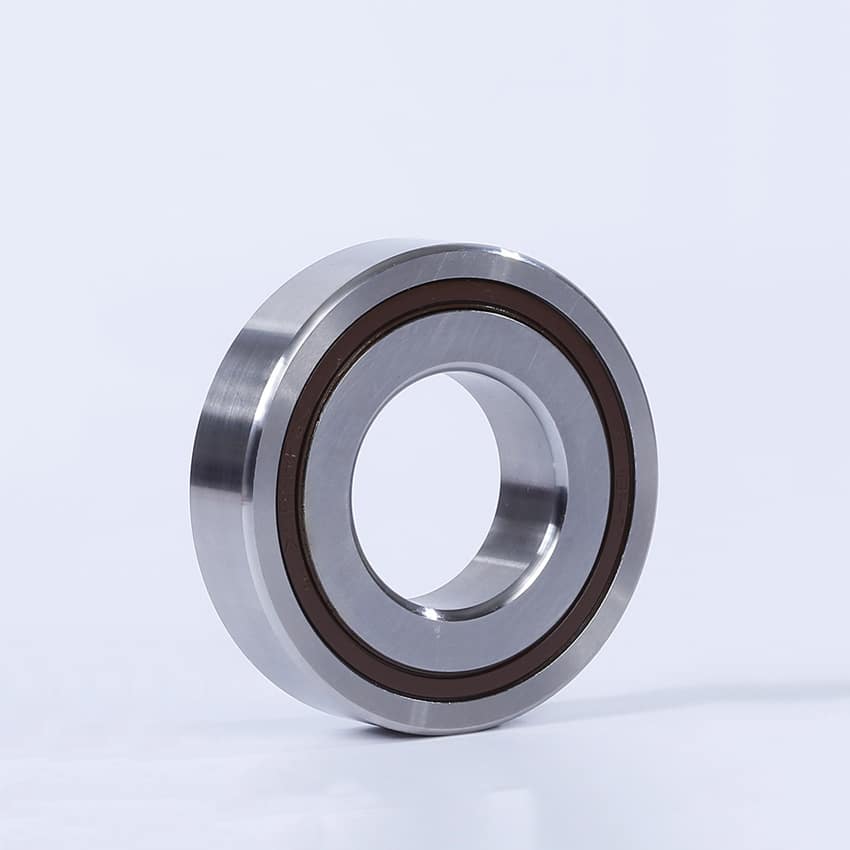

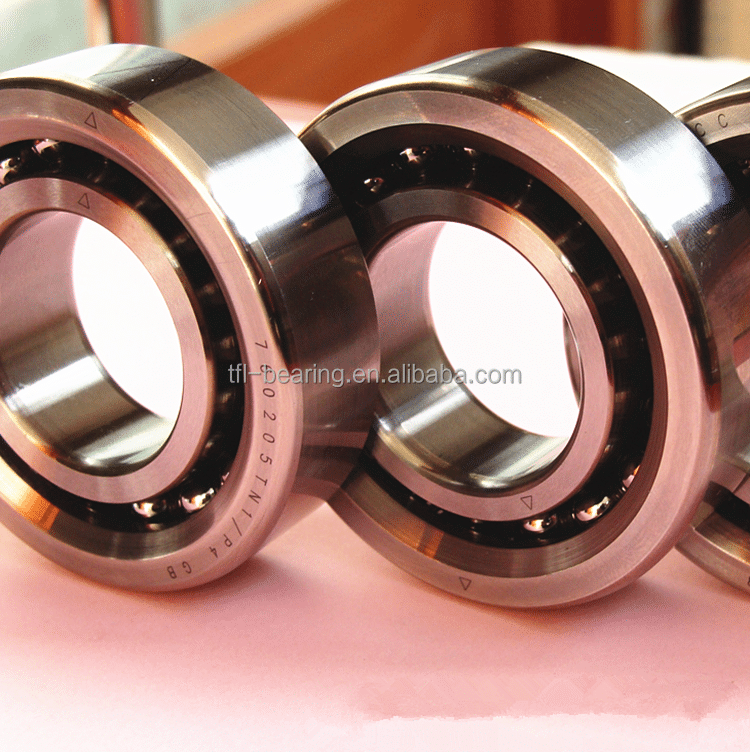

High speed 760205TN1/P4 Japan Ball Screw Support Bearings

Size: 25x52x30 mm

- Samples: High speed 760205TN1/P4 Japan Ball Screw Support Bearings

- $19.60/Piece | 1 Piece (Min. Order) |

Lead Time–If you finish the payment today, your order will ship out within the delivery date.

-

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 100 Pieces)Customized packaging(Min. Order: 100 Pieces)

High speed 760205TN1/P4 Japan Ball Screw Support Bearings

Angular Contact Thrust Ball Bearings for ball screws were specially designed to support Precision Ball Screws. They are used in combinations of more than two bearings and with a preload. Their contact angle is 60°.

The 760205TN1/P4 bearing is a high-precision angular contact ball bearing specifically designed for ball screw support. Its primary application is in machinery where high precision, rigidity, and smooth motion are critical. This includes:

CNC Machinery: Machine tools, machining centers, and CNC lathes for precise linear movement of axes.

Robotics: For the accurate positioning and movement of robotic arms and other components.

Precision Instruments: In various types of precision measuring and testing equipment.

Electric Spindles: Where high speed and accuracy are essential.

CNC Machinery: Machine tools, machining centers, and CNC lathes for precise linear movement of axes.

Robotics: For the accurate positioning and movement of robotic arms and other components.

Precision Instruments: In various types of precision measuring and testing equipment.

Electric Spindles: Where high speed and accuracy are essential.

