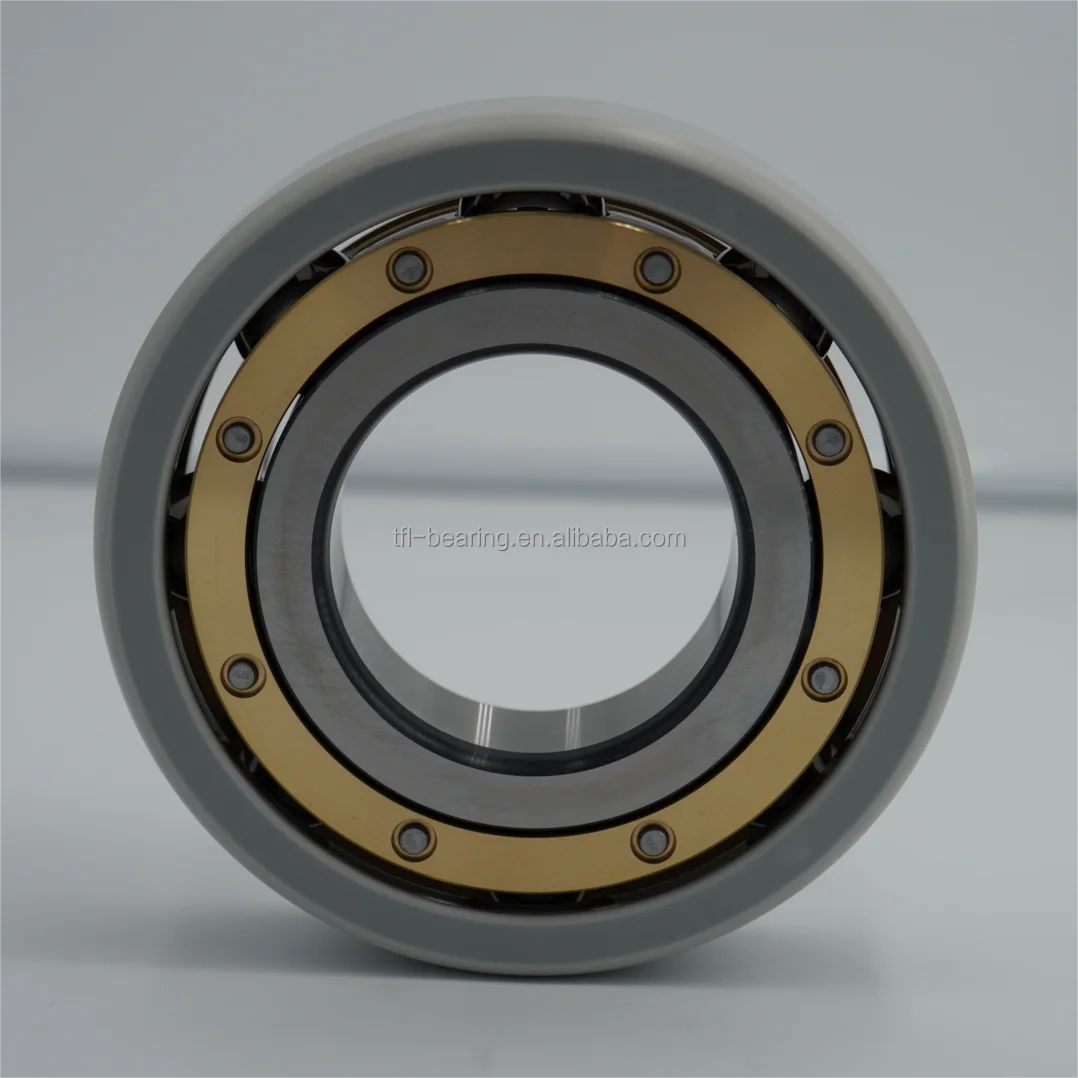

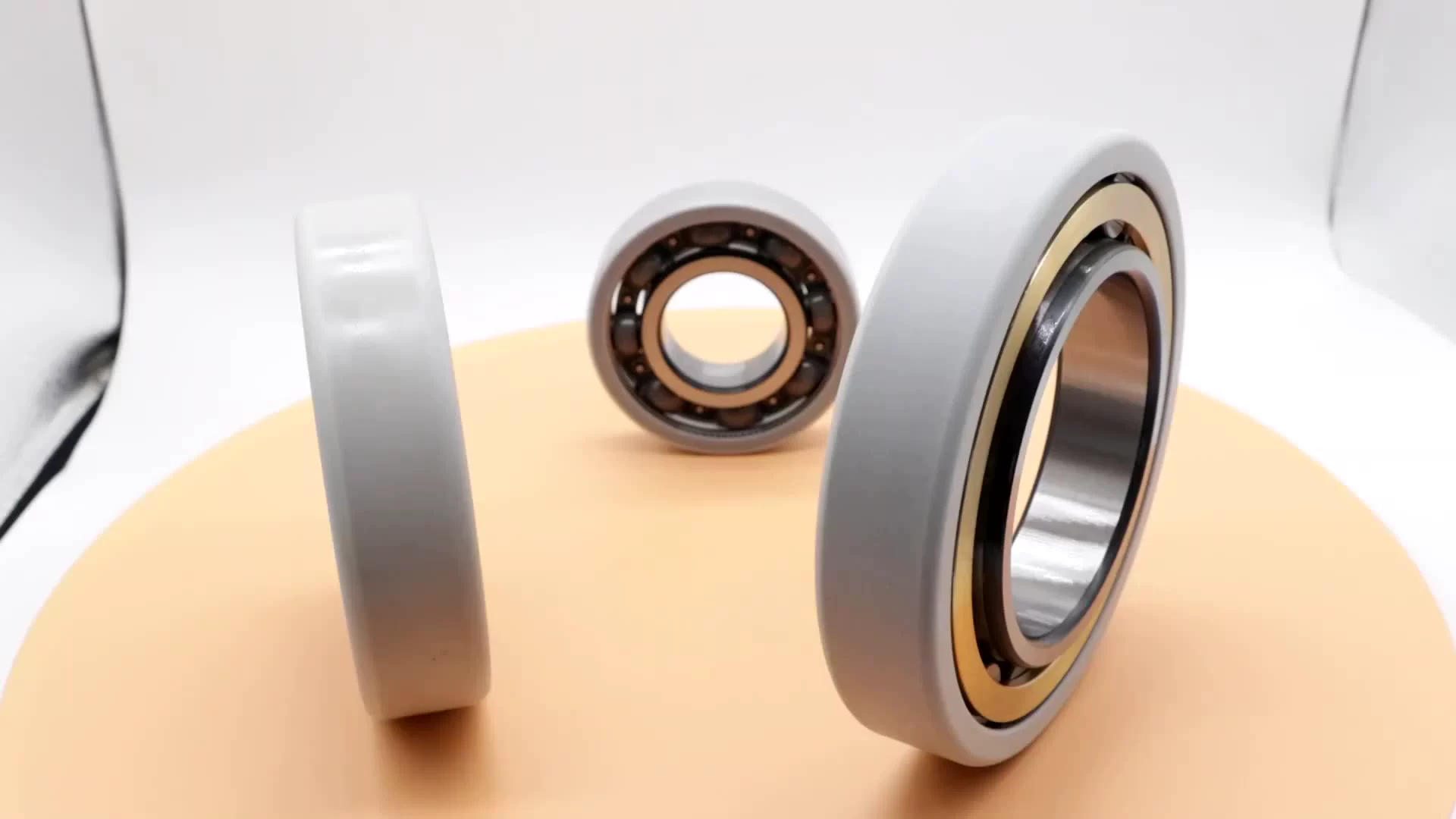

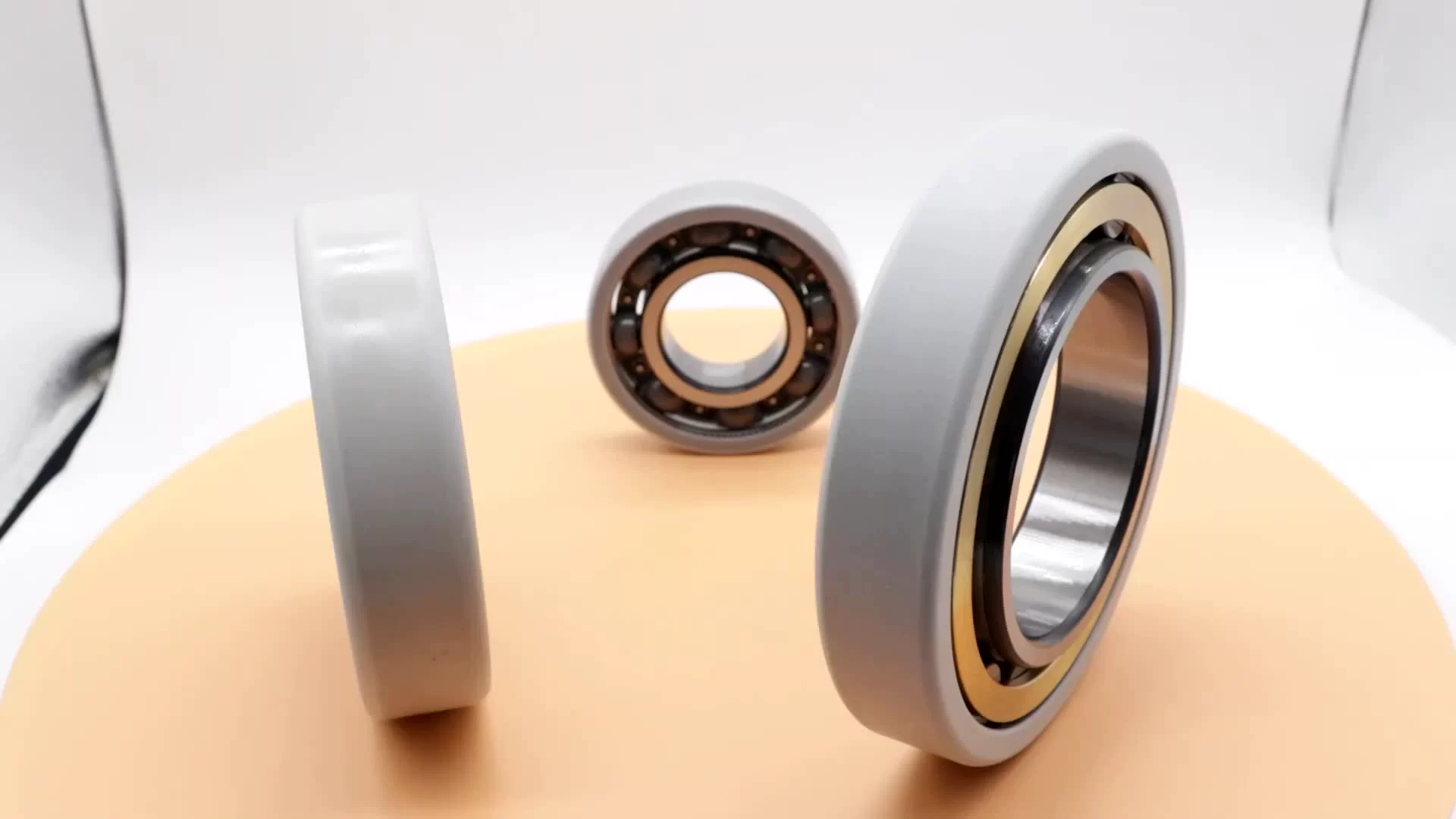

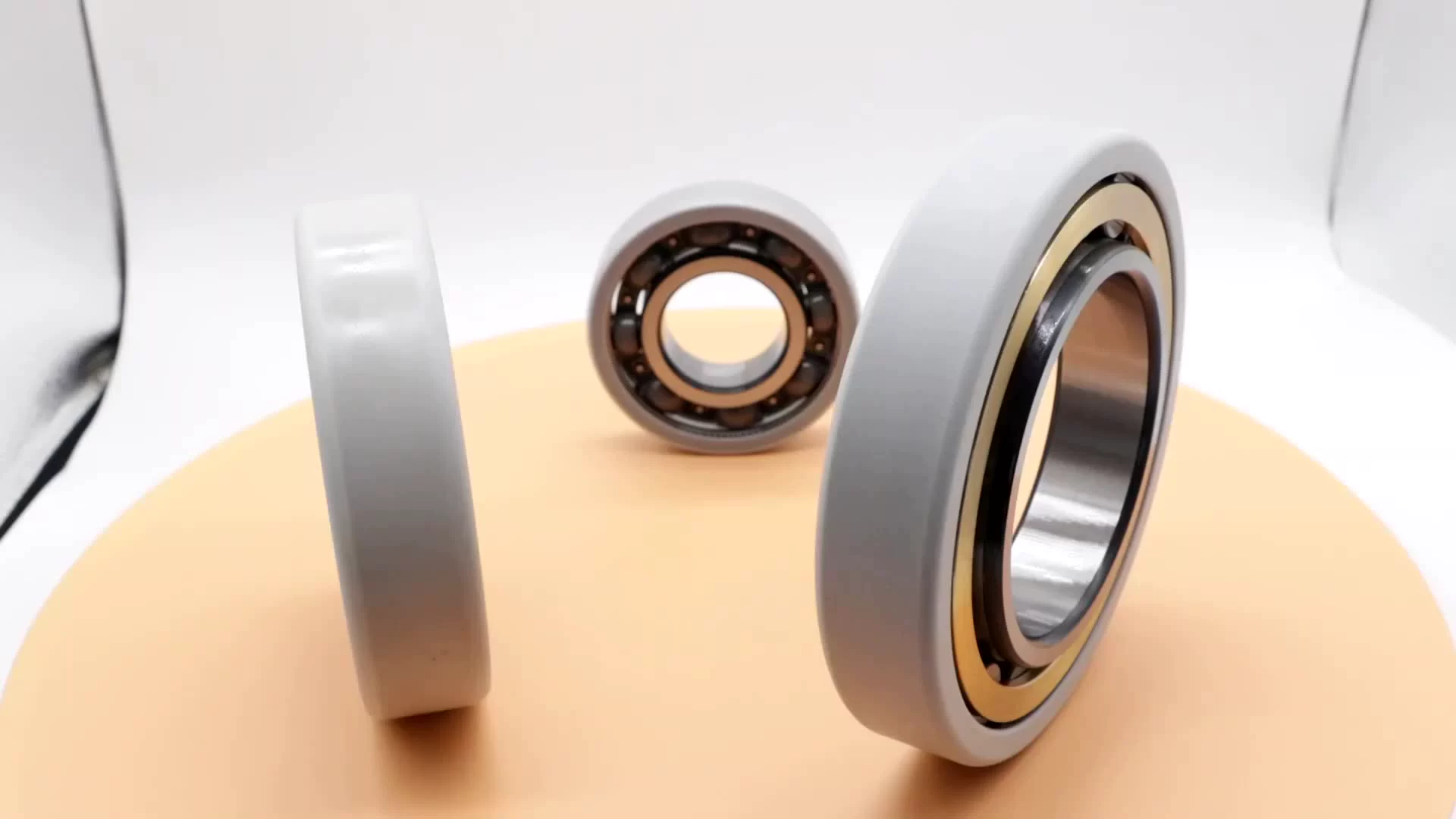

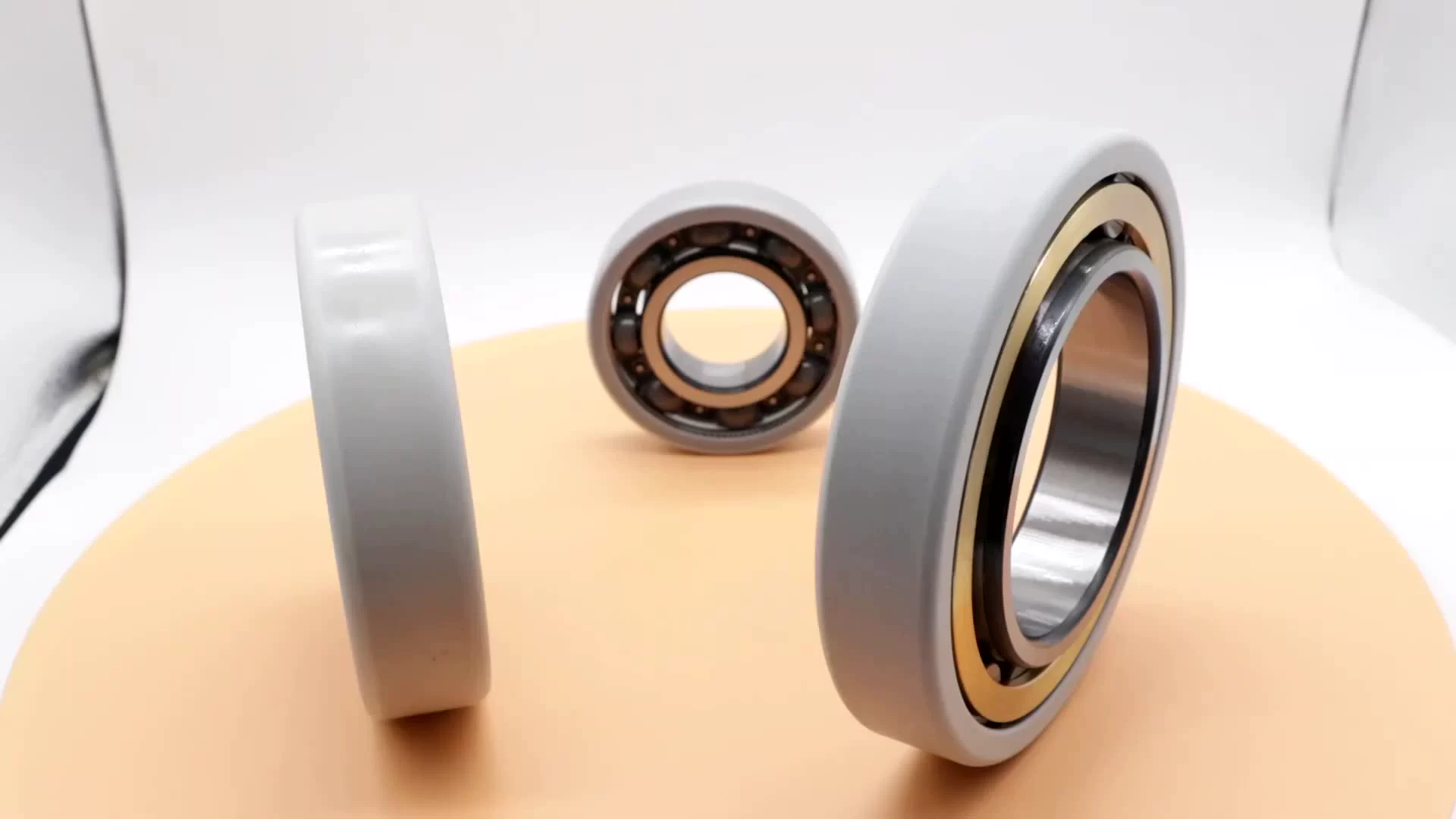

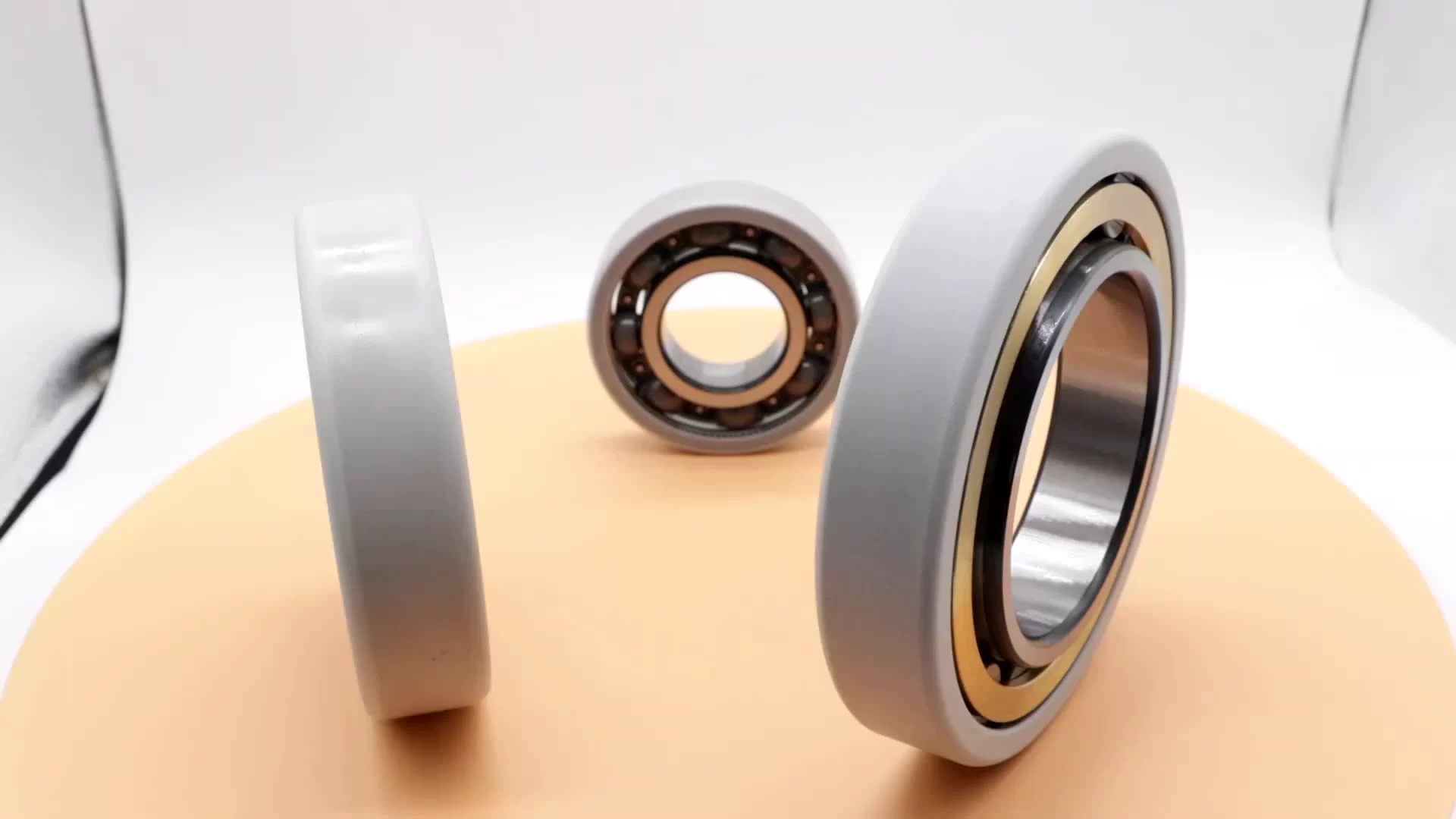

6028M/C3VL0241 6028M/C3J20AA 140x210x33mm outer ring electric insulated bearing for electricity generator

Key attributes

Industry-specific attributes

Applicable Industries

Building Material Shops, Machinery Repair Shops, Retail, Energy & Mining, Other

Bore Size

139.99 - 140 mm

Precision Rating

P5 P6 P2 P0 P4 P3

Number of Row

Single row

Other attributes

Place of Origin

China

Type

BALL

Structure

Deep Groove

Model Number

6028M/C3VL0241

Seals Type

open 2RS ZZ

OEM Service

Custom Bearing's Size Logo Packing

Feature

insulation

Brand

OEM Famous Brand

Product name

insulated bearing

Material

Chrome Steel GCR15

Application

Electric Motors

Model

6320M/C3VL0271

Certificate

ISO 9001:2000

Keywords

ceramic-coated

Sample

Avialable

6028M/C3VL0241 6028M/C3J20AA 140x210x33mm outer ring electric insulated bearing for electricity generator

Insulated bearings are an important member of the bearing industry and are of interest because of their good insulating

properties. When selecting and using insulated bearings, several aspects need to be considered.

