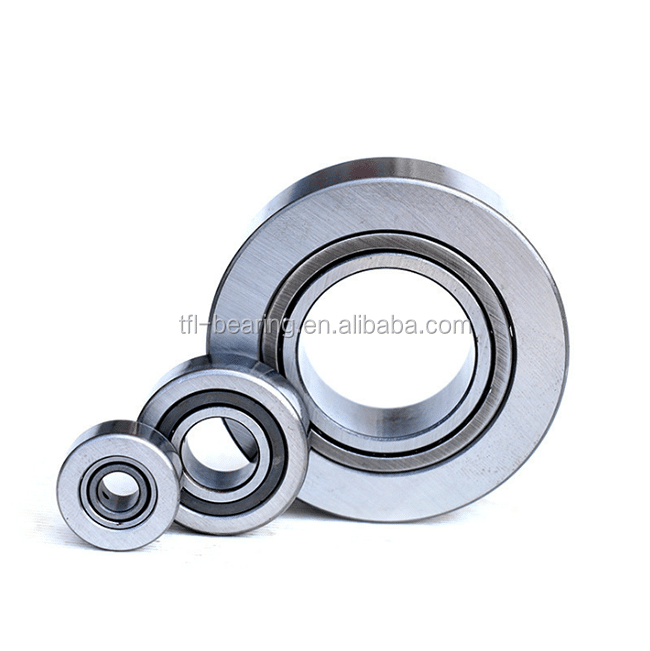

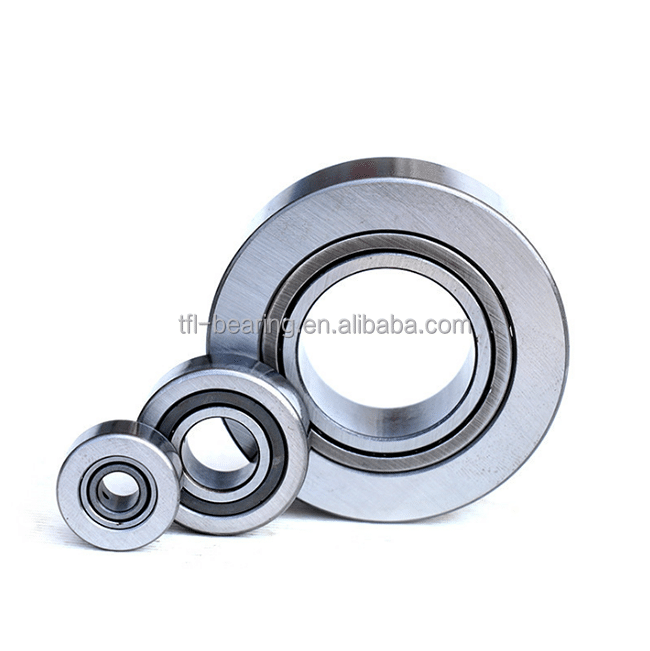

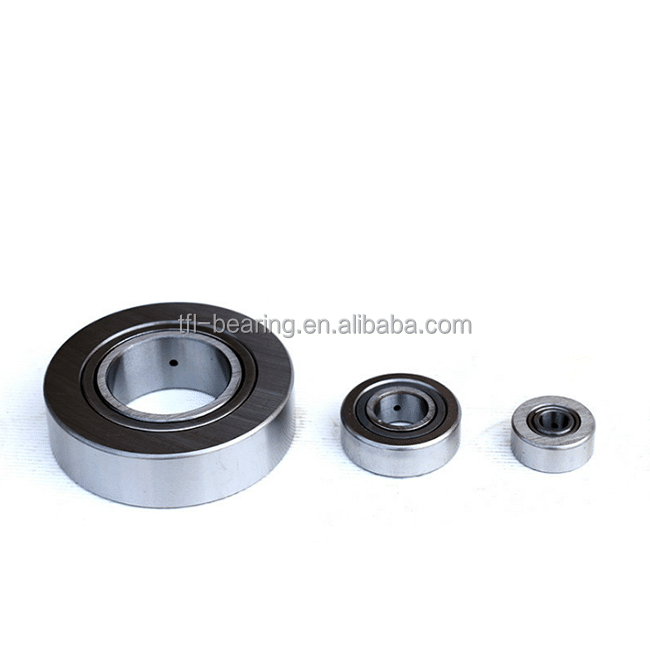

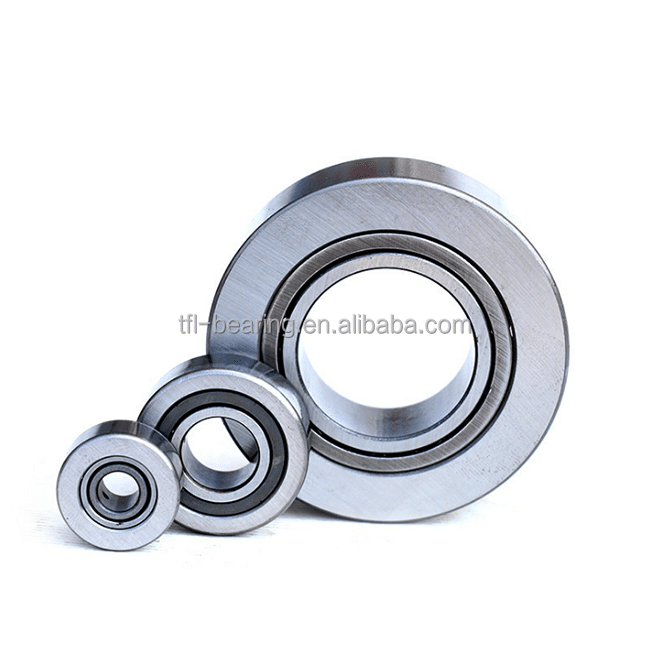

