Shandong Tefule Bearing Co., Ltd. is a company approved by the General Administration of Customs of China with import and export rights. Specializing in bearing trade at home and abroad, it is a large-scale industrial company integrating production and sales. Our bearing products have passed the ISO9001 quality system certification and ROHS lead-free certification. These products are widely used in the construction industry, railway industry, aerospace, agriculture, food industry, petroleum industry, cement industry, automobile industry, steel industry, mining, etc.

Magneto Electric Motor rodamientos E13 E14 E15 Nsk Magnetic Bearings E7

- Samples:

-

7 mm , 22 mm , E7$2.45/Piece | 1 Piece (Min. Order) |

- Customization:

-

Customized logo(Min. Order: 1000 Pieces)Customized packaging(Min. Order: 1000 Pieces)

More

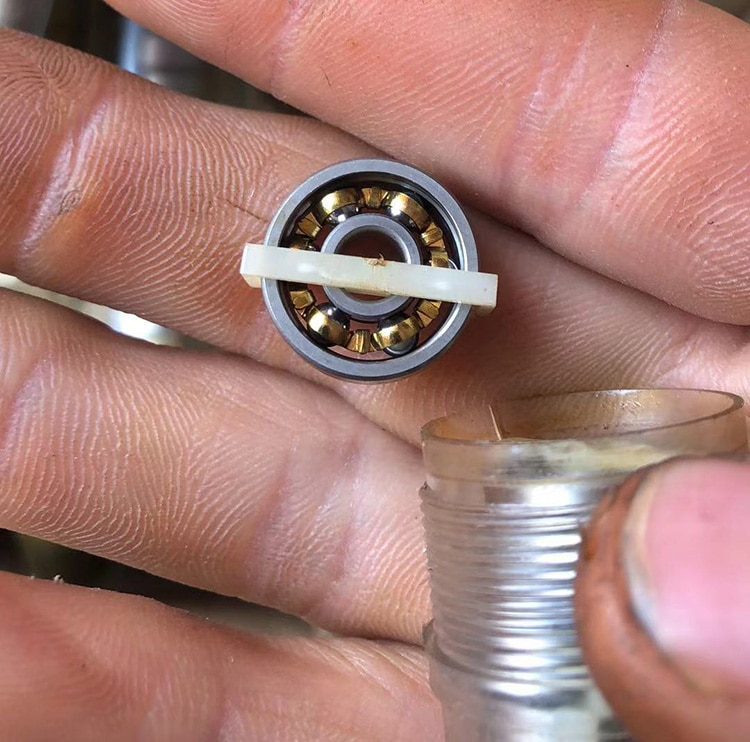

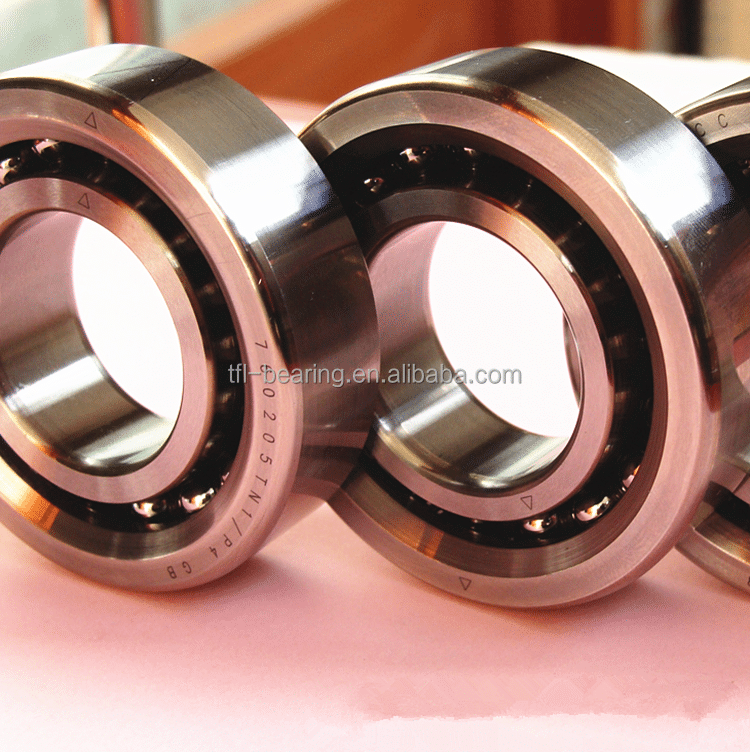

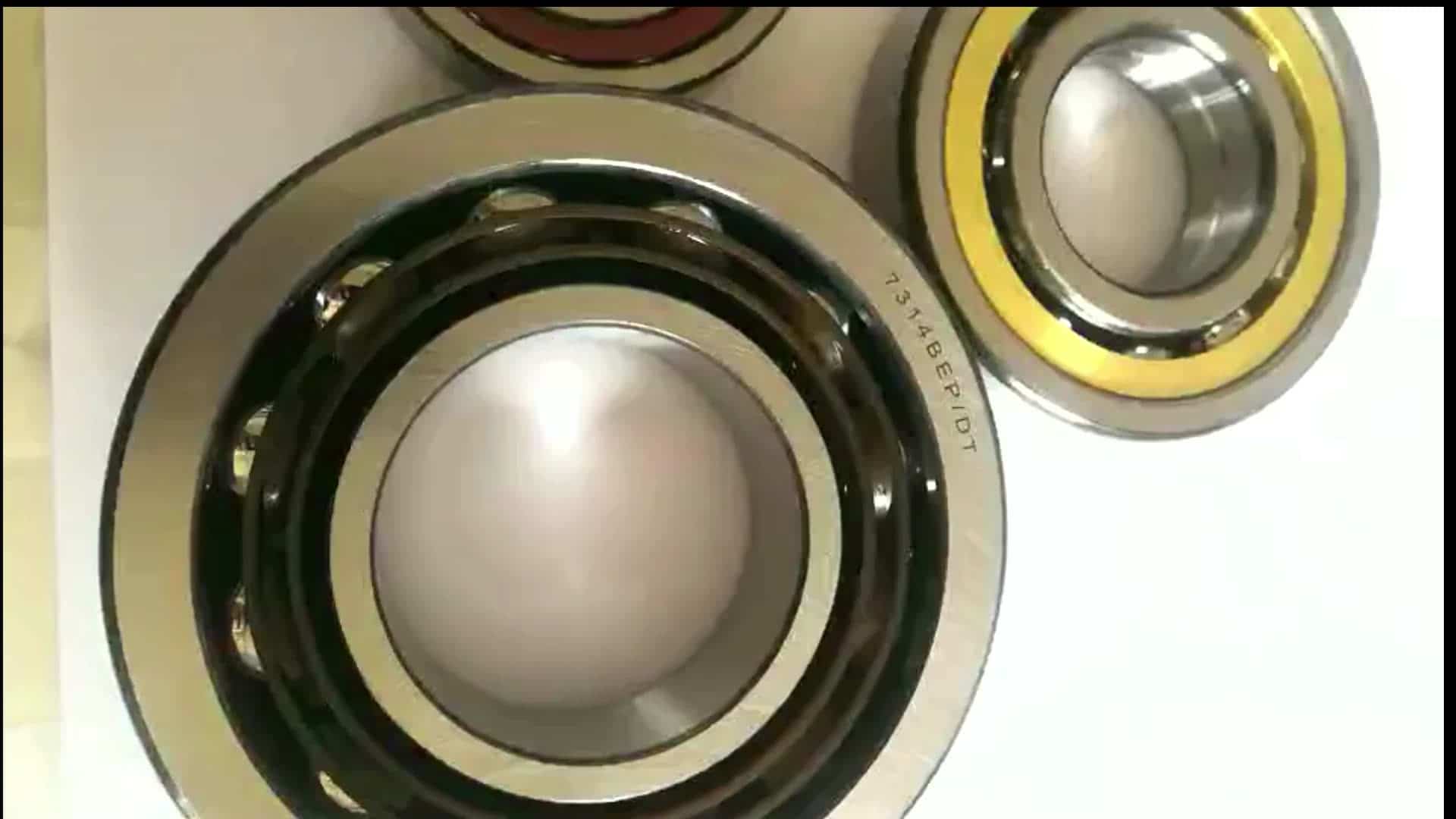

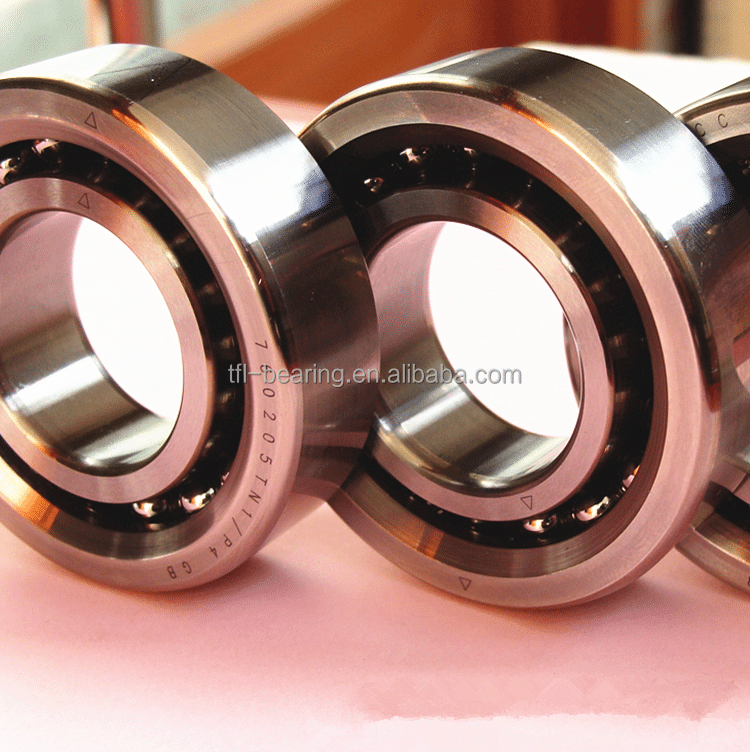

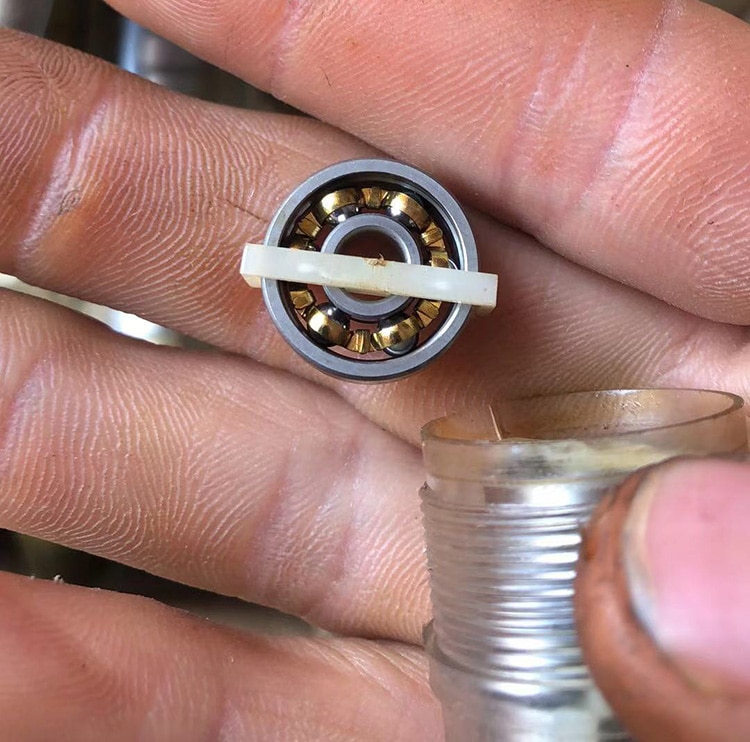

The inner groove of E series magneto bearings is a little shallower than that of deep groove bearings. Since the outer ring has a shoulder on only one side, the outer ring may be removed. This is often advantageous for mounting.

Highly suited to applications involving low loads and high speeds, the internal design of magneto bearings is essentially similar to that of single row deep groove ball bearings. however, the outer ring is counter-bore with a groove track that merges into the cylindrical track, making it easy to separate the two components.

This means the outer ring of a magneto bearing can be fitted separately from the inner ring and cage. As a result, magneto

bearings are significantly easier to mount, fit or remove than standard deep groove ball bearings.

The most common application makes use of two such bearings in a duplex pair. These bearings are adjusted against one another, leaving a small amount of end play. Magneto bearings are typically small, with a bore diameter of between 4mm and 30mm. They are found in a range of applications, including gyroscopes and small magnetos. They can also be used as support bearings at the end of ball-screws on worktables for small milling machines and in generators and starter motors.

