Original CNC NSK precision bearing 7010CTYNDULP4 7010C 7010 angular contact ball bearing

-

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 2000 Pieces)Customized packaging(Min. Order: 2000 Pieces)Shipping: Support Sea freight

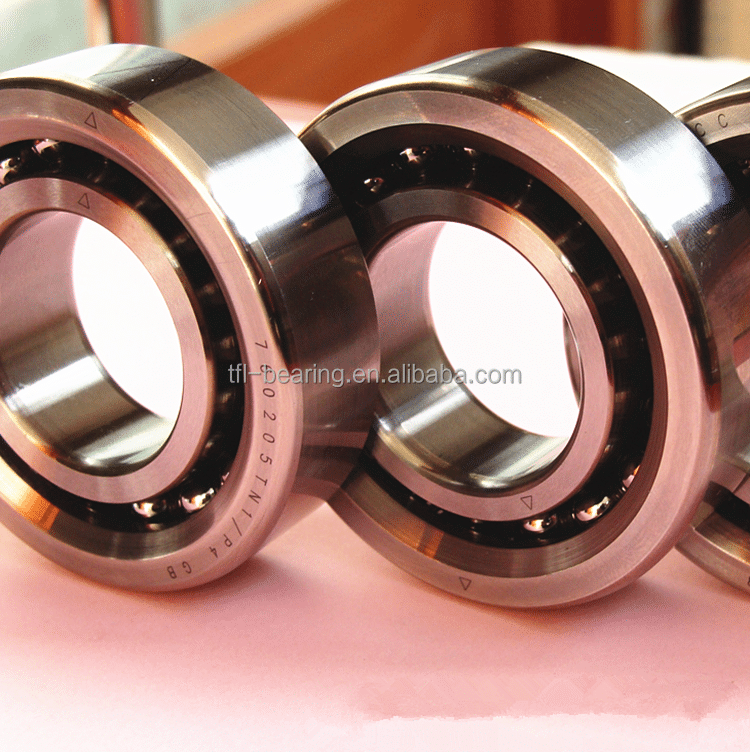

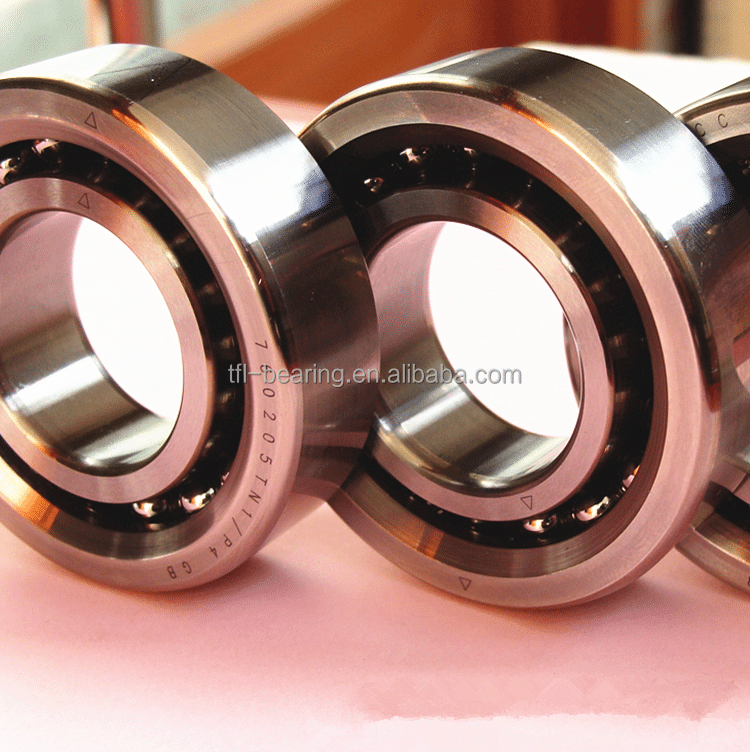

Original CNC NSK precision bearing 7010CTYNDULP4 7010C 7010 angular contact ball bearing

Single row angular contact ball bearings can carry axial load acting in one direction only. In many applications, angular contact ball bearings in pairs or muti-arrangement should be used. The axial load carrying capacity of angular contact ball bearings increases with the increase of contact angle.

