NTN 7309 7309AC 7309B Angular Contact Ball Bearing

- Samples:

-

45mm , 100mm , 7309AC

$5.85/Piece | 1 Piece (Min. Order) |

- Lead Time

If you finish the payment today, your order will ship out within the delivery date.

:

-

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

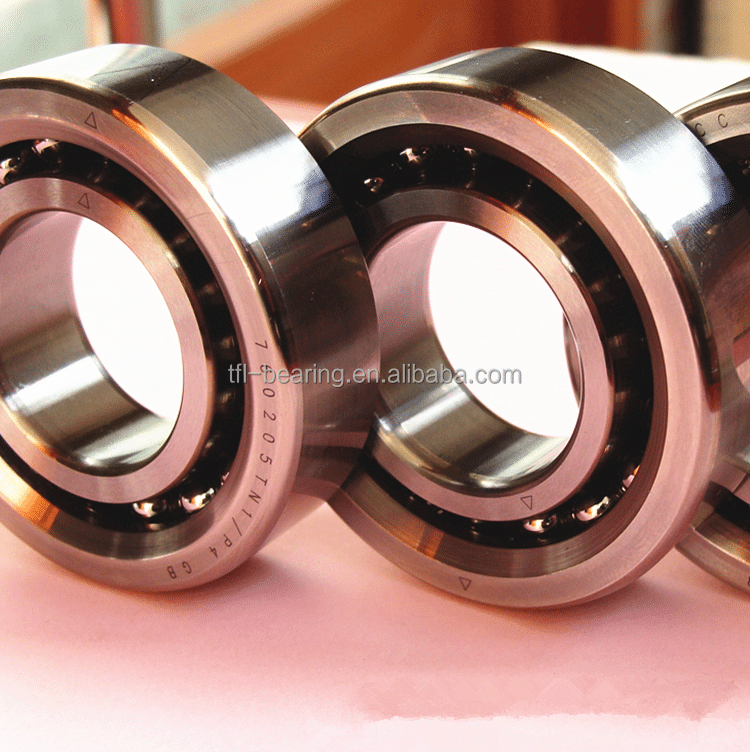

- Inner Diameter (Bore): 45 mm

- Outer Diameter: 100 mm

- Width: 25 mm

- Bearing Type: Ball Bearing

- Contact Angle: 25° (7309AC), 40° (7309B)

- Material: Chrome Steel (GCr15)

- Speed Rating: Up to 12,000 RPM

- Applications: Automotive assemblies, Robotics, Machine tools, Conveyor systems

- Weight: 1.867 lb, 0.847 kg

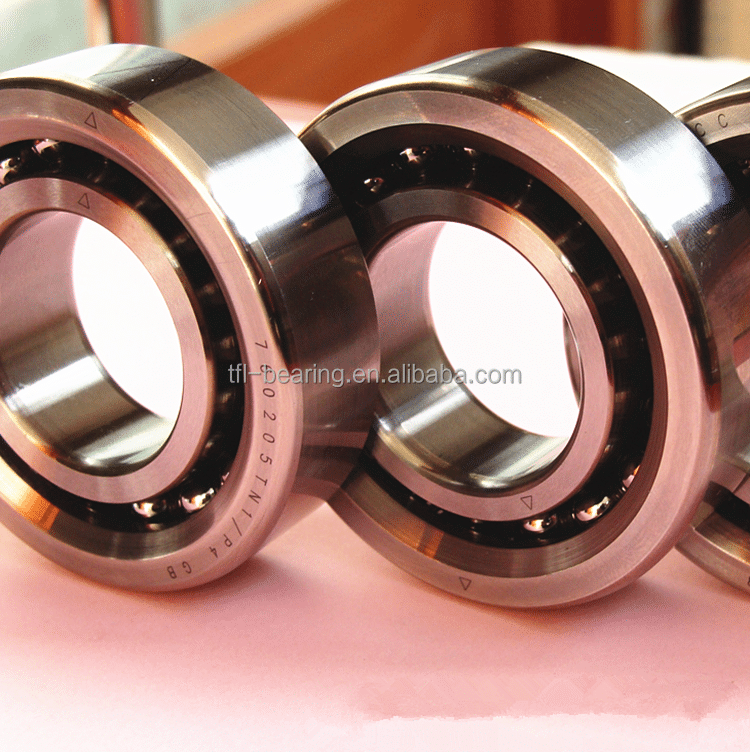

Angular contact ball bearings

Double row angular contact ball bearings can withstand larger radial loads, mainly combined radial and axial loads and moment loads, limiting the axial displacement of the shaft on both sides. The tiltability between the inner and outer rings of the double row angular contact ball bearing is mainly used to limit the bidirectional axial displacement of the shaft and the housing. The allowable tilt angle depends on the internal clearance of the bearing, bearing size, internal design and acting on it. The force and moment on the bearing, and the maximum allowable inclination angle should ensure that no excessively high additional stress is generated in the bearing. If there is an inclination angle between the inner and outer rings of the bearing, it will affect the life of the bearing, and at the same time cause the bearing’s running accuracy to decrease and the running noise to increase. Double row angular contact ball bearings generally use nylon cages or brass solid cages. Pay attention to the installation of double row angular contact ball bearings. Although the bearing can withstand two-way axial loads, if there is a gap for the ball on one side, care should be taken not to allow the main axial load to pass through the gap on the side of the groove. When the bearing is used, attention should be paid to the main load on the side of the raceway without the ball notch.

