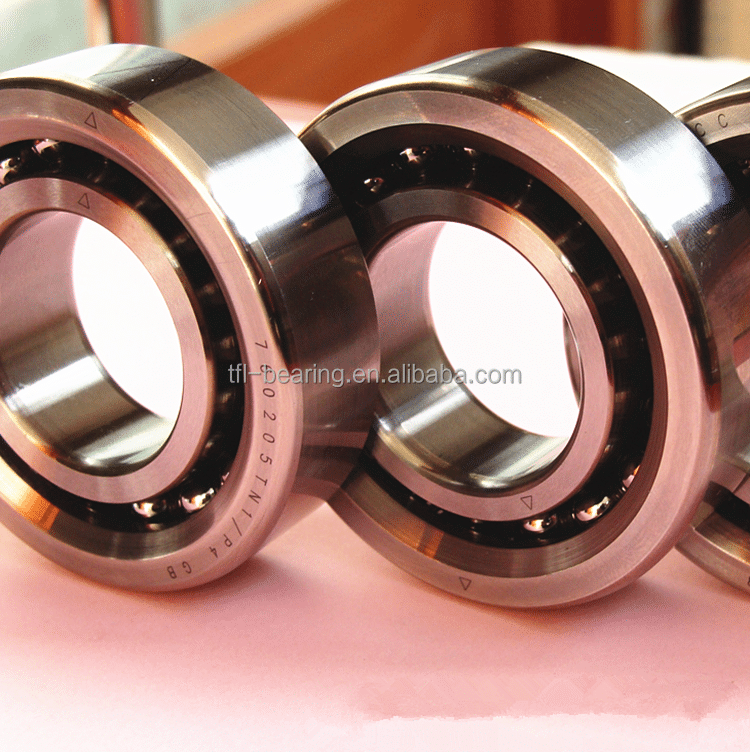

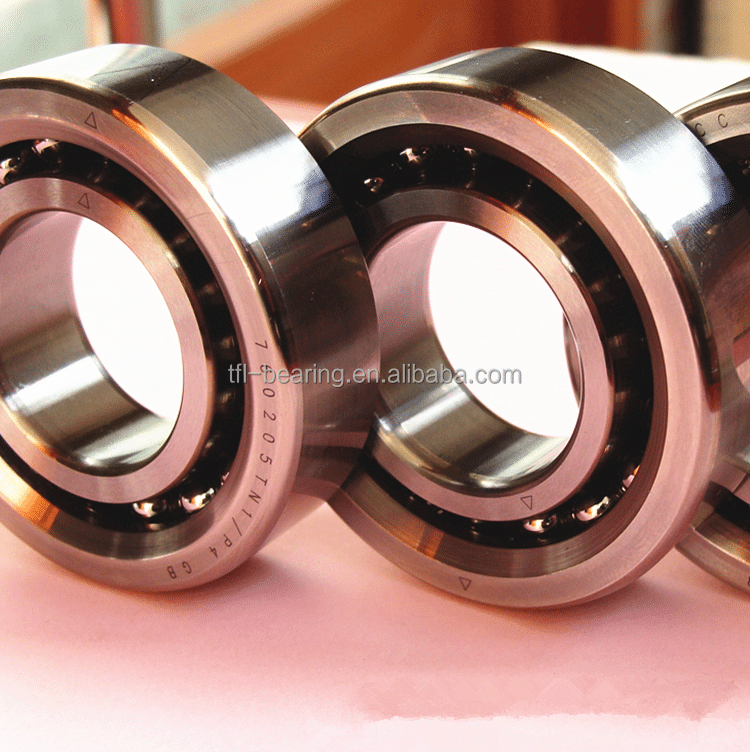

7000 7001 7002 7003 7004 7005 C P4 Angular contact ball bearing

- Samples:

-

12mm , 28mm , 7001

$0.88/Piece | 1 Piece (Min. Order) |

- Lead Time

If you finish the payment today, your order will ship out within the delivery date.