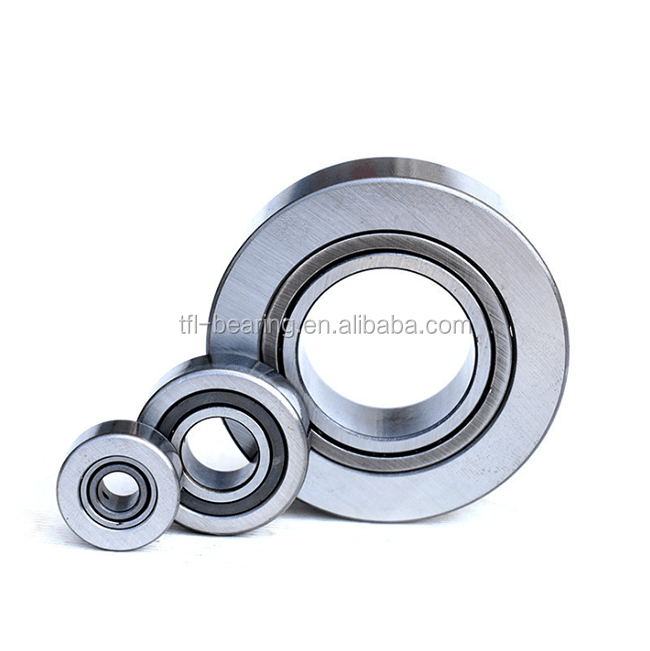

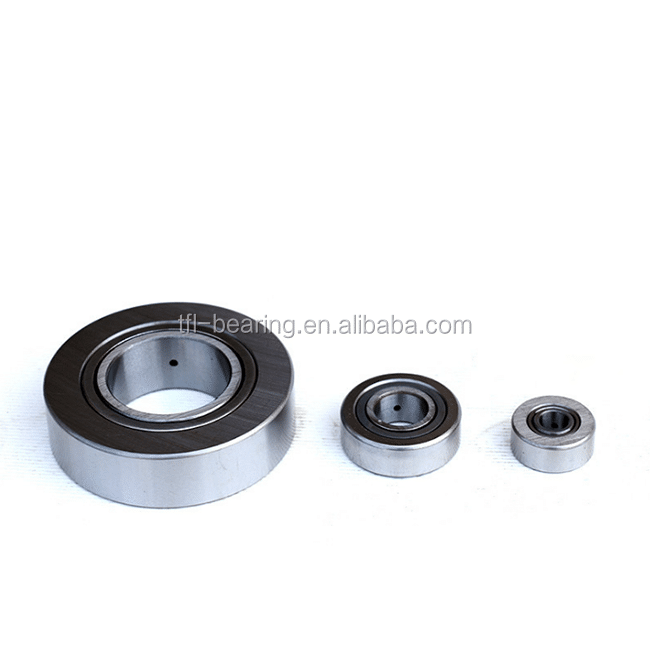

Cam follower needle bearing STO 30 supporting roller bearing

- Samples:

