IKO

Here at TFL-Bearing, we provide a full range of IKO brand products at a very competitive price, including high-quality needle roller bearings, cross roller bearings, thrust bearings, roller bearings, ball linear motion rolling guides, roller rolling Guide rails, linear motion rolling guides, precision positioning tables, and machine parts. Most products can be shipped the same day or the next day.

With 50 years of experience, IKO focuses on high-quality needle roller bearings, linear motion rolling guides, precision tabletops, and mechanical parts. The company’s products are rolling linear motion guides. IKO adopts a linear motion rolling guide, which reduces the linear motion friction of the mechanical positioning mechanism.

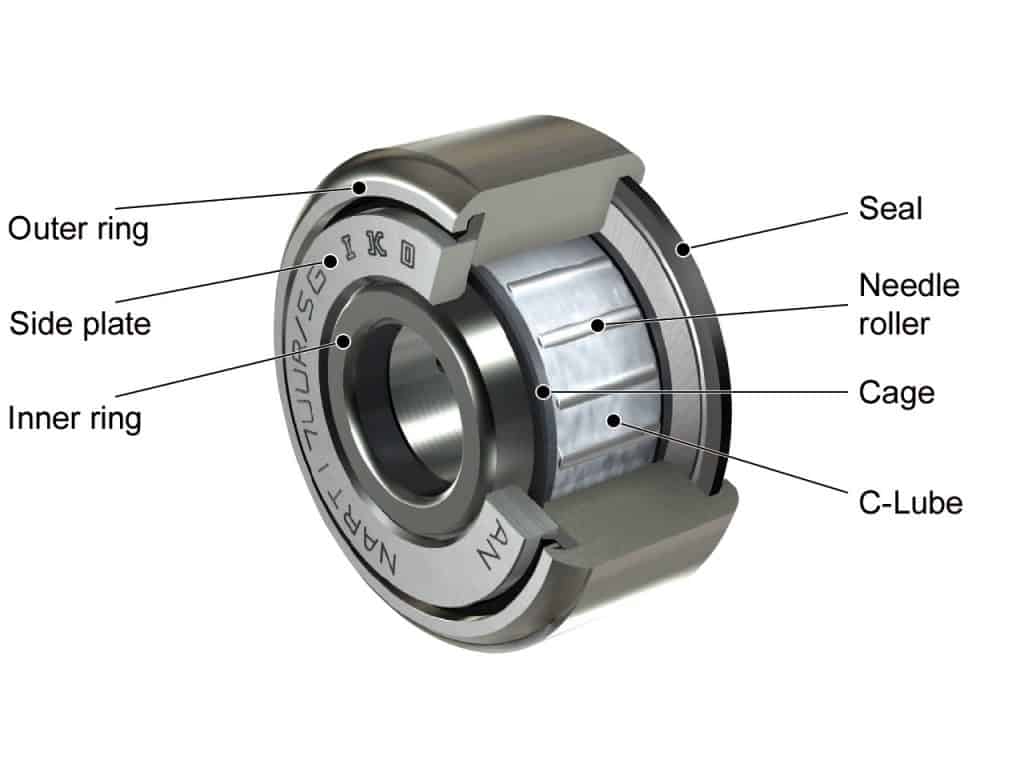

For example, our linear guides and linear roller guide systems, as well as shaft guidance systems based on ball splines. Needle Bearings: The needle roller bearings produced by our company have low cross-section height and high load-bearing capacity and can be rotated. Thin needle rollers are integrated into the rolling elements. Because these bearings are small, they help reduce the overall size of the machine. Precise positioning table Our company’s direct-drive precision positioning table combines precision processing technology with electronic devices, and a ball screw or motor is embedded between the bed and the sliding table.

IKO provides a number of patented products of C-Lube technology. For 20,000 kilometers or more, the built-in lubrication system can be maintenance-free.

Key IKO Bearings Products

TFL Bearings is the authorized distributor of IKO bearing. IKO is a leading manufacturer of linear guides and needle-bearing types. TFL Bearings has the unique ability to support huge IKO bearing products through our inventory location, dedicated bearing application engineering personnel, and experienced IKO bearing sales team.