:

-

Quantity(Pieces) 1 – 2000 >2000 Est. Time(days) 3 To be negotiated

- Customization:

-

Customized logo(Min. Order: 2000 Pieces)Customized packaging(Min. Order: 2000 Pieces)

More

7000 7001 7002 7003 7004 7005 C P4 Angular contact ball bearing

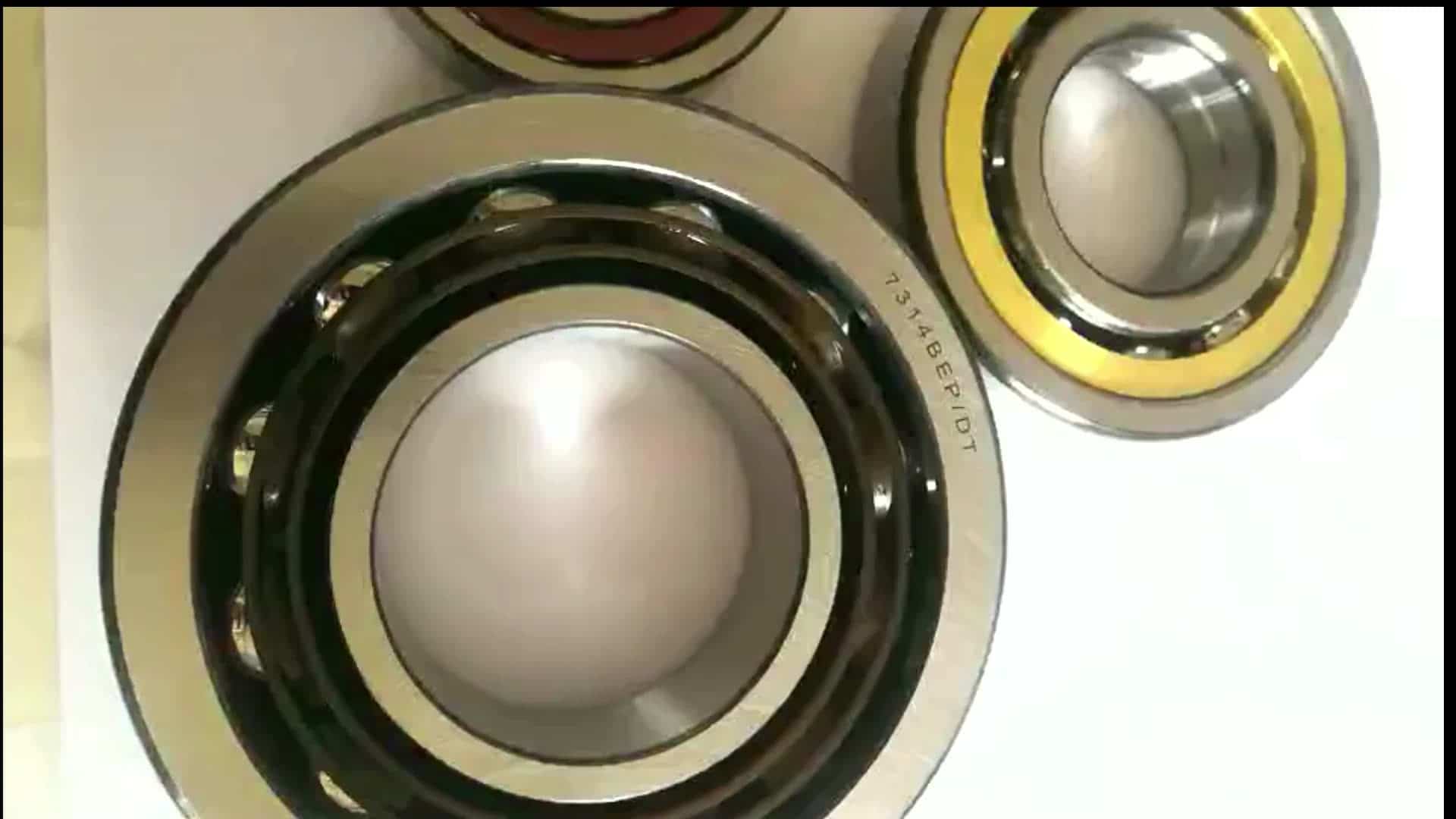

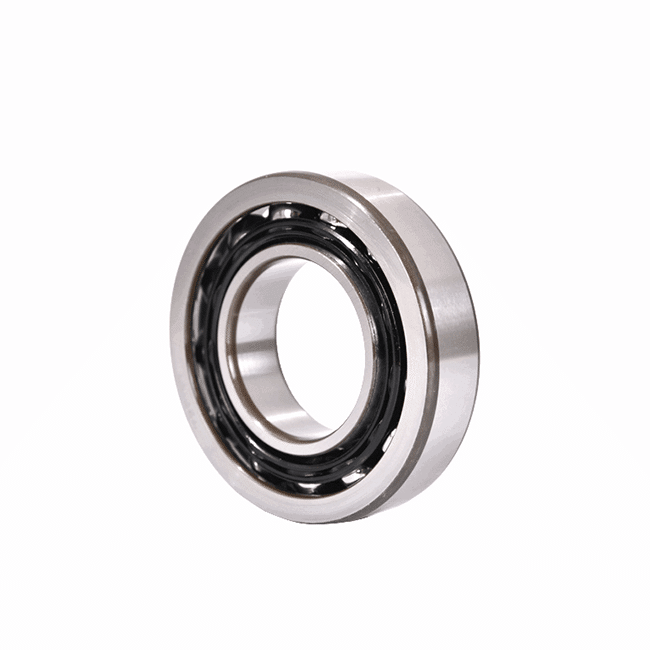

Double row angular contact ball bearings can withstand larger radial loads, mainly combined radial and axial loads and moment loads, limiting the axial displacement of the shaft on both sides. The tiltability between the inner and outer rings of the double row angular contact ball bearing is mainly used to limit the bidirectional axial displacement of the shaft and the housing. The allowable tilt angle depends on the internal clearance of the bearing, bearing size, internal design and acting on it. The force and moment on the bearing, and the maximum allowable inclination angle should ensure that no excessively high additional stress is generated in the bearing. If there is an inclination angle between the inner and outer rings of the bearing, it will affect the life of the bearing, and at the same time cause the bearing’s running accuracy to decrease and the running noise to increase. Double row angular contact ball bearings generally use nylon cages or brass solid cages. Pay attention to the installation of double row angular contact ball bearings. Although the bearing can withstand two-way axial loads, if there is a gap for the ball on one side, care should be taken not to allow the main axial load to pass through the gap on the side of the groove. When the bearing is used, attention should be paid to the main load on the side of the raceway without the ball notch.

Paired double ball bearings

If it is installed in pairs, the outer rings of a pair of bearings are opposite, that is, the wide end faces the wide end face, and the narrow end faces the narrow end face. In this way, additional axial force can be avoided, and the shaft or housing can be restricted to the axial clearance range in both directions.

