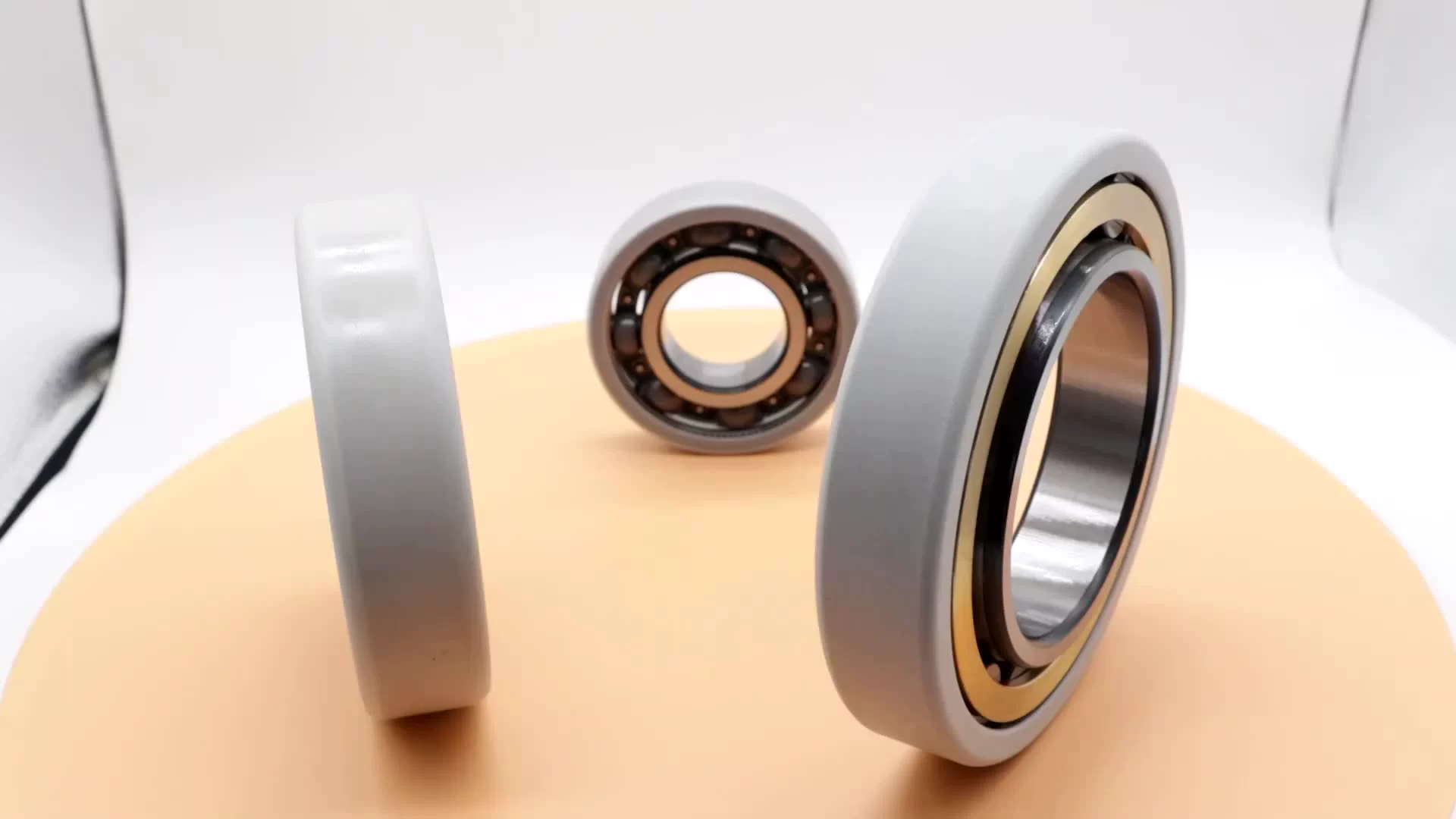

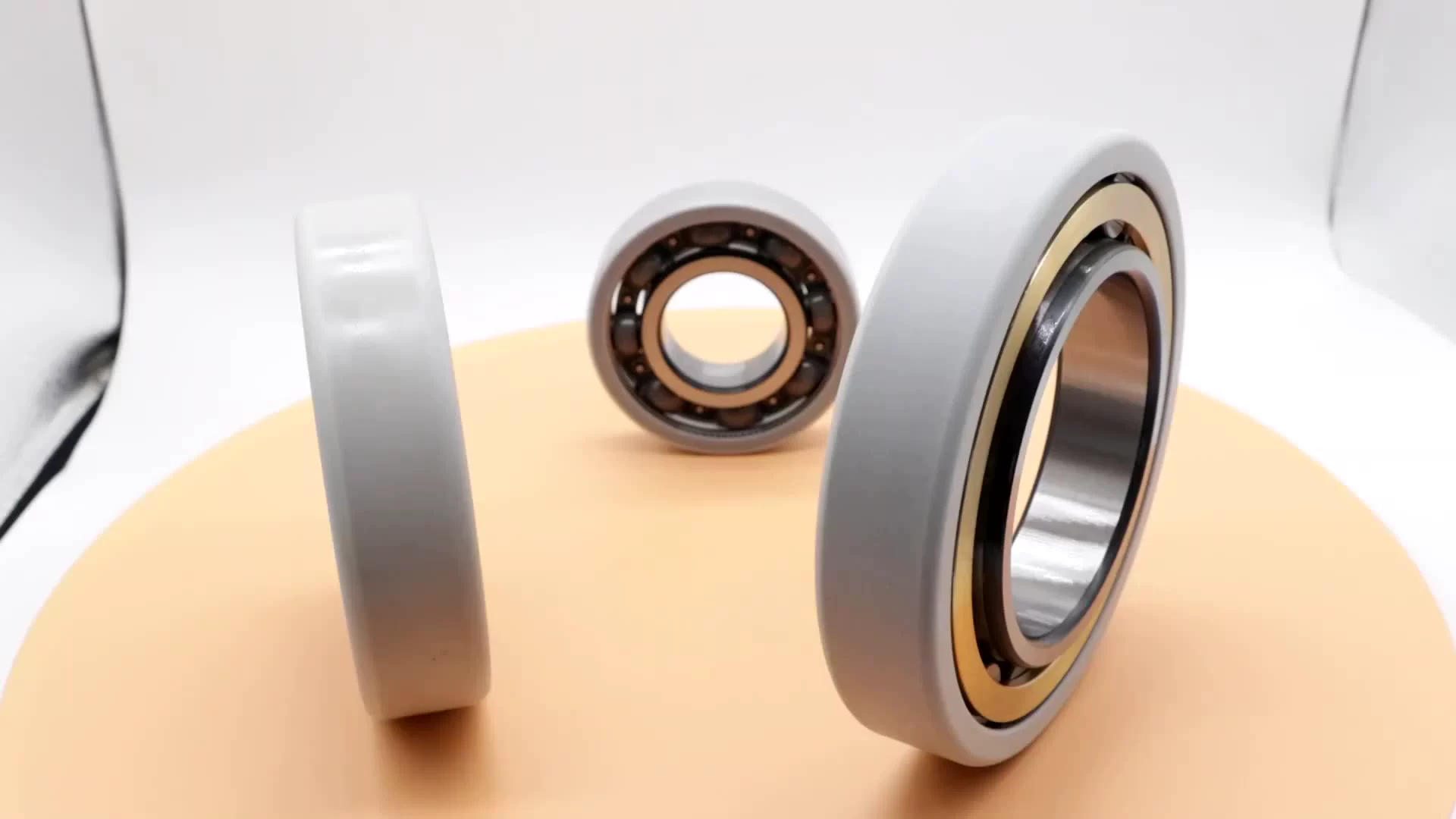

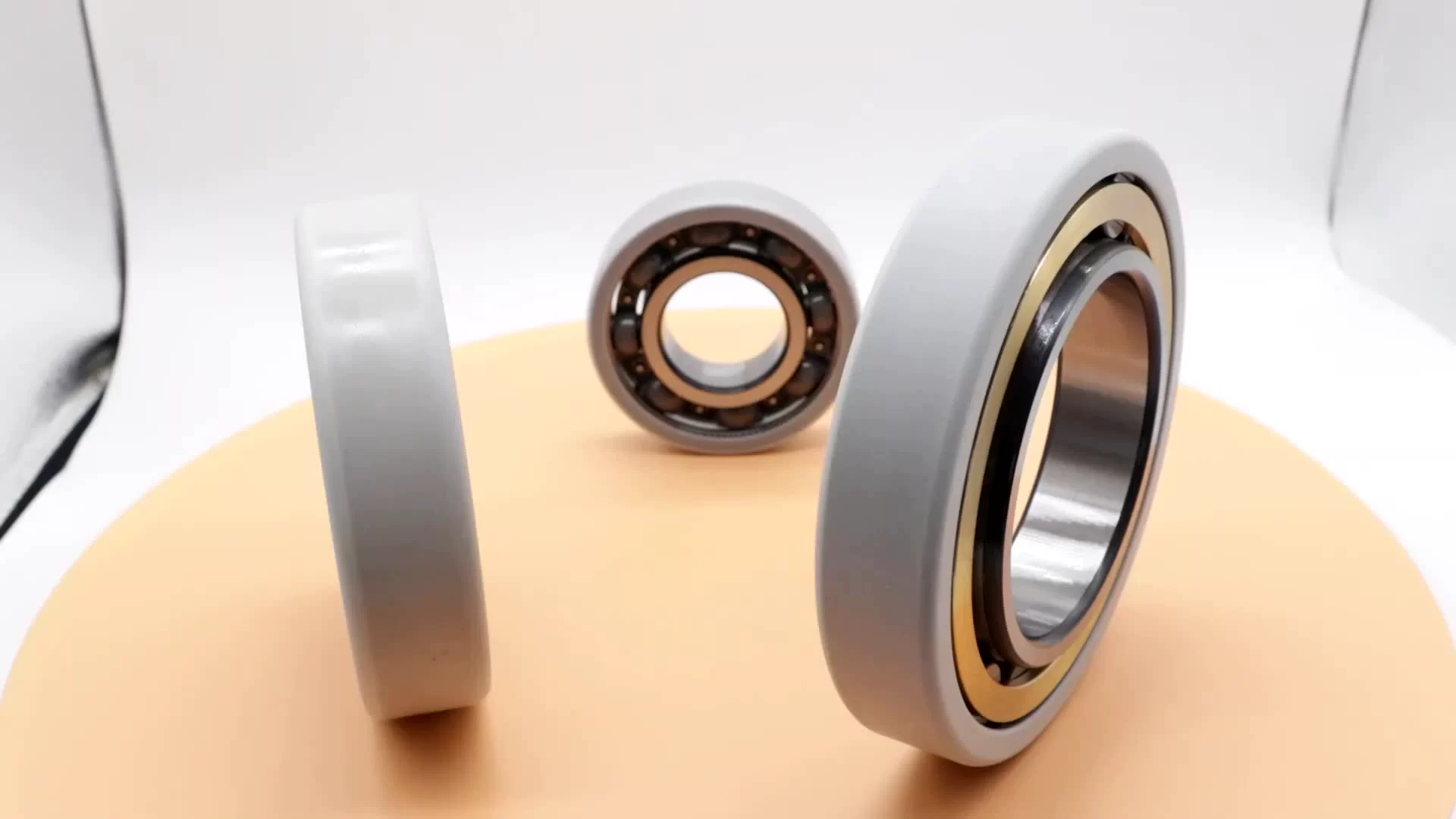

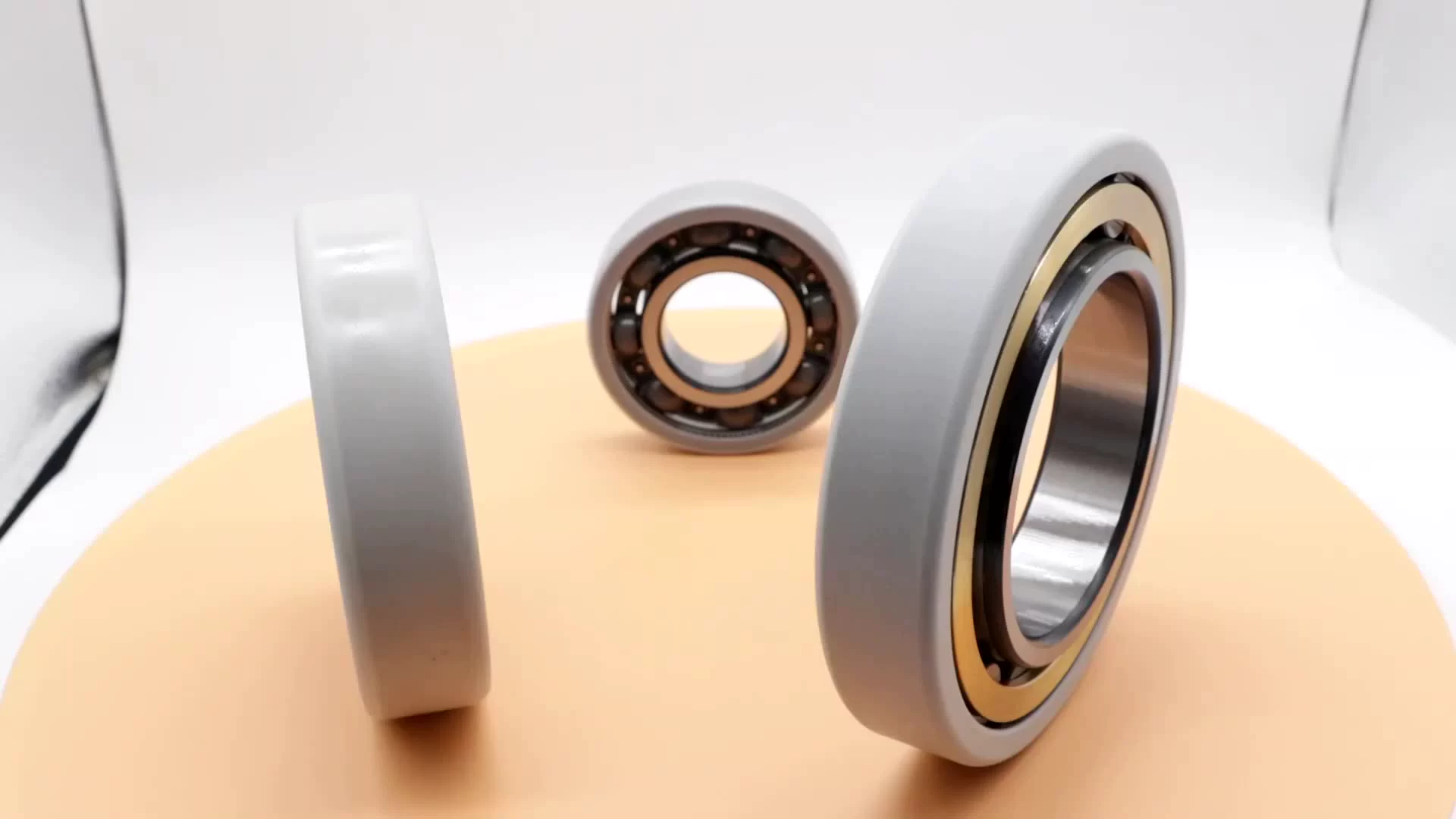

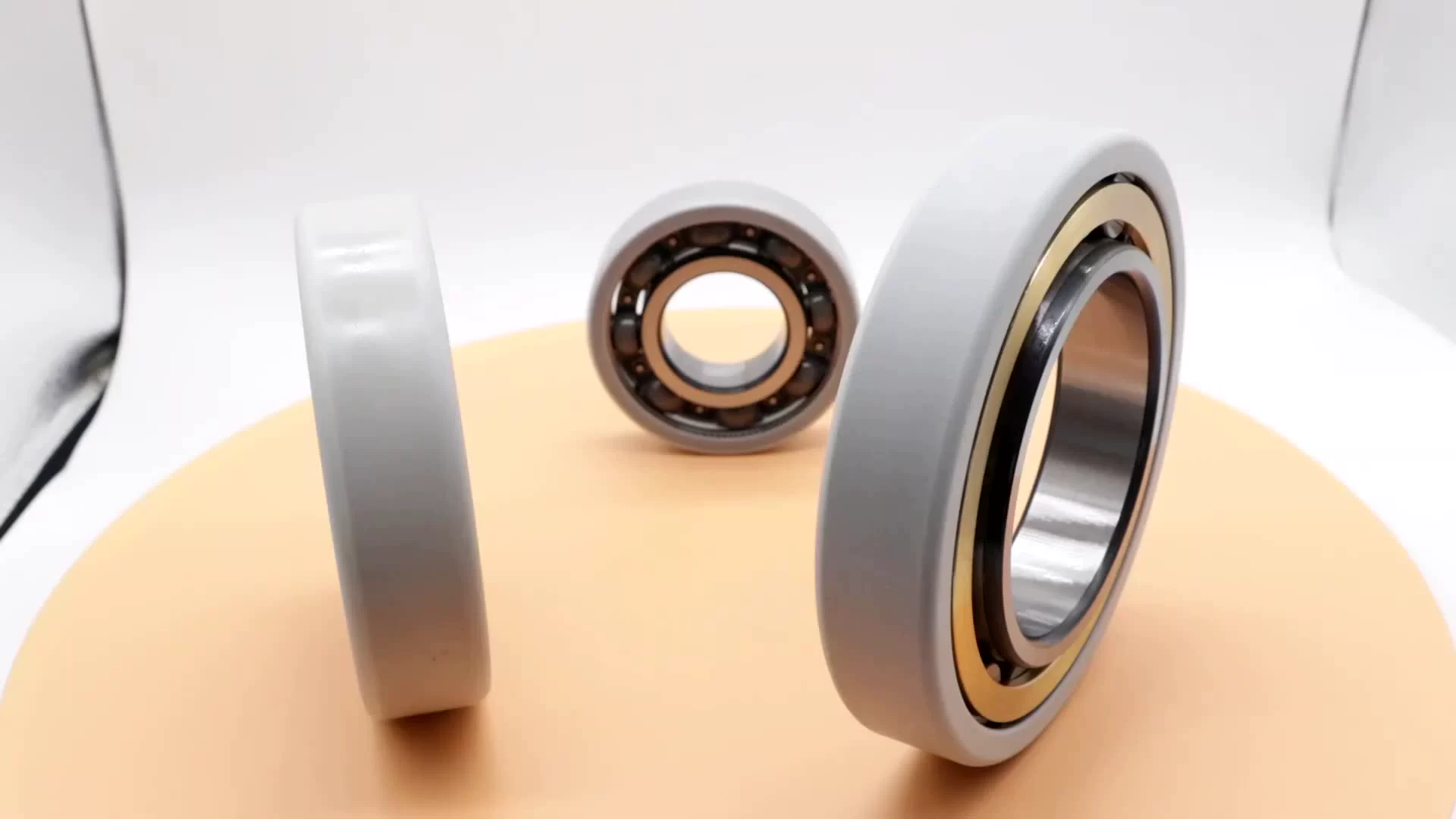

