High precision 6313M/C3VL0271 6313M/C3J20C 65x140x33mm electric insulated bearing for Hydrogenerator

Key attributes

Industry-specific attributes

Applicable Industries

Building Material Shops, Machinery Repair Shops, Retail, Energy & Mining, Other

Bore Size

64.99 – 65 mm

Precision Rating

P5 P6 P2 P0 P4 P3

Number of Row

Single row

Other attributes

Place of Origin

China

Type

BALL

Structure

Deep Groove

Model Number

6313M/C3VL0271

Seals Type

open 2RS ZZ

OEM Service

Custom Bearing’s Size Logo Packing

Feature

insulation

Brand

OEM Famous Brand

Product name

insulated bearing

Material

Chrome Steel GCR15

Application

Electric Motors

Model

6022M/C3VL0241

Certificate

ISO 9001:2000

Keywords

ceramic-coated

Sample

Avialable

High precision 6313M/C3VL0271 6313M/C3J20C 65x140x33mm electric insulated bearing for Hydrogenerator

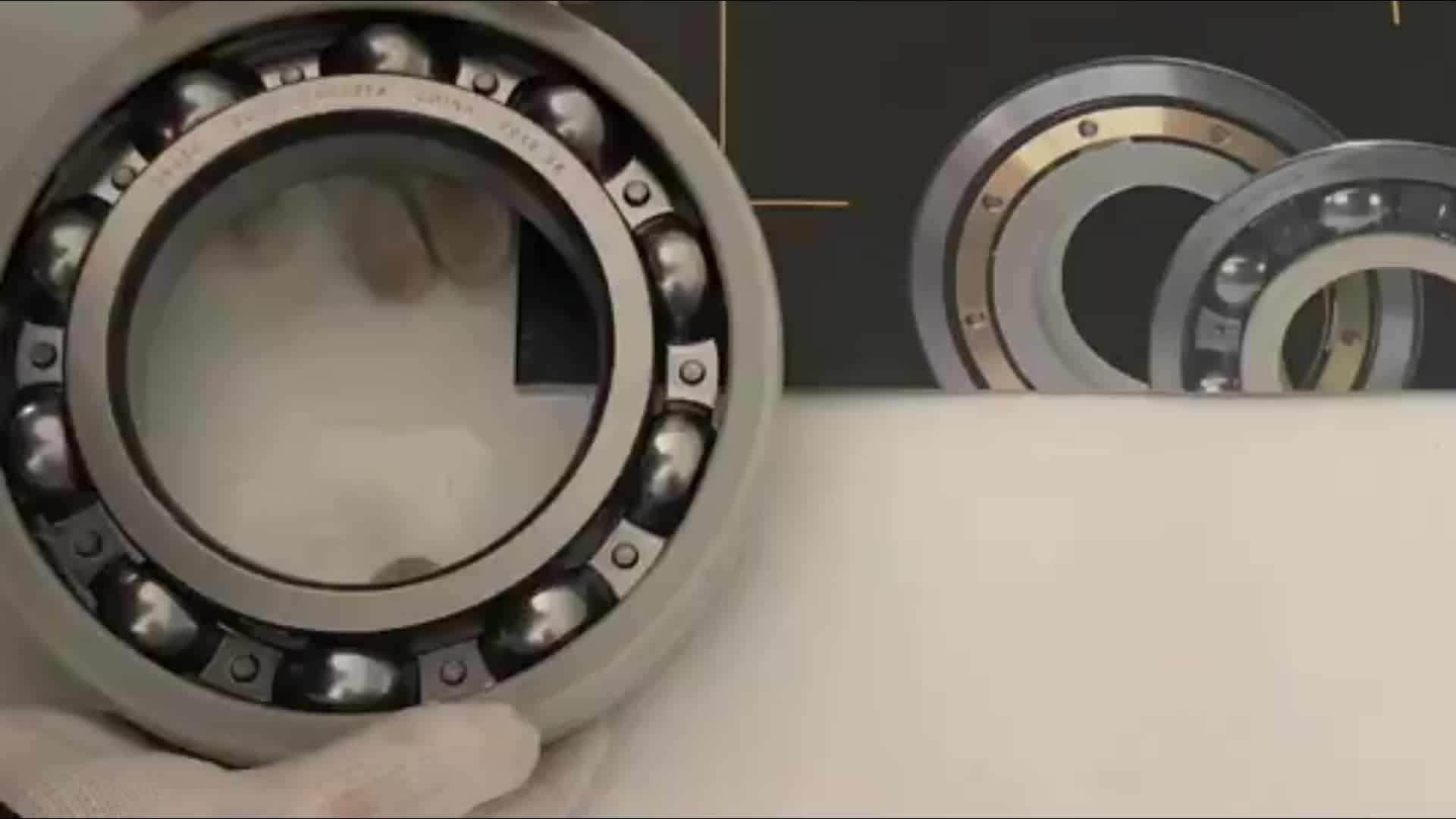

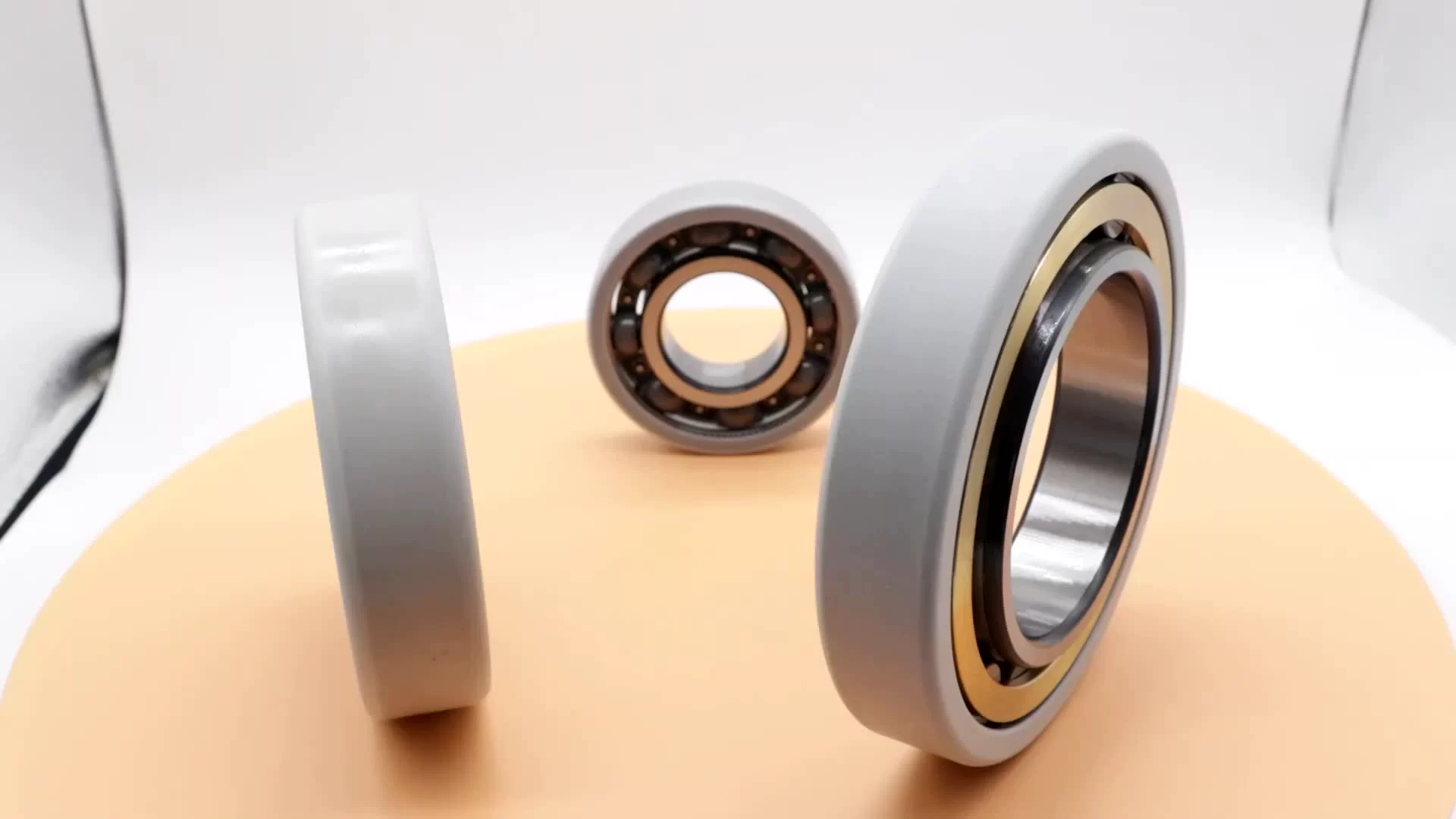

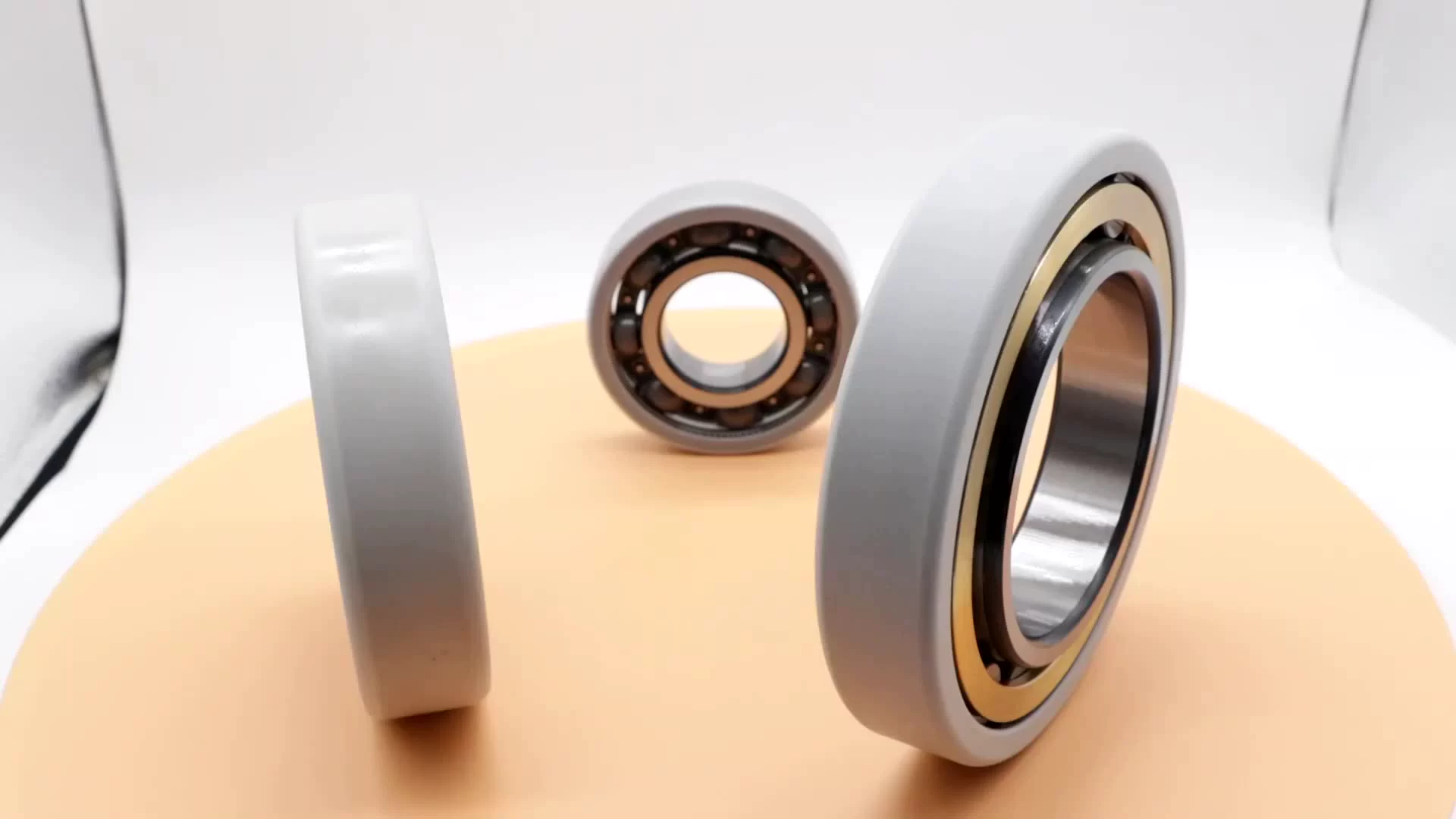

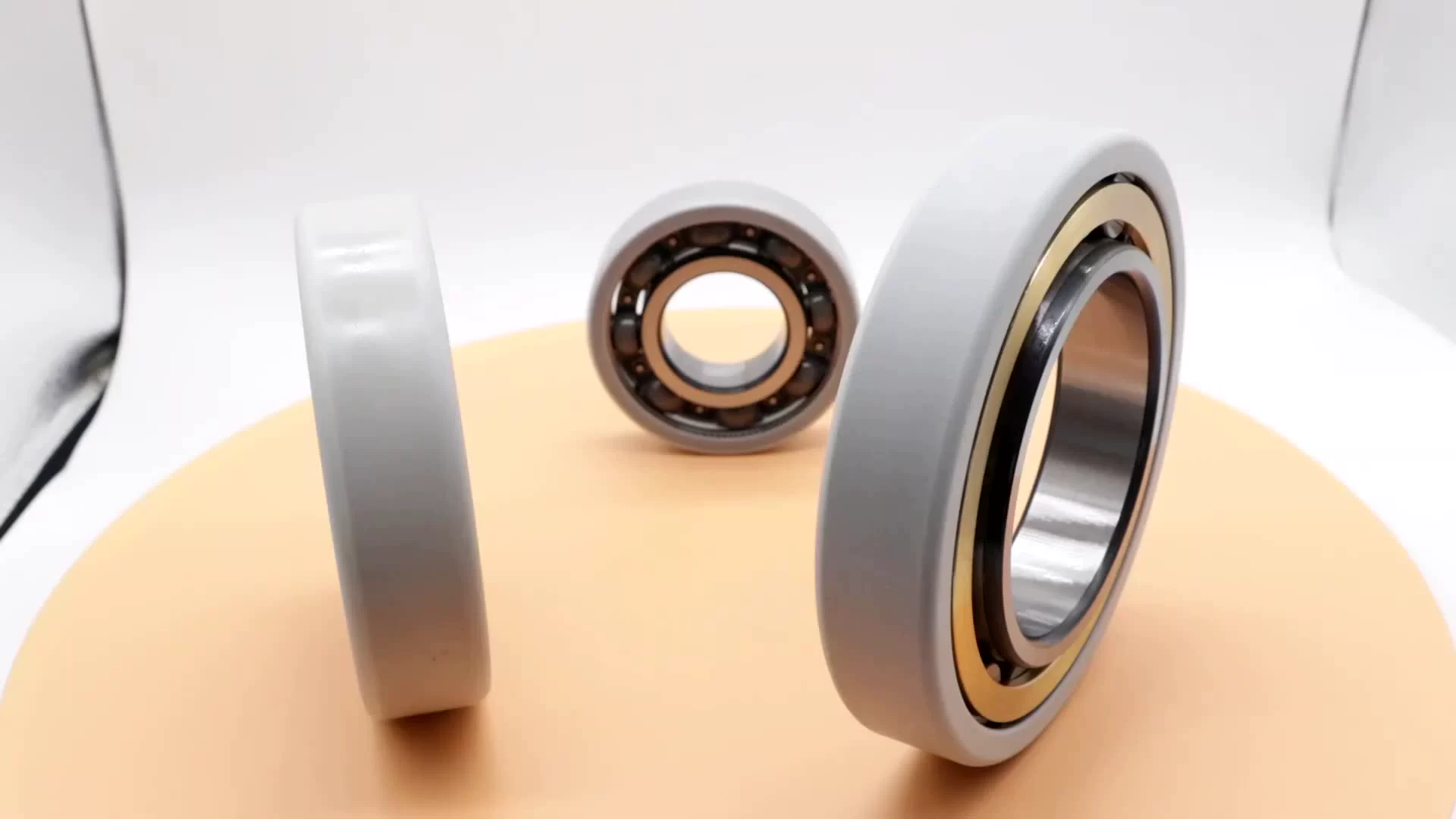

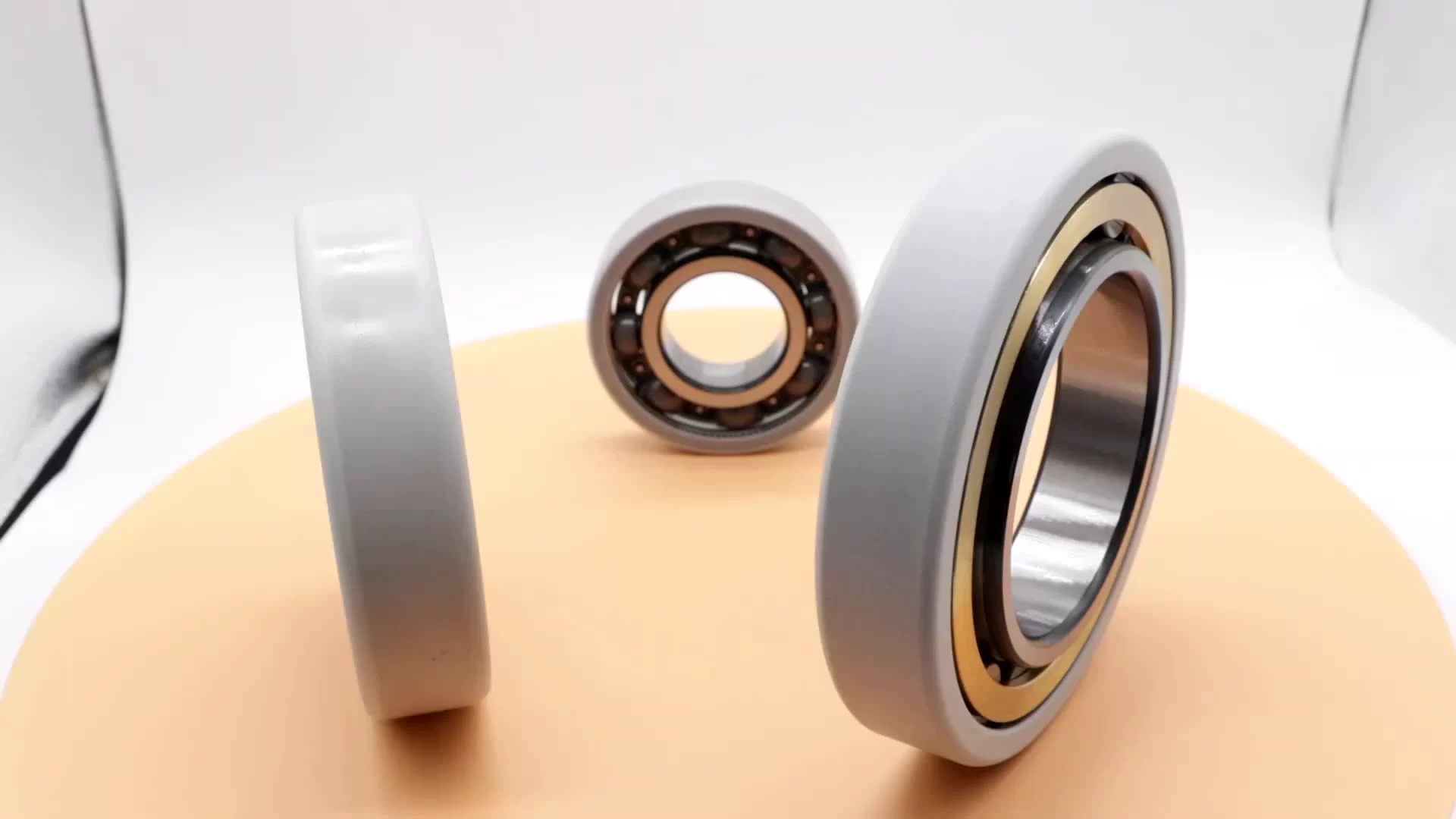

What are insulated bearings?