To select the best possible bearing for a particular job, a number of factors need to be considered. These include the load

capacity, allowable bearing space and permissible speed. The type of bearing may also depend on the specific bearing arrangement that has been selected for the project.

Model |

Boundary Dimensions(mm) |

Basic Load Ratings(kgf) |

Limiting Speeds(rpm) |

Mass(kg) |

|||||||||

E series |

EN Series |

d |

D |

B.T |

Dynamic |

Static |

Grease |

Oil |

|||||

EN4 |

4 |

16 |

5 |

122 |

24 |

34000 |

40000 |

0.005 |

|||||

E5 |

EN5 |

5 |

16 |

5 |

122 |

24 |

34000 |

40000 |

0.005 |

||||

E6 |

EN6 |

6 |

21 |

7 |

224 |

40 |

30000 |

36000 |

0.011 |

||||

E7 |

EN7 |

7 |

22 |

7 |

254 |

40 |

28000 |

34000 |

0.012 |

||||

708 |

8 |

22 |

7 |

255 |

54 |

28000 |

34000 |

0.014 |

|||||

E8 |

EN8 |

8 |

24 |

7 |

255 |

54 |

28000 |

34000 |

0.014 |

||||

6028 |

8 |

24 |

8 |

255 |

54 |

28000 |

34000 |

0.014 |

|||||

E9 |

EN9 |

9 |

28 |

8 |

335 |

73 |

24000 |

30000 |

0.022 |

||||

E10 |

EN10 |

10 |

28 |

8 |

335 |

73 |

24000 |

30000 |

0.021 |

||||

E11 |

EN11 |

11 |

32 |

7 |

270 |

75 |

22000 |

28000 |

0.027 |

||||

E12 |

EN12 |

12 |

32 |

7 |

270 |

75 |

22000 |

28000 |

0.027 |

||||

E13 |

EN13 |

13 |

30 |

7 |

270 |

75 |

22000 |

26000 |

0.021 |

||||

E14 |

EN14 |

14 |

35 |

8 |

450 |

110 |

19000 |

24000 |

0.034 |

||||

7202 |

15 |

35 |

11 |

355 |

102 |

19000 |

24000 |

0.045 |

|||||

E15 |

EN15 |

15 |

35 |

8 |

355 |

102 |

19000 |

24000 |

0.033 |

||||

N3048 |

- |

15 |

37 |

8 |

355 |

102 |

19000 |

24000 |

0.033 |

||||

BO15 |

- |

15 |

40 |

10 |

570 |

153 |

14000 |

18000 |

0.055 |

||||

E16 |

EN16 |

16 |

38 |

10 |

705 |

127 |

16000 |

20000 |

0.048 |

||||

L17 |

- |

17 |

40 |

10 |

450 |

134 |

14000 |

18000 |

0.053 |

||||

E17 |

EN17 |

17 |

44 |

11 |

440 |

134 |

14000 |

18000 |

0.078 |

||||

BO17 |

- |

17 |

44 |

11 |

750 |

138 |

14000 |

18000 |

0.073 |

||||

M17 |

- |

17 |

44 |

10 |

750 |

138 |

14000 |

18000 |

0.073 |

||||

E18 |

EN18 |

18 |

40 |

9 |

270 |

95 |

16000 |

20000 |

0.05 |

||||

E19 |

EN19 |

19 |

40 |

9 |

270 |

95 |

16000 |

20000 |

0.048 |

||||

E20 |

EN20 |

20 |

47 |

12 |

580 |

224 |

14000 |

17000 |

0.087 |

||||

L20 |

- |

20 |

47 |

14 |

580 |

224 |

14000 |

17000 |

0.1 |

||||

M20 |

- |

20 |

52 |

15 |

965 |

270 |

13000 |

16000 |

0.138 |

||||

L25 |

- |

25 |

52 |

15 |

565 |

240 |

12000 |

15000 |

0.122 |

||||

M25 |

- |

25 |

62 |

17 |

1250 |

375 |

11000 |

14000 |

0.217 |

||||

L30 |

- |

30 |

62 |

16 |

630 |

228 |

8000 |

11000 |

0.25 |

||||

M30 |

- |

30 |

72 |

19 |

630 |

228 |

8000 |

11000 |

0.4 |

||||

No.1 We are large entity company.

