Wind Energy

Bearings and Engineering for Wind Energy

As clean energy that does not produce carbon dioxide that can cause the greenhouse effect, wind power is rapidly spreading in countries worldwide.

Special bearings for wind turbines require high reliability. The prerequisite for this kind of bearing design is to ensure that the windmill runs for 20 years because when a failure occurs, the parts are not easy to replace. (When the bearing is used tens of meters above the ground).

Therefore, bearing manufacturers require a high degree of computer analysis techniques and excellent materials and heat treatment skills. They sometimes need to master the test evaluation technology for large-scale bearings.

Large-scale wind turbines (windmills) are colossal machinery. Much 2MW-class wind power generation equipment under construction now has windmill blades about 40 meters long, a rotating shaft height of 60 to 100 meters, and a total weight of no less than 200 tons. Therefore, the bearings used in windmills must also be significant, with an inner diameter ranging from 100 mm to 700 mm. Some models require approaches with an inner diameter of nearly 2 meters. There are only six manufacturers in the world that can stably supply such large bearings to the market. It is a great honor for TFL to represent the brands of bearing manufacturers, including NSK, SKF, FAG, INA, NTN, more.

Since the mid-1990s, NSK began to set foot in this field for the European windmill industry, which had a monopoly at the time, and now supplies such bearings to the United States, China, and India. Users in the wind turbine market fully recognize NSK bearings. At present, 9 of the world’s top 10 wind turbine manufacturers use NSK bearings. Therefore, NSK is making contributions to protecting the global environment. SKF has worked with leading original equipment manufacturers for many years to optimize turbine performance, reliability, and energy output. We design and develop bearings, seals, condition monitoring systems, and lubrication systems, achieving more cost-effective wind power generation and lower lubricant consumption.

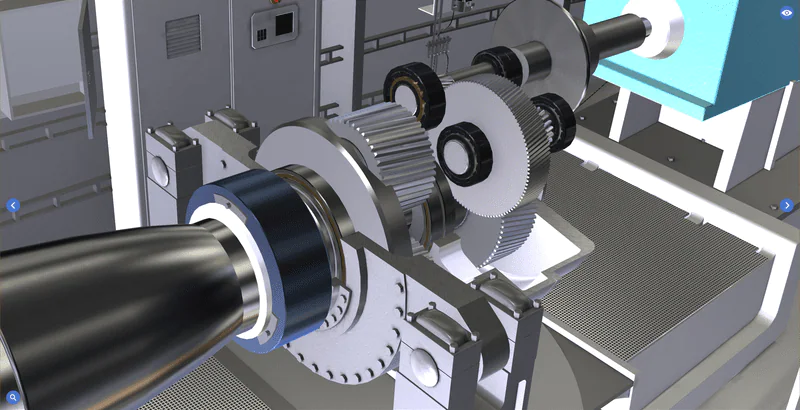

Main products: Wind power series bearings

Yaw bearing, pitch bearing, main shaft bearing, series bearing for drive reducer, series bearing for speed increaser, series bearing for generator

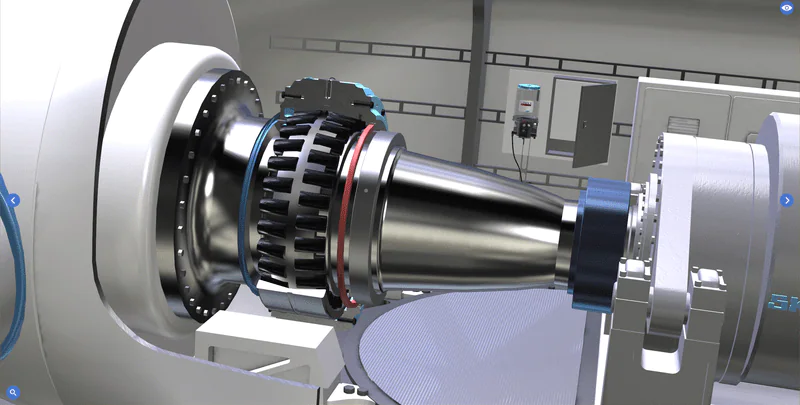

Spindle bearing

It is located in the main shaft of the impeller, the workload is high, and it is required to compensate for the deformation of the main shaft. Therefore, the bearing should have good self-aligning performance, high load capacity, and long service life. Generally, spherical roller bearings with optimized design are used.

Yaw bearing

The yaw mechanism installed in the base assembly of the wind turbine’s nacelle is used to accurately and timely adjust the windward angle of the wind turbine and transmit lightning to the ground. The load is radial, axial load, and overturning moment. It must have good sealing performance, high reliability, flexible operation, and good stability, surface corrosion, and a life span of more than 20 years. This bearing generally adopts an extra-large four-point contact ball or crossed cylindrical roller slewing bearing.

Pitch bearing

The pitch system assembly located on the blade is used to adjust the windward direction of the sword, and it mainly bears the radial load, axial load, and overturning moment. The bearing must have good sealing performance, high reliability, surface corrosion, flexible operation, and a life span of more than 20 years. This bearing generally adopts an extra-large four-point contact ball or double-row ball slewing bearing.

30-Day Money-Back Guarantee

We back every sale with a 30-day money-back guarantee. If you’re somehow not happy with your purchase, just let us know.