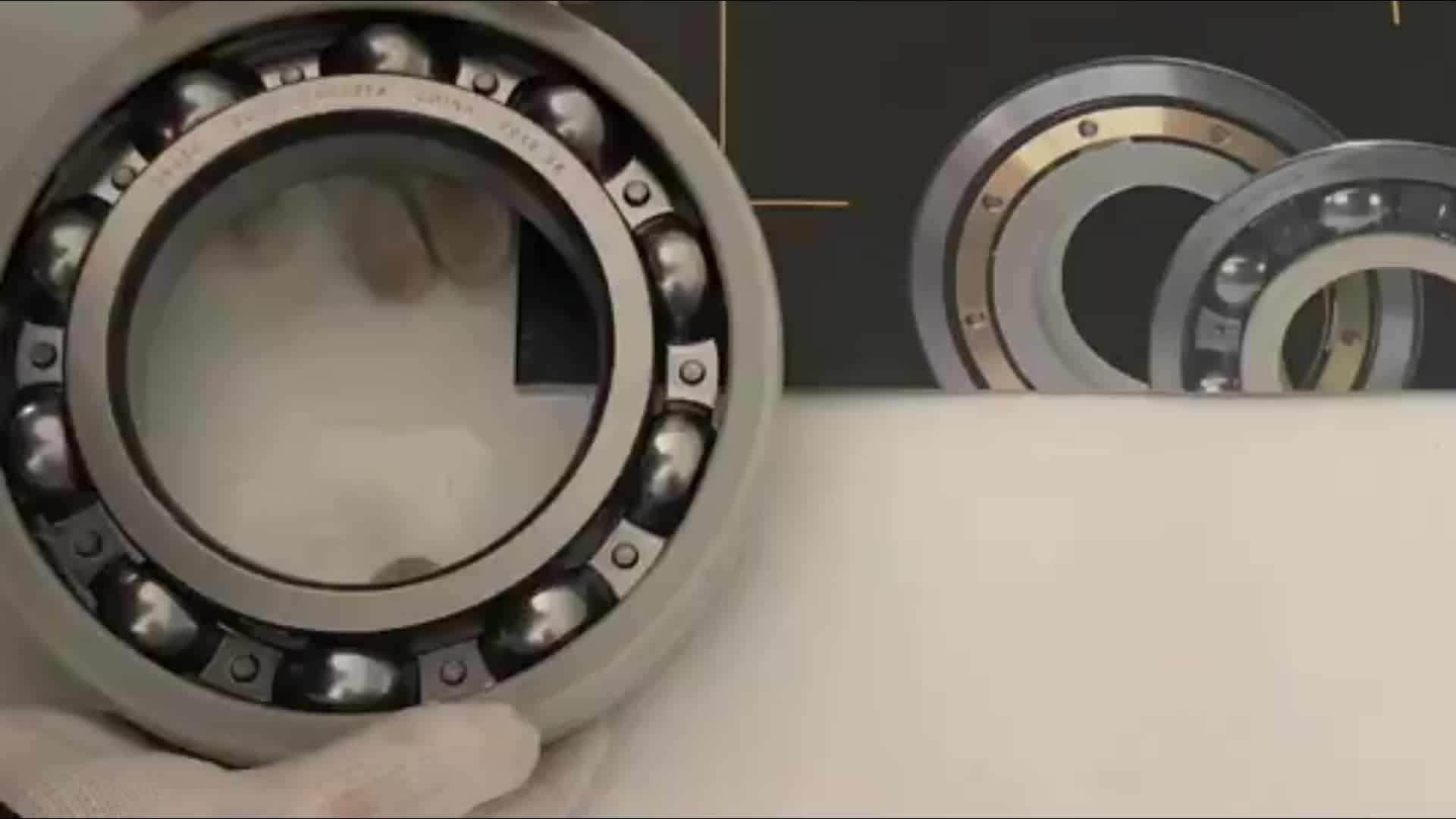

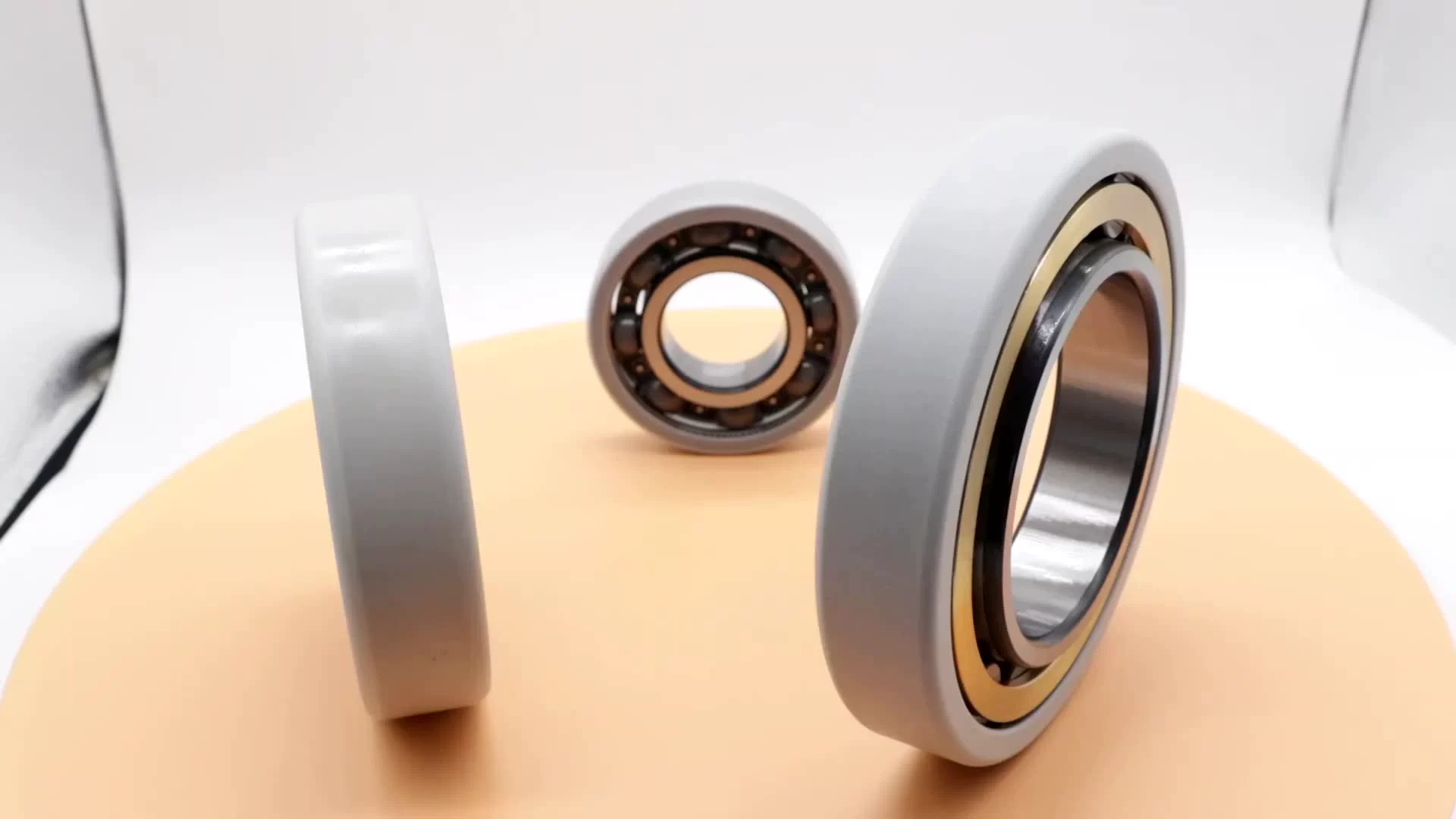

First of all, from the perspective of product structure, insulated bearings are generally composed of housing and bearing, and the housing is mostly made of engineering plastics with good insulating properties. The bearing is divided into two parts, the shaft and sleeve, the shaft is metal material, and the sleeve is made of insulating material. This structure allows sufficient friction between the shaft and sleeve while maintaining stability during relative motion.

When selecting insulated bearings, the following aspects need to be considered:

1. Insulation performance is one of the most important features of insulated bearings. When choosing, you need to pay attention

to its insulation resistance, voltage resistance and other parameters.

2. The size and precision of different application scenarios require different sizes and precision of insulated bearings.

Therefore, the selection needs to be made according to the actual needs.

3. The bearing capacity and life, which is also an important factor to consider when choosing insulated bearings.

Compared with other types of bearings, insulated bearings have the following advantages:

1. They have excellent insulating properties, which can ensure the normal operation of motors and other equipment.

2. They have a low coefficient of friction, smooth running and long bearing life.

3. They have good high-temperature resistance and can be used in harsh environments.

