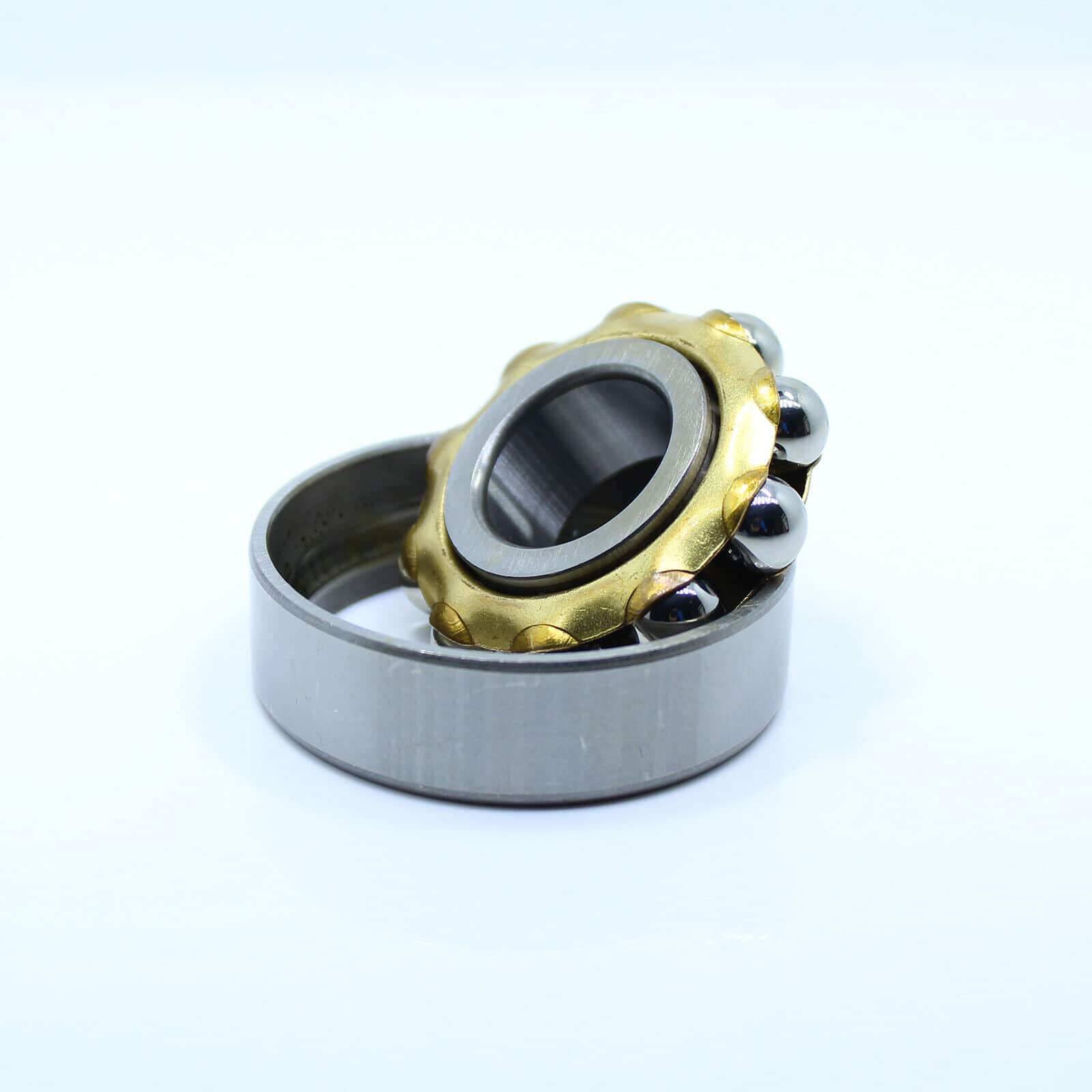

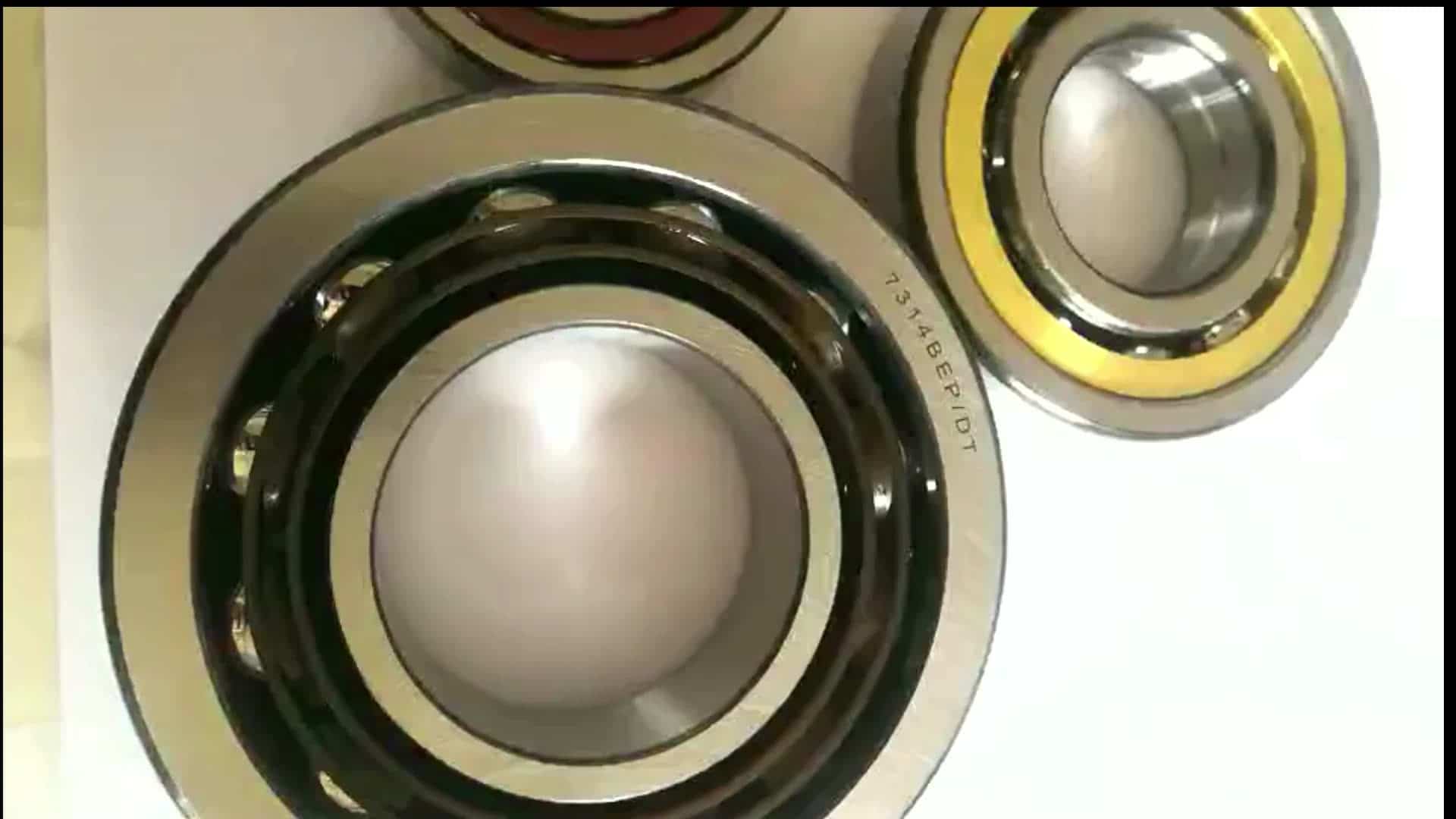

Angular Ball Bearing E11 Magnetic Bearing 11x32x7mm

- Samples:

-

11 mm , 32 mm , E11

$3.15/Piece | 1 Piece (Min. Order) |

- Customization:

-

Customized logo(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

More

The inner groove of E series magneto bearings is a little shallower than that of deep groove bearings. Since the outer ring has a shoulder on only one side, the outer ring may be removed. This is often advantageous for mounting.