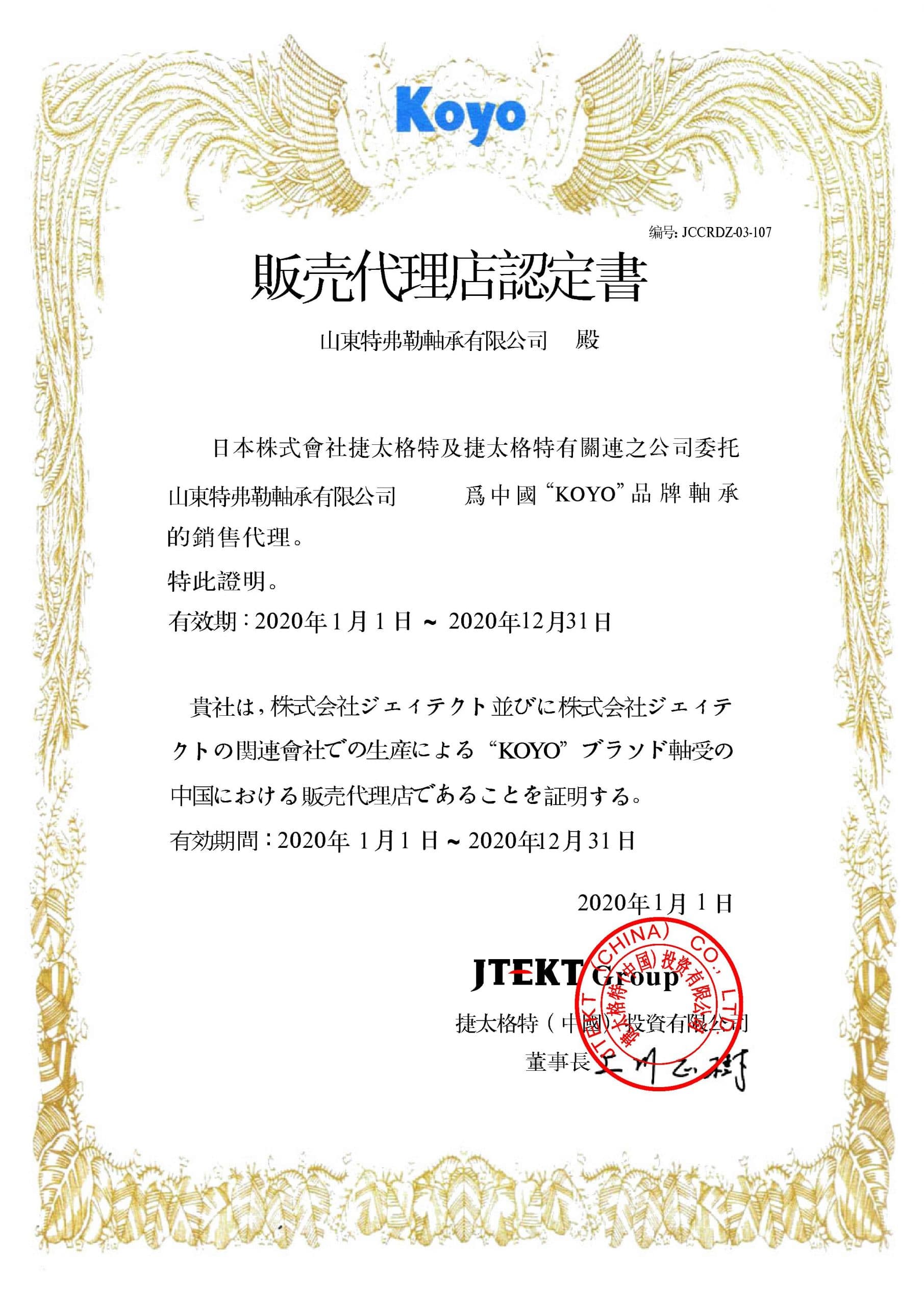

No.2 International quality system certification

Shandong Tefule Bearing Co., Ltd. won the ISO9001-2015 quality management system certificate issued by the authoritative third-party certification company SGS certification body in 2015, and became a company in China that has obtained this authoritative certification.

