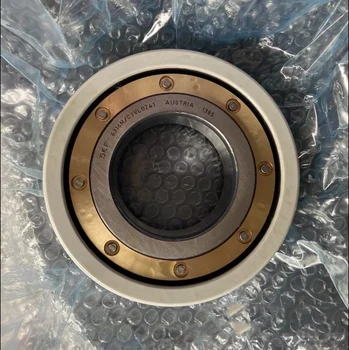

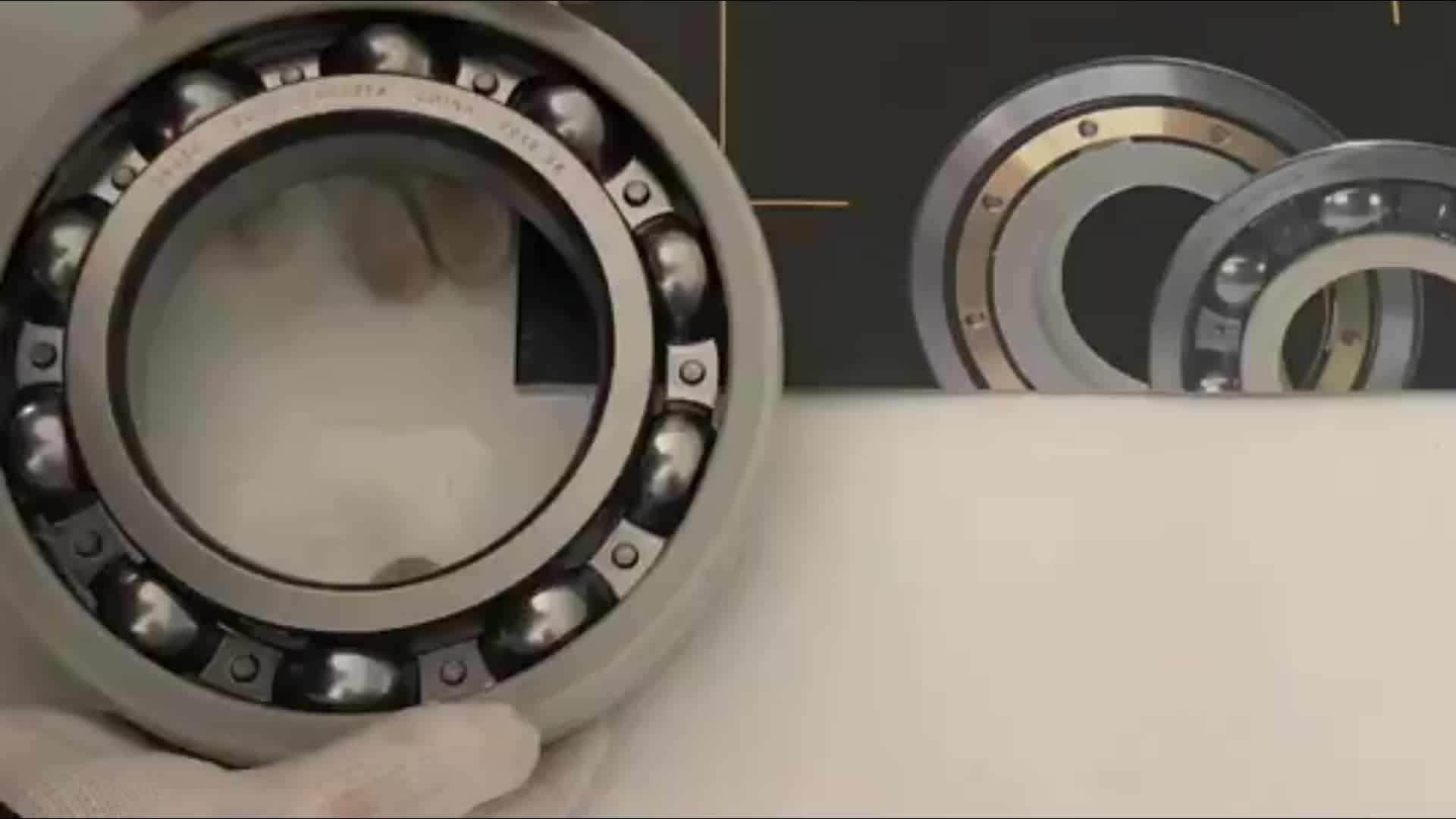

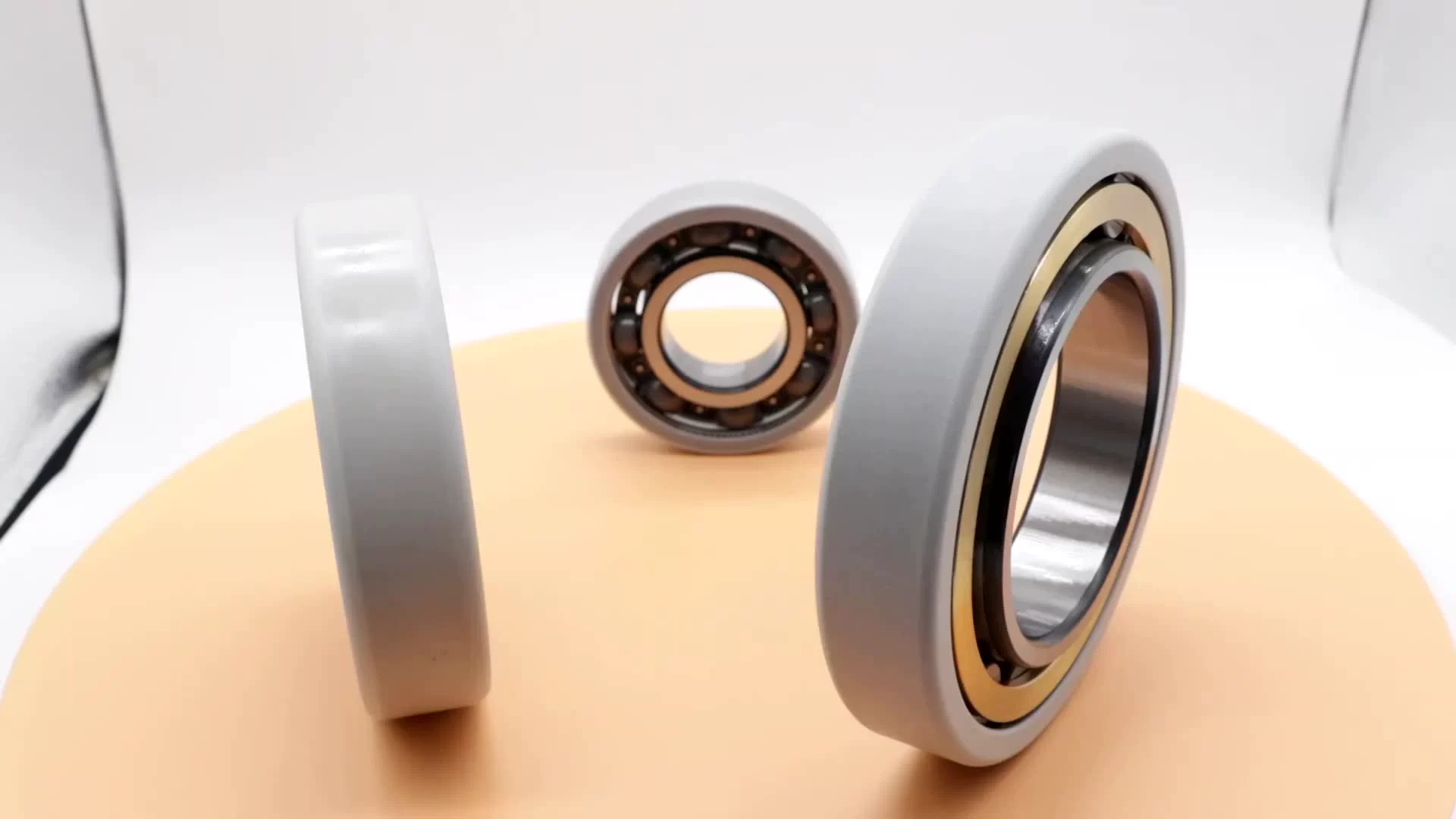

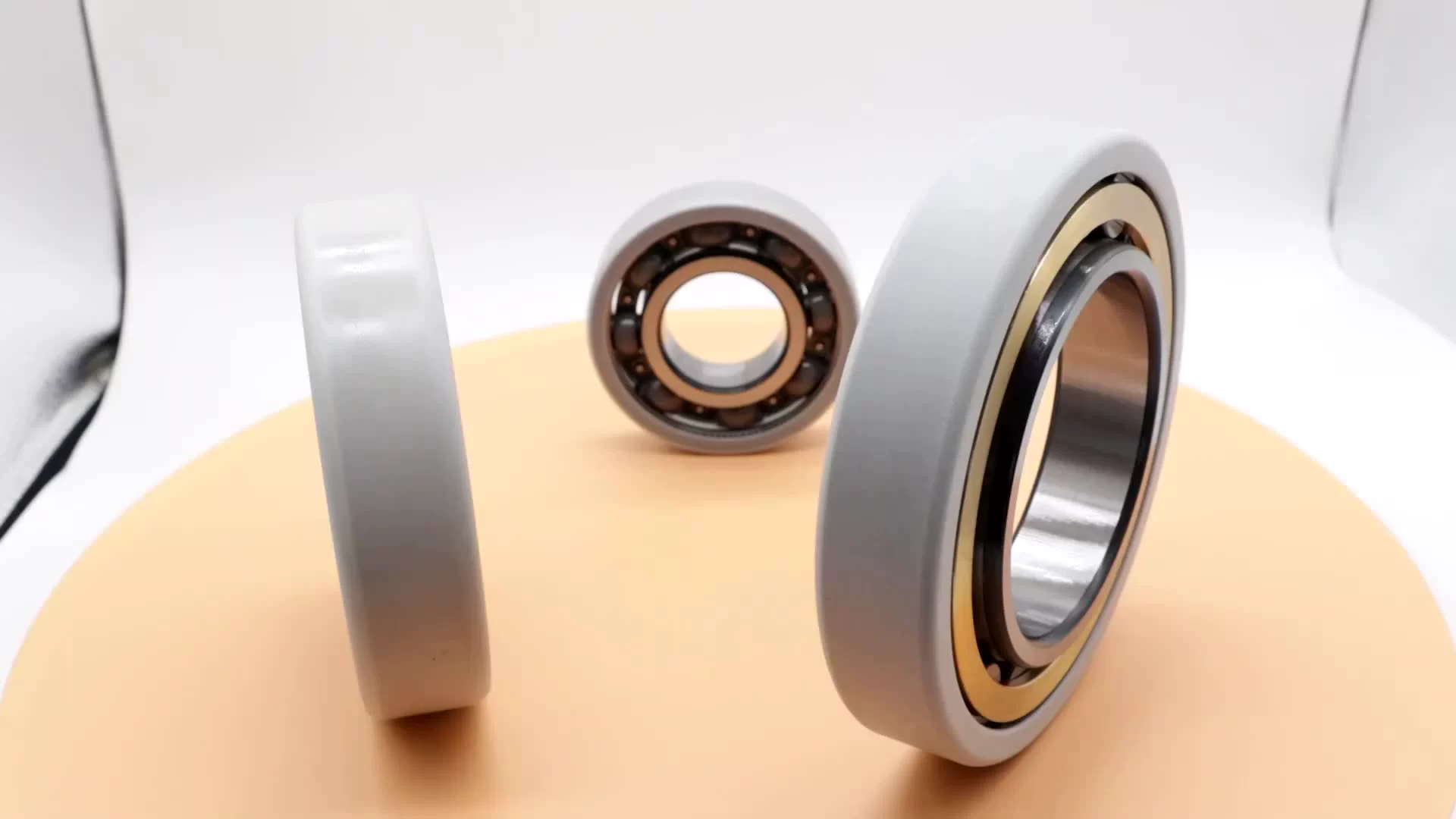

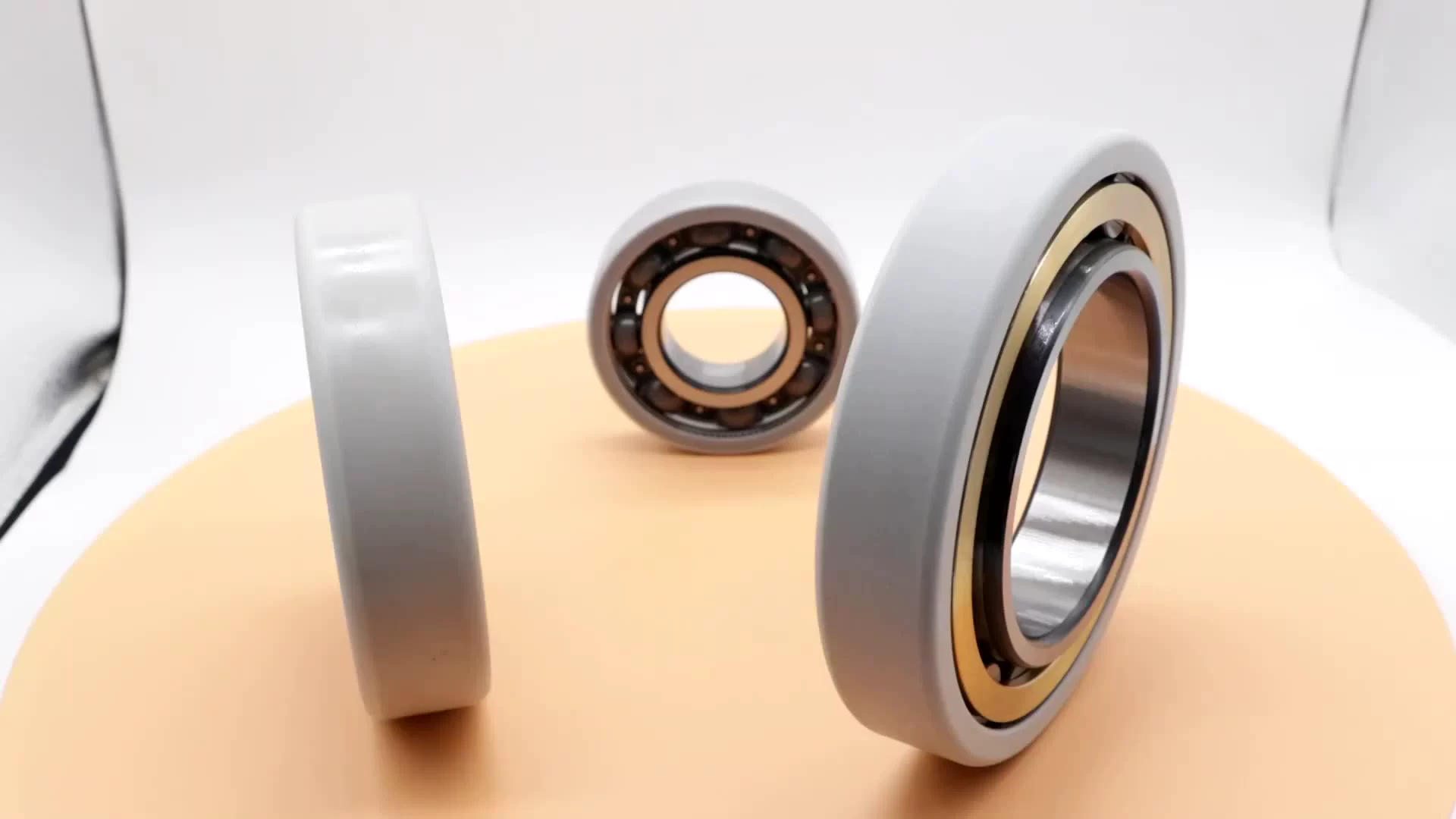

