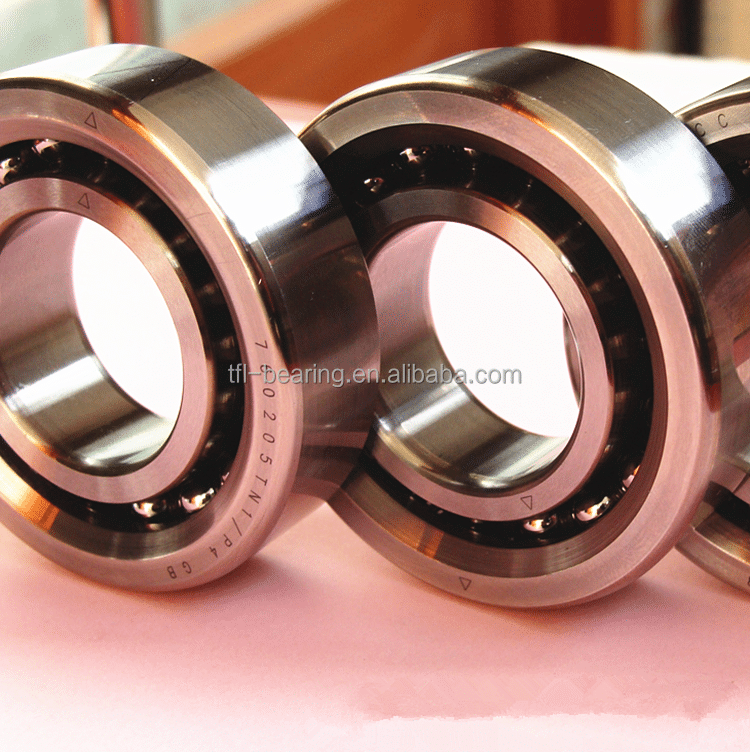

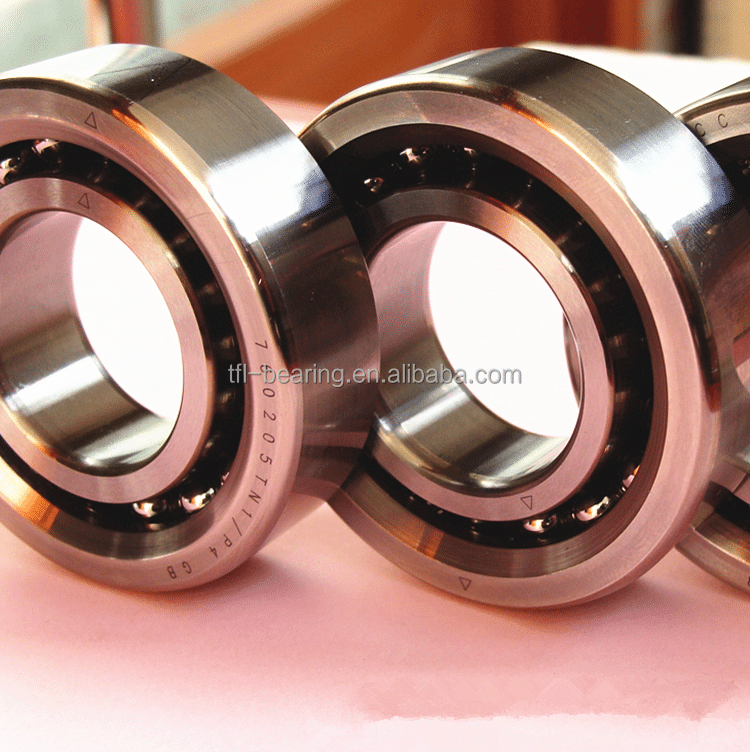

TMB bearing 7321 7322 7324 7326 7328 7330 AC ACM angular contact bearing

Brand Name: NSK Koyo TMB TFL

- Samples: 7321AC angular contact bearing

- $33.00/Piece | 1 Piece (Min. Order) |

Lead Time–If you finish the payment today, your order will ship out within the delivery date.