MECHATRONICS

MECHATRONICS

LINEAR MOTION

IKO designs and manufactures a wide range of machine parts that reduce friction in the positioning mechanisms of industrial equipment and machinery.

Linear Motion Products

Range in size from small to large, high rigidity and to provide guides for large load capacity minimum width of the machine from the guide to the world of 1 mm.

For the semiconductor, medical, life sciences, solar energy, machine tools, construction, and other industries.

Available styles rolling guide comprises a roller, ball-type rolling guide, ball spline, the anti-creep cross roller guide, and a linear ball slide and rotary bush, to meet the needs of different applications and the machine geometry.

BALL TYPE ROLLING GUIDES

IKO designs and manufactures a wide range of ball-type guides to achieve precise linear motion across a diverse range of industries, from semiconductor manufacturing to machine tools. C-Lube models feature built-in lubricating elements to provide long-lasting, maintenance-free operations to perform for 20,000 km. IKO ball type guides focus on high rigidity for complex loads, quiet operation, and other design features to meet specific application requirements.

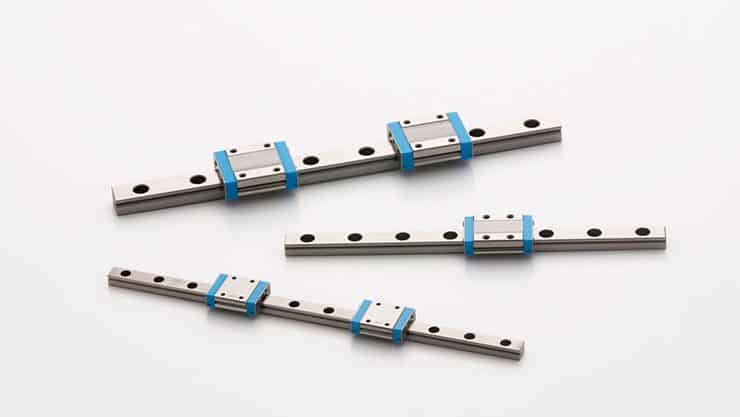

C-Lube Linear Way ML

Our C-Lube Linear Way ML lightweight miniature guides feature built-in lubrication. The C-lube unit doesn’t contact the track rail, enabling smooth motion without increasing rolling resistance.

- Components are made of corrosion-resistant stainless steel. This makes them suitable for applications that don’t use rust-preventive oil such as clean rooms.

- Slide units incorporate ball-retaining bands that prevent the loss of balls when removing them from the rails.

- Both standard and wide versions are available, with slide unit lengths ranging from short to extra-long.

