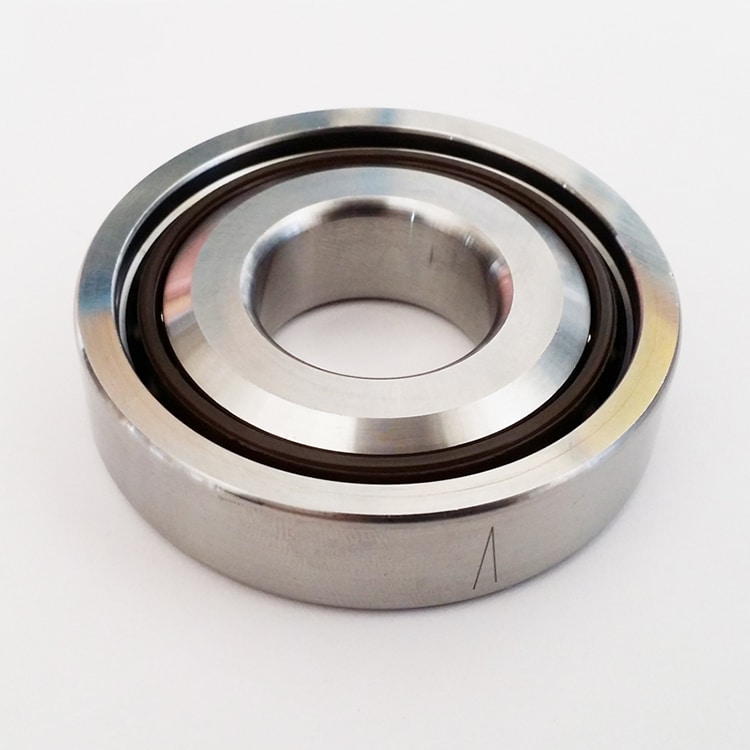

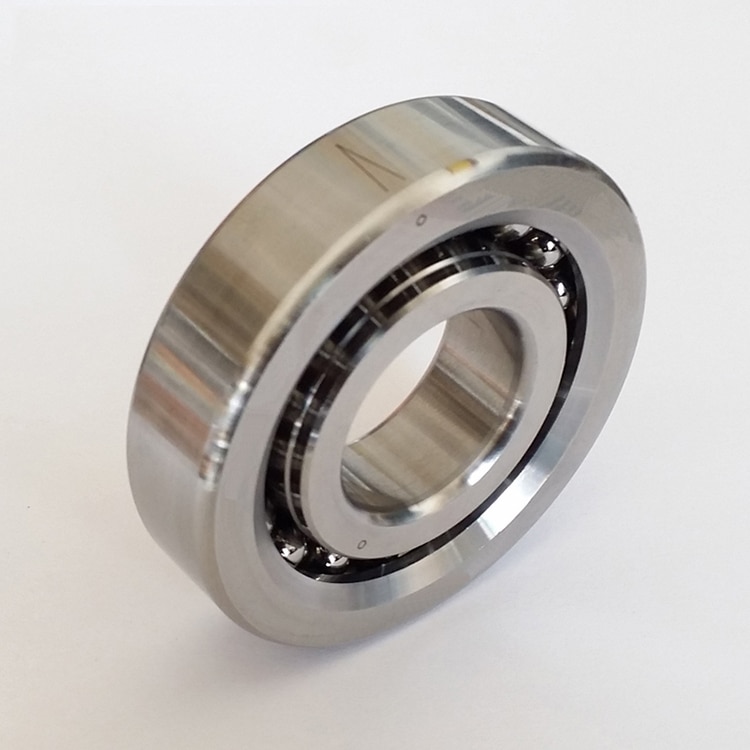

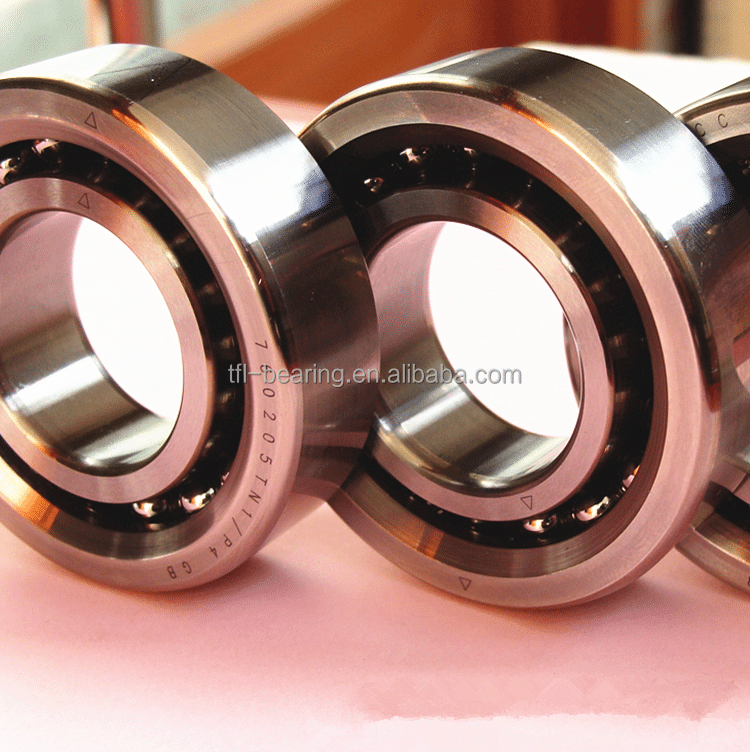

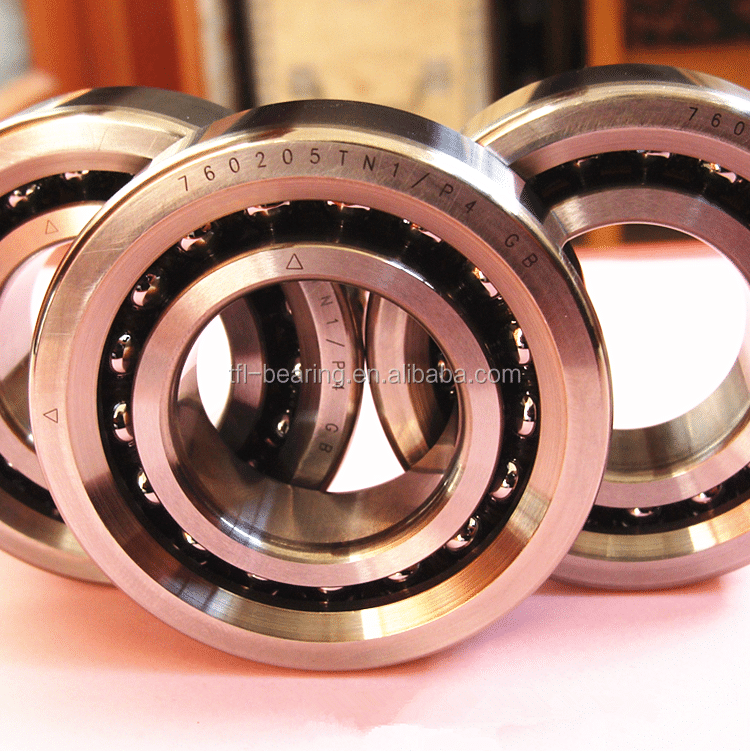

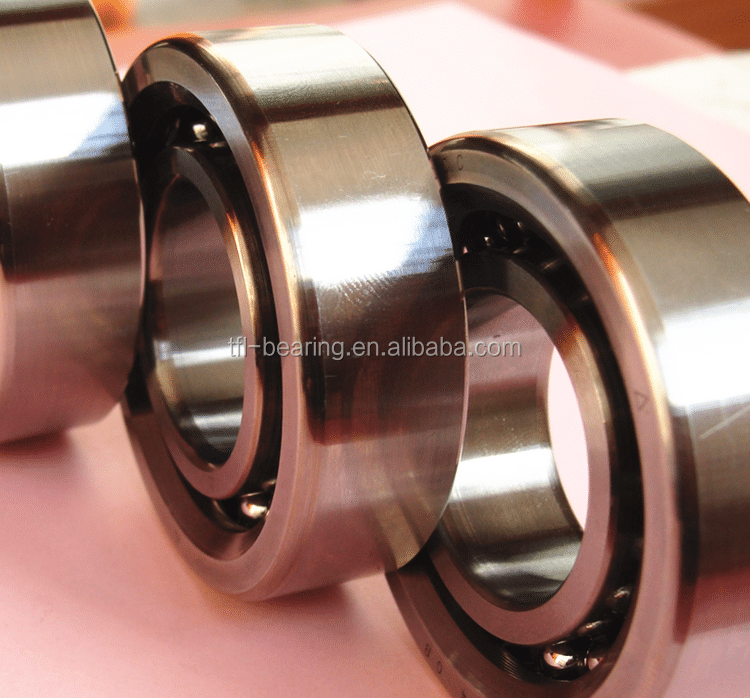

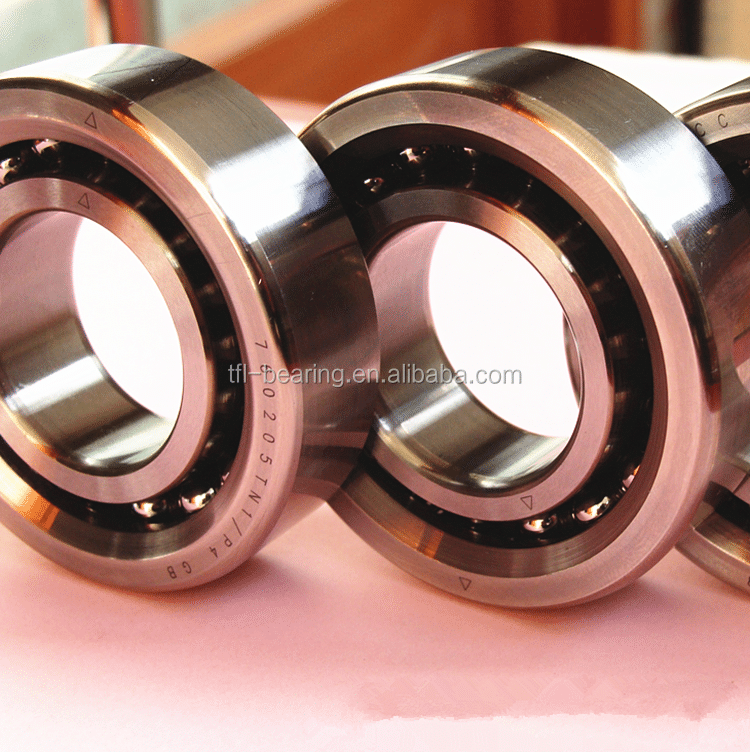

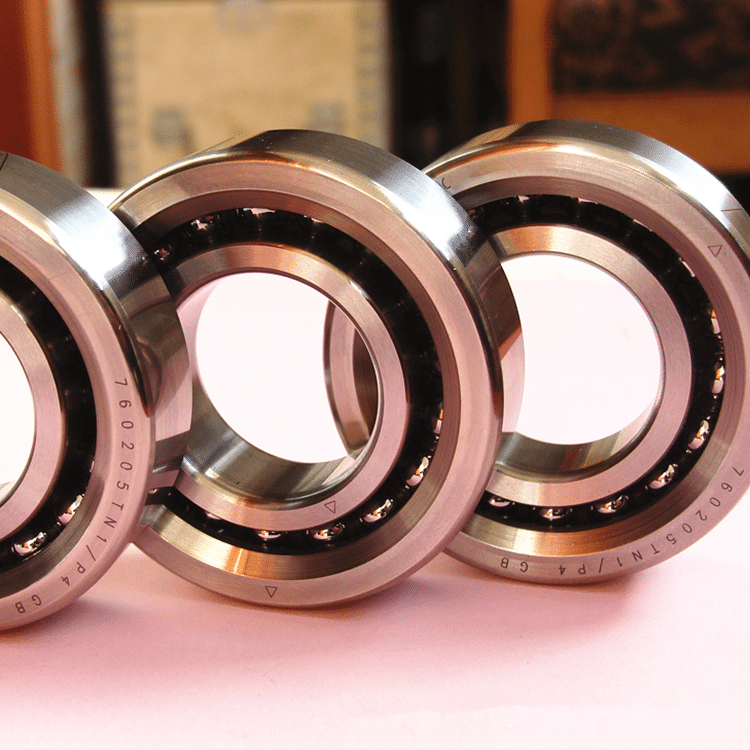

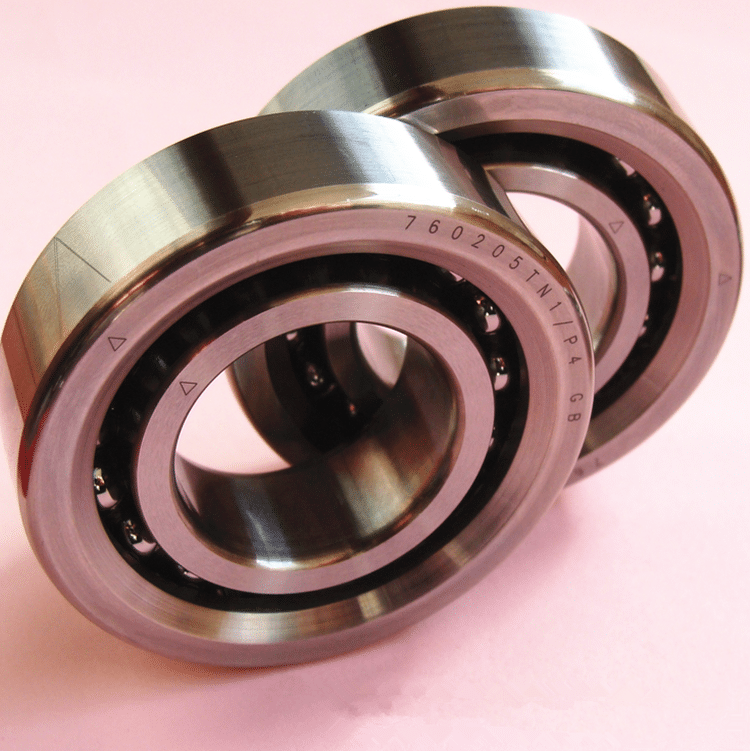

NSK 760202TN1 P4 Ball Screw Support Bearing Angular Contact Ball Bearing

Bore Size: 15mm

- Samples: NSK 760202TN1 P4 Ball Screw Support Bearing Angular Contact Ball Bearing

-

15mm , 35mm , 760202TN1

$12.26/Piece | 1 Piece (Min. Order) |

Lead Time–If you finish the payment today, your order will ship out within the delivery date.

-

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 3 To be negotiated

- Customization:

-

Graphic customization(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

NSK 760202TN1 P4 Ball Screw Support Bearing Angular Contact Ball Bearing

Single row angular contact ball bearings can only bear axial load in one direction. When bearing radial load, an additional axial force will be caused. And it can only limit the axial displacement of the shaft or housing in one direction. Angular contact ball bearings have a contact angle of 40 degrees, so they can withstand large axial loads. Angular contact ball bearings are of a non-separable design, and the shoulders on both sides of the inner and outer rings are different in height. In order to improve the load capacity of the bearing, the shoulder on one side will be processed lower so that the bearing can be loaded with more steel balls.