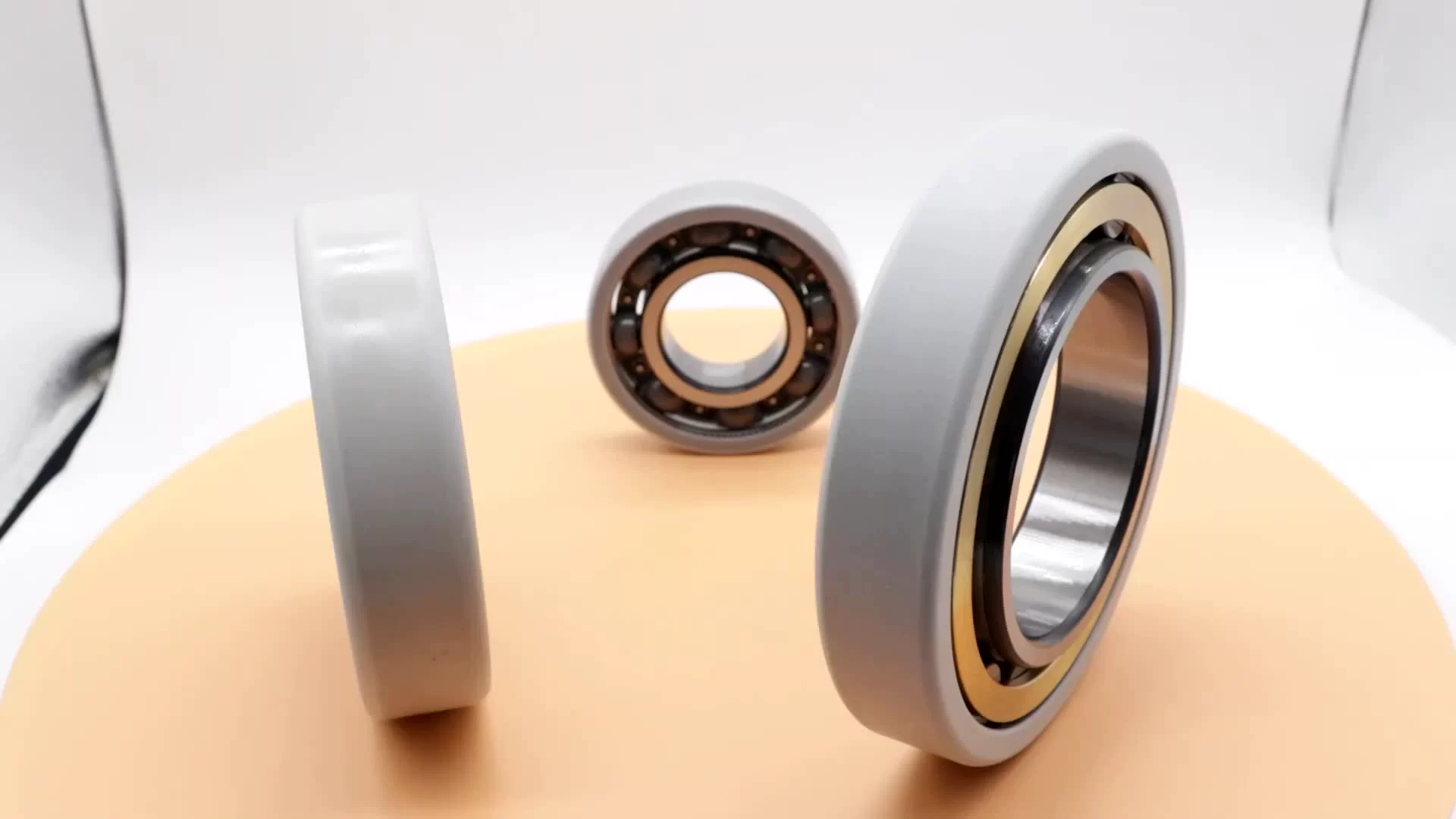

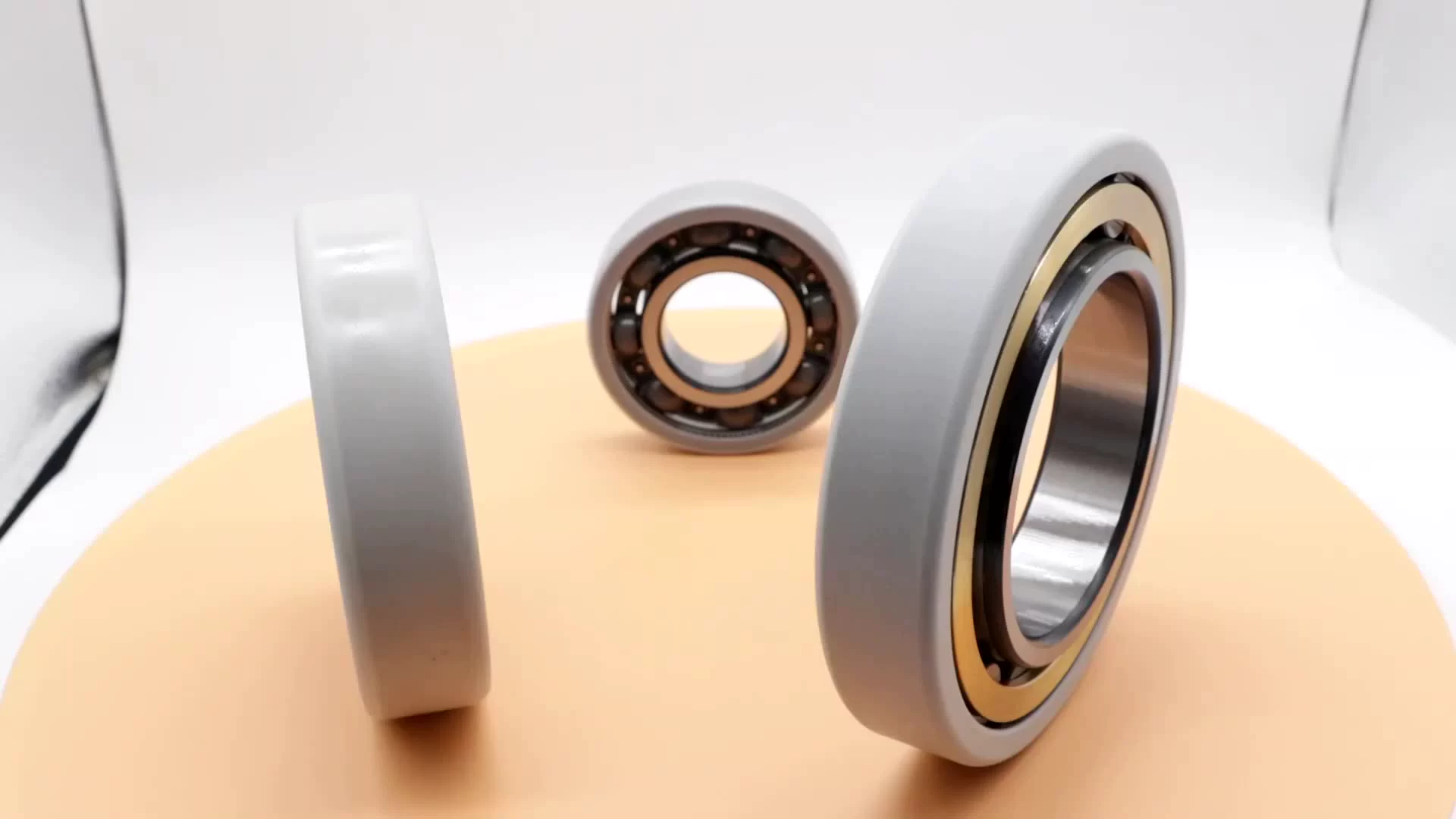

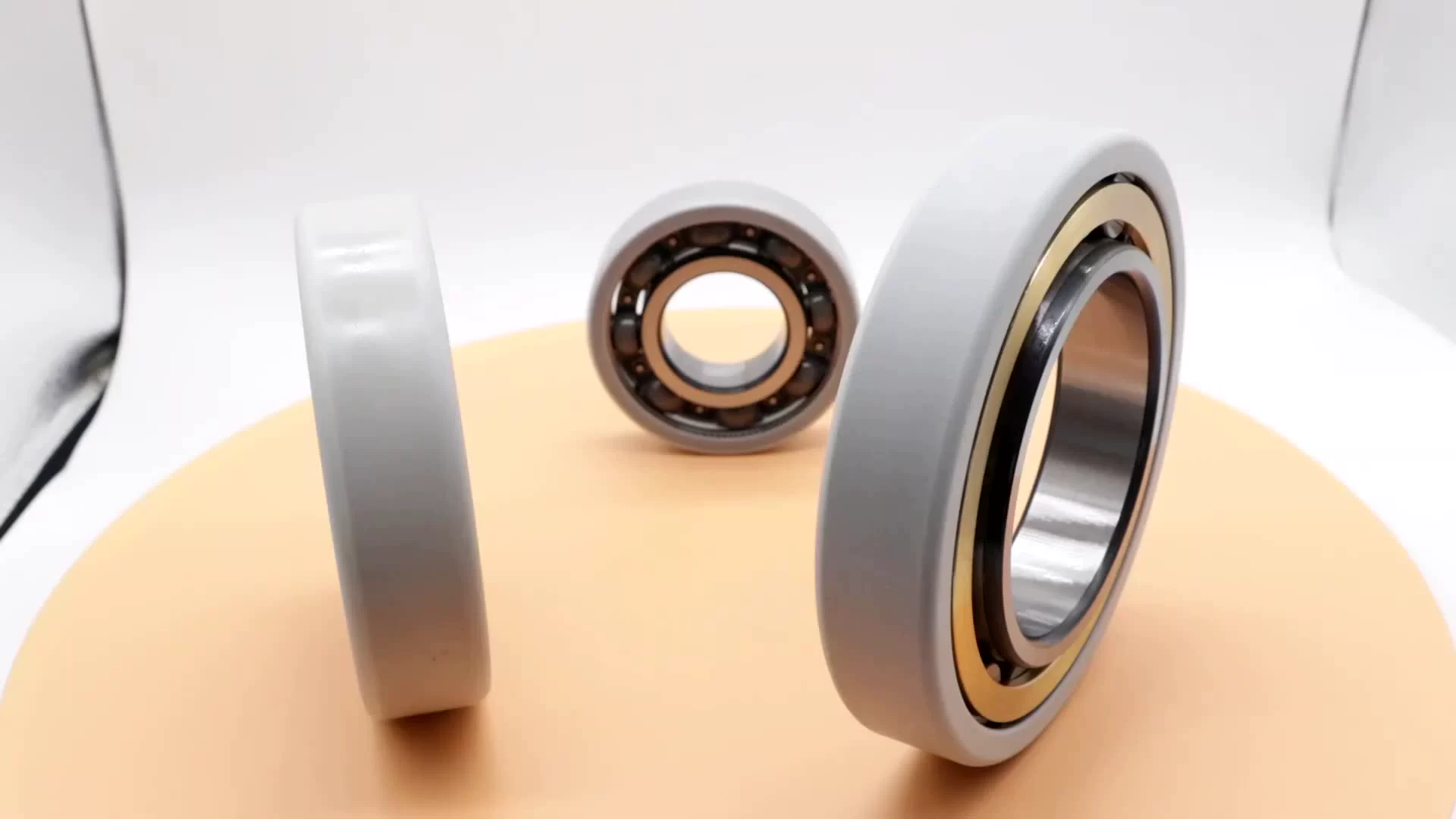

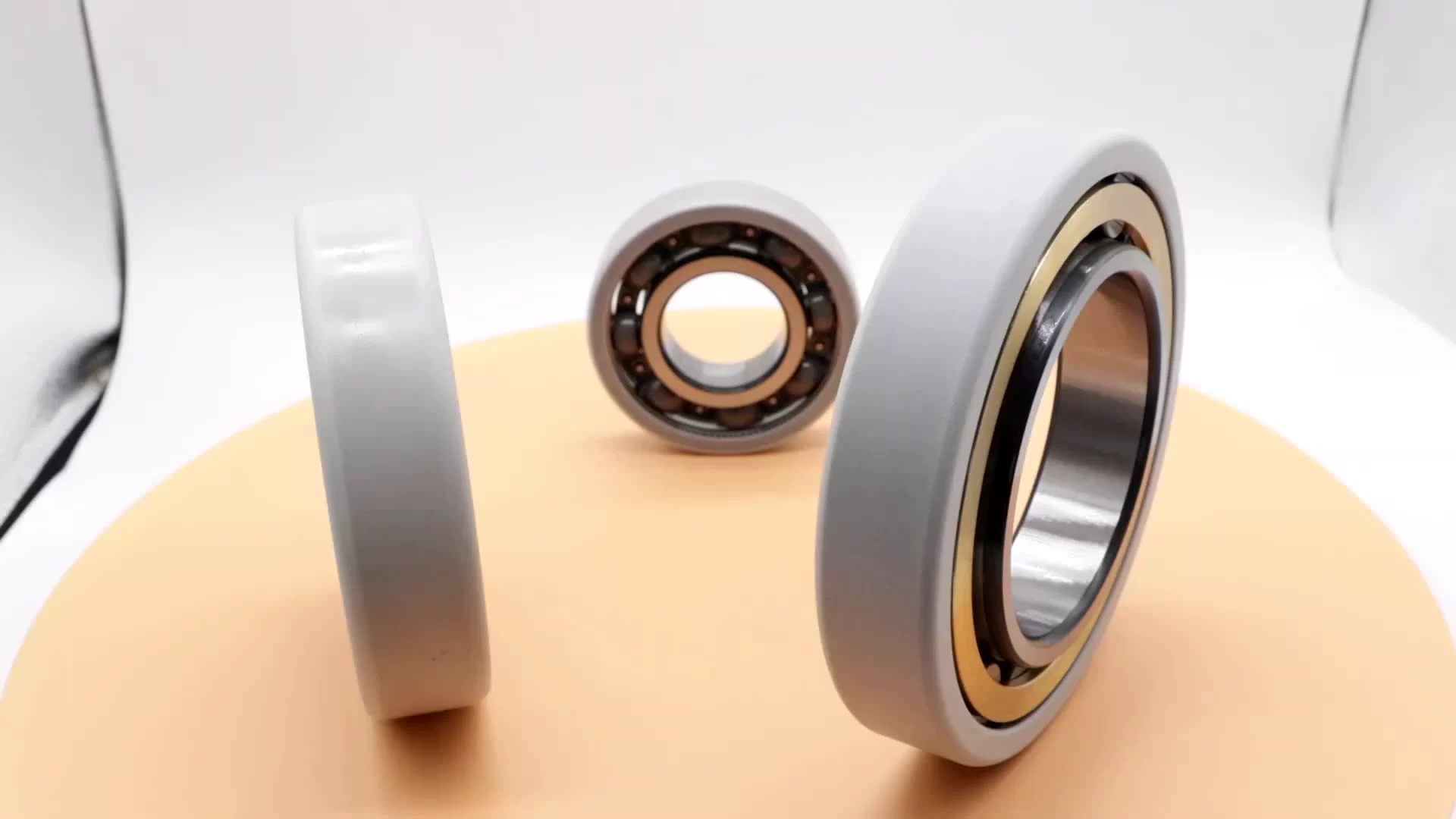

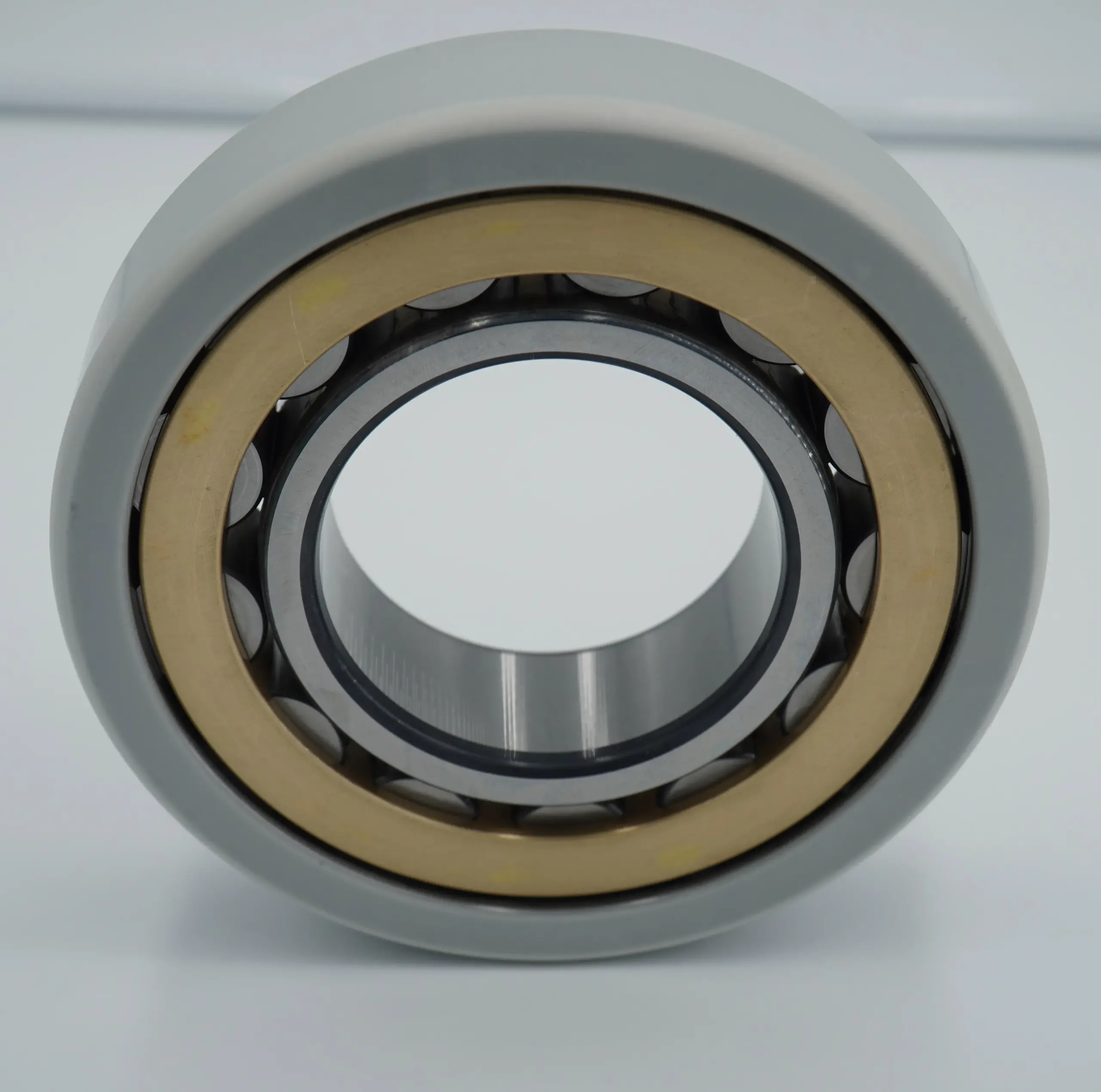

