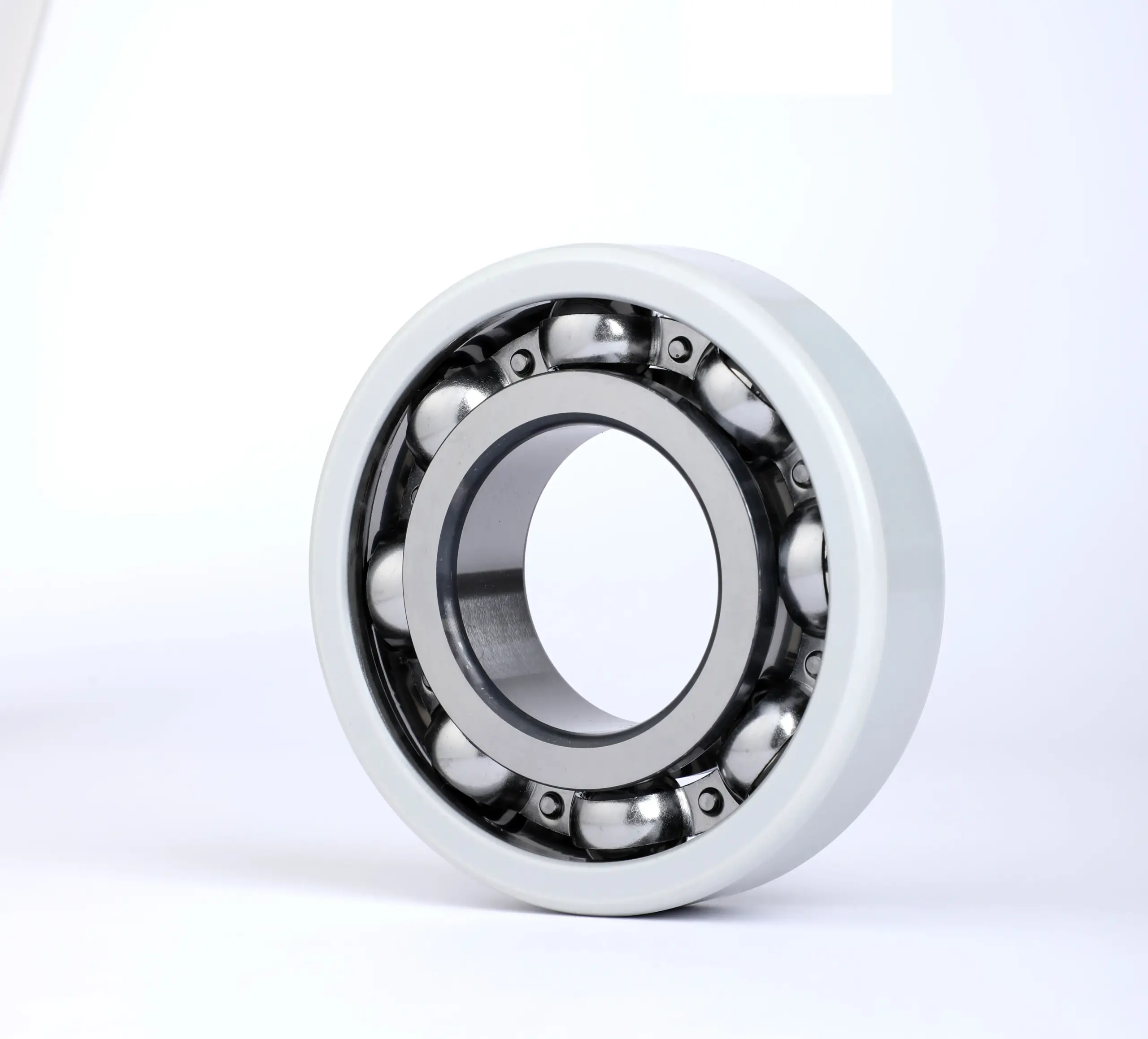

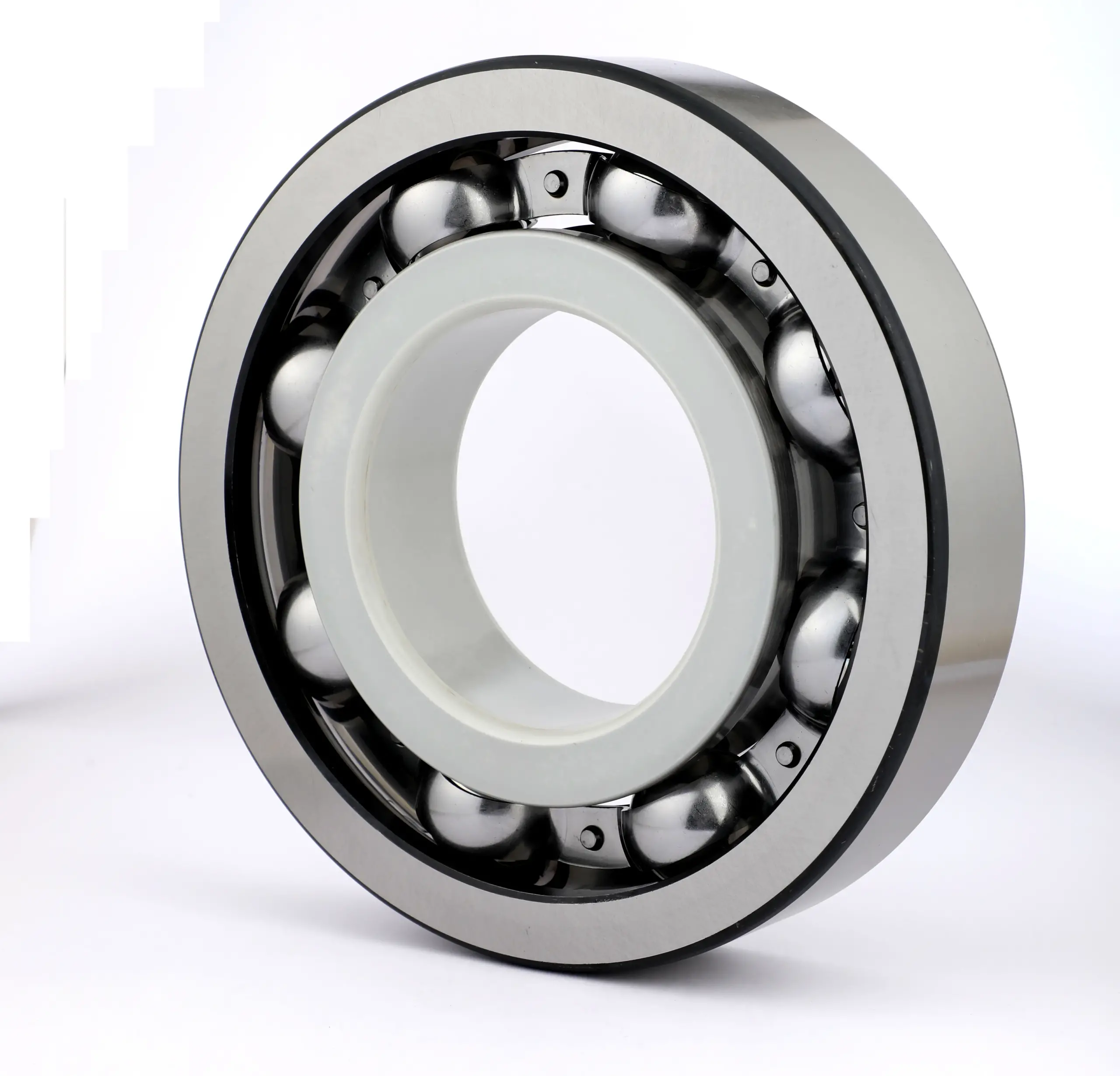

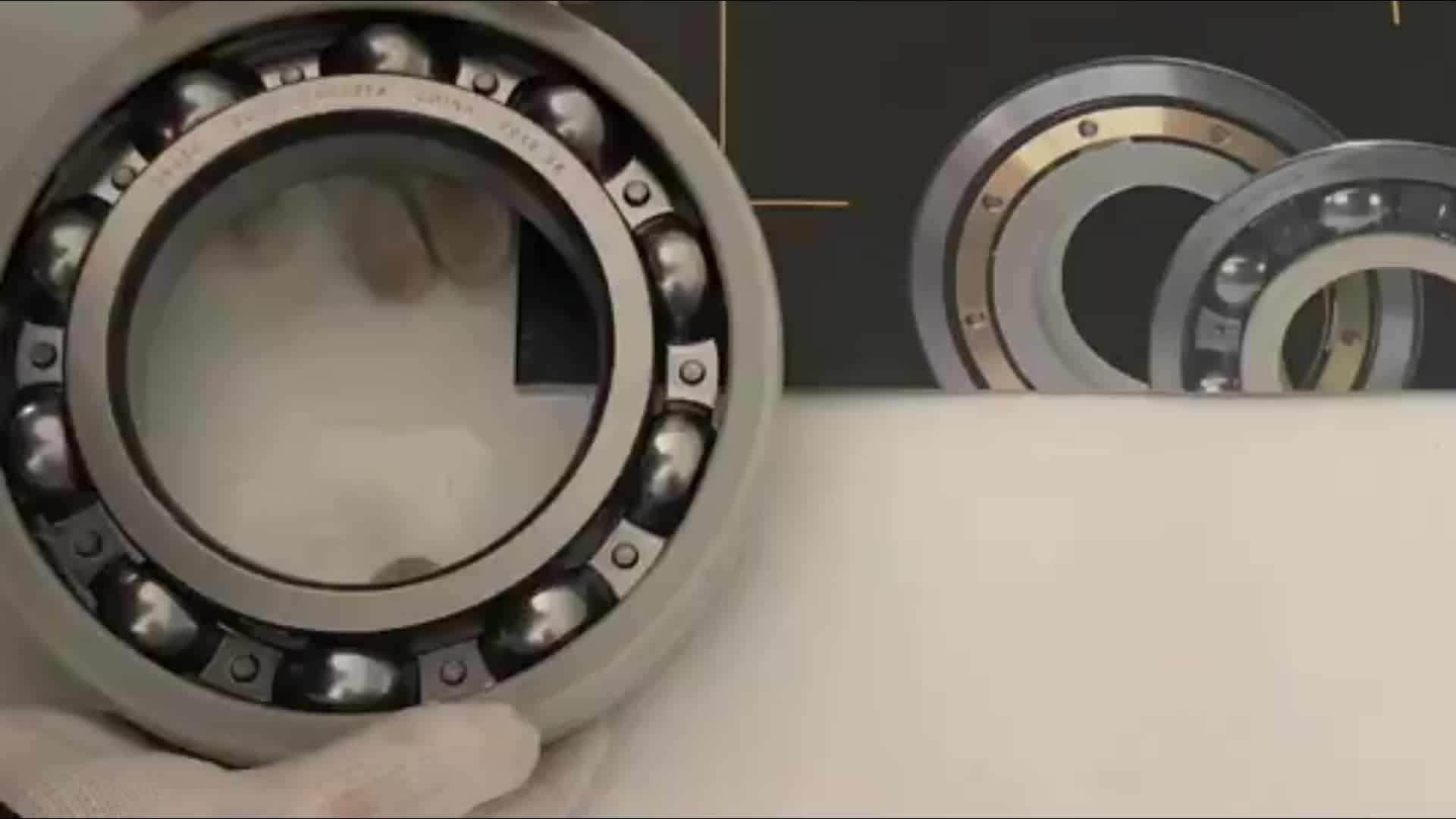

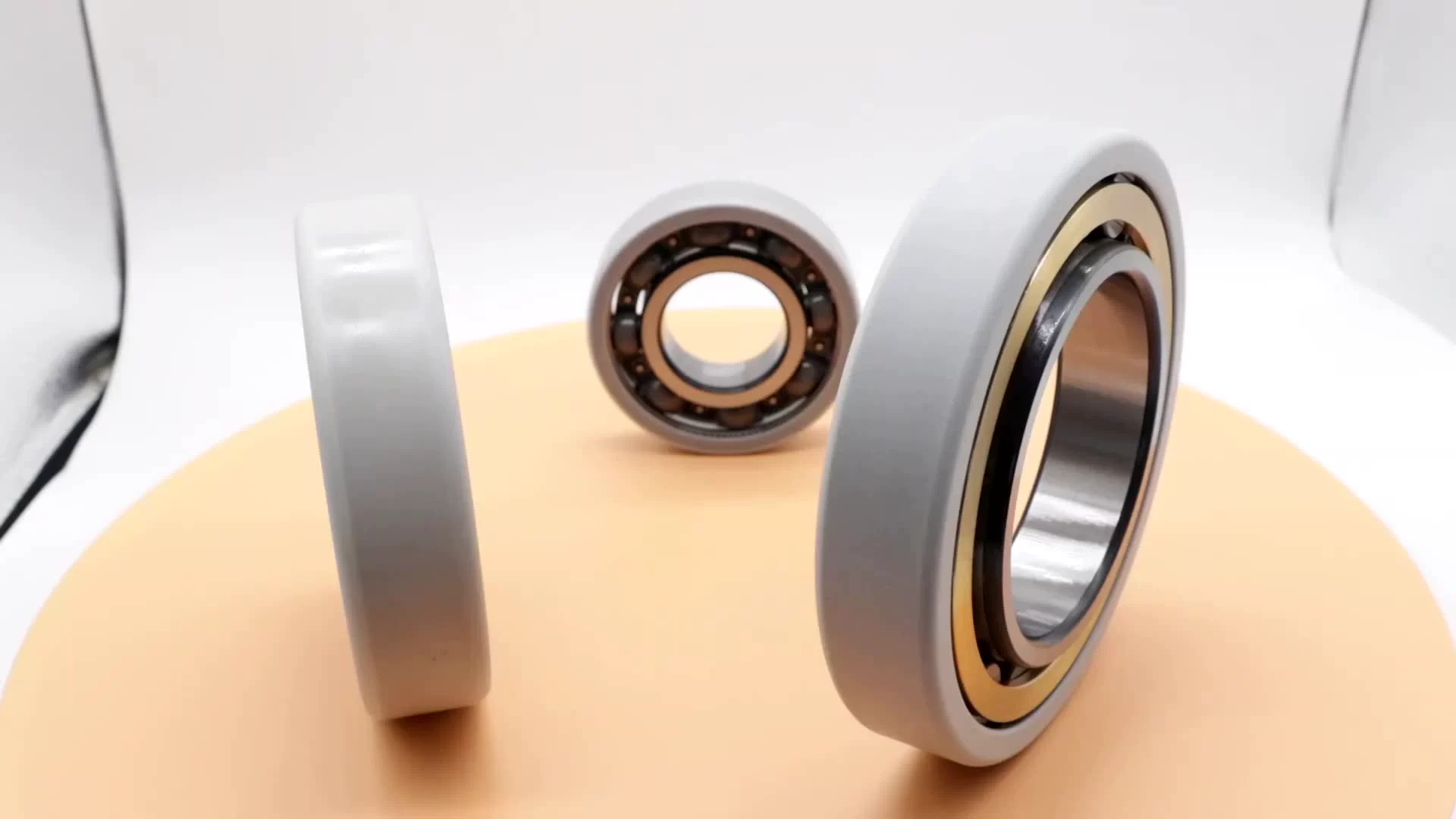

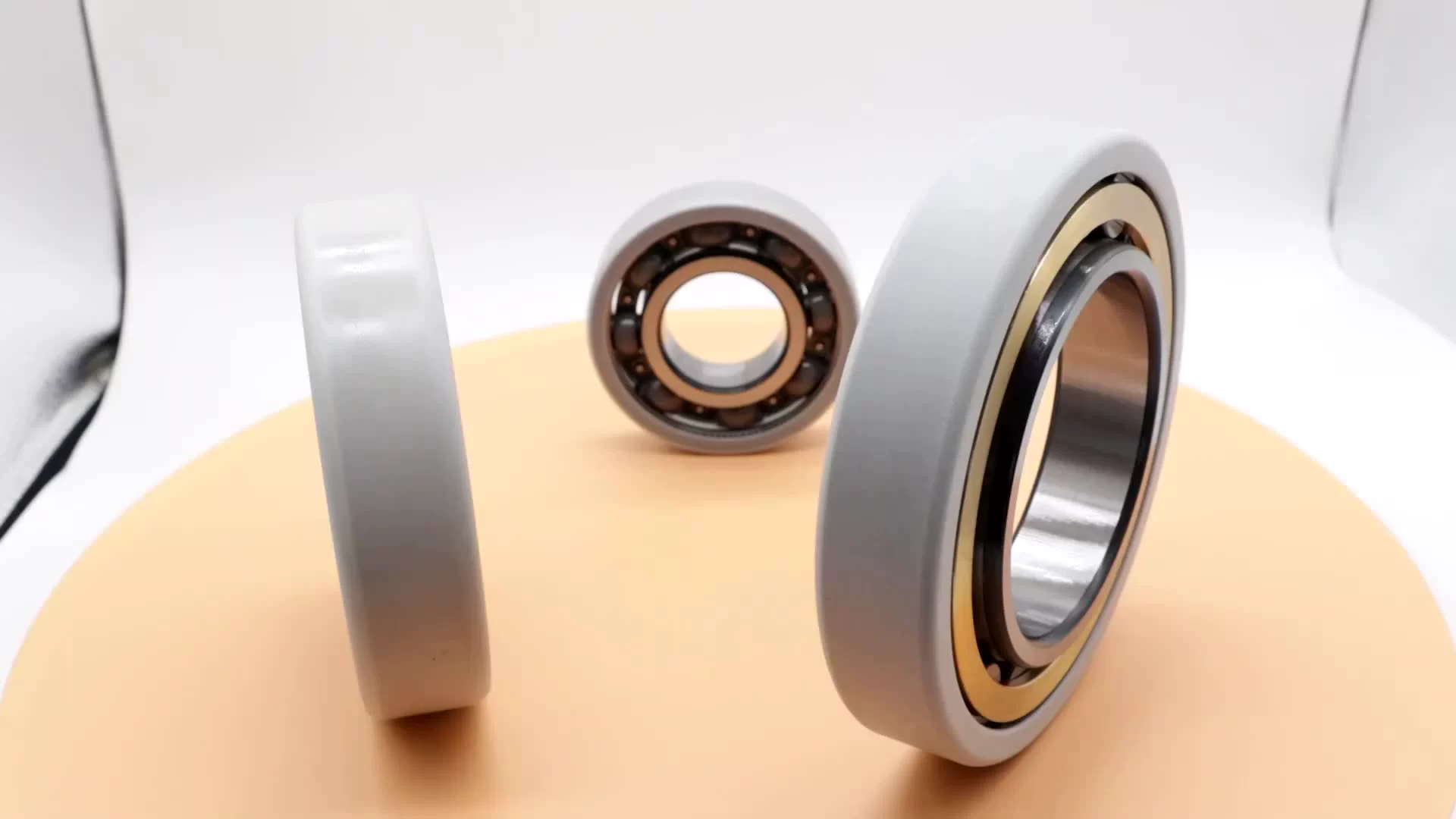

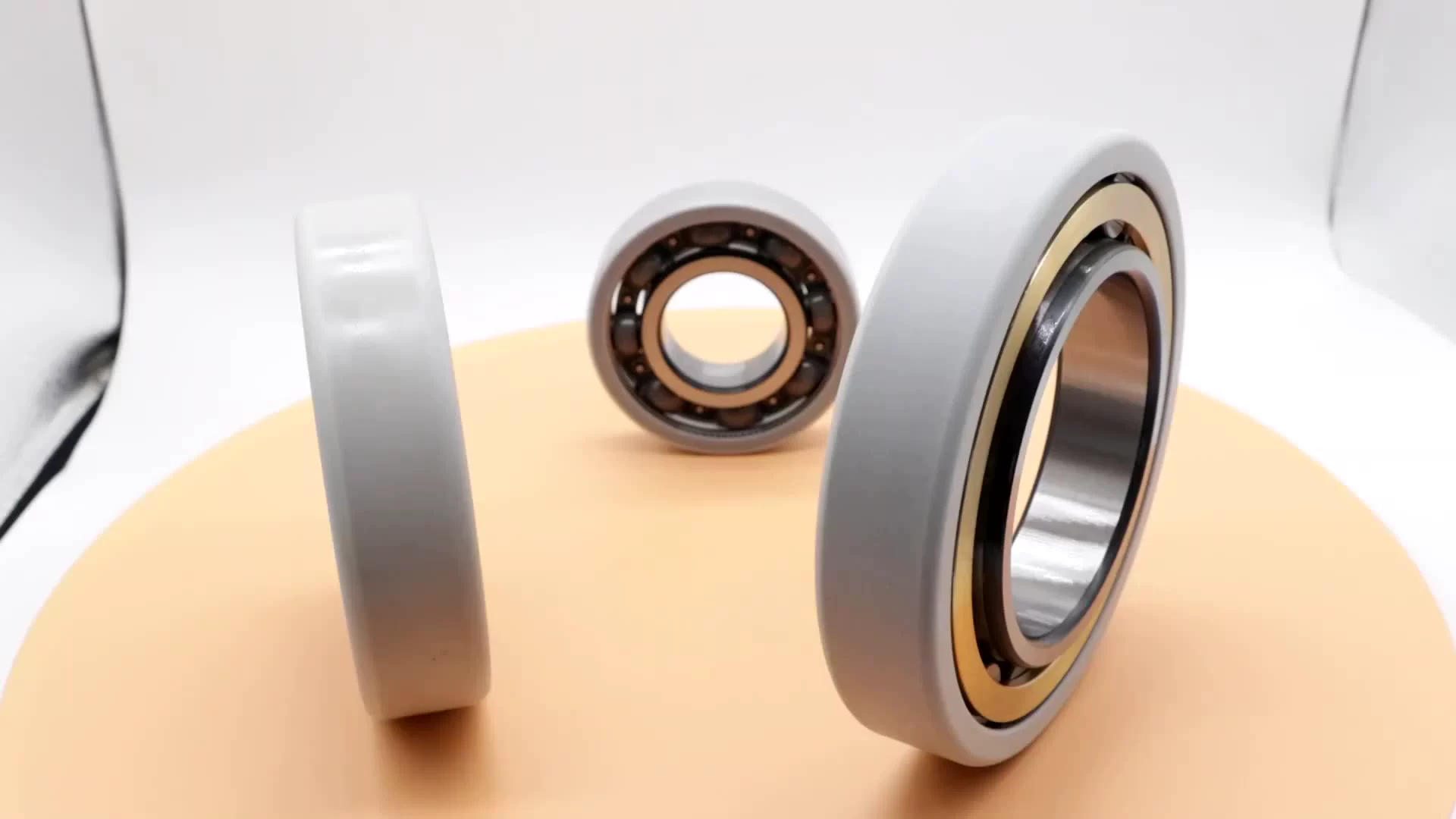

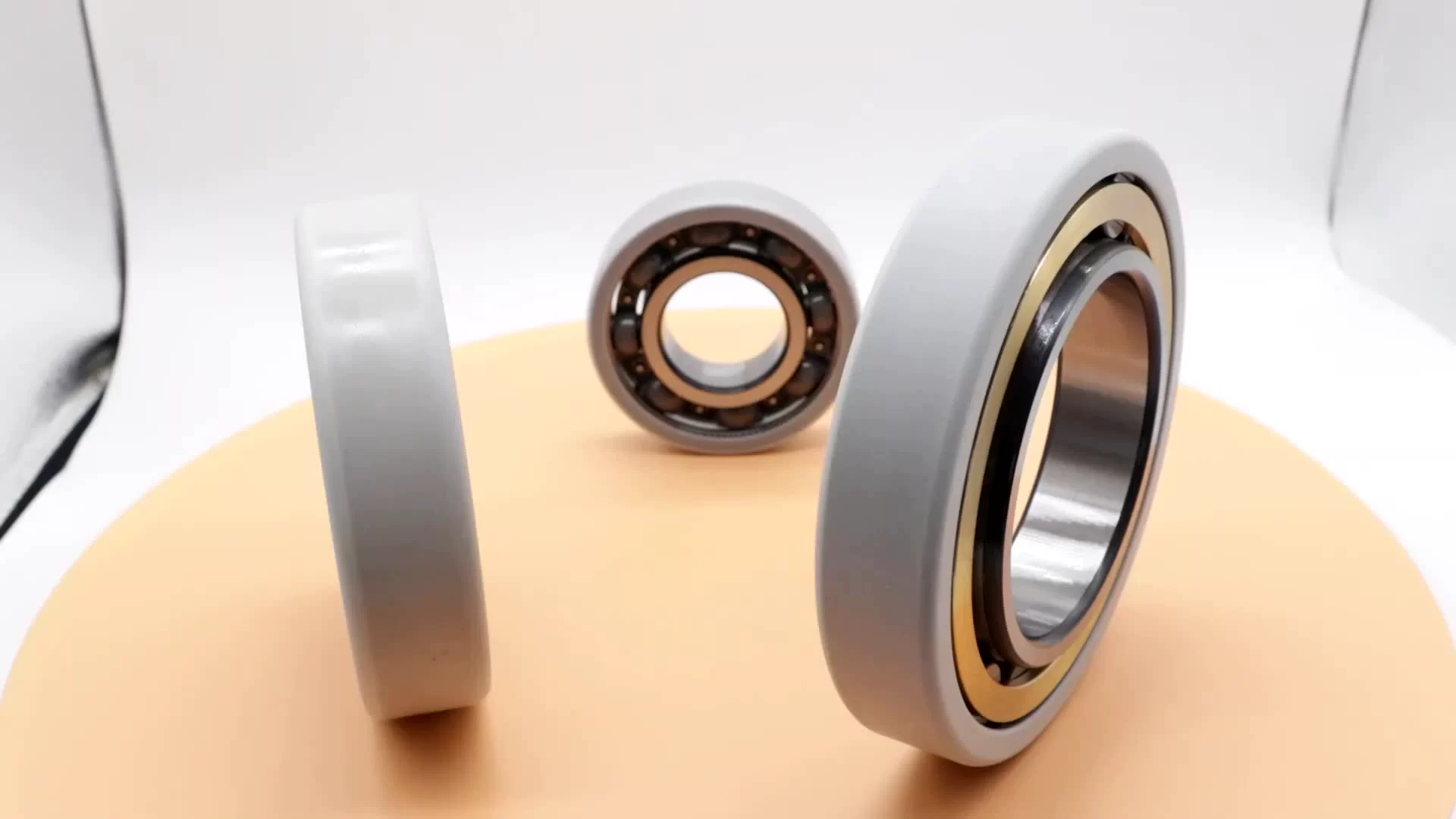

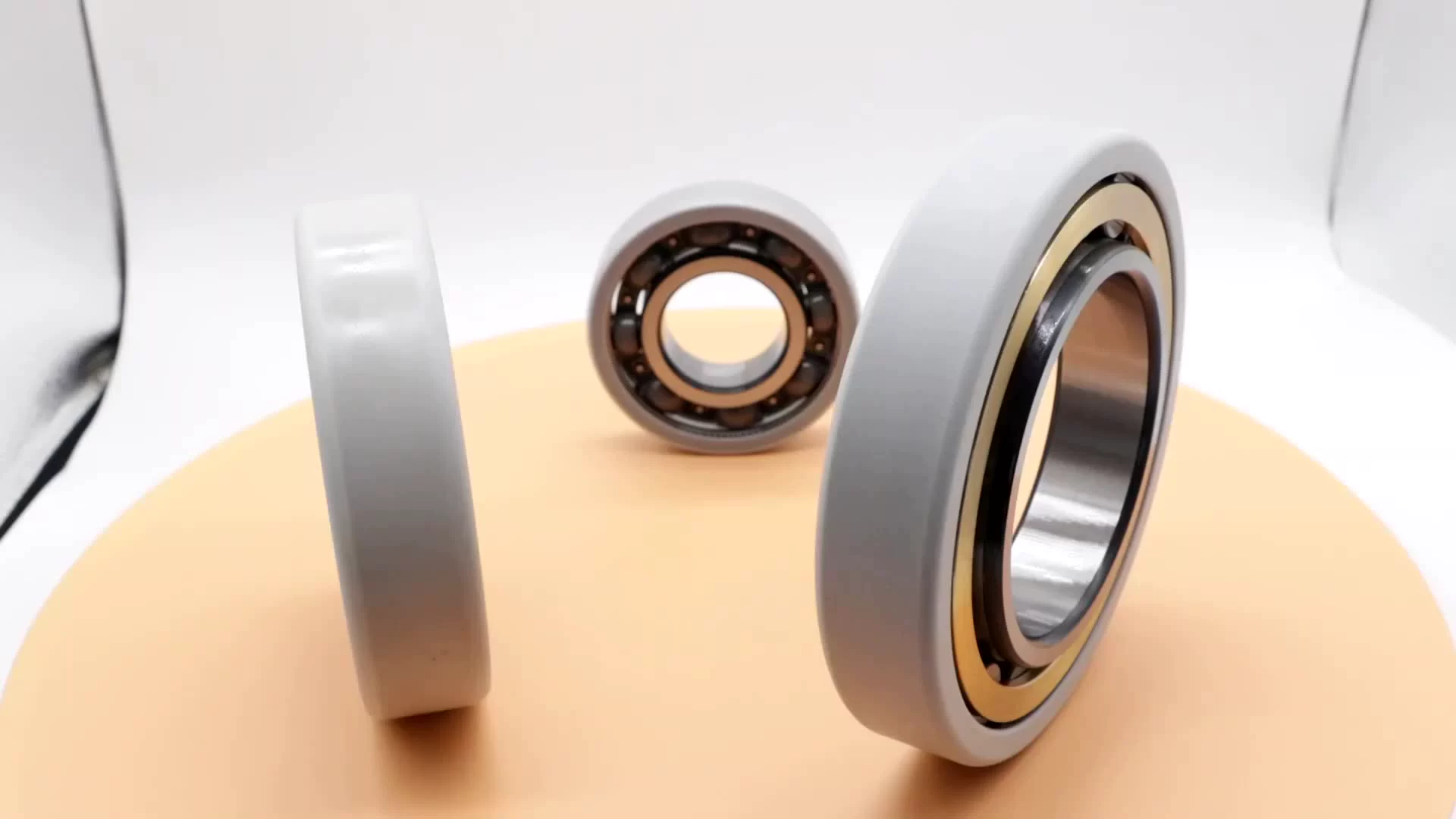

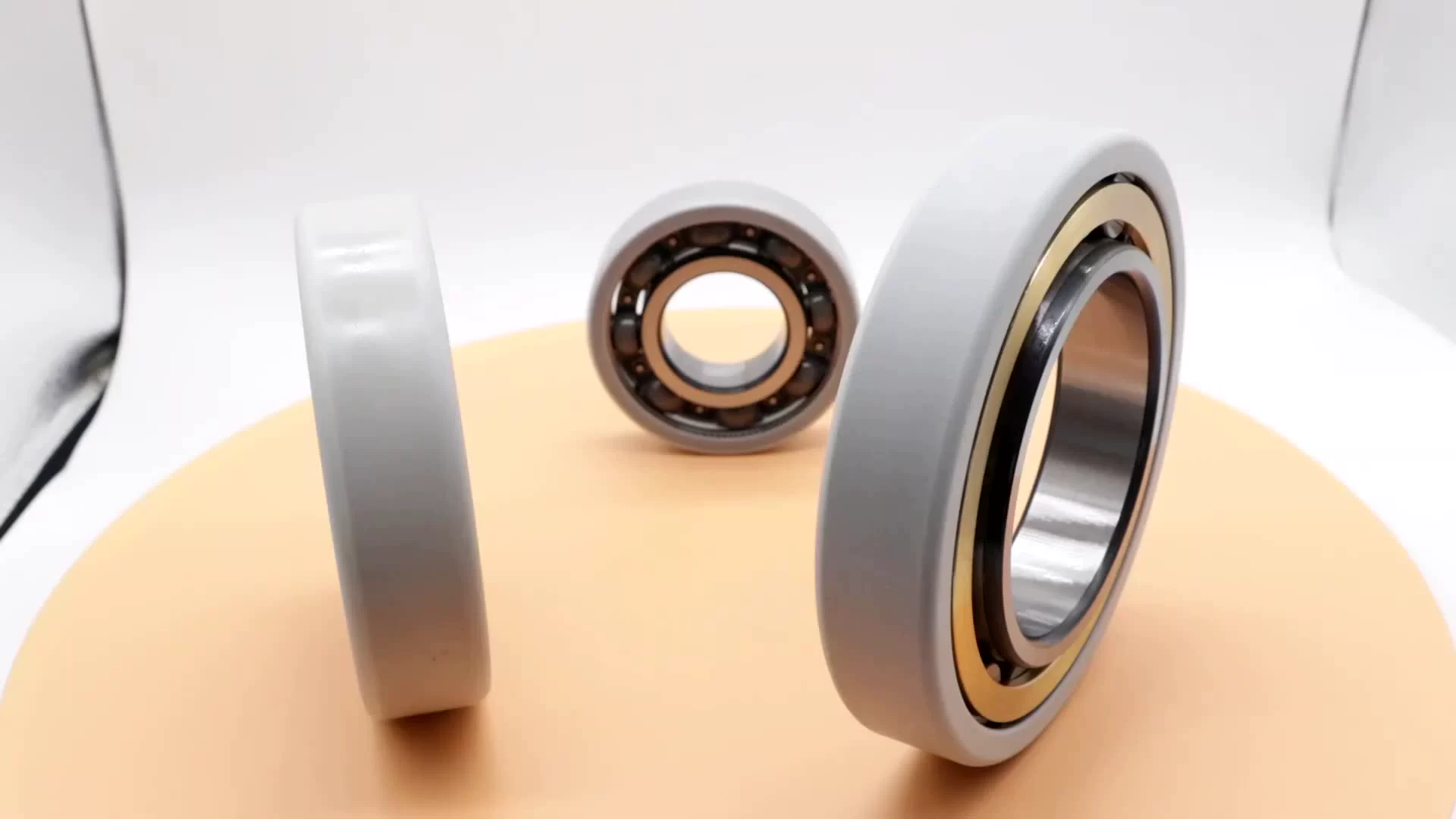

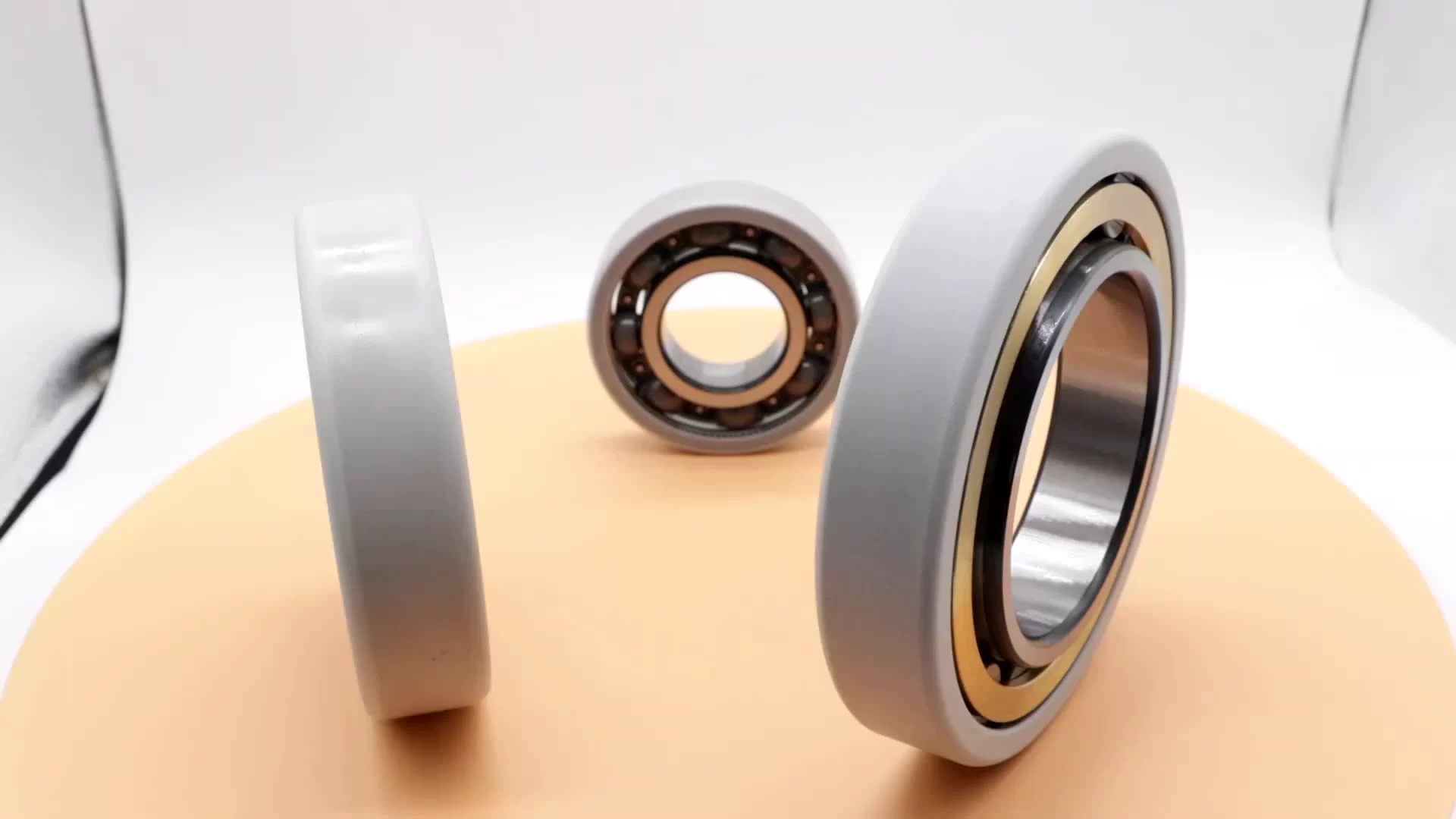

6028M/C3VL0271 6028M/C3J20C 140x210x33mm inner ring electric insulated bearing for electricity generator

Key attributes

Industry-specific attributes

Applicable Industries