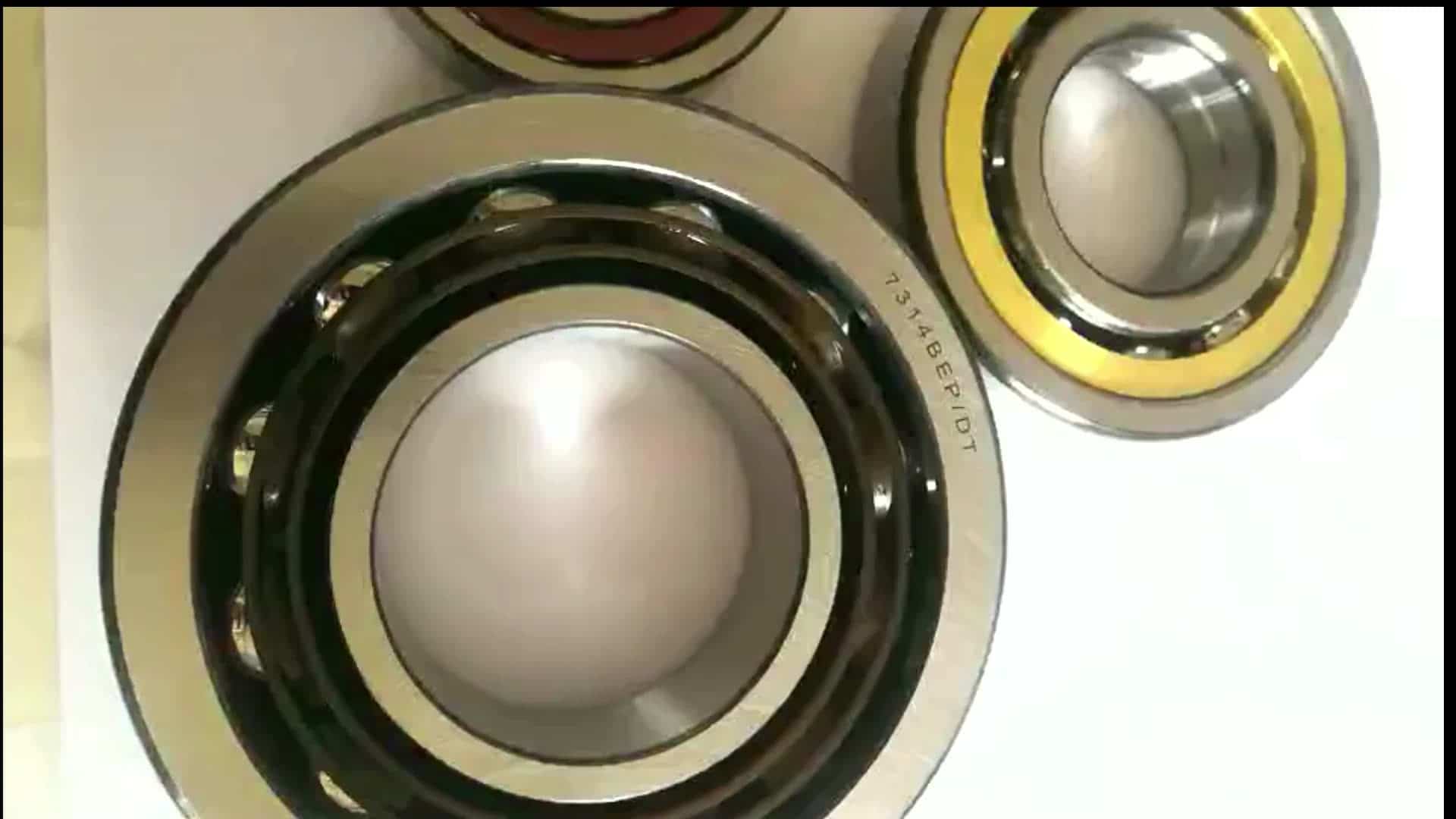

Double row angular contact ball bearings can withstand larger radial loads, mainly combined radial and axial loads and moment loads, limiting the axial displacement of the shaft on both sides. The tiltability between the inner and outer rings of the double row angular contact ball bearing is mainly used to limit the bidirectional axial displacement of the shaft and the housing. The allowable tilt angle depends on the internal clearance of the bearing, bearing size, internal design and acting on it. The force and moment on the bearing, and the maximum allowable inclination angle should ensure that no excessively high additional stress is generated in the bearing. If there is an inclination angle between the inner and outer rings of the bearing, it will affect the life of the bearing, and at the same time cause the bearing’s running accuracy to decrease and the running noise to increase. Double row angular contact ball bearings generally use nylon cages or brass solid cages. Pay attention to the installation of double-row angular contact ball bearings. Although the bearing can withstand two-way axial loads, if there is a gap for the ball on one side, care should be taken not to allow the main axial load to pass through the gap on the side of the groove. When the bearing is used, attention should be paid to the main load on the side of the raceway without the ball notch.