-

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

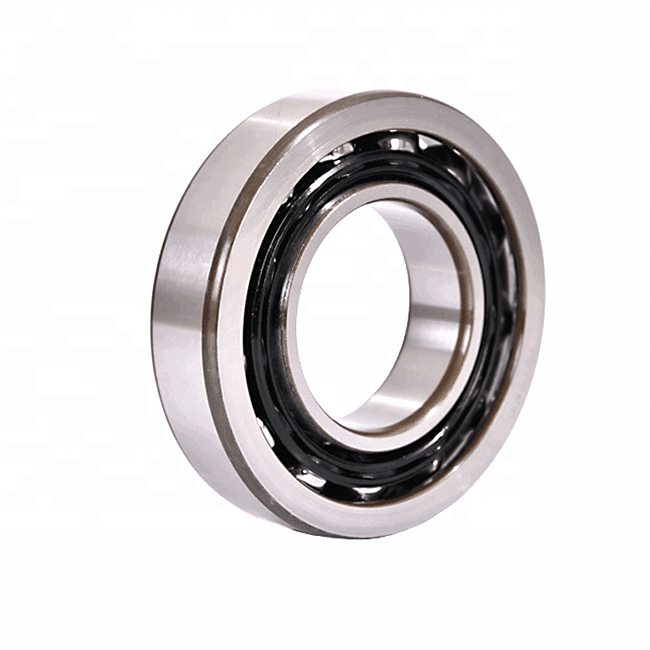

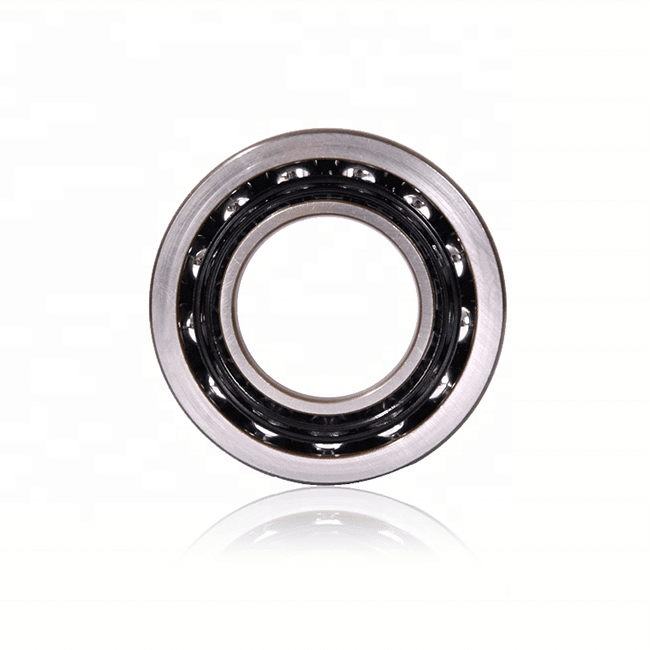

TMB bearing 732 AC angular contact bearing

Single-row angular contact ball bearings can only bear axial load in one direction. When bearing radial load, additional axial force will be caused. And it can only limit the axial displacement of the shaft or housing in one direction. Angular contact ball bearings have a contact angle of 40 degrees, so they can withstand large axial loads. Angular contact ball bearings are of non-separable design, and the shoulders on both sides of the inner and outer rings are different in height. In order to improve the load capacity of the bearing, the shoulder on one side will be processed lower so that the bearing can be loaded with more steel balls.