-

$6.23/Piece | 1 Piece (Min. Order) |

- Customization:

-

Customized logo(Min. Order: 100 Pieces)Customized packaging(Min. Order: 100 Pieces)

More

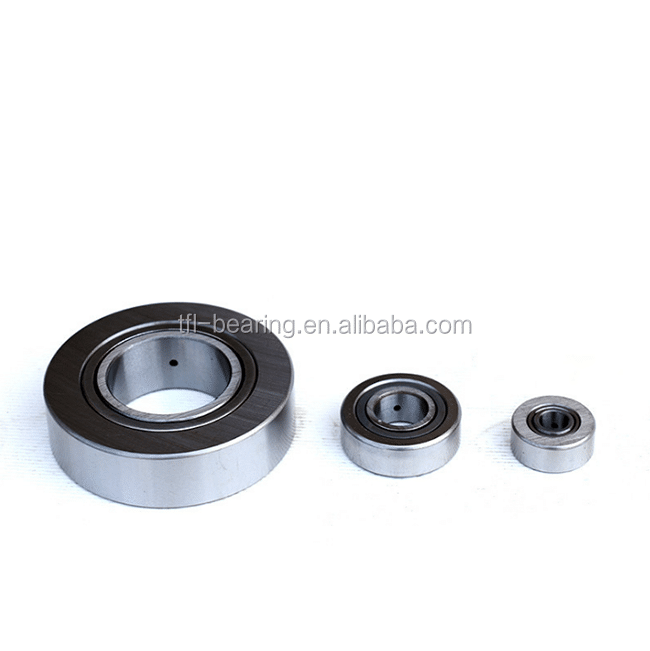

Needle Roller Bearings are the roller bearings with cylindrical roller elements, compared with the diameter, the needle roller are both thin and long, so they are called needle roller. Although the section is small, the type of bearings still has the high ablity of load, it specially can be used to the situation of being restricted of the radial space..

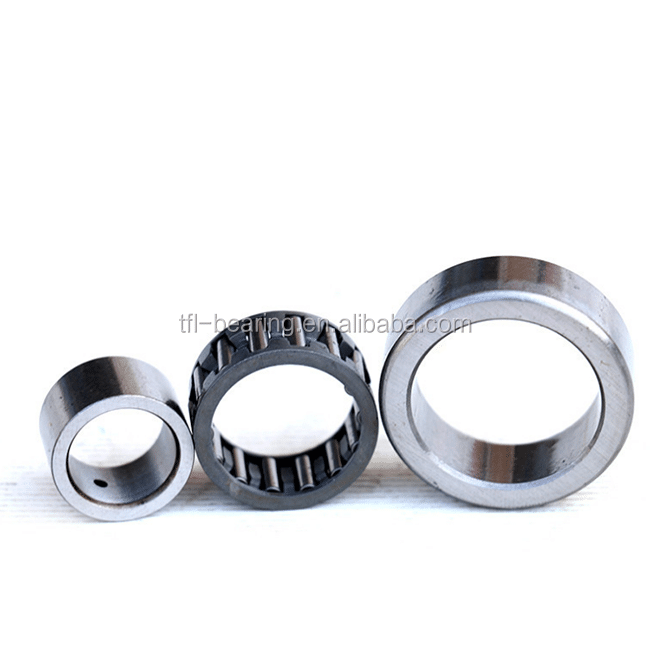

Product construction

Needle roller bearings consist of an inner race (shaft), needle cage, needle rollers and an outer race. The rollers are cylindrical, thin, and long. These bearings are compact because there is less clearance between the diameter of the shaft and that of the bearing. This quality makes them suitable for situations where there is limited radial space.

