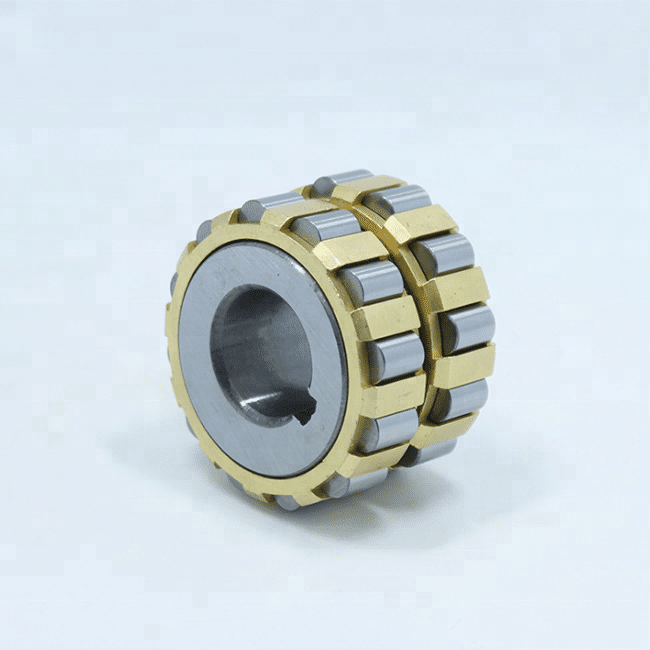

Double Row 130752904 Overall Eccentric Bearing 22×53.5x32mm

Bore Size: 30 mm

Outside Diameter: 53.5 mm

Samples: Double Row 130752904 Overall Eccentric Bearing 22×53.5x32mm

$13.50/Piece | 1 Piece (Min. Order) |

-

Lead Time–If you finish the payment today, your order will ship out within the delivery date.

-

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 100 Pieces)Customized packaging(Min. Order: 100 Pieces)

|

Bearing No

|

Size(mm)

