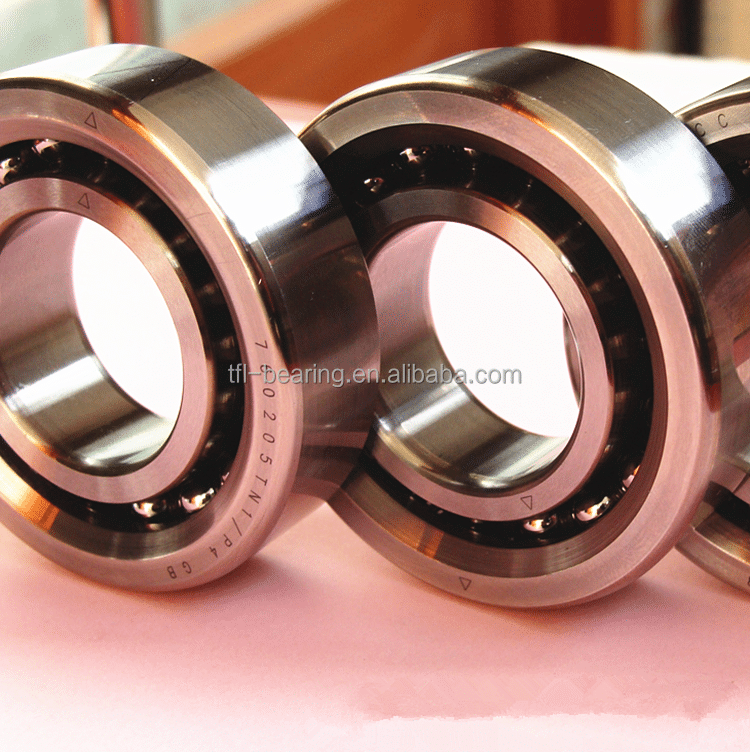

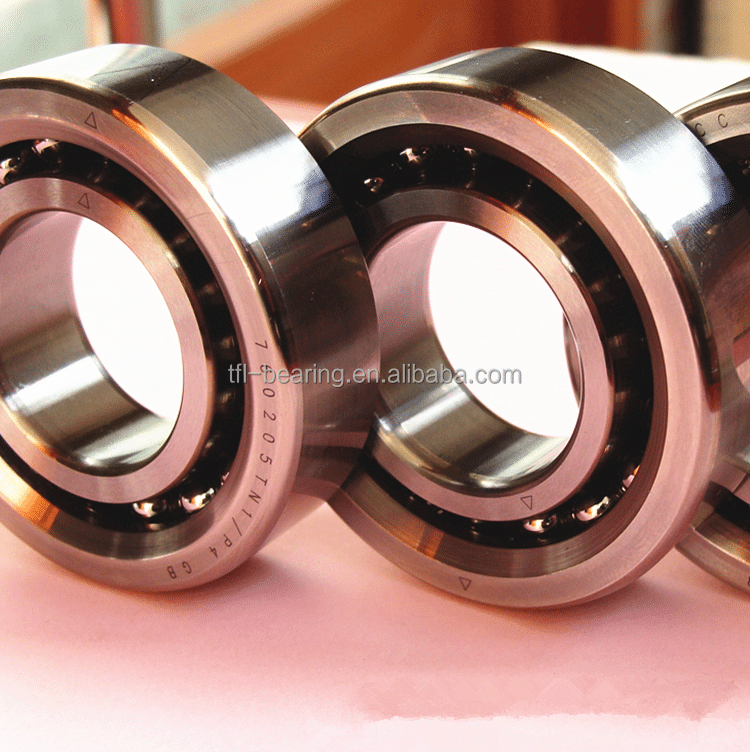

High precision Angular Contact Ball Bearing HRB 7005 AC P5 DBB

-

Customization:

-

Customized logo(Min. Order: 10 Pieces)Customized packaging(Min. Order: 10 Pieces)