Product types

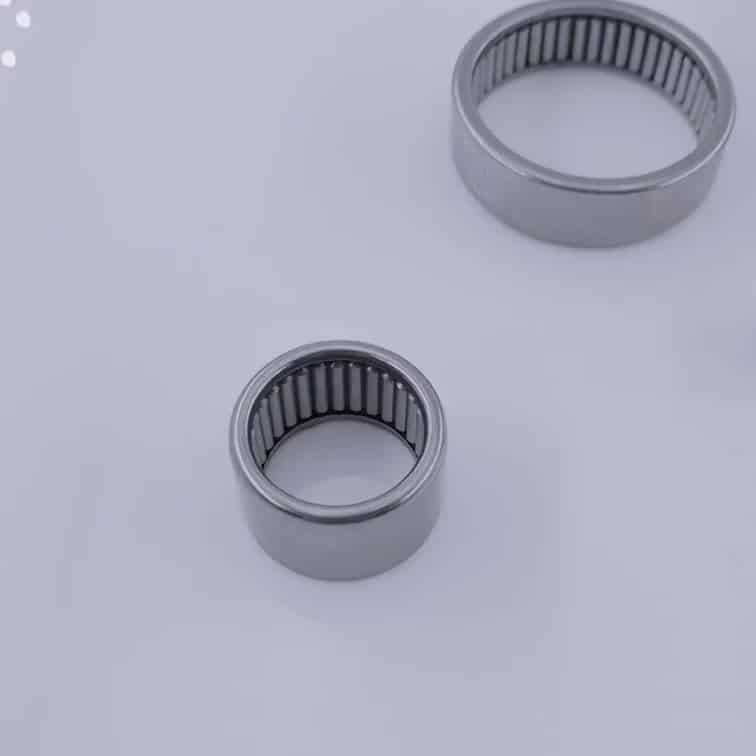

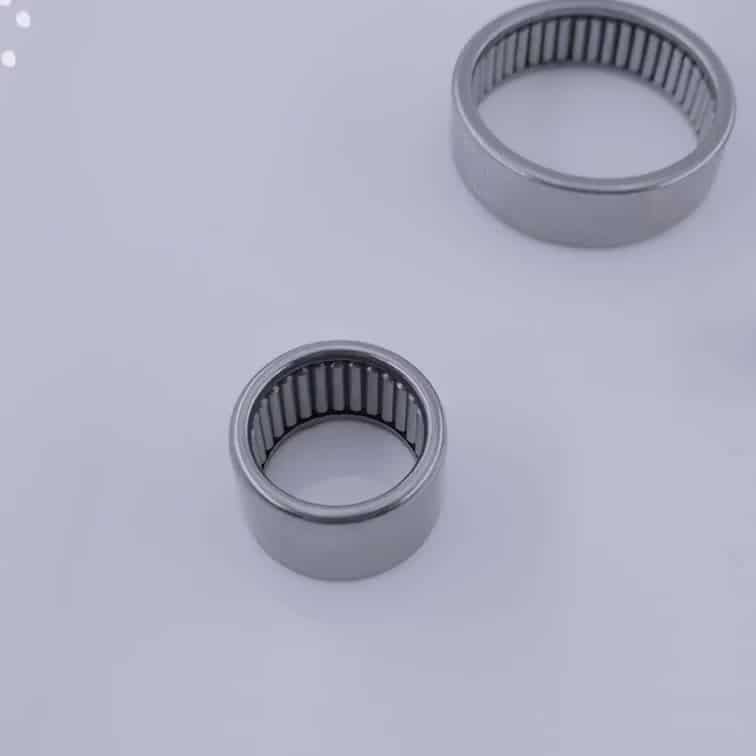

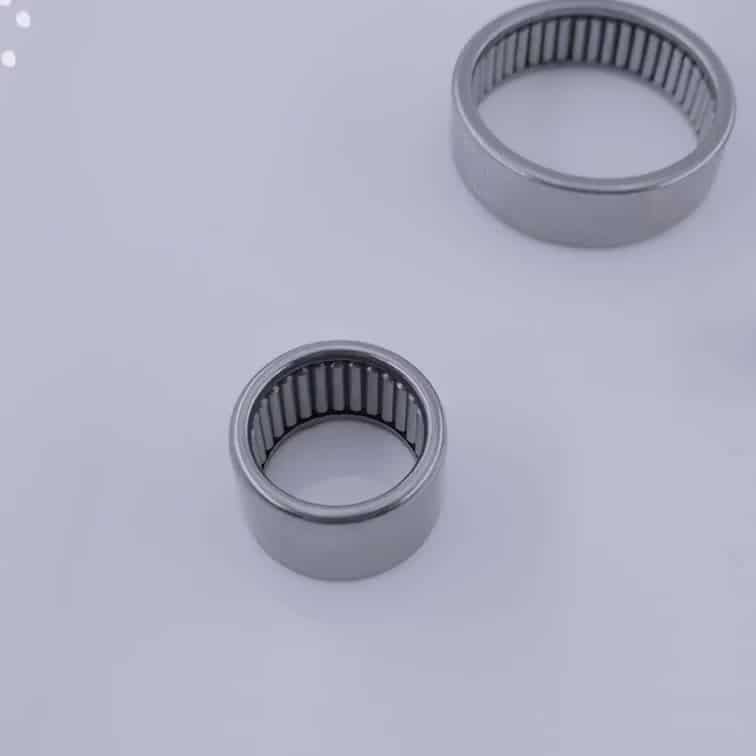

1. Drawn Cup needle roller Bearing: HK, HK..(2)RS, BA, SCE, HMK, BK, B, F, FY, FH etc series.

2.: AXK, AS, NTA, TC, TRA, TRB, TRC,TRD,K811TN, K812TN, AX series.

3.Heavy Duty needle roller bearing: NA, NK, NKI, NAV, NAO, HJ, BR, BRI etc.

4. Combine bearing: NKIA, NKIB, ZARN, ZARF, SL04, SL 18 etc series

5. roller and cage assemblies; KZK, KBK, K.ZW etc series.

6. inner ring: IR, LR etc series.

7.cam followers: KR, CF, NATR, NUTR, NUKR etc series.

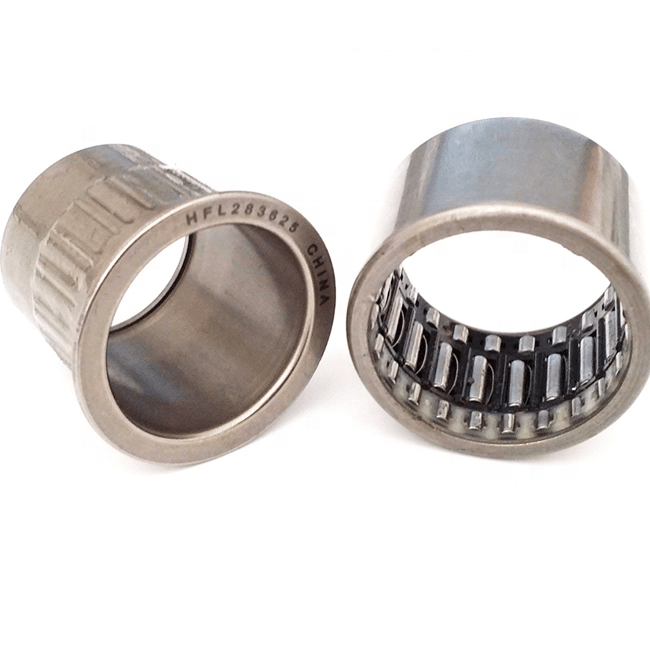

8.clutches: HF, HFL, RC, RCB, CSK, TNS, TFS, DC etc series.

9.Bearing for Peugeot Car: DB68933. DB 68934, NE 70214, NE 70216 etc series.

Of course, if you need other bearing, we also can help you to purchase in China.

Material:

Material for needle roller is GCr15 bearing steel,quench-hardening HRC60-65

Material for inner and outer rings is GCr15 bearing steel,quench-hardening HRC60-65

Material for cages is quality low-carbon steel or reinforced nylon.

Special Directions:

Bearing running clearance and inner-cutting roundness should be regulated according to different

conditions.

Machine tolls should be used for press-in fitting or thermal fitting when install the bearing.

Limited by plastic cages(suffixed with TN) and sealing-element material ,operating temperature

is -30℃--+100℃

For general-disposition design of bearings,refer to the relevant recommendation in the applied

technology of roller bearings.