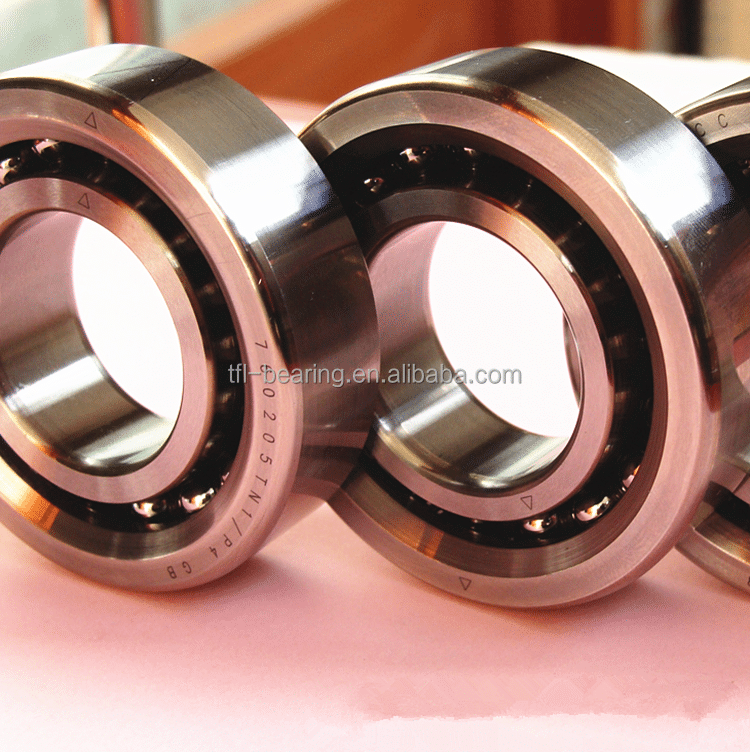

Paired double ball bearings

If it is installed in pairs, the outer rings of a pair of bearings are opposite, that is, the wide end faces the wide end face, and the narrow end faces the narrow end face. In this way, additional axial force can be avoided, and the shaft or housing can be restricted to the axial clearance range in both directions.

Because the raceways of the inner and outer rings can have relative displacement on the horizontal axis, they can bear radial load and axial load-combined load (single row angular contact ball bearings can only bear axial load in one direction, so they are usually installed in pairs).

The material of the cage is brass, synthetic resin, etc., which are differentiated according to the bearing type and use conditions.

Double row angular contact ball bearings can withstand larger radial loads, mainly combined radial and axial loads and moment loads, limiting the axial displacement of the shaft on both sides. The tiltability between the inner and outer rings of the double row angular contact ball bearing is mainly used to limit the bidirectional axial displacement of the shaft and the housing. The allowable tilt angle depends on the internal clearance of the bearing, bearing size, internal design and acting on it. The force and moment on the bearing, and the maximum allowable inclination angle should ensure that no excessively high additional stress is generated in the bearing. If there is an inclination angle between the inner and outer rings of the bearing, it will affect the life of the bearing, and at the same time cause the bearing’s running accuracy to decrease and the running noise to increase. Double row angular contact ball bearings generally use nylon cages or brass solid cages. Pay attention to the installation of double-row angular contact ball bearings. Although the bearing can withstand two-way axial loads, if there is a gap for the ball on one side, care should be taken not to allow the main axial load to pass through the gap on the side of the groove. When the bearing is used, attention should be paid to the main load on the side of the raceway without the ball notch.

Paired double ball bearings

If it is installed in pairs, the outer rings of a pair of bearings are opposite, that is, the wide end faces the wide end face, and the narrow end faces the narrow end face. In this way, additional axial force can be avoided, and the shaft or housing can be restricted to the axial clearance range in both directions.

Because the raceways of the inner and outer rings can have relative displacement on the horizontal axis, they can bear radial load and axial load-combined load (single row angular contact ball bearings can only bear axial load in one direction, so they are usually installed in pairs).

The material of the cage is brass, synthetic resin, etc., which are differentiated according to the bearing type and use conditions.

|

Boundary dimensions

(mm)

|

Weight

|

bearing NO.

|

||||

|

d

|

D

|

B

|

0.5kg

|

760202TN1

|

||

|

15

|

35

|

11

|

||||

Shandong Tefule Bearing Co.,Ltd is a professional bearing manufacturer and dealer in china.We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.We have our own brand “TFL” and applied ISO9001:2000 certificate for certification authority.We attend international bearing fairs, put in many B2B website and achieve many customers all over the world also bulid up good reputation from our customers.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

FAQ: Why choose a P4 precision grade bearing?