Building Material Shops, Machinery Repair Shops, Retail, Energy & Mining, Other

Bore Size

139.99 - 140 mm

Precision Rating

P5 P6 P2 P0 P4 P3

Number of Row

Single row

Other attributes

Place of Origin

China

Type

BALL

Structure

Deep Groove

Model Number

6028M/C3VL0271

Seals Type

open 2RS ZZ

OEM Service

Custom Bearing's Size Logo Packing

Feature

insulation

Brand

OEM Famous Brand

Product name

insulated bearing

Material

Chrome Steel GCR15

Application

Electric Motors

Model

6320M/C3VL0271

Certificate

ISO 9001:2000

Keywords

ceramic-coated

Sample

Avialable

6028M/C3VL0271 6028M/C3J20C 140x210x33mm inner ring electric insulated bearing for electricity generator

The correct installation method for insulated bearings includes the following key steps:

Use specialized tools for mounting and dismounting: The use of specialized bearing dismounting tools can avoid damage to insulated bearings caused by improper tools and operation. For example, please avoid the use of the copper rod knock-in method because it may lead to uneven axial force, resulting in cage deformation and rolling element damage.

Inspection before mounting: Before mounting, check whether the packaging of the bearing is complete and whether the bearing insulation is damaged. If any damage is found, the bearing should be avoided to prevent current corrosion.