A: Tube packing+carton+pallets

B: single box packing+carton+pallets

C:as customer's requirement

Shandong Tefule Bearing Co.,Ltd

is a professional bearing manufacturer and dealer in china.We have been engaged in bearing industry for 10 years and made international trade of bearing import and export for more than 8 years.

Our company is specialized in ball bearing,roller bearing,housing units, wheel hub bearing,bearing parts and accessories, cross roller bearing.Also we can customize various large non-standard products such as the most competitive products according to customers' demands.

1. who are we?

We are based in Shandong, China,sell to Mid East(30.00%),South Asia(20.00%),Northern Europe(15.00%),Africa(15.00%),Southeast Asia(10.00%),Western Europe(10.00%),North America(10.00%).

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Ball Bearing,Roller Bearing,Wheel Bearing,Linear Bearing,Pillow Block Bearing

4. why should you buy from us not from other suppliers?

Our company has gained rich experience: we know how to exactly handle every step of production.

Our products possess the advantages of competitive price and good service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese

The inner groove of E series magneto bearings is a little shallower than that of deep groove bearings. Since the outer ring has a shoulder on only one side, the outer ring may be removed. This is often advantageous for mounting.

Highly suited to applications involving low loads and high speeds, the internal design of magneto bearings is essentially similar to that of single row deep groove ball bearings. however, the outer ring is counter-bore with a groove track that merges into the cylindrical track, making it easy to separate the two components.

This means the outer ring of a magneto bearing can be fitted separately from the inner ring and cage. As a result, magneto

bearings are significantly easier to mount, fit or remove than standard deep groove ball bearings.

The most common application makes use of two such bearings in a duplex pair. These bearings are adjusted against one another, leaving a small amount of end play. Magneto bearings are typically small, with a bore diameter of between 4mm and 30mm. They are found in a range of applications, including gyroscopes and small magnetos. They can also be used as support bearings at the end of ball-screws on worktables for small milling machines and in generators and starter motors.

To select the best possible bearing for a particular job, a number of factors need to be considered. These include the load

capacity, allowable bearing space and permissible speed. The type of bearing may also depend on the specific bearing arrangement that has been selected for the project.

The inner groove of E series magneto bearings is a little shallower than that of deep groove bearings. Since the outer ring has a shoulder on only one side, the outer ring may be removed. This is often advantageous for mounting.

Highly suited to applications involving low loads and high speeds, the internal design of magneto bearings is essentially similar to that of single row deep groove ball bearings. however, the outer ring is counter-bore with a groove track that merges into the cylindrical track, making it easy to separate the two components.

This means the outer ring of a magneto bearing can be fitted separately from the inner ring and cage. As a result, magneto

bearings are significantly easier to mount, fit or remove than standard deep groove ball bearings.

The most common application makes use of two such bearings in a duplex pair. These bearings are adjusted against one another, leaving a small amount of end play. Magneto bearings are typically small, with a bore diameter of between 4mm and 30mm. They are found in a range of applications, including gyroscopes and small magnetos. They can also be used as support bearings at the end of ball-screws on worktables for small milling machines and in generators and starter motors.

To select the best possible bearing for a particular job, a number of factors need to be considered. These include the load

capacity, allowable bearing space and permissible speed. The type of bearing may also depend on the specific bearing arrangement that has been selected for the project.

The inner groove of E series magneto bearings is a little shallower than that of deep groove bearings. Since the outer ring has a shoulder on only one side, the outer ring may be removed. This is often advantageous for mounting.

Highly suited to applications involving low loads and high speeds, the internal design of magneto bearings is essentially similar to that of single row deep groove ball bearings. however, the outer ring is counter-bore with a groove track that merges into the cylindrical track, making it easy to separate the two components.

This means the outer ring of a magneto bearing can be fitted separately from the inner ring and cage. As a result, magneto

bearings are significantly easier to mount, fit or remove than standard deep groove ball bearings.

The most common application makes use of two such bearings in a duplex pair. These bearings are adjusted against one another, leaving a small amount of end play. Magneto bearings are typically small, with a bore diameter of between 4mm and 30mm. They are found in a range of applications, including gyroscopes and small magnetos. They can also be used as support bearings at the end of ball-screws on worktables for small milling machines and in generators and starter motors.

To select the best possible bearing for a particular job, a number of factors need to be considered. These include the load

capacity, allowable bearing space and permissible speed. The type of bearing may also depend on the specific bearing arrangement that has been selected for the project.