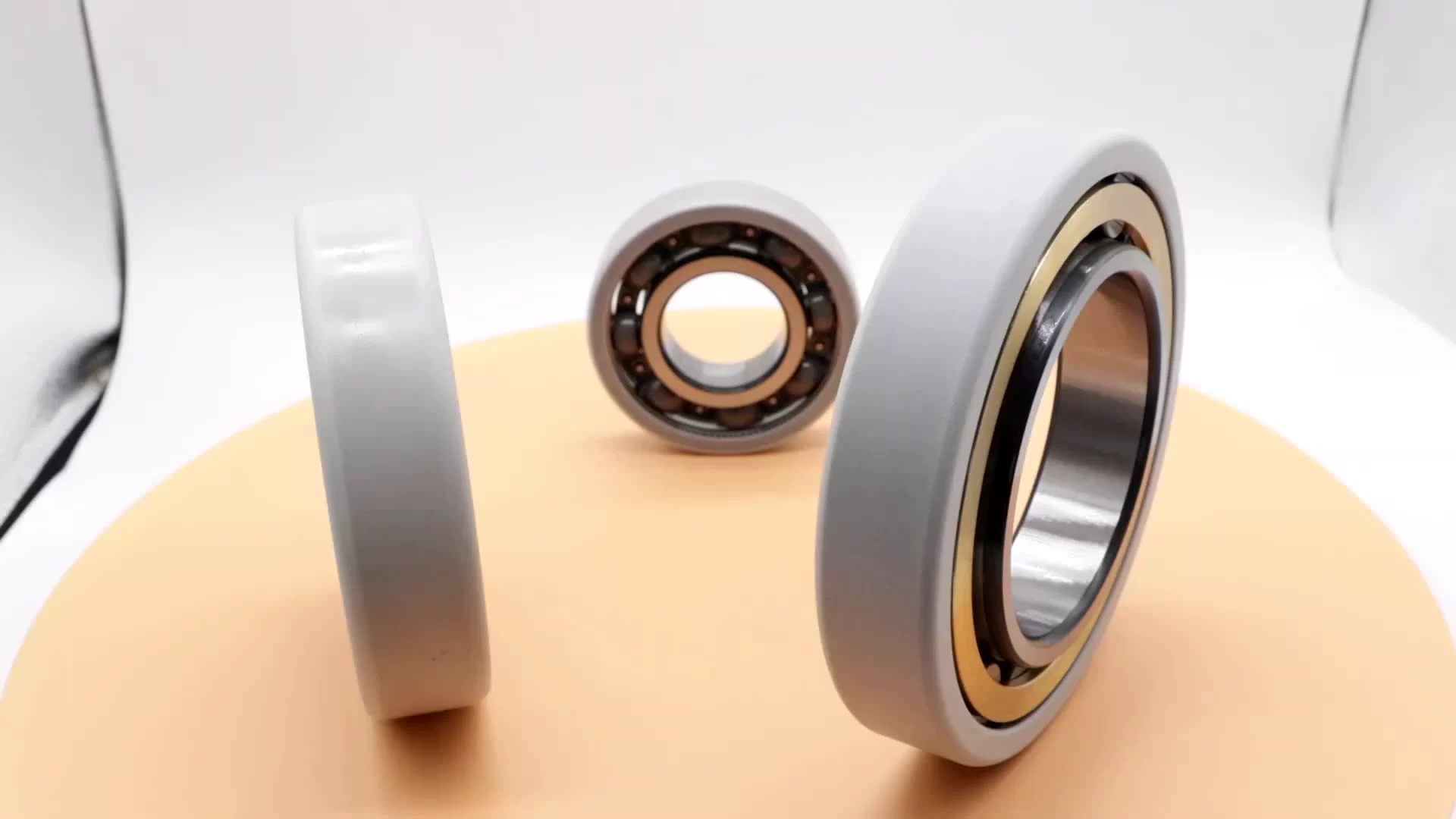

6030M/C3VL0271 6030M/C3J20C 150x225x35mm inner ring electric insulated bearing for water pump

Key attributes

Industry-specific attributes

Applicable Industries

Building Material Shops, Machinery Repair Shops, Retail, Energy & Mining, Other

Bore Size

149.99 - 150 mm

Precision Rating

P5 P6 P2 P0 P4 P3

Number of Row

Single row

Other attributes

Place of Origin

China

Type

BALL

Structure

Deep Groove

Model Number

6030M/C3VL0271

Seals Type

open 2RS ZZ

OEM Service

Custom Bearing's Size Logo Packing

Feature

insulation

Brand

OEM Famous Brand

Product name

insulated bearing

Material

Chrome Steel GCR15

Application

Electric Motors

Model

6320M/C3VL0271

Certificate

ISO 9001:2000

Keywords

ceramic-coated

Sample

Avialable

6030M/C3VL0271 6030M/C3J20C 150x225x35mm inner ring electric insulated bearing for water pump