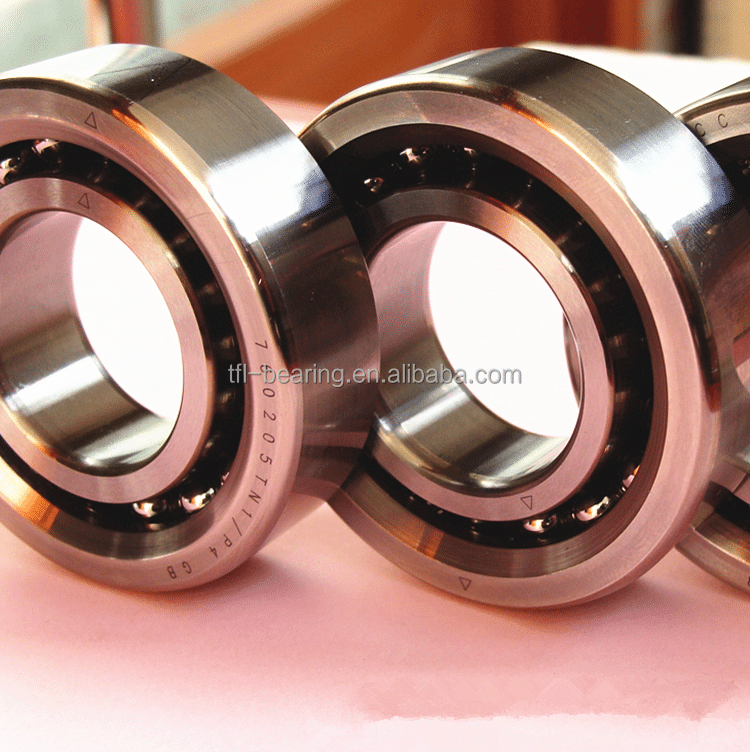

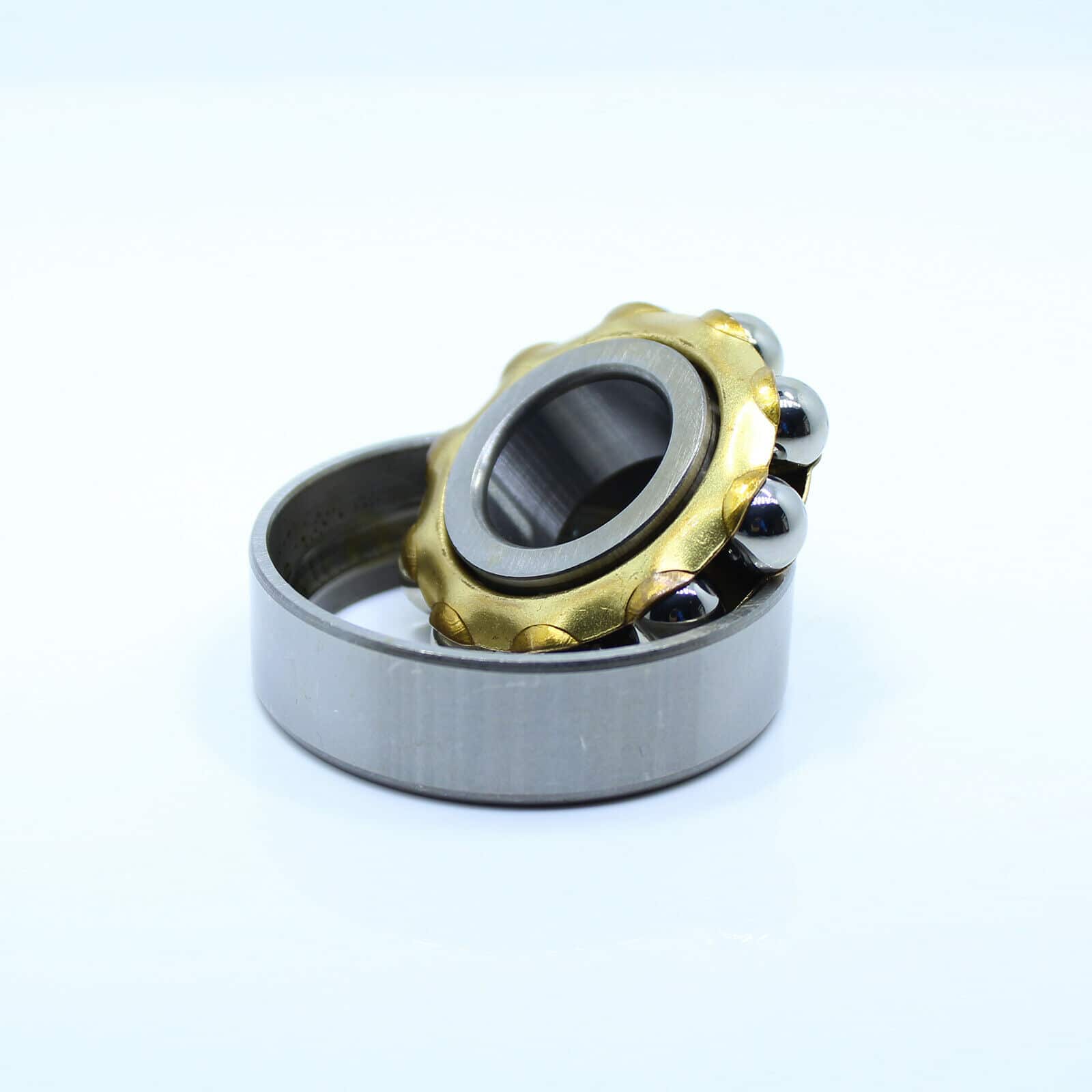

Highly suited to applications involving low loads and high speeds, the internal design of magneto bearings is essentially similar to that of single row deep groove ball bearings. however, the outer ring is counter-bore with a groove track that merges into the cylindrical track, making it easy to separate the two components.

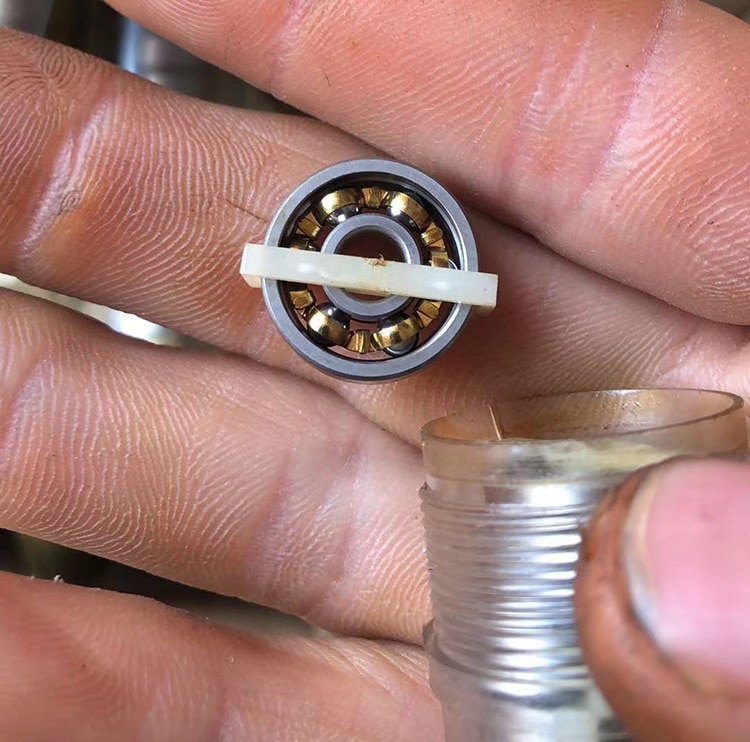

This means the outer ring of a magneto bearing can be fitted separately from the inner ring and cage. As a result, magneto

bearings are significantly easier to mount, fit or remove than standard deep groove ball bearings.

The most common application makes use of two such bearings in a duplex pair. These bearings are adjusted against one another, leaving a small amount of end play. Magneto bearings are typically small, with a bore diameter of between 4mm and 30mm. They are found in a range of applications, including gyroscopes and small magnetos. They can also be used as support bearings at the end of ball-screws on worktables for small milling machines and in generators and starter motors.