Part of the bearing specification :

| Dimensions | Dynamic | Static | Dynamic | Static | Designations | ||

| D(mm) | d(mm) | C(mm) | C kn | C0 | Fr | F0r | |

| 19 | 6 | 9,8 | 3,74 | 4,5 | 4,25 | 6,1 | STO 6 TN |

| 19 | 6 | 11,8 | 3,52 | 3 | 1,93 | 2,75 | NA 22/6.2RS |

| 24 | 8 | 9,8 | 4,13 | 5,4 | 7,5 | 10,8 | STO 8 TN |

| 24 | 8 | 11,8 | 4,46 | 4,4 | 5 | 7,1 | NA 22/8.2RS |

| 30 | 10 | 11,8 | 8,25 | 8,8 | 8,5 | 12,2 | STO 10 |

| 30 | 10 | 13,8 | 6,44 | 7,2 | 12 | 17 | NA 2200.2RS |

| 32 | 12 | 11,8 | 8,8 | 9,8 | 8,3 | 12 | STO 12 |

| 32 | 12 | 13,8 | 6,93 | 8,15 | 11,6 | 16,6 | NA 2201.2RS |

| 35 | 15 | 11,8 | 9,13 | 10,6 | 7,1 | 10 | STO 15 |

| 35 | 15 | 13,8 | 7,21 | 9 | 9,65 | 13,7 | NA 2202.2RS |

| 40 | 17 | 15,8 | 9,35 | 12,9 | 16 | 22,8 | NA 2203.2RS |

| 40 | 17 | 15,8 | 14,2 | 17,6 | 12 | 17,3 | STO 17 |

| 47 | 20 | 15,8 | 16,1 | 21,2 | 18,6 | 26,5 | STO 20 |

| 47 | 20 | 17,8 | 15,4 | 17,3 | 17,6 | 25,5 | NA 2204.2RS |

| 52 | 25 | 15,8 | 16,5 | 22,8 | 18 | 26 | STO 25 |

| 52 | 25 | 17,8 | 16,1 | 19 | 17,3 | 24,5 | NA 2205.2RS |

| 62 | 30 | 19,8 | 17,6 | 24,5 | 28,5 | 40,5 | NA 2206.2RS |

| 62 | 30 | 19,8 | 22,9 | 34,5 | 23,6 | 33,5 | STO 30 |

| 72 | 35 | 19,8 | 25,5 | 40,5 | 36 | 51 | STO 35 |

| 72 | 35 | 22,7 | 22 | 34 | 39 | 56 | NA 2207.2RS |

| 80 | 40 | 19,8 | 23,8 | 39 | 34,5 | 49 | STO 40 |

| 80 | 40 | 22,7 | 27 | 39 | 37,5 | 53 | NA 2208.2RS |

| 85 | 45 | 19,8 | 25,1 | 43 | 34,5 | 50 | STO 45 |

| 90 | 50 | 19,8 | 26 | 45,5 | 34,5 | 50 | STO 50 |

| 90 | 50 | 22,7 | 27 | 41,5 | 36,5 | 52 | NA 2210.2RS |

Needle Roller Bearings are the roller bearings with cylindrical roller elements, compared with the diameter, the needle roller are both thin and long, so they are called needle roller. Although the section is small, the type of bearings still has the high ablity of load, it specially can be used to the situation of being restricted of the radial space..

Product construction

Needle roller bearings consist of an inner race (shaft), needle cage, needle rollers and an outer race. The rollers are cylindrical, thin, and long. These bearings are compact because there is less clearance between the diameter of the shaft and that of the bearing. This quality makes them suitable for situations where there is limited radial space.

Product types

1. Drawn Cup needle roller Bearing: HK, HK..(2)RS, BA, SCE, HMK, BK, B, F, FY, FH etc series.

2.: AXK, AS, NTA, TC, TRA, TRB, TRC,TRD,K811TN, K812TN, AX series.

3.Heavy Duty needle roller bearing: NA, NK, NKI, NAV, NAO, HJ, BR, BRI etc.

