Travel Motor excavator bearing Large Bearing BA222-1WSA

-

Lead Time–If you finish the payment today, your order will ship out within the delivery date.

-

Quantity(Pieces) 1 – 2000 >2000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

Travel Motor excavator bearing Large Bearing BA222-1WSA

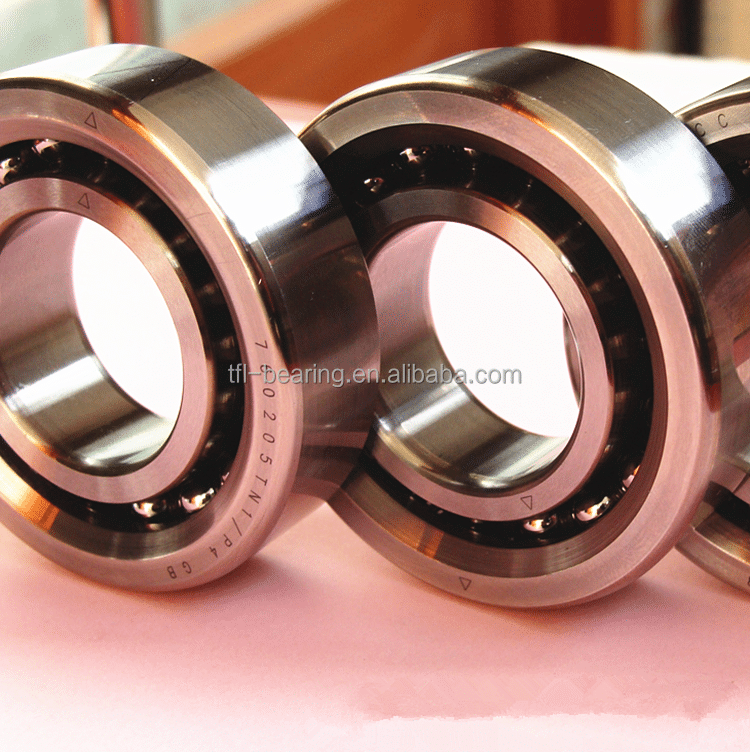

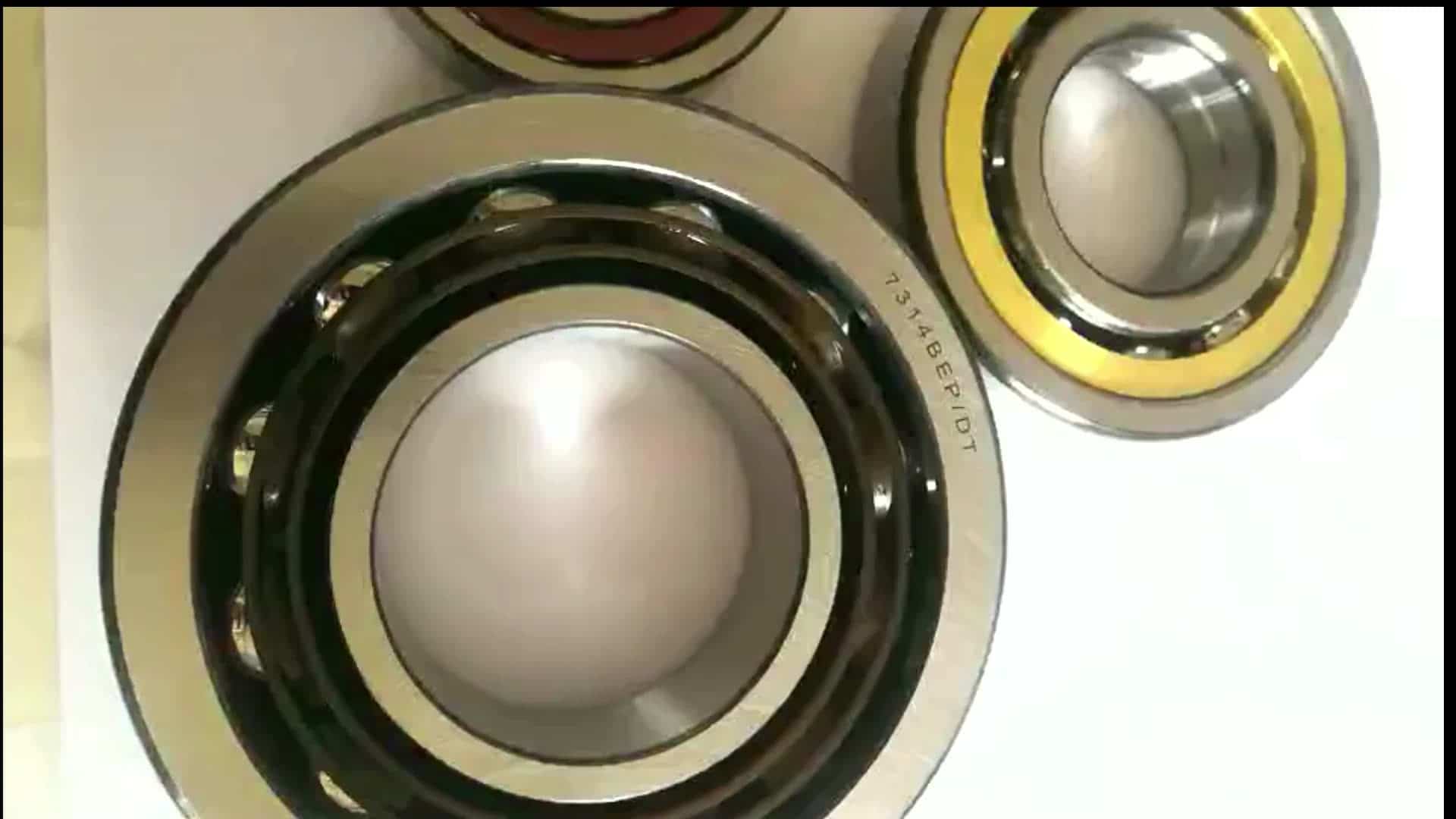

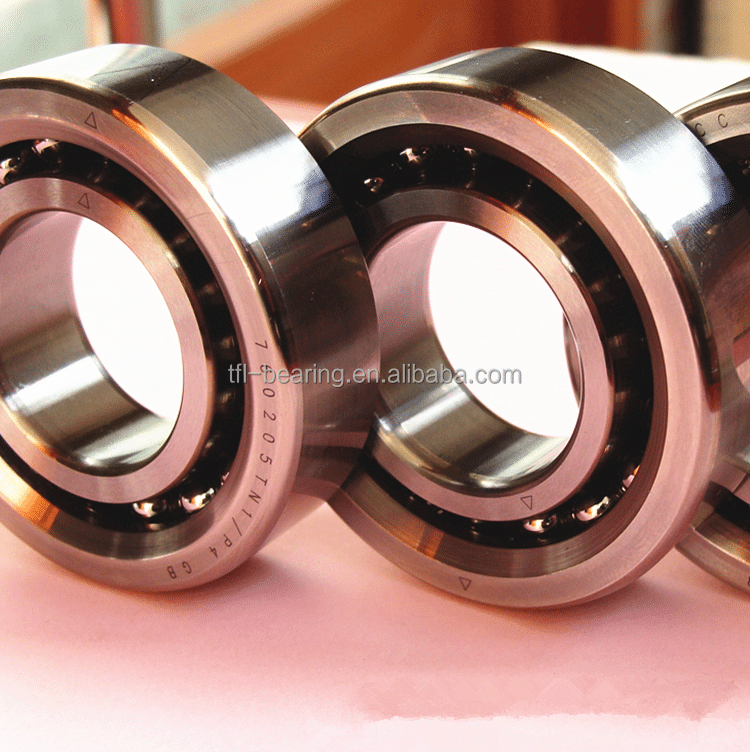

Angular contact ball bearings are particularly suitable for carrying combined (axial and radial) loads. Sometimes, they also can carry pure axial load and operate in higher speed. Under radial load, an axial component force will be produced, which must be counteracted. So the bearings are normally adjusted against a second bearing.

Single row angular contact ball bearings can carry axial load acting in one direction only. In many applications, angular contact ball bearings in pairs or muti-arrangement should be used. The axial load carrying capacity of angular contact ball bearings increases with the increase of contact angle.

|

Dimension(mm)

|

Bearing Model

|

Weight (kg)

|

||||

|

d

|

D

|

T

|

||||

|

222

|

273

|

26

|

BA222-1WSA

|

0.5

|

||

FAQ1: What is the BA222-1WSA travel motor bearing used for in excavators?

The BA222-1WSA is a specialized angular contact ball bearing used in the travel motor and final drive of excavators. Its primary function is to support the heavy, combined loads (both axial and radial) that the travel motor experiences. The angular contact