High precision Angular Contact Ball Bearing HRB 7005 AC P5 DBB

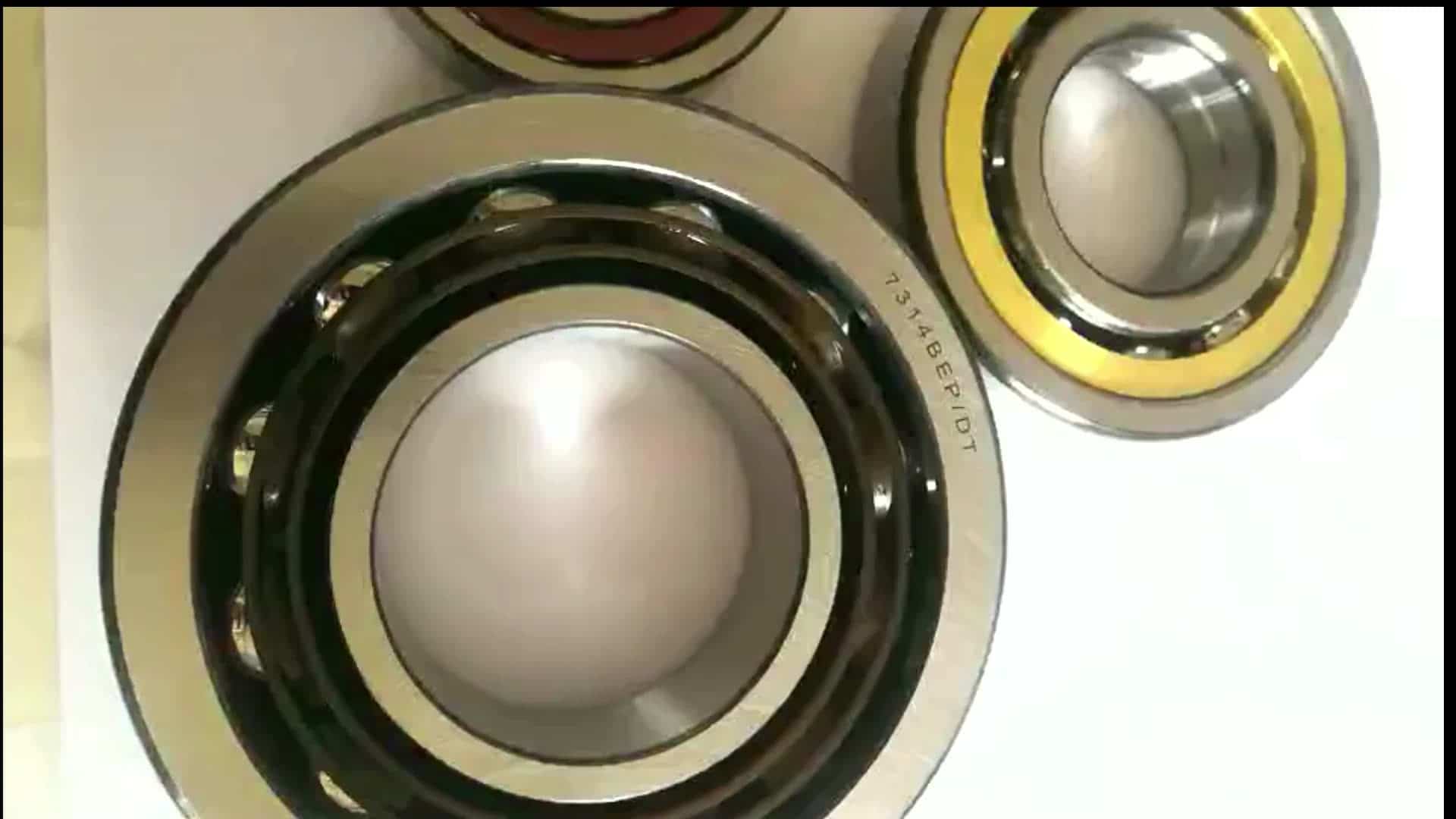

Single row angular contact ball bearings can carry axial load acting in one direction only. In many applications, angular contact ball bearings in pairs or muti-arrangement should be used. The axial load carrying capacity of angular contact ball bearings increases with the increase of contact angle.