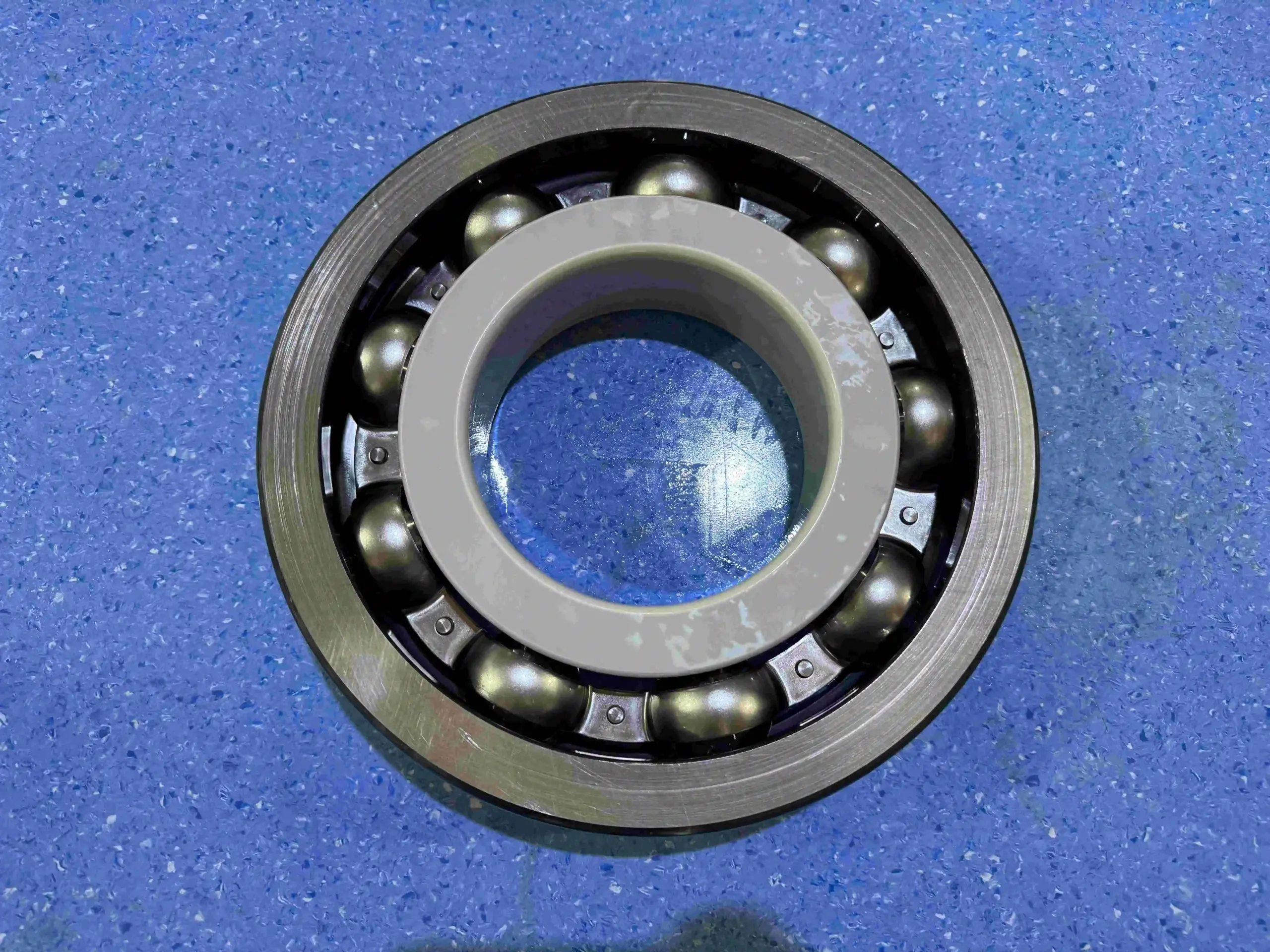

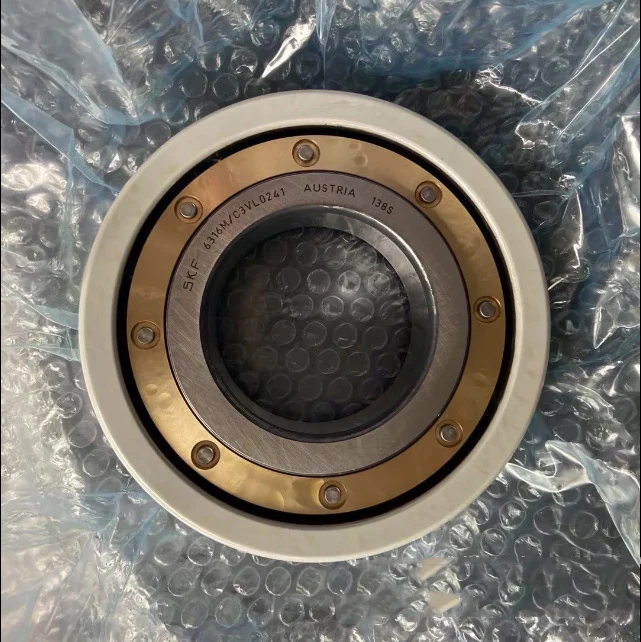

NU213 NU211ECM Insulated Cylindrical roller bearing with ceramic coating NU212ECM C3

Key attributes

Industry-specific attributes

Applicable Industries

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Construction works , Energy & Mining

Bore Size

59.9999 - 60 mm

Precision Rating

P0 P6 P5 P4 P2

Number of Row

Single row

Other attributes

Place of Origin

Shandong, China

Type

BALL

Structure

Deep Groove

Model Number

NU212ECM C3

Seals Type

OPEN ZZ 2RS RS

Material

Chrome Steel Gcr15 and ceramic coating

Precision Rating

P6 P5 P4

Package

Standard

Size

80x170x39mm

Feature

Electrically Insulated;Long work-time; C3 Clearance

Standard

ISO3547

Heat Stabilization

Temperatures up to 120 °C

Service

OEM Customized Services

Electrical Resistance

Min. 50MΩ, Breakdown Voltage: Max. Operating Voltage 1.000v DC

Precision

Breakdown Voltage 1000V

NU213 NU211ECM Insulated Cylindrical roller bearing with ceramic coating NU212ECM C3