Check fit dimensions: When assembling the motor, carefully check the fit dimensions of the bearing and the rotor shaft, as well as the fit dimensions of the outer ring of the bearing and the hole in the end cap, to ensure a proper fit.

Control oil quantity: The amount of oil in the bearings and case should be properly controlled to avoid excessive oil causing the rolling elements to slip, thus damaging the bearings. Too much oil will reduce the density of the grease, making the rolling body lubricant film thin and affecting the lubrication conditions.

Ensure insulation function: For bearings with outer ring insulation design, care must be taken to ensure that the insulation is intact during installation. If the bearing insulation is damaged during mounting, it may cause electrical sparks to form galvanic corrosion on the rolling elements, accelerating bearing wear.

By following these steps, it is possible to ensure that insulated bearings are mounted correctly, thus avoiding galvanic corrosion and other mechanical damage and extending the service life of the bearings.

Use specialized tools for mounting and dismounting: The use of specialized bearing dismounting tools can avoid damage to insulated bearings caused by improper tools and operation. For example, please avoid the use of the copper rod knock-in method because it may lead to uneven axial force, resulting in cage deformation and rolling element damage.

Inspection before mounting: Before mounting, check whether the packaging of the bearing is complete and whether the bearing insulation is damaged. If any damage is found, the bearing should be avoided to prevent current corrosion.

Check fit dimensions: When assembling the motor, carefully check the fit dimensions of the bearing and the rotor shaft, as well as the fit dimensions of the outer ring of the bearing and the hole in the end cap, to ensure a proper fit.

Control oil quantity: The amount of oil in the bearings and case should be properly controlled to avoid excessive oil causing the rolling elements to slip, thus damaging the bearings. Too much oil will reduce the density of the grease, making the rolling body lubricant film thin and affecting the lubrication conditions.

Ensure insulation function: For bearings with outer ring insulation design, care must be taken to ensure that the insulation is intact during installation. If the bearing insulation is damaged during mounting, it may cause electrical sparks to form galvanic corrosion on the rolling elements, accelerating bearing wear.

By following these steps, it is possible to ensure that insulated bearings are mounted correctly, thus avoiding galvanic corrosion and other mechanical damage and extending the service life of the bearings.

Model |

Cage |

Cr(KN) |

Cor (KN) |

Grease lubrication speed |

Oil lubricated speed |

Weight (kg) |

Insulation class |

||

6028/C3VL0271 |

Steel |

111 |

108 |

6700 |

4000 |

3.4 |

2000V |

3000V |

|

6028M/C3VL0271 |

Brass |

111 |

108 |

6700 |

4000 |

3.4 |

2000V |

3000V |

|