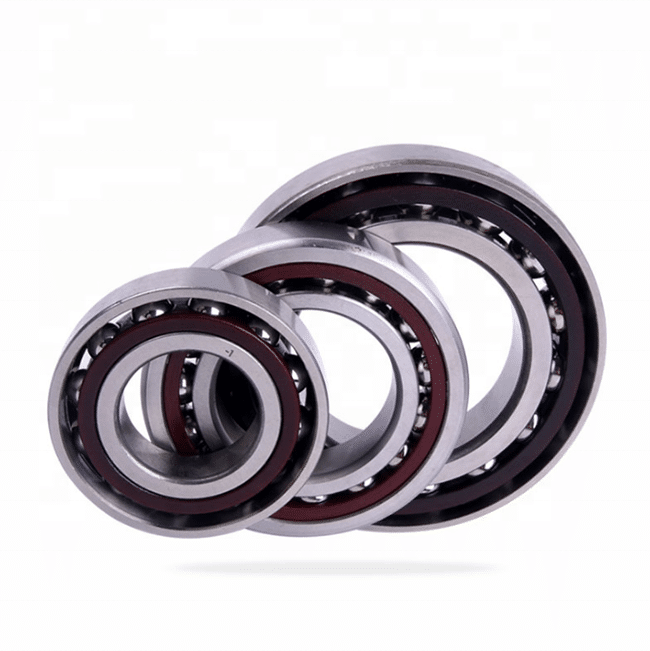

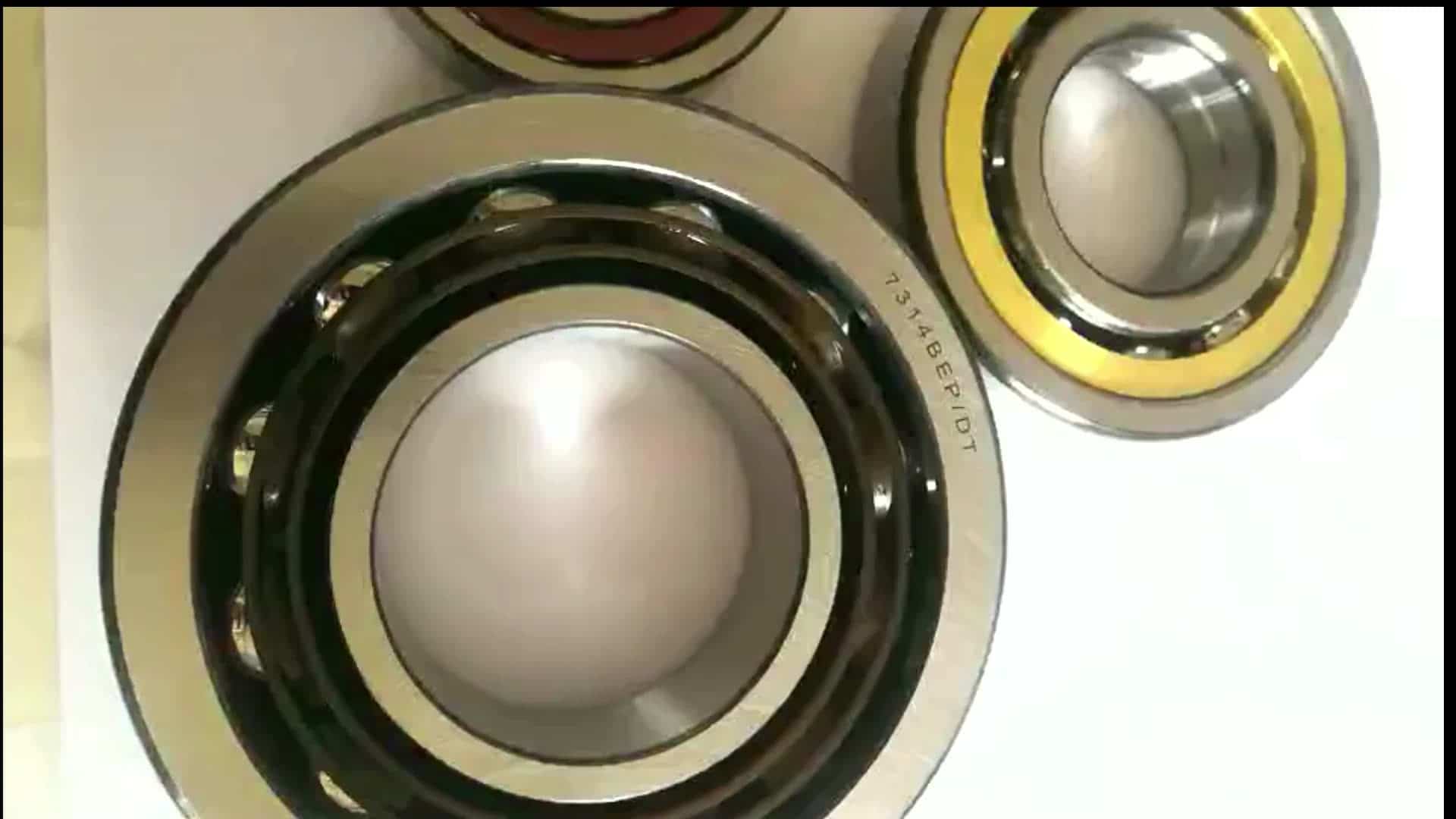

Double-row angular contact ball bearings can withstand larger radial loads, mainly combined radial and axial loads and moment loads, limiting the axial displacement of the shaft on both sides. The tiltability between the inner and outer rings of the double-row angular contact ball bearing is mainly used to limit the bidirectional axial displacement of the shaft and the housing. The allowable tilt angle depends on the internal clearance of the bearing, bearing size, internal design and acting on it. The force and moment on the bearing, and the maximum allowable inclination angle should ensure that no excessively high additional stress is generated in the bearing. If there is an inclination angle between the inner and outer rings of the bearing, it will affect the life of the bearing, and at the same time cause the bearing’s running accuracy to decrease and the running noise to increase. Double-row angular contact ball bearings generally use nylon cages or brass solid cages. Pay attention to the installation of double-row angular contact ball bearings. Although the bearing can withstand two-way axial loads, if there is a gap for the ball on one side, care should be taken not to allow the main axial load to pass through the gap on the side of the groove. When the bearing is used, attention should be paid to the main load on the side of the raceway without the ball notch.

Paired double ball bearings

If it is installed in pairs, the outer rings of a pair of bearings are opposite, that is, the wide end faces the wide end face, and the narrow end faces the narrow end face. In this way, additional axial force can be avoided, and the shaft or housing can be restricted to the axial clearance range in both directions. Because the raceways of the inner and outer rings can have relative displacement on the horizontal axis, they can bear radial load and axial load-combined load (single-row angular contact ball bearings can only bear axial load in one direction, so they are usually Install in pairs).