Because the raceways of the inner and outer rings can have relative displacement on the horizontal axis, they can bear radial load and axial load-combined load (single row angular contact ball bearings can only bear axial load in one direction, so they are usually Install in pairs).

The material of the cage is brass, synthetic resin, etc., which are differentiated according to the bearing type and use conditions.

|

Boundary dimensions

(mm)

|

Weight

|

bearing NO.

|

||||

|

d

|

D

|

B

|

0.02kg

|

7001AC

|

||

|

12

|

28

|

8

|

||||

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers’ demands.

How does the 7005 angular contact bearing improve performance in high-speed systems?

The 7005 angular contact bearing improves performance in high-speed systems through the following features:

-

Precision Design: The angular contact configuration allows for a higher degree of accuracy and tighter tolerances, reducing runout and enhancing stability at high speeds.

-

Reduced Friction: The design of the 7005 bearing minimizes friction, resulting in less heat generation and smoother operation, which is crucial for maintaining performance in high-speed applications.

-

Support for Axial and Radial Loads: With its ability to handle both radial and axial loads, the 7005 can withstand the forces generated in high-speed machinery, ensuring reliable performance under dynamic conditions.

-

High-Speed Capability: Its precision ball arrangement and optimized contact angle reduce vibrations and noise, making it suitable for high-speed applications like motors, turbines, or high-performance automotive systems.

-

Durability: Built with high-quality materials, the 7005 bearing offers durability and longer service life in high-speed environments, reducing maintenance and downtime.

-

Efficient Heat Dissipation: The bearing is designed to maintain stable operation even at high speeds, helping to manage the heat that typically builds up in fast-moving systems.

These features make the 7005 angular contact bearing ideal for applications where high-speed performance, precision, and reliability are essential.