With high temperature resistance, cold resistance, wear resistance, corrosion resistance, magnetic electrical insulation resistance, oilless self-lubrication, high speed, etc.properties. Ceramic bearing is a hi-tech product using new materials that can be used in extreme environments and special condition, and can be widely used in aviation,

aerospace, shipbuilding, petroleum, chemical industry, automobile, electronics, metallurgy, electric power, textile,medical equipment, pumps, scientific research and national defense military and other fields. The ring and roller of our ceramic bearing adopts full ceramic materials including zirconia (ZrO2), silicon nitride(Si₃N₄),silicon carbide(SiC), aluminum oxide(Al₂O₃). The cage are made of plastic material: PTEE, PEEK, UPE, PVDF, PA66, SUS304, SUS316, which extends the application of ceramic bearing, high temperature resistant, corrosion resistant, anti magnetic bearings, bearing, electrical insulation bearing, etc.

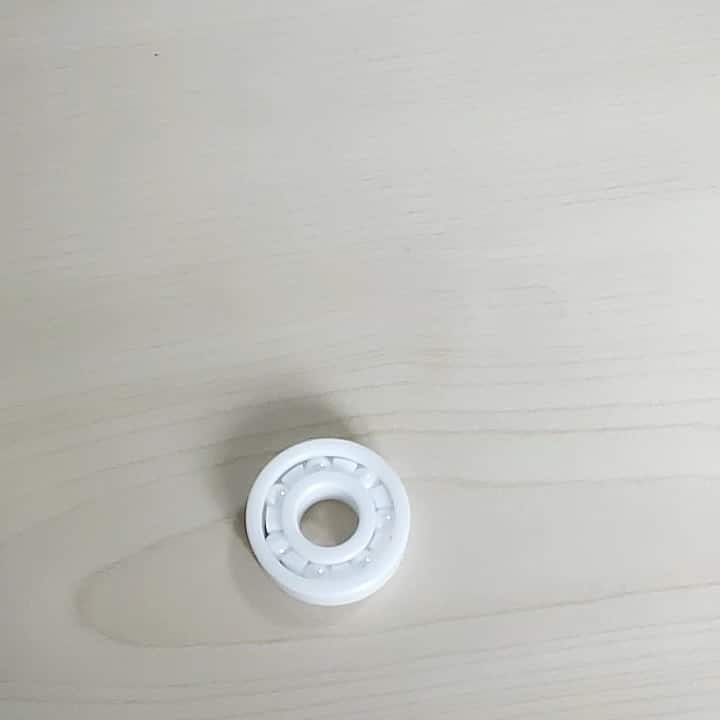

self lubricating zro2 ceramic ball bearing r8 r10 r12 r14 r16 2rs for industry

Key attributes

Industry-specific attributes

Applicable Industries

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Other attributes

Place of Origin

Shandong, China

Precision Rating

PO P5 P2 P4 P5 P6

Type

CERAMIC BALL

Brand Name

customized

Model Number

r8 r10 r12 r14 r16 2rs

COLOR

White

Application

SEMICONDUCTOR EQUIPMENT, FOOD MACHINERY, LCD EQUIPMENT

CAGE MATERIAL

PEEK, PTEE, PFA, PP, PET, NO CAGE

BEARING

r8 r10 r12 r14 r16 2rs

RING Material

Zro2 / si3n4 Ceramic

Product name

zro2 ceramic ball bearing r8 r10 r12 r14 r16 2rs for industry

Lubrication

Self-lubricating

Advantage

High temperature and corrosion resistant, Anti oxidation

Balls Material

zro2 Si3N4 Ceramic

OEM Service

Custom Bearing’s Size Logo Packing

Best Solutions for Special Working Conditions such as:

vacuum, corrosion, clean, high temperature, non-magnetism, insulation, and dust, etc.

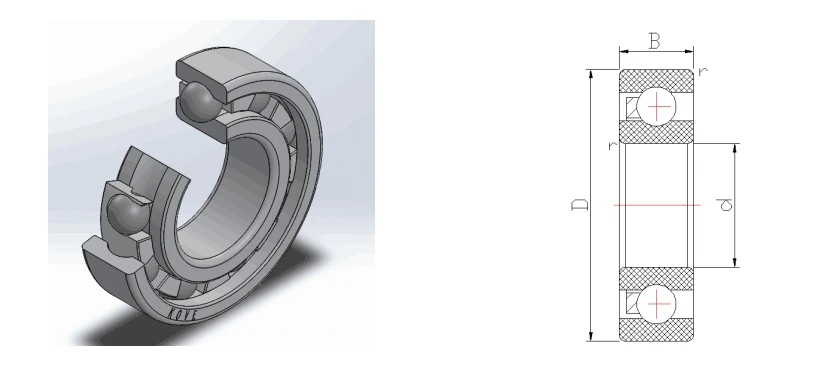

Full Ceramic bearing range introduction.