|

Mass

|

||||||||

|

d

|

D

|

L

|

r

|

e

|

kg

|

|||||

|

70752904K2

|

19

|

53.5

|

32

|

1

|

0.65

|

0.38

|

||||

|

80752904K2

|

53.5

|

32

|

1

|

0.75

|

0.38

|

|||||

|

100752904K2

|

53.5

|

32

|

1

|

1

|

0.38

|

|||||

|

130752904K2

|

53.5

|

32

|

1

|

1.25

|

0.38

|

|||||

|

150752904K2

|

53.5

|

32

|

1

|

1.5

|

0.38

|

|||||

|

200752904K2

|

53.5

|

32

|

1

|

2

|

0.38

|

|||||

|

250752904K2

|

53.5

|

32

|

1

|

2.5

|

0.38

|

|||||

|

300752904K2

|

53.5

|

32

|

1

|

3

|

0.38

|

|||||

|

350752904K2

|

53.5

|

32

|

1

|

3.5

|

0.38

|

|||||

|

80752904Y1

|

61.8

|

34

|

1.1

|

0.75

|

0.51

|

|||||

|

100752904Y1

|

61.8

|

34

|

1.1

|

1

|

0.51

|

|||||

|

130752904Y1

|

61.8

|

34

|

1.1

|

1.25

|

0.51

|

|||||

|

150752904Y1

|

61.8

|

34

|

1.1

|

1.5

|

0.51

|

|||||

|

200752904Y1

|

61.8

|

34

|

1.1

|

2

|

0.51

|

|||||

|

300752904Y1

|

61.8

|

34

|

1.1

|

3

|

0.51

|

|||||

|

80752904K1

|

70

|

36

|

1.1

|

0.75

|

0.82

|

|||||

|

100752904K1

|

70

|

36

|

1.1

|

1

|

0.82

|

|||||

|

130752904K1

|

70

|

36

|

1.1

|

1.25

|

0.82

|

|||||

|

150752904K1

|

19

|

70

|

36

|

1.1

|

1.5

|

0.82

|

||||

|

200752904K1

|

70

|

36

|

1.1

|

2

|

0.82

|

|||||

|

70752904

|

22

|

53.5

|

32

|

1.1

|

0.65

|

0.35

|

||||

|

80752904

|

53.5

|

32

|

1.1

|

0.75

|

0.35

|

|||||

|

100752904

|

53.5

|

32

|

1.1

|

1

|

0.35

|

|||||

|

130752904

|

53.5

|

32

|

1.1

|

1.25

|

0.35

|

|||||

|

150752904

|

53.5

|

32

|

1.1

|

1.5

|

0.35

|

|||||

|

180752904

|

53.5

|

32

|

1.1

|

1.75

|

0.35

|

|||||

|

200752904

|

53.5

|

32

|

1.1

|

2

|

0.35

|

|||||

|

250752904

|

53.5

|

32

|

1.1

|

2.5

|

0.35

|

|||||

|

300752904

|

53.5

|

32

|

1.1

|

3

|

0.35

|

|||||

|

350752904

|

53.5

|

32

|

1.1

|

3.5

|

0.35

|

|||||

|

400752904

|

53.5

|

32

|

1.1

|

4

|

0.35

|

|||||

|

130752904K

|

61.8

|

34

|

1.1

|

1.25

|

0.5

|

|||||

Shandong Tefule Bearing Co., Ltd. won the ISO9001-2015 quality management system certificate issued by the authoritative third-party certification company SGS certification body in 2015, and became a company in China that has obtained this authoritative certification.

Shandong Tefule Bearing Co., Ltd

is a professional bearing manufacturer and dealer in China. We have been engaged in the bearing industry for 10 years and have made international trade of bearing import and export for more than 8 years.

Our company specializes in ball bearings,roller bearings, housing units, wheel hub bearings, bearing parts and accessories, and cross roller bearings. Als,o we can customize various large non-standard products such as the most competitive products according to customers’ demands.

FAQ1: What are the uses of integral eccentric bearings?

As the name implies, the central axis of the inner ring or outer ring of the integral eccentric bearing has a fixed eccentric distance from the central axis of the bearing’s rotation. This design makes it produce eccentric motion when rotating, and its main uses are:

1. Realize reciprocating motion or swing: Convert eccentric rotation into linear or arc motion, such as in punching machines, sewing machines and other equipment.

2. Adjust the position or gap of the mechanism: By rotating the eccentric bearing, the position of the parts connected to it can be fine-tuned, such as adjusting the position of the cam in a cam mechanism.

3. Generate vibration: In some equipment, the rotation of the eccentric bearing can produce the desired vibration effect, such as in equipment such as vibrating screens and mixers.

4. As part of a special transmission mechanism: In some specific mechanical designs, eccentric bearings can be used as transmission elements to achieve specific motion trajectories or speed changes.

1. Realize reciprocating motion or swing: Convert eccentric rotation into linear or arc motion, such as in punching machines, sewing machines and other equipment.

2. Adjust the position or gap of the mechanism: By rotating the eccentric bearing, the position of the parts connected to it can be fine-tuned, such as adjusting the position of the cam in a cam mechanism.

3. Generate vibration: In some equipment, the rotation of the eccentric bearing can produce the desired vibration effect, such as in equipment such as vibrating screens and mixers.

4. As part of a special transmission mechanism: In some specific mechanical designs, eccentric bearings can be used as transmission elements to achieve specific motion trajectories or speed changes.

FAQ2: Application of eccentric bearings in textile and printing machines?

Eccentric bearings are widely used in textile machinery and printing machinery, mainly using the characteristics of eccentric motion to achieve various precise controls and movements:

1. Textile machinery:

Yarn feeding mechanism: Control the feeding speed and tension of the yarn.

Winding mechanism: Control the winding speed and coil arrangement of the yarn.

Jacquard mechanism: Control the movement of the knitting needle to weave different patterns.

Other auxiliary mechanisms: Such as thread cutting, yarn guiding and other mechanisms.

2. Printing machinery:

Paper feeding mechanism: Control the smooth delivery of paper.

Imprinting mechanism: Provide uniform imprinting force.

Ink supply mechanism: Control the movement of the ink roller and the distribution of ink.

Register mechanism: Accurately adjust the alignment of different colour printing plates.

Cutting mechanism: Control the movement of the cutting knife.

In these applications, eccentric bearings can achieve precise reciprocating motion, intermittent motion and fine-tuning to ensure the stability of the machinery and the quality of printing/textiles.

1. Textile machinery:

Yarn feeding mechanism: Control the feeding speed and tension of the yarn.

Winding mechanism: Control the winding speed and coil arrangement of the yarn.

Jacquard mechanism: Control the movement of the knitting needle to weave different patterns.

Other auxiliary mechanisms: Such as thread cutting, yarn guiding and other mechanisms.

2. Printing machinery:

Paper feeding mechanism: Control the smooth delivery of paper.

Imprinting mechanism: Provide uniform imprinting force.

Ink supply mechanism: Control the movement of the ink roller and the distribution of ink.

Register mechanism: Accurately adjust the alignment of different colour printing plates.

Cutting mechanism: Control the movement of the cutting knife.

In these applications, eccentric bearings can achieve precise reciprocating motion, intermittent motion and fine-tuning to ensure the stability of the machinery and the quality of printing/textiles.