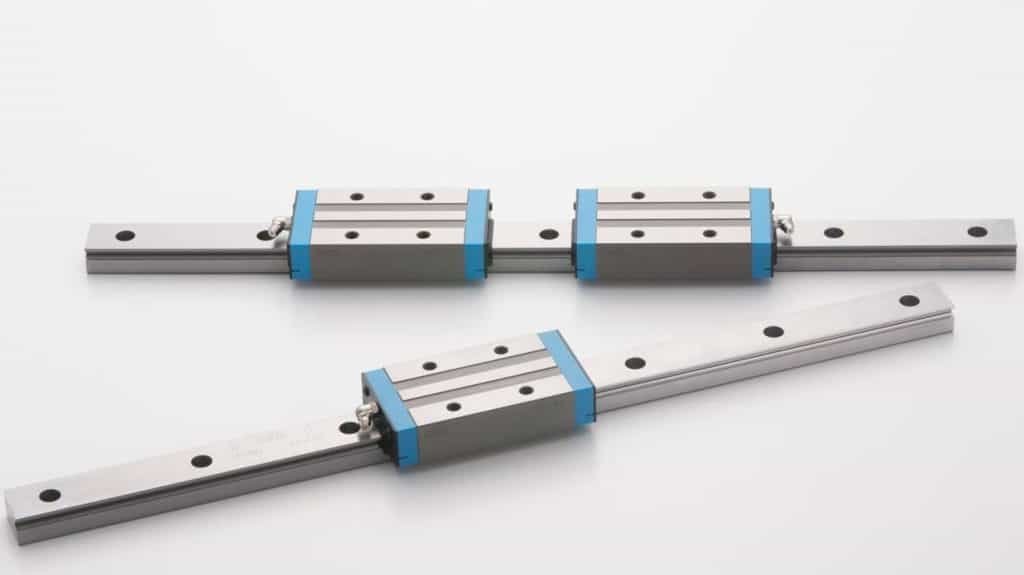

C-Lube Linear Way MLV

IKO C-Lube Linear Way MLV is a small linear motion rolling guide utilizing a simple, two-row raceway with a four-point contact structure. Long-term, maintenance-free operation is achieved by using built-in C-Lube lubrication. MLV has the same basic performance as C-Lube Linear Way ML but is more economical because of a review and redesign of the structure, including the ball recirculation section.

- Built-in lubrication saves time and money on maintenance.

- Corrosion-resistant stainless steel components make them suitable for clean rooms and other demanding environments.

- Slide units feature ball-retaining bands to prevent ball loss when removing slide units from rails.

C-Lube Linear MV

Despite its extra-low profile and light-weight, the IKO C-Lube Linear Way MV has the maximum downward load rating among ball types with high load capacity. It also provides long-term, maintenance-free operation since the slide unit has built-in C-Lube lubrication.

- Low profile, lightweight design with a large load capacity and high rigidity.

- Built-in lubrication means long-term maintenance-free operation.

- Slide units incorporate ball-retaining bands that prevent the loss of balls when removing them from the rails.

C-Lube Linear Way ME

Linear Way E is a linear motion rolling guide with a compact slide unit that provides endless linear motion over a track rail. Two rows of steel balls come in contact with the raceway surface at four points, enabling stable accuracy and rigidity, even in applications where loads have variable direction and size, or complex loads are applied. This compact, highly-versatile universal series is available in many shapes and sizes.

- External dimensions of C-Lube ME guides are the same as standard Linear Way LWE guides, making these units interchangeable without adjusting stroke length.

- The C-Lube unit does not contact the track rail, enabling smooth motion without increasing frictional resistance.

- Multiple slide unit shapes, lengths, and sizes give you the ability to choose the configuration that best suits your specific application.

C-Lube Linear Way MH

C-Lube Linear Way MH is an H-Series linear motion rolling guide with a high load rating and rigidity. It uses large-diameter steel balls and has built-in C-Lube lubrication which provides long-term, maintenance-free operation.

- Multiple slide unit shapes, lengths, and sizes are available in several accuracy grades and preload, allowing you to choose the best configuration for your application.

- The external dimensions of the MH guides are the same as the LWH guides so that slide units can be easily swapped out.

- Optional design choices include an ultra-seal specification for dust protection, stainless steel models for demanding environments, and extra high rigidity long slide units.

C-Lube Linear Way MUL

The IKO Linear Way U is a linear motion rolling guide with a structure containing a raceway inside the U-section track rail and a slide unit in its interior. With the U-shaped track rail, rigidity against the track rail moment load and torsion is significantly improved. Therefore, it is possible to not only fix the track rail to the mounting base as conventionally done but to use the track rail as a structure beam, such as a cantilever or double-ended support in machines and equipment.

- Corrosion-resistant stainless steel components make them suitable for harsh environments and clean rooms.

- Slide units incorporate ball-retaining bands that prevent the loss of balls when removing them from the rails.

- U-shaped rails are rigid and can be used as structural components, either in a cantilever position or supported at both ends.

Linear Way LWL

The IKO Linear Way L has two rows of balls that contact the raceway at four points. Despite its very small body, it provides stable accuracy and rigidity even in applications where load has variable direction and size, or complex load is applied. The stainless steel specification, which is the base model, is available in a range of shapes and sizes that can be selected according to the application.

- A wide range of interchangeable shapes and sizes for both slide units and track rails are available to meet the needs of different applications.

- Standard and wide models are available with slide unit lengths offered in short, standard and high rigidity long versions.