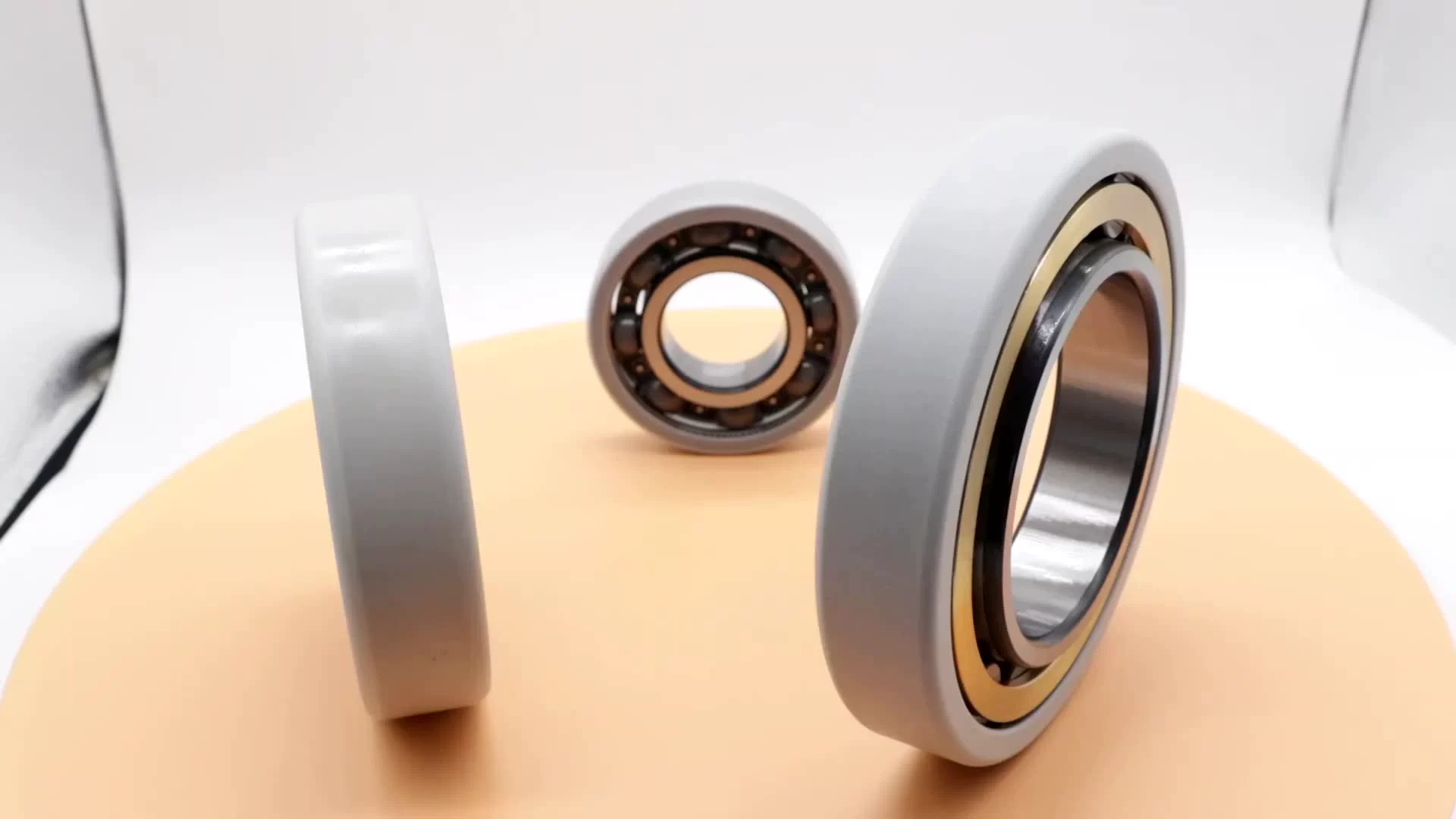

The so-called insulating bearing refers to the general term for bearings that can block the current passing through the bearing itself and have insulating properties. Its insulation performance is usually ensured by coating a layer of insulating material on the outer or inner ring of the bearing using a special process, or the rolling elements are made of ceramics.

Under what circumstances should insulated bearings be used?

Even if the production of the motor is strictly controlled during the manufacturing process, it is difficult to completely avoid the magnetic asymmetry of the armature and the rotor. This asymmetry will generate a voltage between the stator, which will generate a current passing through the bearings, especially in AC motors. In severe cases, this current will cause corrosion pits, melt marks, electric corrosion filings, discoloration, damage and other damage on the surface of the bearing raceway and rolling elements. Of course, motors using inverter and frequency conversion technology will also produce this phenomenon. In order to block this current from flowing through the bearing, it is necessary to cut off its circuit, so insulated bearings and insulated bearing chambers came into being. The insulated bearing chamber is made of insulating material with a certain hardness in the bore and end face of the bearing chamber.