| Model | Dimesion(mm) | ||

| d | D | T | |

| 7000AC | 10 | 26 | 8 |

| 7002AC | 15 | 32 | 8 |

| 7003AC | 17 | 35 | 10 |

| 7004AC | 20 | 42 | 10 |

| 7005AC | 25 | 47 | 12 |

| 7006AC | 30 | 55 | 13 |

| 7008AC | 40 | 68 | 15 |

| 7030ACM | 150 | 225 | 35 |

| 7032ACM | 160 | 240 | 38 |

| 7038ACM | 190 | 290 | 46 |

| 7040ACM | 200 | 310 | 51 |

| 7044ACM | 220 | 340 | 56 |

| 7217ACM | 85 | 150 | 28 |

| 7222ACM | 110 | 200 | 38 |

| 7224ACM | 120 | 215 | 40 |

| 7226ACM | 130 | 230 | 40 |

| 7228ACM | 140 | 250 | 42 |

| 7302AC | 15 | 42 | 13 |

| 7303AC | 17 | 47 | 14 |

| 7304AC | 20 | 52 | 15 |

| 7305AC | 25 | 62 | 17 |

| 7306AC | 30 | 72 | 19 |

| 7307AC | 35 | 80 | 21 |

| 7307ACM | 35 | 80 | 21 |

| 7308AC | 40 | 90 | 23 |

| 7308ACM | 40 | 90 | 23 |

| 7309AC | 45 | 100 | 25 |

| 7309ACM | 45 | 100 | 25 |

| 7310AC | 50 | 110 | 27 |

| 7310ACM | 50 | 110 | 27 |

| 7311AC | 55 | 120 | 29 |

| 7311ACM | 55 | 120 | 29 |

| 7312AC | 60 | 130 | 31 |

| 7312ACM | 60 | 130 | 31 |

| 7313AC | 65 | 140 | 33 |

| 7313ACM | 65 | 140 | 33 |

| 7314AC | 70 | 150 | 35 |

| 7314ACM | 70 | 150 | 35 |

| 7315AC | 75 | 160 | 37 |

| 7315ACM | 75 | 160 | 37 |

| 7316AC | 80 | 170 | 39 |

| 7316ACM | 80 | 170 | 39 |

| 7317AC | 85 | 180 | 41 |

| 7317ACM | 85 | 180 | 41 |

| 7318AC | 90 | 190 | 43 |

| 7318ACM | 90 | 190 | 43 |

| 7319ACM | 95 | 200 | 45 |

| 7320ACM | 100 | 215 | 47 |

FAQ1: What does DBB mean in angular contact bearings?

DBB stands for Duplex Back-to-Back. It’s a common arrangement for mounting two angular contact bearings. In a DBB configuration, the wider sides (higher shoulders) of the outer rings face each other. This arrangement provides excellent rigidity and can accommodate axial loads in both directions, making it suitable for applications where moment loads are present.

FAQ2:What is the difference between P5 and P4 precision grades?

P5 and P4 are ISO precision grades for bearings, with P4 being a higher precision grade than P5.

P5 (ISO Class 5): This is a high-precision grade suitable for many demanding applications, including machine tool spindles, gearboxes, and other machinery requiring good rotational accuracy.

P4 (ISO Class 4): This is a super-precision grade, even more precise than P5. Bearings with P4 accuracy have tighter tolerances for dimensions, runout, and rotational accuracy. They are used in the most critical applications where extreme precision, minimal vibration, and maximum stiffness are required, such as ultra-high-speed CNC machine tool spindles, precision measuring equipment, and aerospace applications.

The difference lies in the manufacturing tolerances; P4 bearings are produced to even stricter specifications than P5.

FAQ3: How is HRB 7005 AC P5 used in CNC spindle systems?

An HRB 7005 AC P5 bearing is a high-precision angular contact ball bearing often used in CNC spindle systems due to its specific characteristics:

HRB: This refers to the manufacturer, Harbin Bearing Group, a common Chinese bearing manufacturer.

7005: This is the basic bearing designation. “70” indicates it’s a single-row angular contact ball bearing.

AC: This indicates a contact angle, typically 15 degrees, which is a standard contact angle for general-purpose angular contact bearings, offering a balance of radial and axial load capacity.

P5: This signifies a precision grade of P5 (ISO class 5), which is a high precision standard. This level of precision is crucial for CNC spindles to ensure high rotational accuracy, minimal runout, and consistent machining performance.

In CNC spindles, these bearings are often used in pairs (or sets of three or four) with a preload to achieve high stiffness and accuracy, supporting the cutting tool and resisting forces during machining.