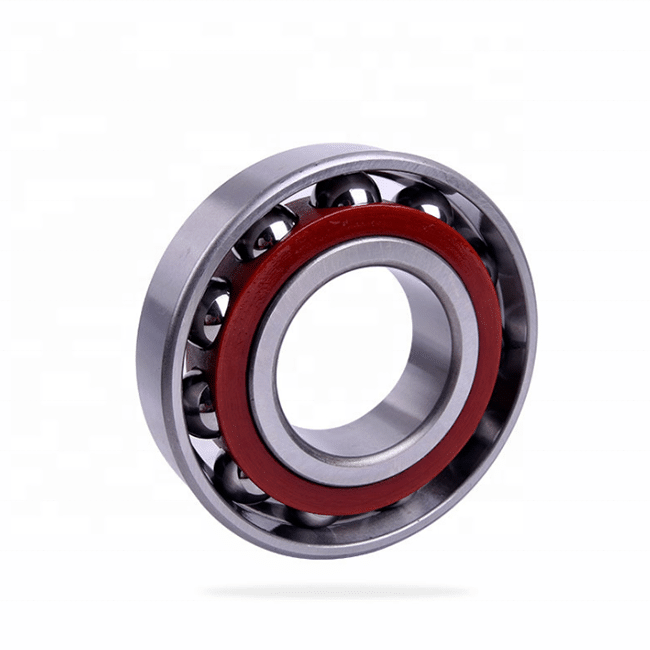

The material of the cage is brass, synthetic resin, etc., which are differentiated according to the bearing type and use conditions.

Double-row angular contact ball bearings can withstand larger radial loads, mainly combined radial and axial loads and moment loads, limiting the axial displacement of the shaft on both sides. The tiltability between the inner and outer rings of the double-row angular contact ball bearing is mainly used to limit the bidirectional axial displacement of the shaft and the housing. The allowable tilt angle depends on the internal clearance of the bearing, bearing size, internal design and acting on it. The force and moment on the bearing, and the maximum allowable inclination angle should ensure that no excessively high additional stress is generated in the bearing. If there is an inclination angle between the inner and outer rings of the bearing, it will affect the life of the bearing, and at the same time cause the bearing’s running accuracy to decrease and the running noise to increase. Double-row angular contact ball bearings generally use nylon cages or brass solid cages. Pay attention to the installation of double-row angular contact ball bearings. Although the bearing can withstand two-way axial loads, if there is a gap for the ball on one side, care should be taken not to allow the main axial load to pass through the gap on the side of the groove. When the bearing is used, attention should be paid to the main load on the side of the raceway without the ball notch.

Paired double ball bearings

If it is installed in pairs, the outer rings of a pair of bearings are opposite, that is, the wide end faces the wide end face, and the narrow end faces the narrow end face. In this way, additional axial force can be avoided, and the shaft or housing can be restricted to the axial clearance range in both directions. Because the raceways of the inner and outer rings can have relative displacement on the horizontal axis, they can bear radial load and axial load-combined load (single-row angular contact ball bearings can only bear axial load in one direction, so they are usually Install in pairs).

The material of the cage is brass, synthetic resin, etc., which are differentiated according to the bearing type and use conditions.

| Bearing Type | Angular Contact Ball Bearings |

| Model NO. | 46321/7321AC |

| Size (mm) | 105x225x49 |

| Service | OEM |

| Cage | Brass Cage, Steel Cage, Polyamide Cage, Bakelite Cage |

| Precision | P0, P6, P5, P4 |

| Material | Chrome Steel GCr15 |

| Weight | 8.6 kg |

| Package | Tube Packing / Industrial Packing |

FAQ1: What applications of 7321AC angular contact bearings in industrial machinery?

1. The high precision and rigidity of 7321AC bearings make them the first choice for spindle bearings in high-precision machining centers, which can ensure the dimensional accuracy and surface quality of the workpiece.

2. On CNC lathes, 7321AC bearings can withstand large radial and axial loads while ensuring high-speed and high-precision operation of the spindle.

3. Grinding machines have extremely high requirements for bearing accuracy and rigidity. 7321AC bearings can meet the high-precision and high-rigidity requirements of grinder spindles.

2. On CNC lathes, 7321AC bearings can withstand large radial and axial loads while ensuring high-speed and high-precision operation of the spindle.

3. Grinding machines have extremely high requirements for bearing accuracy and rigidity. 7321AC bearings can meet the high-precision and high-rigidity requirements of grinder spindles.

FAQ2: Why choose 7321AC bearings for high-speed spindle alignment?

The manufacturing tolerance of 7321AC bearings is extremely small, ensuring high concentricity of the inner and outer rings of the bearings, thereby achieving high-precision rotation of the spindle; the contact angle of 7321AC bearings is reasonably designed, which can effectively bear axial loads while bearing radial loads, thereby improving the positioning accuracy of the spindle.