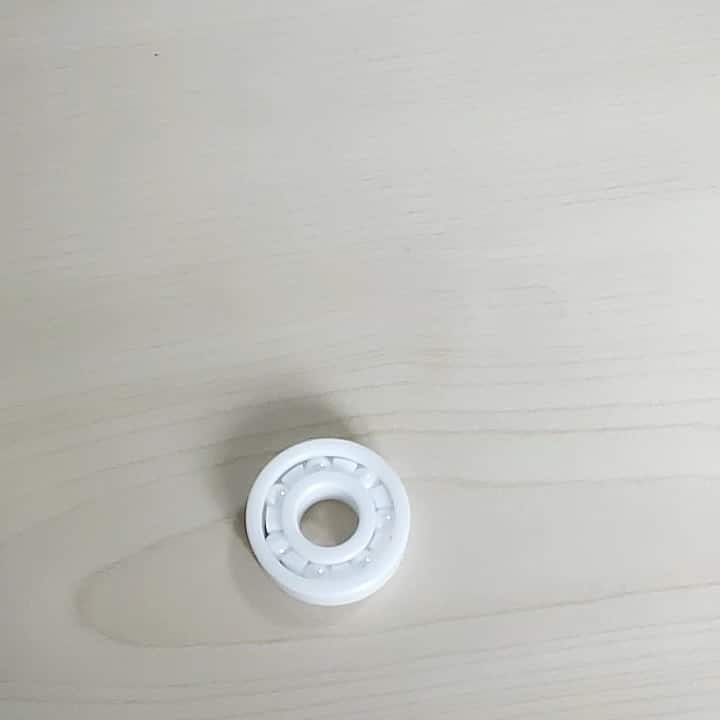

High speed ABEC-5 Full ZrO2 ceramic insert bearing SB202 CE

- Samples:

-

15 mm , 40 mm

$6.99/Piece | 1 Piece (Min. Order) |

- Lead Time

If you finish the payment today, your order will ship out within the delivery date.

:

-

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 100 Pieces)Customized packaging(Min. Order: 100 Pieces)

High speed ABEC-5 Full ZrO2 ceramic insert bearing SB202 CE

We can supply the following kinds of ceramic bearings

1. Full ceramic: inner ring, outer ring, and ball are all ZrO2, cage: PTFE

2. Hybrid ceramic bearing: Inner ring, outer ring: stainless steel, ball:si3n4 or ZrO2, cage: stainless steel using: Ceramic bearing has the characteristics of high-temperature resistance, cold resistance, abrasion resistance, corrosion resistance, anti-magnetic insulation, oil-free self-lubrication, and high speed. It can be used in extremely harsh environments and the special operating mode, can be widely used in aviation, spaceflight, navigation, petroleum, chemical industry, automobile, electronics, metallurgy, electric power, textile, pumps, medical equipment, scientific research and national defense military and other fields, is the new materials of high-tech products.

Advantages:

1. Because ceramics are almost impervious to corrosion, ceramic rolling bearings are suitable for operating under the harsh conditions of corrosive media.

2. Because the density of the ceramic rolling ball is lower than that of steel, the weight is much lighter, so the centrifugal

effect of the outer ring can be reduced by 40%, and the service life is greatly extended.

3. Ceramic is less affected by thermal expansion and shrinkage than steel, so the bearing can be allowed to work in an environment where the temperature difference is more severe when the bearing gap is certain.

4. Because the elastic modulus of ceramics is higher than steel, the force is not easy to deform, so it can improve operating speed and achieve high precision.

1. Full ceramic: inner ring, outer ring, and ball are all ZrO2, cage: PTFE

2. Hybrid ceramic bearing: Inner ring, outer ring: stainless steel, ball:si3n4 or ZrO2, cage: stainless steel using: Ceramic bearing has the characteristics of high-temperature resistance, cold resistance, abrasion resistance, corrosion resistance, anti-magnetic insulation, oil-free self-lubrication, and high speed. It can be used in extremely harsh environments and the special operating mode, can be widely used in aviation, spaceflight, navigation, petroleum, chemical industry, automobile, electronics, metallurgy, electric power, textile, pumps, medical equipment, scientific research and national defense military and other fields, is the new materials of high-tech products.

Advantages:

1. Because ceramics are almost impervious to corrosion, ceramic rolling bearings are suitable for operating under the harsh conditions of corrosive media.

2. Because the density of the ceramic rolling ball is lower than that of steel, the weight is much lighter, so the centrifugal

effect of the outer ring can be reduced by 40%, and the service life is greatly extended.

3. Ceramic is less affected by thermal expansion and shrinkage than steel, so the bearing can be allowed to work in an environment where the temperature difference is more severe when the bearing gap is certain.

4. Because the elastic modulus of ceramics is higher than steel, the force is not easy to deform, so it can improve operating speed and achieve high precision.

|

Bearing No.

|

Shaft Dia.

|

Dimensions(mm)(in.)

|

||||||||

|

d

|

D

|

B

|

C

|

S

|

||||||

|

(in.)

|

(mm)

|

|||||||||

|

SB201

|

12

|

40

|

22

|

12

|

6

|

|||||

|

SB201-8

|

1/2

|

40

|

22

|

12

|

6

|

|||||

|

SB202

|

15

|

40

|

22

|

12

|

6

|

|||||

|

SB202-10

|

5/8

|

40

|

22

|

12

|

6

|

|||||

|

SB203

|

17

|

40

|

22

|

12

|

6

|

|||||

|

SB203-11

|

11/16

|

40

|

22

|

12

|

6

|

|||||

|

SB204-12

|

3/4

|

47

|

25

|

14

|

7

|

|||||

|

SB204

|

20

|

47

|

25

|

14

|

7

|

|||||

|

SB205-14

|

7/8

|

52

|

27

|

15

|

7.5

|

|||||

|

SB205-15

|

15/16

|

52

|

27

|

15

|

7.5

|

|||||

|

SB205

|

25

|

52

|

27

|

15

|

7.5

|

|||||

|

SB205-16

|

1

|

52

|

27

|

15

|

7.5

|

|||||

|

SB206-18

|

1-1/8

|

62

|

30

|

16

|

8

|

|||||

|

SB206

|

30

|

62

|

30

|

16

|

8

|

|||||

|

SB206-19

|

1-3/16

|

62

|

30

|

16

|

8

|

|||||

|

SB206-20

|

1-1/4

|

62

|

30

|

16

|

8

|

|||||

|

SB207-20

|

1-1/4

|

72

|

32

|

17

|

8.5

|

|||||

|

SB207-21

|

1-5/16

|

72

|

32

|

17

|

8.5

|

|||||

|

SB207-22

|

1-3/8

|

72

|

32

|

17

|

8.5

|

|||||

|

SB207

|

35

|

72

|

32

|

17

|

8.5

|

|||||

|

SB207-23

|

1-7/16

|

72

|

32

|

17

|

8.5

|

|||||

|

SB208-24

|

1-1/2

|

80

|

34

|

18

|

9

|

|||||

|

SB208-25

|

1-9/16

|

80

|

34

|

18

|

9

|

|||||

|

SB208

|

40

|

80

|

34

|

18

|

9

|

|||||

|

SB209-26

|

1-5/8

|

85

|

41.2

|

19

|

10.2

|

|||||

|

SB209

|

45

|

85

|

41.2

|

19

|

10.2

|

|||||

|

SB210

|

50

|

90

|

43.5

|

20

|

10.9

|

|||||

|

SB211

|

55

|

100

|

45.3

|

23

|

11.8

|

|||||

|

SB212

|

60

|

110

|

53.7

|

24

|

14.9

|

|||||