Deep Groove Ball Bearings of the series C-69 (Hybrid)

- designed as hybrid deep groove ball bearing: rolling elements made of ceramic, inner and outer ring made of stainless steel

- cage material: plastic; the low weight and the elasticity of the plastic have a positive effect on the sliding and emergency running properties as well as the shock resistance; suitable for quiet running

- lighter than comparable deep groove ball bearings with steel balls as rolling elements; ceramic balls have a current-insulating effect; withstands higher speeds and has a high wear resistance

- thin section bearing with a thin, square cross section

- suitable for space-saving installation in radial and axial directions

- suitable for high speeds compared to deep groove ball bearings with a larger cross section

- extra light series with compact dimensions and low weight

- suitable for radial loads and light axial loads in both directions

- offers high running accuracy, quiet running and very high speeds

- seal: open (without seal); for higher speeds than with sealed ball bearings and easy relubrication

- good fixed bearing property, but can also be used as a floating bearing, each in both directions

- manufacturers of bearings, such as FAG, KOYO, NSK, SKF, SNR, OEM, etc. assign different suffixes for their characteristics, for better orientation take note of the comparison table of bearings (see further information)

| Bearing number | Bore Diameter (d) | Outer Diameter (D) | Width (B) | Seal | Ring Material | Rolling Element Material | Cage Material |

|---|---|---|---|---|---|---|---|

| SS-C-6900-TN-OIL | 10 | 22 | 6 | open | Stainless Steel | Ceramics | Plastic |

| SS-C-6900-ZZ-TN-OIL | 10 | 22 | 6 | ZZ | Stainless Steel | Ceramics | Plastic |

| C-6900-ZZ | 10 | 22 | 6 | ZZ | Chrome Steel | Ceramics | Sheet Steel |

| SS-C-6901-2RS-DRY | 12 | 24 | 6 | 2RS | Stainless Steel | Ceramics | Stainless Steel |

| SS-C-6901-2RS-TN-DRY | 12 | 24 | 6 | 2RS | Stainless Steel | Ceramics | Plastic |

| SS-C-6901-ZZ-TN-DRY | 12 | 24 | 6 | ZZ | Stainless Steel | Ceramics | Plastic |

| C-6901-2RS | 12 | 24 | 6 | 2RS | Chrome Steel | Ceramics | Sheet Steel |

| SS-C-6902-ZZ | 15 | 28 | 7 | ZZ | Stainless Steel | Ceramics | Stainless Steel |

| SS-C-6902-ZZ-TN-OIL | 15 | 28 | 7 | ZZ | Stainless Steel | Ceramics | Plastic |

| C-6902-TN-OIL | 15 | 28 | 7 | open | Chrome Steel | Ceramics | Plastic |

| SS-C-6903-DRY | 17 | 30 | 7 | open | Stainless Steel | Ceramics | Stainless Steel |

| SS-C-6903-TN-OIL | 17 | 30 | 7 | open | Stainless Steel | Ceramics | Plastic |

| SS-C-6903-ZZ-DRY | 17 | 30 | 7 | ZZ | Stainless Steel | Ceramics | Stainless Steel |

| SS-C-6903-ZZ-TN-OIL | 17 | 30 | 7 | ZZ | Stainless Steel | Ceramics | Plastic |

| SS-C-6904-2RS | 20 | 37 | 9 | 2RS | Stainless Steel | Ceramics | Stainless Steel |

| SS-C-6904-2RS-TN | 20 | 37 | 9 | 2RS | Stainless Steel | Ceramics | Plastic |

| SS-C-6904-TN-OIL | 20 | 37 | 9 | open | Stainless Steel | Ceramics | Plastic |

| SS-C-6904-TN-DRY | 20 | 37 | 9 | open | Stainless Steel | Ceramics | Plastic |

| SS-C-6904-ZZ | 20 | 37 | 9 | ZZ | Stainless Steel | Ceramics | Stainless Steel |

| SS-C-6904-ZZ-TN-OIL | 20 | 37 | 9 | ZZ | Stainless Steel | Ceramics | Plastic |

| C-6904-2RS-DRY | 20 | 37 | 9 | 2RS | Chrome Steel | Ceramics | Sheet Steel |

| SS-C-6905-TN | 25 | 42 | 9 | open | Stainless Steel | Ceramics | Plastic |

| SS-C-6905-TN-OIL | 25 | 42 | 9 | open | Stainless Steel | Ceramics | Plastic |

| SS-C-6905-ZZ-TN-OIL | 25 | 42 | 9 | ZZ | Stainless Steel | Ceramics | Plastic |

| C-6905-2RS-OIL | 25 | 42 | 9 | 2RS | Chrome Steel | Ceramics | Sheet Steel |

| SS-C-6906-2RS | 30 | 47 | 9 | 2RS | Stainless Steel | Ceramics | Stainless Steel |

| SS-C-6906-2RS-TN | 30 | 47 | 9 | 2RS | Stainless Steel | Ceramics | Plastic |

| SS-C-6906-TN-OIL | 30 | 47 | 9 | open | Stainless Steel | Ceramics | Plastic |

| SS-C-6906-ZZ | 30 | 47 | 9 | ZZ | Stainless Steel | Ceramics | Stainless Steel |