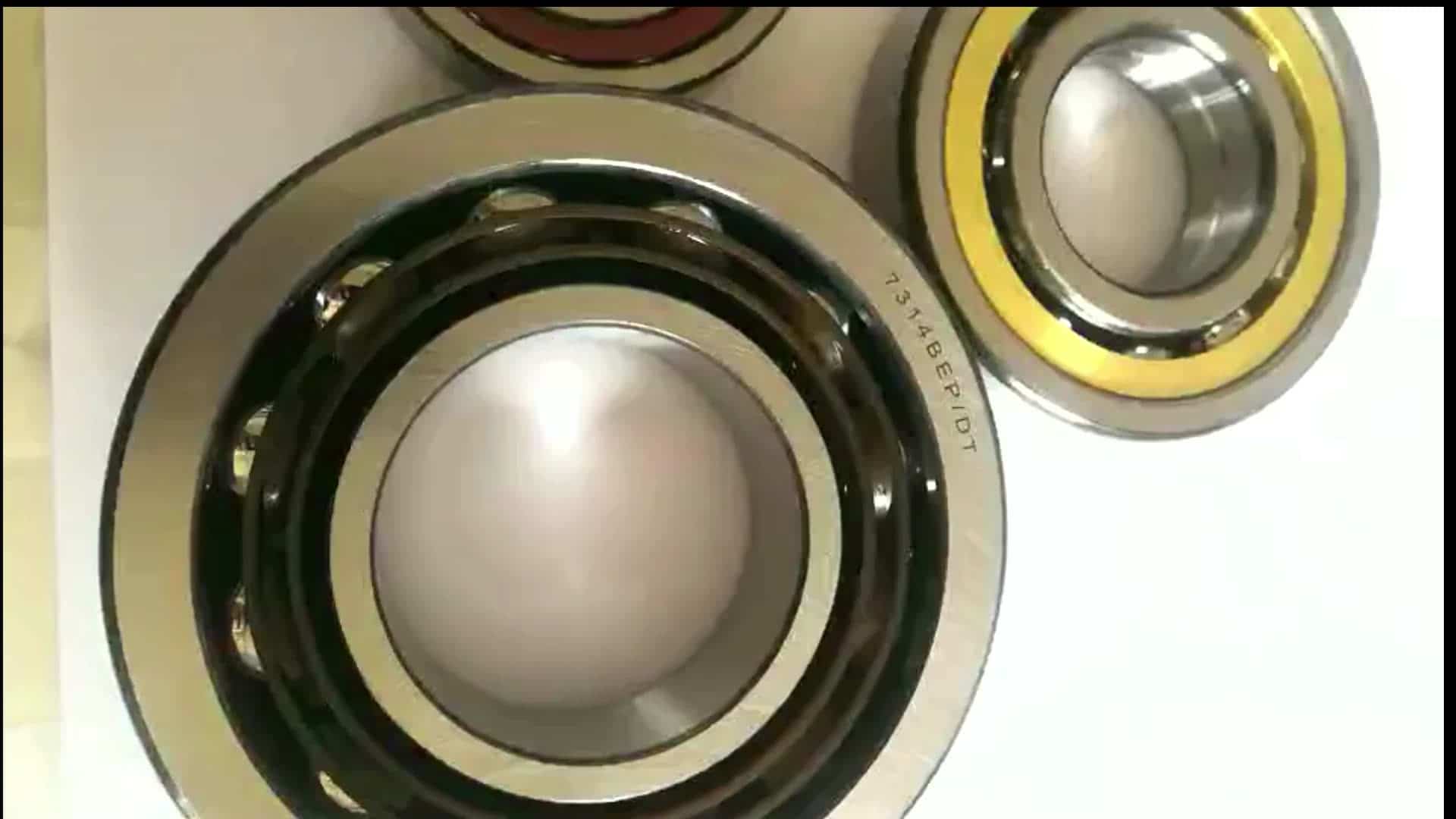

Paired double ball bearings

If it is installed in pairs, the outer rings of a pair of bearings are opposite, that is, the wide end faces the wide end face, and the narrow end faces the narrow end face. In this way, additional axial force can be avoided, and the shaft or housing can be restricted to the axial clearance range in both directions.

Because the raceways of the inner and outer rings can have relative displacement on the horizontal axis, they can bear radial load and axial load-combined load (single row angular contact ball bearings can only bear axial load in one direction, so they are usually Install in pairs).

The material of the cage is brass, synthetic resin, etc., which are differentiated according to the bearing type and use conditions.

|

Boundary dimensions

(mm)

|

Weight

|

Angle

|

||||

|

d

|

D

|

B

|

0.86kg

|

15°

25°

40 °

|

||

|

45

|

100

|

25

|

||||

FAQs

What are the main features of NTN 7309 Angular Contact Ball Bearings?

The NTN 7309 offers high-speed performance, excellent radial and axial load capacity, and precision engineering for reliable operation.

Where can I use NTN 7309 bearings?

These bearings are commonly used in automotive assemblies, robotics, machine tools, and conveyor systems requiring high accuracy and durability.

What is the difference between 7309AC and 7309B variants?

The 7309AC has a 25° contact angle for balanced performance, while the 7309B has a 40° angle for higher axial load capacity.

How long does an NTN 7309 bearing last?

With proper maintenance, the NTN 7309 provides extended service life due to its robust design and high-quality materials.

Can NTN 7309 handle both radial and axial loads?

Yes, the NTN 7309 is specifically designed to handle combined radial and axial loads efficiently, ensuring stability in demanding conditions.