|

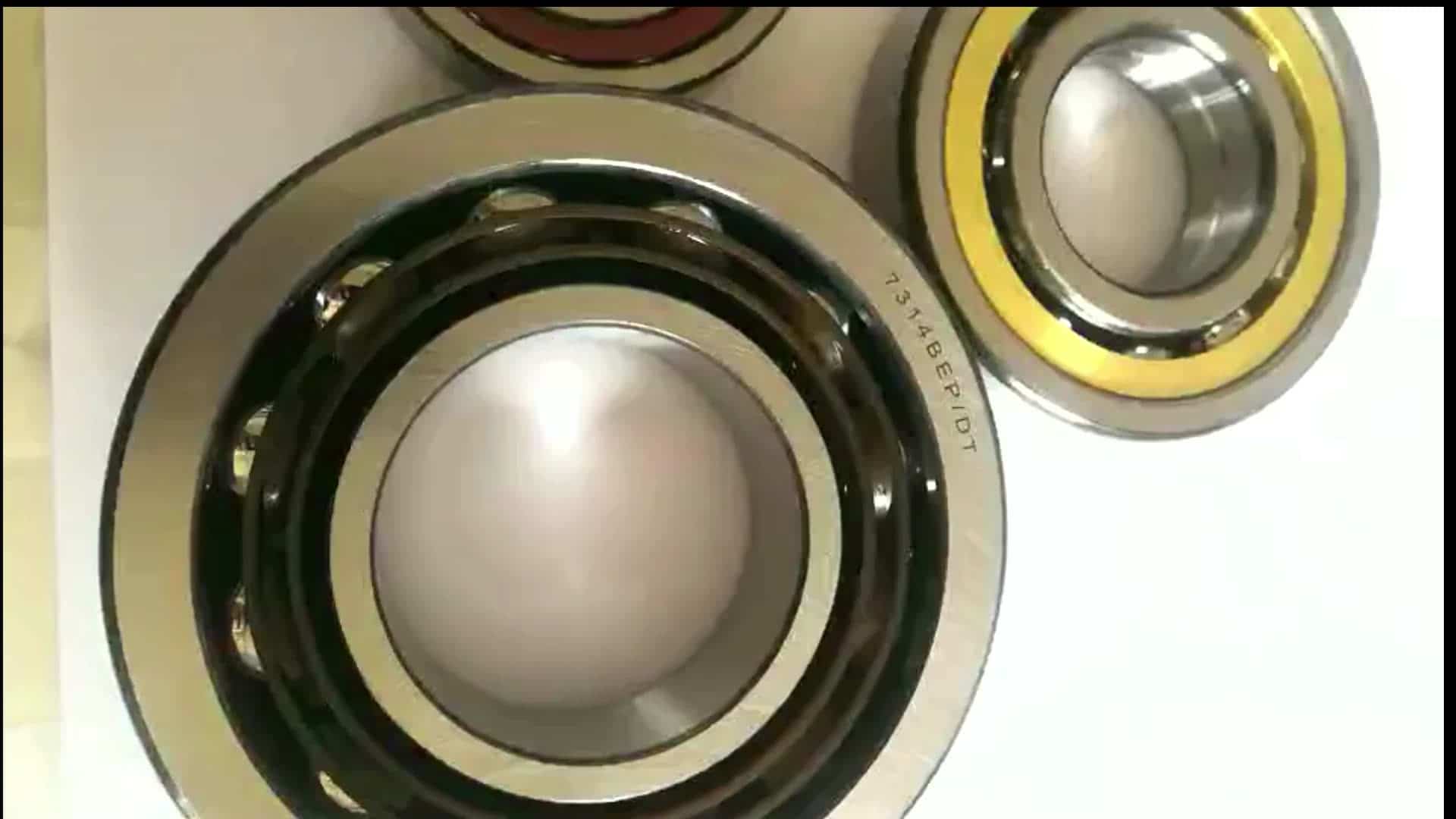

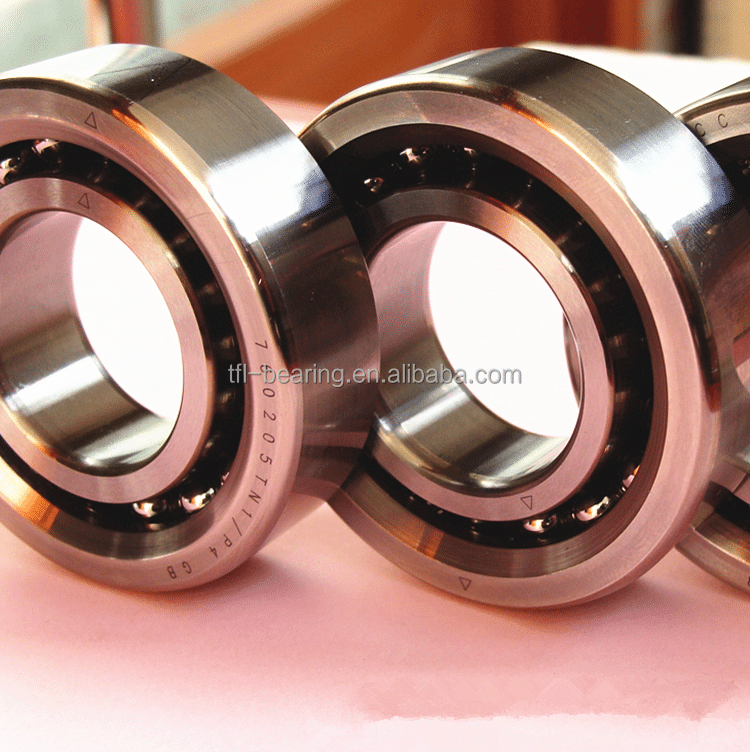

Angular Contact Thrust Ball Bearings for Supporting Screw

|

||||||

|

Model No.