Series Range

7000C(∝=15°)

7000AC(∝=25°)

7000B(∝=40°)

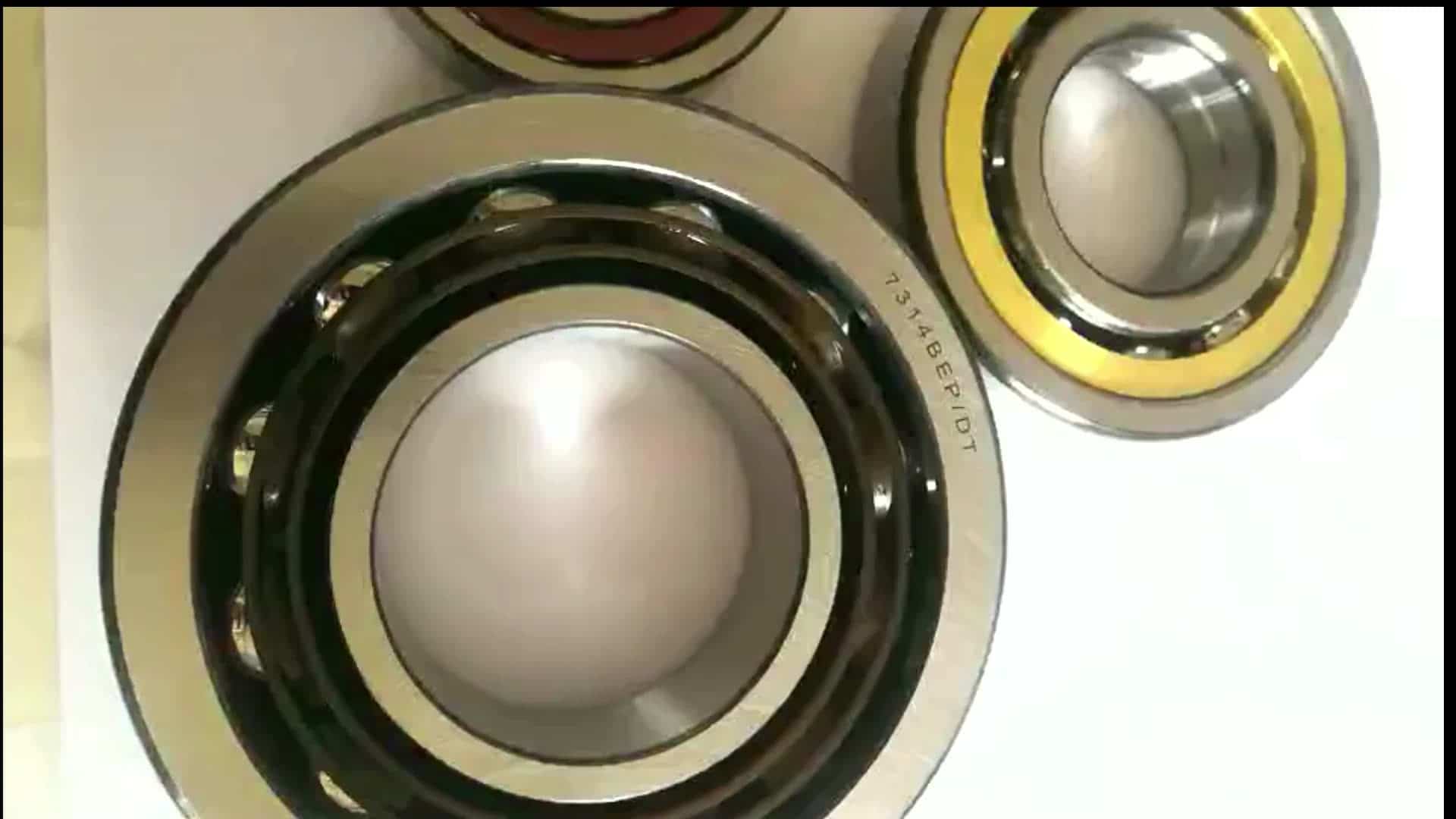

Back-to-back configuration, code-named DB (such as 70000 / DB)