Insulated bearings are mainly used in various motors, electrical appliances, chemical equipment, medical equipment and other occasions. In these use scenarios, due to the excellent performance performance of the insulated bearings, the efficiency and stability of the equipment can be effectively improved and the service life of the equipment can be extended.

In short, when choosing and using insulated bearings, it is necessary to analyze them from multiple perspectives, such as product structure, product selection, product advantages, and usage scenarios. Only after a comprehensive understanding of the characteristics and application scope of the product can it better play its role.

properties. When selecting and using insulated bearings, several aspects need to be considered.

First of all, from the perspective of product structure, insulated bearings are generally composed of housing and bearing, and the housing is mostly made of engineering plastics with good insulating properties. The bearing is divided into two parts, the shaft and sleeve, the shaft is metal material, and the sleeve is made of insulating material. This structure allows sufficient friction between the shaft and sleeve while maintaining stability during relative motion.

When selecting insulated bearings, the following aspects need to be considered:

1. Insulation performance is one of the most important features of insulated bearings. When choosing, you need to pay attention

to its insulation resistance, voltage resistance and other parameters.

2. The size and precision of different application scenarios require different sizes and precision of insulated bearings.

Therefore, the selection needs to be made according to the actual needs.

3. The bearing capacity and life, which is also an important factor to consider when choosing insulated bearings.

Compared with other types of bearings, insulated bearings have the following advantages:

1. They have excellent insulating properties, which can ensure the normal operation of motors and other equipment.

2. They have a low coefficient of friction, smooth running and long bearing life.

3. They have good high-temperature resistance and can be used in harsh environments.

Insulated bearings are mainly used in various motors, electrical appliances, chemical equipment, medical equipment and other occasions. In these use scenarios, due to the excellent performance performance of the insulated bearings, the efficiency and stability of the equipment can be effectively improved and the service life of the equipment can be extended.

In short, when choosing and using insulated bearings, it is necessary to analyze them from multiple perspectives, such as product structure, product selection, product advantages, and usage scenarios. Only after a comprehensive understanding of the characteristics and application scope of the product can it better play its role.

Model |

Cage |

Cr(KN) |

Cor (KN) |

Grease lubrication speed |

Oil lubricated speed |

Weight (kg) |

Insulation class |

||

6028/C3VL0241 |

Steel |

111 |

108 |

6700 |

4000 |

3.4 |

2000V |

3000V |

|

6028M/C3VL0241 |

Brass |

111 |

108 |

6700 |

4000 |

3.4 |

2000V |

3000V |

|