Thin Wall LIN0230 30x34x50mm Compact plastic linear bearing for printing machinery

Key attributes

Industry-specific attributes

Applicable Industries

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Construction works , Energy & Mining

Precision Rating

P0 P6 P2 P5 P4

Other attributes

Place of Origin

Shandong, China

Type

LINEAR

Brand Name

TFL

Model Number

LIN0230

Package

Standard

Market:

Global

Service

OEM Customized Services

Stock

Rich Stocks

Samples

Offerd

Certification

ISO9001:2008

Application

Engineering Machinery

Size

16x18x29mm

Feature

High Speed Low Noise

Precision Rating

High Priecision

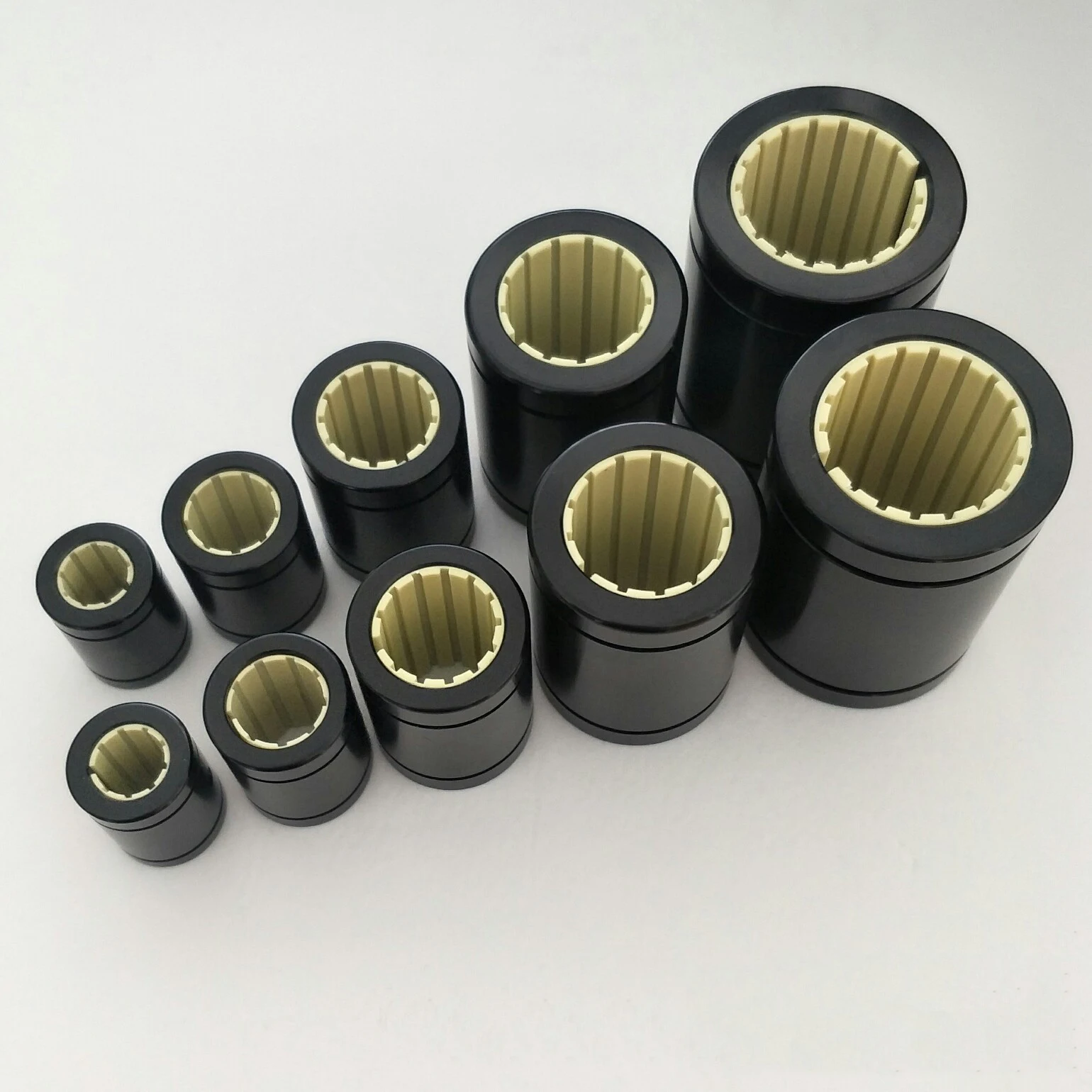

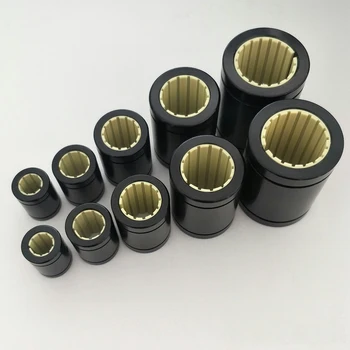

Thin Wall LIN0230 30x34x50mm Compact plastic linear bushing for printing machinery

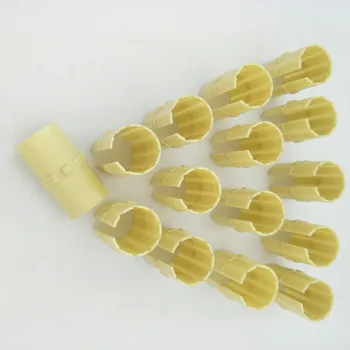

Plastic linear bearing is a kind of linear motion system with self-lubricating characteristics. The biggest difference between it and metal linear bearing is that metal linear bearing is rolling friction, and there is point contact between the bearing and the cylindrical shaft, so this kind of low-load high-speed motion; and plastic linear bearing Linear bearings are sliding friction, and there is surface contact between the bearing and the cylindrical shaft, so this type is suitable for high-load, medium-low speed motion. There are no special requirements for the shaft of the plastic linear bearing bearing; it can bear a greater load than the metal bearing, but because the movement between the bearing and the shaft is sliding friction, the movement speed of the plastic linear bearing is limited to a certain extent; the movement resistance is lower than that of the metal linear bearing. The bearing is larger; but its motion noise is lower than that of metal linear bearings, especially in the case of medium and high speeds, and the noise of plastic linear bearings has very little influence with speed. Plastic linear bearings are allowed to be used in places with a lot of dust due to the design of chip removal grooves inside. The dust is automatically taken out of the friction surface of the bearing body from the chip removal grooves during movement; Clean, the internal sliding membrane made of special materials can even be used for long-term operation in liquids.

|

Model

|

d(mm)

|

D(mm)

|

B(mm)

|

r(mm)

|

t(mm)

|

|

LIN-02-10

|

10

|

12

|

26

|

3.0

|

1.0

|

|

LIN-02-12

|

12

|

14

|

28

|

3.0

|

1.0

|

|

LIN-02-16

|

16

|

18

|

30

|

3.5

|

1.0

|

|

LIN-02-20

|

20

|

23

|

30

|

5.0

|

1.0

|

|

LIN-02-25

|

25

|

28

|

40

|

5.0

|

1.0

|

|

LIN-02-30

|

30

|

34

|

50

|

5.0

|

1.0

|

|

LIN-02-40

|

40

|

44

|

60

|

6.0

|

1.5

|

|

LIN-02-50

|

50

|

55

|

70

|

7.0

|

1.5

|