design allows it to handle the thrust forces created when the excavator moves, while also supporting the radial loads from the gearing. This bearing is a critical component that ensures the smooth and efficient operation of the excavator’s tracks.

FAQ2: Signs of wear or failure in excavator travel motor bearings

Early detection of a failing travel motor bearing is crucial to prevent more extensive damage. Look out for these signs:

Unusual Noise: A grinding, whining, or rattling sound coming from the travel motor. This noise often gets louder as the excavator moves or when under load.

Vibration: Excessive vibration felt through the machine’s chassis.

Overheating: The travel motor housing feels unusually hot to the touch.

Oil Leaks: Leaks of gear oil from the final drive, which can indicate a damaged seal caused by a worn or failed bearing.

Loss of Power: The excavator’s travel speed slows down, or it loses power, especially on inclines.

FAQ3: How to extend the life of BA222-1WSA travel motor bearings?

Regular Lubrication: Follow the manufacturer’s recommended schedule for checking and changing the final drive gear oil.

Avoid Overloading: Do not exceed the excavator’s rated load capacity, as this puts extreme stress on the travel motor and its bearings.

Maintain Seals: Regularly inspect the seals around the final drive and replace them if there are any signs of leaks to prevent contamination.

Proper Operation: Avoid sudden changes in speed or direction, which can put unnecessary stress on the bearings.