The so-called insulating bearing refers to the general term for bearings that can block the current passing through the bearing itself and have insulating properties. Its insulation performance is usually ensured by coating a layer of insulating material on the outer or inner ring of the bearing using a special process, or the rolling elements are made of ceramics.

Under what circumstances should insulated bearings be used?

Even if the production of the motor is strictly controlled during the manufacturing process, it is difficult to completely avoid the magnetic asymmetry of the armature and the rotor. This asymmetry will generate a voltage between the stator, which will generate a current passing through the bearings, especially in AC motors. In severe cases, this current will cause corrosion pits, melt marks, electric corrosion filings, discoloration, damage and other damage on the surface of the bearing raceway and rolling elements. Of course, motors using inverter and frequency conversion technology will also produce this phenomenon. In order to block this current from flowing through the bearing, it is necessary to cut off its circuit, so insulated bearings and insulated bearing chambers came into being. The insulated bearing chamber is made of insulating material with a certain hardness in the bore and end face of the bearing chamber.

|

Model

|

Cage

|

Cr(KN)

|

Cor (KN)

|

Grease lubrication speed

|

Oil lubricated speed

|

Weight (kg)

|

Insulation class

|

||

|

6313/C3VL0271

|

Steel

|

97.5

|

60

|

10000

|

6700

|

2.05

|

2000V

|

3000V

|

|

|

6313M/C3VL0271

|

Brass

|

97.5

|

60

|

10000

|

6700

|

4.83

|

2000V

|

3000V

|

|