4. Combine bearing: NKIA, NKIB, ZARN, ZARF, SL04, SL 18 etc series

5. roller and cage assemblies; KZK, KBK, K.ZW etc series.

6. inner ring: IR, LR etc series.

7.cam followers: KR, CF, NATR, NUTR, NUKR etc series.

8.clutches: HF, HFL, RC, RCB, CSK, TNS, TFS, DC etc series.

9.Bearing for Peugeot Car: DB68933. DB 68934, NE 70214, NE 70216 etc series.

Of course, if you need other bearing, we also can help you to purchase in China.

Material:

Material for needle roller is GCr15 bearing steel,quench-hardening HRC60-65

Material for inner and outer rings is GCr15 bearing steel,quench-hardening HRC60-65

Material for cages is quality low-carbon steel or reinforced nylon.

Special Directions:

Bearing running clearance and inner-cutting roundness should be regulated according to different

conditions.

Machine tolls should be used for press-in fitting or thermal fitting when install the bearing.

Limited by plastic cages(suffixed with TN) and sealing-element material ,operating temperature

is -30℃--+100℃

For general-disposition design of bearings,refer to the relevant recommendation in the applied

technology of roller bearings.

Part of the bearing specification :

| Dimensions | Dynamic | Static | Dynamic | Static | Designations | ||

| D(mm) | d(mm) | C(mm) | C kn | C0 | Fr | F0r | |

| 19 | 6 | 9,8 | 3,74 | 4,5 | 4,25 | 6,1 | STO 6 TN |

| 19 | 6 | 11,8 | 3,52 | 3 | 1,93 | 2,75 | NA 22/6.2RS |

| 24 | 8 | 9,8 | 4,13 | 5,4 | 7,5 | 10,8 | STO 8 TN |

| 24 | 8 | 11,8 | 4,46 | 4,4 | 5 | 7,1 | NA 22/8.2RS |

| 30 | 10 | 11,8 | 8,25 | 8,8 | 8,5 | 12,2 | STO 10 |

| 30 | 10 | 13,8 | 6,44 | 7,2 | 12 | 17 | NA 2200.2RS |

| 32 | 12 | 11,8 | 8,8 | 9,8 | 8,3 | 12 | STO 12 |

| 32 | 12 | 13,8 | 6,93 | 8,15 | 11,6 | 16,6 | NA 2201.2RS |

| 35 | 15 | 11,8 | 9,13 | 10,6 | 7,1 | 10 | STO 15 |

| 35 | 15 | 13,8 | 7,21 | 9 | 9,65 | 13,7 | NA 2202.2RS |

| 40 | 17 | 15,8 | 9,35 | 12,9 | 16 | 22,8 | NA 2203.2RS |

| 40 | 17 | 15,8 | 14,2 | 17,6 | 12 | 17,3 | STO 17 |

| 47 | 20 | 15,8 | 16,1 | 21,2 | 18,6 | 26,5 | STO 20 |

| 47 | 20 | 17,8 | 15,4 | 17,3 | 17,6 | 25,5 | NA 2204.2RS |

| 52 | 25 | 15,8 | 16,5 | 22,8 | 18 | 26 | STO 25 |

| 52 | 25 | 17,8 | 16,1 | 19 | 17,3 | 24,5 | NA 2205.2RS |

| 62 | 30 | 19,8 | 17,6 | 24,5 | 28,5 | 40,5 | NA 2206.2RS |

| 62 | 30 | 19,8 | 22,9 | 34,5 | 23,6 | 33,5 | STO 30 |

| 72 | 35 | 19,8 | 25,5 | 40,5 | 36 | 51 | STO 35 |

| 72 | 35 | 22,7 | 22 | 34 | 39 | 56 | NA 2207.2RS |

| 80 | 40 | 19,8 | 23,8 | 39 | 34,5 | 49 | STO 40 |

| 80 | 40 | 22,7 | 27 | 39 | 37,5 | 53 | NA 2208.2RS |

| 85 | 45 | 19,8 | 25,1 | 43 | 34,5 | 50 | STO 45 |

| 90 | 50 | 19,8 | 26 | 45,5 | 34,5 | 50 | STO 50 |

| 90 | 50 | 22,7 | 27 | 41,5 | 36,5 | 52 | NA 2210.2RS |