Face to face configuration, code-named DF (such as 70000 / DF)

Original CNC NSK precision bearing 7010CTYNDULP4 7010C 7010 angular contact ball bearing

| Bearing No. | Brand | d(mm) | D(mm) | B(mm) |

| 7000CTYNDULP4 | NSK | 10 | 26 | 8 |

| 7001CTYNDULP4 | NSK | 12 | 28 | 8 |

| 7002CTYNDULP4 | NSK | 15 | 32 | 9 |

| 7003CTYNDULP4 | NSK | 17 | 35 | 10 |

| 7004CTYNDULP4 | NSK | 20 | 42 | 12 |

| 7005CTYNDULP4 | NSK | 25 | 47 | 12 |

| 7006CTYNDULP4 | NSK | 30 | 55 | 13 |

| 7007CTYNDULP4 | NSK | 35 | 62 | 14 |

| 7008CTYNDULP4 | NSK | 40 | 68 | 15 |

| 7009CTYNDULP4 | NSK | 45 | 75 | 16 |

| 7010CTYNDULP4 | NSK | 50 | 80 | 16 |

| 7011CTYNDULP4 | NSK | 55 | 90 | 18 |

| 7012CTYNDULP4 | NSK | 60 | 95 | 18 |

| 7013CTYNDULP4 | NSK | 65 | 100 | 18 |

| 7014CTYNDULP4 | NSK | 70 | 110 | 20 |

| 7015CTYNDULP4 | NSK | 75 | 115 | 20 |

| 7016CTYNDULP4 | NSK | 80 | 125 | 22 |

| 7017CTYNDULP4 | NSK | 85 | 130 | 22 |

| 7018CTYNDULP4 | NSK | 90 | 140 | 24 |

| 7019CTYNDULP4 | NSK | 95 | 145 | 24 |

| 7020CTYNDULP4 | NSK | 100 | 150 | 24 |

FAQ1: What are the 7010CTYNDULP4 Specifications?

This is a Super Precision Angular Contact Ball Bearing.

7010: The series and size. Bore diameter = 50 mm, Outer diameter = 80 mm, Width = 16 mm (per single bearing).

C: 15° contact angle (designed for high speed).

TYN: High-performance polyamide (resin) cage; quiet and low heat.

DU: Duplex universal mounting (can be used in pairs).

L: Light preload.

P4: ISO Class 4 high precision.

FAQ2: What is the difference between 7010C and 7010A bearings?

The letter usually indicates the contact angle, which affects speed and load capacity:

7010C: 15° angle. Best for high-speed applications with lower axial loads.

7010A/AC: 25° or 30° angle. Better for heavy axial loads but has a lower speed limit compared to “C”.

FAQ3: What does the P4 Precision for CNC Spindles mean?

CNC spindles require P4 (or higher like P2) bearings because:

Runout Control: Ensures the tool rotates perfectly centered, preventing “wobble.”

Heat Management: P4 tolerances reduce friction, allowing the spindle to run at 10,000+ RPM without overheating.

Surface Finish: Higher precision leads to better quality on the finished metal parts.

FAQ5: How to Select Spindle Bearings?

Check Dimensions: Confirm Bore (d), OD (D), and Width (B).

Determine Speed: If your spindle runs at very high RPM, choose a 15° (C) angle and Ceramic balls (SN24) if possible.

Choose Arrangement: Common sets are DB (Back-to-back) for high rigidity or DT (Tandem) for high axial load.

Lubrication: Decide if you will use Grease (easier maintenance) or Oil-Air (for maximum RPM).