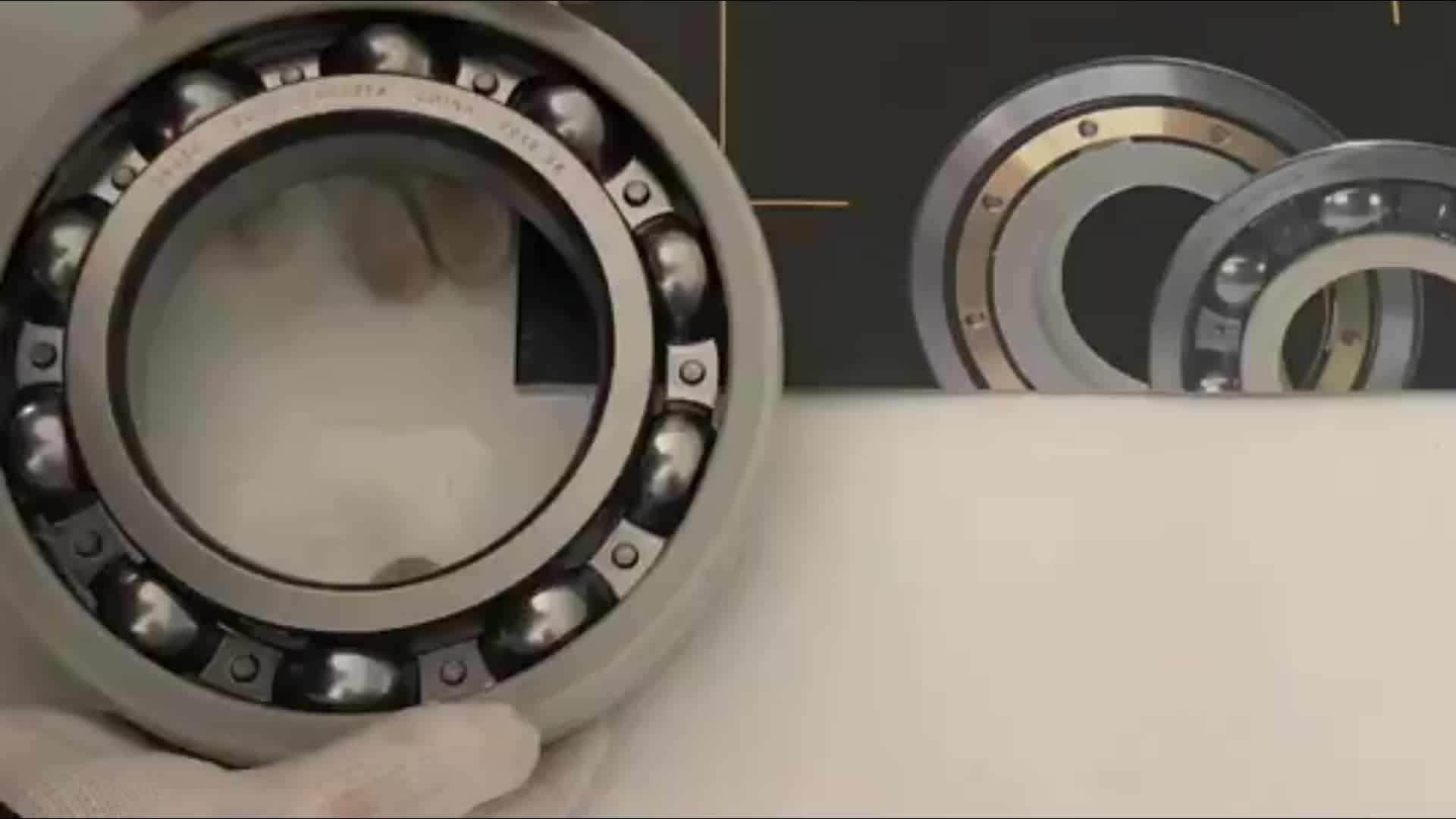

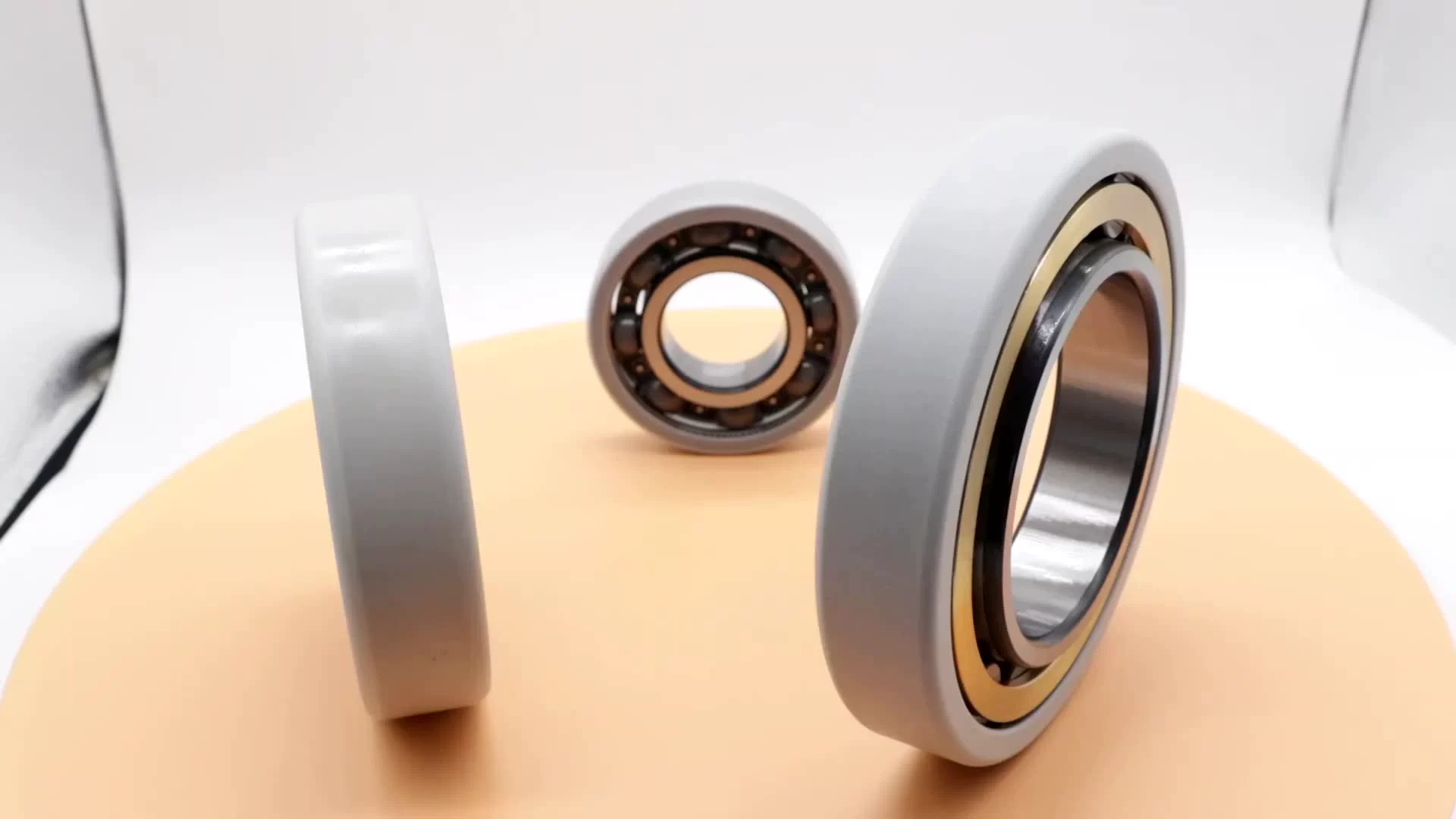

Pressure resistance standard for insulated bearings

The pressure resistance of insulated bearings depends mainly on the type and thickness of their insulating coating. The pressure resistance of insulated bearings varies depending on the application requirements. The following is an overview of the different kinds of insulated bearings and their pressure resistance criteria

Special spraying process insulated bearings: This type of bearing adopts a special spraying process, spraying and plating a high-quality coating on the outer surface, which has a strong bonding force with the substrate and good insulating properties. The outer or inner ring has a 100 μm thick coating on the surface, which can withstand voltages of up to 1000 V DC. This coating has a uniform thickness and extremely strong adhesion and is further processed to be resistant to moisture and humidity.

Insulated bearings prepared with KNM22 two-component nano insulating coating: Insulated bearings prepared using KNM22 two-component nano insulating layer material with a coating thickness of 0.6mm can withstand voltages up to 3500 V DC. This coating can withstand salt spray for 3000h, can be constructed with rust, with no need for sandblasting to remove rust, and can be sprayed directly to obtain an insulating coating that can resist galvanic corrosion.