|

d(mm)

|

D(mm)

|

B(mm)

|

|||

|

50TAC03AT85

|

50

|

110

|

27

|

|||

|

55TAC03AT85

|

55

|

120

|

29

|

|||

|

60TAC03AT85

|

60

|

130

|

31

|

|||

|

100TAC03CMC

|

100

|

215

|

47

|

|||

|

120TAC03CMC

|

120

|

260

|

55

|

|||

|

760202TN1

|

15

|

35

|

11

|

|||

|

760203TN1

|

17

|

40

|

12

|

|||

|

760204TN1

|

20

|

47

|

14

|

|||

|

760205TN1

|

25

|

52

|

15

|

|||

|

760206TN1

|

30

|

62

|

16

|

|||

|

760207TN1

|

35

|

72

|

17

|

|||

|

760208TN1

|

40

|

80

|

18

|

|||

|

760209TN1

|

45

|

85

|

19

|

|||

|

760210TN1

|

50

|

90

|

20

|

|||

|

760211TN1

|

55

|

100

|

21

|

|||

|

760212TN1

|

60

|

110

|

22

|

|||

|

760213TN1

|

65

|

120

|

23

|

|||

|

760214TN1

|

70

|

125

|

24

|

|||

|

760215TN1

|

75

|

130

|

25

|

|||

|

760216TN1

|

80

|

140

|

26

|

|||

|

760217TN1

|

85

|

150

|

28

|

|||

|

760218TN1

|

90

|

160

|

30

|

|||

|

760219TN1

|

95

|

170

|

32

|

|||

Shandong Tefule Bearing Co.,Ltd

is a professional bearing manufacturer and dealer in China. We have been engaged inthe bearing industry for 10 years and made international trade of bearing import and export for more than 8 years. We have our own brand “TFL” and applied ISO9001:2000certificate for certification authority. We attend international bearing fairs, put in many B2B website and achieve many customers all over the world also bulid up good reputation from our customers.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing. Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing. Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

FAQ: Why choose the P4 precision class for CNC support bearings?

The P4 precision class (equivalent to ABEC 7) is chosen for CNC support bearings for several critical reasons:

Extremely Tight Tolerances: P4 bearings are manufactured with very small dimensional tolerances. This means the inner and outer rings, as well as the rolling elements, are made with extremely high accuracy, which is essential for the precise positioning required by CNC machines.

Superior Running Accuracy: The tight tolerances result in minimal radial and axial runout. This “wobble” is a major source of error in a machine’s movement. By using P4 bearings, you ensure the ball screw rotates smoothly and accurately, which directly translates to the high-quality finish and dimensional accuracy of the machined part.

Reduced Vibration and Noise: The precision manufacturing and excellent surface finish of P4 bearings result in smoother operation, minimizing vibration and heat generation. This is crucial for high-speed operation and for preventing “chatter” marks on machined surfaces.

High Rigidity: High-precision bearings are often designed for preloading, which increases the rigidity of the ball screw assembly. A rigid system is less susceptible to deflection under load, maintaining accuracy under cutting forces.

Extremely Tight Tolerances: P4 bearings are manufactured with very small dimensional tolerances. This means the inner and outer rings, as well as the rolling elements, are made with extremely high accuracy, which is essential for the precise positioning required by CNC machines.

Superior Running Accuracy: The tight tolerances result in minimal radial and axial runout. This “wobble” is a major source of error in a machine’s movement. By using P4 bearings, you ensure the ball screw rotates smoothly and accurately, which directly translates to the high-quality finish and dimensional accuracy of the machined part.

Reduced Vibration and Noise: The precision manufacturing and excellent surface finish of P4 bearings result in smoother operation, minimizing vibration and heat generation. This is crucial for high-speed operation and for preventing “chatter” marks on machined surfaces.

High Rigidity: High-precision bearings are often designed for preloading, which increases the rigidity of the ball screw assembly. A rigid system is less susceptible to deflection under load, maintaining accuracy under cutting forces.