Choosing a P4 precision grade bearing (equivalent to ABEC 7 in the American system) is essential for applications where high accuracy, rigidity, and performance at speed are critical. Here’s why:

High Rotational Accuracy:

Reduced Runout: P4 bearings have extremely tight tolerances on bore and outer diameter runout, as well as face runout. This translates to minimal eccentricity and wobble during rotation, which is crucial for precision components.

Improved Machining Quality: For machine tool spindles and ball screws, high rotational accuracy directly leads to superior surface finish, tighter dimensional tolerances on machined parts, and extended tool life.

Enhanced Rigidity and Stiffness:

Precise Geometry: The precise manufacturing of raceways and rolling elements ensures consistent load distribution and minimal deformation under load. This allows the bearing to maintain high stiffness, preventing unwanted deflection in the system.

Accurate Preload: P4 bearings are often manufactured with specific preload characteristics, ensuring the desired stiffness is achieved in paired arrangements.

High-Speed Capability:

Minimized Friction and Heat: The precise internal geometry, smooth raceway finishes, and often specialized cage designs (like TN1 polyamide) in P4 bearings lead to lower friction and less heat generation at high rotational speeds. This prevents thermal expansion issues and extends bearing life.

Reduced Vibration: Lower vibration levels contribute to smoother operation and higher dynamic stability.

Longer Service Life:

Optimized Load Distribution: The superior manufacturing quality ensures loads are evenly distributed across the rolling elements, reducing stress concentrations and extending fatigue life.

Reduced Wear: Smoother surfaces and better lubricant film formation minimize wear, leading to a longer operational lifespan, even in demanding conditions.

Consistency and Reliability:

P4 grade bearings undergo stringent quality control during manufacturing. This ensures that each bearing consistently meets the high precision standards, providing reliable and predictable performance in critical machinery.

Common applications requiring P4 precision grade bearings include:

CNC Machine Spindles: Where cutting accuracy and surface finish are paramount.

High-Precision Ball Screws: For accurate linear positioning in machine tools and robotics.

Measuring Instruments: Where minimal error and high repeatability are needed.

High-Speed Grinders and Routers: To maintain precision at very high RPMs.

High Rotational Accuracy:

Reduced Runout: P4 bearings have extremely tight tolerances on bore and outer diameter runout, as well as face runout. This translates to minimal eccentricity and wobble during rotation, which is crucial for precision components.

Improved Machining Quality: For machine tool spindles and ball screws, high rotational accuracy directly leads to superior surface finish, tighter dimensional tolerances on machined parts, and extended tool life.

Enhanced Rigidity and Stiffness:

Precise Geometry: The precise manufacturing of raceways and rolling elements ensures consistent load distribution and minimal deformation under load. This allows the bearing to maintain high stiffness, preventing unwanted deflection in the system.

Accurate Preload: P4 bearings are often manufactured with specific preload characteristics, ensuring the desired stiffness is achieved in paired arrangements.

High-Speed Capability:

Minimized Friction and Heat: The precise internal geometry, smooth raceway finishes, and often specialized cage designs (like TN1 polyamide) in P4 bearings lead to lower friction and less heat generation at high rotational speeds. This prevents thermal expansion issues and extends bearing life.

Reduced Vibration: Lower vibration levels contribute to smoother operation and higher dynamic stability.

Longer Service Life:

Optimized Load Distribution: The superior manufacturing quality ensures loads are evenly distributed across the rolling elements, reducing stress concentrations and extending fatigue life.

Reduced Wear: Smoother surfaces and better lubricant film formation minimize wear, leading to a longer operational lifespan, even in demanding conditions.

Consistency and Reliability:

P4 grade bearings undergo stringent quality control during manufacturing. This ensures that each bearing consistently meets the high precision standards, providing reliable and predictable performance in critical machinery.

Common applications requiring P4 precision grade bearings include:

CNC Machine Spindles: Where cutting accuracy and surface finish are paramount.

High-Precision Ball Screws: For accurate linear positioning in machine tools and robotics.

Measuring Instruments: Where minimal error and high repeatability are needed.

High-Speed Grinders and Routers: To maintain precision at very high RPMs.