The pressure resistance of insulated bearings depends mainly on the type and thickness of their insulating coating. The pressure resistance of insulated bearings varies depending on the application requirements. The following is an overview of the different kinds of insulated bearings and their pressure resistance criteria

Special spraying process insulated bearings: This type of bearing adopts a special spraying process, spraying and plating a high-quality coating on the outer surface, which has a strong bonding force with the substrate and good insulating properties. The outer or inner ring has a 100 μm thick coating on the surface, which can withstand voltages of up to 1000 V DC. This coating has a uniform thickness and extremely strong adhesion and is further processed to be resistant to moisture and humidity.

Insulated bearings prepared with KNM22 two-component nano insulating coating: Insulated bearings prepared using KNM22 two-component nano insulating layer material with a coating thickness of 0.6mm can withstand voltages up to 3500 V DC. This coating can withstand salt spray for 3000h, can be constructed with rust, with no need for sandblasting to remove rust, and can be sprayed directly to obtain an insulating coating that can resist galvanic corrosion.

some famous brand insulated bearings: the breakdown strength of the insulating coatings of some brands of

insulated bearings is at least as follows: J20AB coating reaches at least 1,000 V; J20AA/J20C coating reaches at least 3,000 V; J20B coating reaches at least 500 V. These values indicate that, below the above voltage, the insulating coatings allow only a very small current to pass through the bearings.