| SS-C-6906-ZZ-TN | 30 | 47 | 9 | ZZ | Stainless Steel | Ceramics | Plastic |

| SS-C-6906-ZZ-TN-OIL | 30 | 47 | 9 | ZZ | Stainless Steel | Ceramics | Plastic |

| C-6906-TN-OIL | 30 | 47 | 9 | open | Chrome Steel | Ceramics | Plastic |

Special feature of this series

Main dimensions according to DIN 625-1. Hybrid thin section bearings of the 69 series are equipped with low-wear, current insulating ceramic balls withstanding extremely high speeds. They have considerably smaller dimensions than deep groove ball bearings of the 60, 62, 63 and 64 series with their thin, square cross section at the same inside diameter. In comparison to their inside diameter they have a small outside diameter – and furthermore – they are relatively narrow. Relatively high shaft- and axis diameters can thereby be installed at an also extremely confined installation space. They are light and are suitable for comparatively high speeds. They are available with rings made of stainless steel or rolling bearing steel.

Manufacturers of bearings: such as FAG, KOYO, NSK, SKF, SNR, etc. assign different suffixes for their characteristics, for better orientation take note of the comparison table of bearings (see further information)

Can be customized to meet your specific needs.

The hybrid deep groove ball bearing SS-C-6900-TN has excellent properties due to the ceramic rolling elements. It is narrow and can also be used in a limited space. The low weight allows very high speeds. Main dimensions according to DIN 625-1.

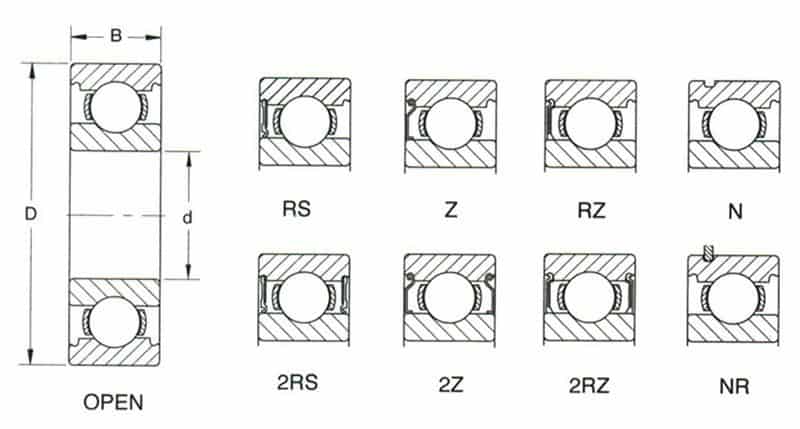

Other options: Metal shield (ZZ) or rubber seal (2RS) can be provided.

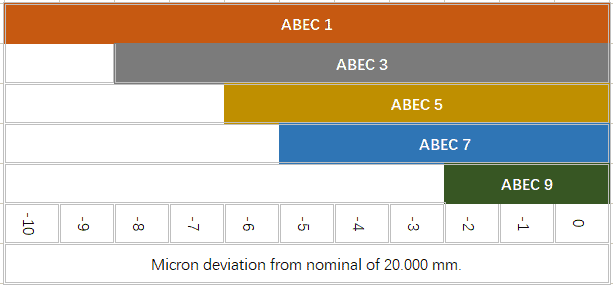

Deep Groove Ball Bearings are able to accommodate low to heavy radial loads and low to moderate thrust loads in either direction. They are available with metal shields (ZZ) or rubber seals (2RS). Several tolerance grades (Abec 1-9), internal clearance (C2 to C4) and cage designs are available to best suit the running precision and speed of the application.

Common Options:

- ZZ– Two Metal Shields

- 2RS– Two Rubber Seals

- NR– Snap Ring

- M– Brass Cage

- C0– Normal Internal Clearance

- C3– Greater than normal

Related Deep Groove Ball Bearings Products

Latest content

Application of Deep Groove Ball Bearing in Coal Industry

The Complete ABEC Rating Guide: Scale, Chart, and What They Actually Mean

316 stainless steel bearing material

Further Information

Quality And Pricing.

We have our own brand “TFL” and have passed ISO9001: 2000 certification. We have the most advanced production equipment bearings, bearing testing equipment, first-class production lines, and a rigorous testing process, which directly ensures product bearing quality.

Because our range of products consists of products of neutral brands, we have the possibility to offer our customers an attractive price, more quantities for purchasing, the lower price will get.

Don’t hesitate to contact us via our contact form if you have any further questions…

Find more products in China.

You can contact us any convenient way. We are available 24/7 via fax or email.

You can also use the quick contact form below or visit our office personally. Please email us with any questions or inquires or use our contact data. We would be happy to answer your questions.

30-Day Money-Back Guarantee

We back every sale with a 30-day money-back guarantee. If you’re somehow not happy with your purchase, just let us know.