The correct installation method of insulated bearings involves multiple steps to ensure that the insulation and mechanical properties of the bearings are optimally utilized. Here are some key steps:

1. Check the bearings before installation: Check whether the packaging is intact. If there is any damage, carefully check whether the insulation layer of the bearing is damaged. If this type of bearing is damaged, its insulation capacity is greatly reduced, and it is easy to be corroded by current and lose its insulation effect;

2. Check the matching size of the insulated bearing and the rotor shaft: When assembling the motor, carefully check the matching size of the bearing and the rotor shaft during bearing installation, as well as the matching size of the bearing outer ring and the end cover hole;

3. Cleaning before installation: Before installing the bearing, check the relevant components to ensure that they are clean. Do not open the original packaging of the bearing until the moment before installation. Remove burrs, chips, rust and dirt on the installation surface, otherwise, the bearing will generate noise and vibration when working;

4. Use special tools to install and remove bearings: Avoid damage to insulated bearings due to improper tools and operation. For example, the copper rod knocking method during installation may cause uneven axial force of the bearing, deformation of the cage and damage to the rolling element, so professional bearing removal tools must be used.

5. Control the amount of oil in the bearing and bearing seat: Too much oil in the bearing and housing will cause the rolling element of the bearing to slip, and the rolling friction will change from rolling friction to sliding friction, thereby damaging the rolling element of the bearing. Therefore, the amount of oil should be controlled to avoid too much or too little.

6. Pay attention to ensure the insulation function: For bearings with insulation design on the outer ring, it is necessary to ensure that the insulation is intact. If the bearing insulation is damaged during the installation process, the thin oil film of the bearing will be broken down by the shaft voltage, not only will the lubrication condition of the rolling element deteriorate, but the generated electric sparks will cause electrical corrosion to the rolling element of the bearing, causing the surface of the rolling element to be unpolished and accelerate the wear of the bearing.

By following these steps, you can ensure the correct installation of the insulated bearing, thereby extending its service life and maintaining good insulation properties.

Model No |

d(mm) |

D(mm) |

Width(mm) |

NU310ECM/C3VL0241 VL2071 |

50 |

110 |

27 |

NU311ECM/C3VL0241 VL2071 |

55 |

120 |

29 |

NU312ECM/C3VL0241 VL2071 |

60 |

130 |

31 |

NU313ECM/C3VL0241 VL2071 |

65 |

140 |

33 |

NU314ECM/C3VL0241 VL2071 |

70 |

150 |

35 |

NU315ECM/C3VL0241 VL2071 |

75 |

160 |

37 |

NU316ECM/C3VL0241 VL2071 |

80 |

170 |

39 |

NU317ECM/C3VL0241 VL2071 |

85 |

180 |

41 |

NU318ECM/C3VL0241 VL2071 |

90 |

190 |

43 |

NU319ECM/C3VL0241 VL2071 |

95 |

200 |

45 |

NU320ECM/C3VL0241 VL2071 |

100 |

215 |

47 |

NU322ECM/C3VL0241 VL2071 |

110 |

240 |

50 |

NU324ECM/C3VL0241 VL2071 |

120 |

260 |

55 |

NU326ECM/C3VL0241 VL2071 |

130 |

280 |

58 |

NU328ECM/C3VL0241 VL2071 |

140 |

300 |

62 |

NU330ECM/C3VL0241 VL2071 |

150 |

320 |

65 |

NU210ECM/C3VL0241 VL2071 |

50 |

90 |

20 |

NU211ECM/C3VL0241 VL2071 |

55 |

100 |

21 |

NU212ECM/C3VL0241 VL2071 |

60 |

110 |

22 |

NU213ECM/C3VL0241 VL2071 |

65 |

120 |

23 |

NU214ECM/C3VL0241 VL2071 |

70 |

125 |

24 |

NU215ECM/C3VL0241 VL2071 |

75 |

130 |

25 |

NU216ECM/C3VL0241 VL2071 |

80 |

140 |

26 |

NU217ECM/C3VL0241 VL2071 |

85 |

150 |

28 |

NU218ECM/C3VL0241 VL2071 |

90 |

160 |

30 |

NU219ECM/C3VL0241 VL2071 |

95 |

170 |

32 |

NU220ECM/C3VL0241 VL2071 |

100 |

180 |

34 |

NU222ECM/C3VL0241 VL2071 |

110 |

200 |

38 |

NU224ECM/C3VL0241 VL2071 |

120 |

215 |

40 |

NU226ECM/C3VL0241 VL2071 |

130 |

230 |

40 |

NU228ECM/C3VL0241 VL2071 |

140 |

250 |

42 |

NU230ECM/C3VL0241 VL2071 |

150 |

270 |

45 |

NU1011ECM/C3VL0241 VL2071 |

55 |

90 |

18 |

NU1012ECM/C3VL0241 VL2071 |

60 |

95 |

18 |

NU1013ECM/C3VL0241 VL2071 |

65 |

100 |

18 |

NU1014ECM/C3VL0241 VL2071 |

70 |

110 |

20 |

NU1015ECM/C3VL0241 VL2071 |

75 |

115 |

20 |

NU1016ECM/C3VL0241 VL2071 |

80 |

125 |

22 |

NU1017ECM/C3VL0241 VL2071 |

85 |

130 |

22 |

NU1018ECM/C3VL0241 VL2071 |

90 |

140 |

24 |

NU1019ECM/C3VL0241 VL2071 |

95 |

145 |

24 |

NU1020ECM/C3VL0241 VL2071 |

100 |

150 |

24 |

NU1022ECM/C3VL0241 VL2071 |

110 |

170 |

28 |

NU1024ECM/C3VL0241 VL2071 |

120 |

180 |

28 |

NU1026ECM/C3VL0241 VL2071 |

130 |

200 |

33 |

NU1028ECM/C3VL0241 VL2071 |

140 |

210 |

33 |

NU1030ECM/C3VL0241 VL2071 |

150 |

225 |

35 |