In summary, insulated bearings have a wide range of voltage resistance criteria, from the ability to withstand voltages of 1,000 V to 3,500 V, depending on the insulating coating technology and materials used. These properties enable the safe operation of insulated bearings in environments where induced currents are present, protecting the bearings from galvanic corrosion and thus prolonging their service life.

insulated bearings is at least as follows: J20AB coating reaches at least 1,000 V; J20AA/J20C coating reaches at least 3,000 V; J20B coating reaches at least 500 V. These values indicate that, below the above voltage, the insulating coatings allow only a very small current to pass through the bearings.

In summary, insulated bearings have a wide range of voltage resistance criteria, from the ability to withstand voltages of 1,000 V to 3,500 V, depending on the insulating coating technology and materials used. These properties enable the safe operation of insulated bearings in environments where induced currents are present, protecting the bearings from galvanic corrosion and thus prolonging their service life.

Model |

Cage |

Cr(KN) |

Cor (KN) |

Grease lubrication speed |

Oil lubricated speed |

Weight (kg) |

Insulation class |

||

6030/C3VL0271 |

Steel |

125 |

125 |

6000 |

3800 |

4.2 |

2000V |

3000V |

|

6030M/C3VL0271 |

Brass |

125 |

125 |

6000 |

3800 |

4.2 |

2000V |

3000V |

|