To select the best possible bearing for a particular job, a number of factors need to be considered. These include the load

capacity, allowable bearing space, and permissible speed. The type of bearing may also depend on the specific bearing arrangement that has been selected for the project.

|

Model

|

Boundary Dimensions(mm)

|

Basic Load Ratings(kgf)

|

Limiting Speeds(rpm)

|

Mass(kg)

|

|||||||||

|

E series

|

EN Series

|

d

|

D

|

B.T

|

Dynamic

|

Static

|

Grease

|

Oil

|

|||||

|

EN4

|

4

|

16

|

5

|

122

|

24

|

34000

|

40000

|

0.005

|

|||||

|

E5

|

EN5

|

5

|

16

|

5

|

122

|

24

|

34000

|

40000

|

0.005

|

||||

|

E6

|

EN6

|

6

|

21

|

7

|

224

|

40

|

30000

|

36000

|

0.011

|

||||

|

E7

|

EN7

|

7

|

22

|

7

|

254

|

40

|

28000

|

34000

|

0.012

|

||||

|

708

|

8

|

22

|

7

|

255

|

54

|

28000

|

34000

|

0.014

|

|||||

|

E8

|

EN8

|

8

|

24

|

7

|

255

|

54

|

28000

|

34000

|

0.014

|

||||

|

6028

|

8

|

24

|

8

|

255

|

54

|

28000

|

34000

|

0.014

|

|||||

|

E9

|

EN9

|

9

|

28

|

8

|

335

|

73

|

24000

|

30000

|

0.022

|

||||

|

E10

|

EN10

|

10

|

28

|

8

|

335

|

73

|

24000

|

30000

|

0.021

|

||||

|

E11

|

EN11

|

11

|

32

|

7

|

270

|

75

|

22000

|

28000

|

0.027

|

||||

|

E12

|

EN12

|

12

|

32

|

7

|

270

|

75

|

22000

|

28000

|

0.027

|

||||

|

E13

|

EN13

|

13

|

30

|

7

|

270

|

75

|

22000

|

26000

|

0.021

|

||||

|

E14

|

EN14

|

14

|

35

|

8

|

450

|

110

|

19000

|

24000

|

0.034

|

||||

|

7202

|

15

|

35

|

11

|

355

|

102

|

19000

|

24000

|

0.045

|

|||||

|

E15

|

EN15

|

15

|

35

|

8

|

355

|

102

|

19000

|

24000

|

0.033

|

||||

|

N3048

|

–

|

15

|

37

|

8

|

355

|

102

|

19000

|

24000

|

0.033

|

||||

|

BO15

|

–

|

15

|

40

|

10

|

570

|

153

|

14000

|

18000

|

0.055

|

||||

|

E16

|

EN16

|

16

|

38

|

10

|

705

|

127

|

16000

|

20000

|

0.048

|

||||

|

L17

|

–

|

17

|

40

|

10

|

450

|

134

|

14000

|

18000

|

0.053

|

||||

|

E17

|

EN17

|

17

|

44

|

11

|

440

|

134

|

14000

|

18000

|

0.078

|

||||

|

BO17

|

–

|

17

|

44

|

11

|

750

|

138

|

14000

|

18000

|

0.073

|

||||

|

M17

|

–

|

17

|

44

|

10

|

750

|

138

|

14000

|

18000

|

0.073

|

||||

|

E18

|

EN18

|

18

|

40

|

9

|

270

|

95

|

16000

|

20000

|

0.05

|

||||

|

E19

|

EN19

|

19

|

40

|

9

|

270

|

95

|

16000

|

20000

|

0.048

|

||||

|

E20

|

EN20

|

20

|

47

|

12

|

580

|

224

|

14000

|

17000

|

0.087

|

||||

|

L20

|

–

|

20

|

47

|

14

|

580

|

224

|

14000

|

17000

|

0.1

|

||||

|

M20

|

–

|

20

|

52

|

15

|

965

|

270

|

13000

|

16000

|

0.138

|

||||

|

L25

|

–

|

25

|

52

|

15

|

565

|

240

|

12000

|

15000

|

0.122

|

||||

|

M25

|

–

|

25

|

62

|

17

|

1250

|

375

|

11000

|

14000

|

0.217

|

||||

|

L30

|

–

|

30

|

62

|

16

|

630

|

228

|

8000

|

11000

|

0.25

|

||||

|

M30

|

–

|

30

|

72

|

19

|

630

|

228

|

8000

|

11000

|

0.4

|

||||