- Slide units feature ball-retaining bands to prevent ball loss when removing slide units from rails.

Linear Way LWE

Our Linear Way E rolling guides feature an ultra-compact slide unit that allows continuous linear motion along the track rail. Two rows of steel balls make four-point contact with raceways to ensure high stability and accuracy, even under fluctuating and complex loads.

- A wide variety of interchangeable shapes and sizes for both slide units and track rails meet the needs of different applications.

- Slide units come in three shapes, two flange types for different mounting options and a block style with narrow width.

- Lengths are available in short, standard, and highly rigid long versions.

- Stainless steel versions for use in cleanrooms and other demanding environments.

Low Decibel Linear Way LWE…Q

The Low Decibel Linear Way E is a linear motion rolling guide optimally designed based on a thorough analysis of steel ball re-circulation behavior and sound quality analysis. Due to a resin separator built-in between the balls, direct contact is eliminated and smooth and quiet motion is achieved. Especially in manufacturing machinery that uses several linear motion rolling guides, they can reduce the noise level in the factory, contributing to a better work environment for the employees.

- Slide units come in three shapes, two flange types for different mounting options and a block style with narrow width.

- Low decibel units are interchangeable with standard Linear Way E guides.

Linear Way LWH

Our Linear Way H rolling guides feature two rows of large-diameter steel balls in four-point contact with raceways to ensure high stability and accuracy, even under fluctuating and complex loads. The H series offers the largest load ratings and highest rigidity among all the ball guides.

- A wide range of interchangeable shapes and sizes for both slide units and track rails meet the needs of different applications.

- Slide units come in five shapes, two flange types for different mounting options, and three block styles with narrow widths.

- Lengths are also available in short, standard, and highly rigid long versions.

- Optional design choices include an ultra-seal specification for dust protection, stainless steel models for demanding environments, and miniature sizes with track rail widths of eight, 10, and 12 millimeters.

Linear Way LWF

IKO Linear Way F is a linear motion rolling guide with a highly rigid slide unit that performs endless linear motion over a wide track rail. Two rows of steel balls contact the raceway at four points with a high number of load-bearing balls. This enables stable high accuracy and rigidity even in applications where the load has variable direction and size or complex load is applied. Since it is wide, it is also resistant to moment load in the width direction, so it is suitable for single row use as well.

- Slide units come in three shapes, two flange types with different dimensions for top and bottom mounting and a block style with narrow width.

- Stainless steel versions enable use in cleanrooms and other demanding environments.

Linear Way LWU

The IKO Linear Way U is a linear motion rolling guide with a structure containing a raceway inside the U-section track rail and a slide unit in its interior. With the U-shaped track rail, rigidity against the track rail moment load and torsion is significantly improved. Therefore, it is possible to not only fix the track rail to the mounting base as conventionally done but to use the track rail as a structure beam, such as a cantilever or double-ended support in machines and equipment.

- U-shaped rails are rigid and can be used as structural components, either in a cantilever position or supported at both ends.

- Two rows of large-diameter steel balls in four-point contact with raceways ensure high stability and accuracy, even under fluctuating and complex loads.

- Slide units feature ball-retaining bands to prevent ball loss when removing slide units from rails.

ROLLER TYPE ROLLING GUIDES

IKO designs and manufactures several roller-type guides to achieve precise linear machine motion across a wide range of industries, from machine tools to semiconductor manufacturing. C-Lube Linear Roller Way Super MX guides and Linear Roller Way Super X LRX guides are high-performance roller style component families that offer high rigidity and high accuracy along with the repeatable and smooth linear motion.

C-Lube Linear Roller Way Super MX

C-Lube Linear Roller Way Super MX incorporates C-Lube lubrication into the Linear Roller Way Super X. The same high performance can be achieved for applications requiring high load capacity and running accuracies such as machine tools and semiconductor/liquid crystal-related manufacturing equipment, but with C-Lube, long-term, maintenance-free performance can also be realized. This reduces the cost of the whole system by reducing the running costs and the work hours required for lubrication.

- Built-in lubricating element provides long lasting, maintenance-free operation through capillary action. Zero maintenance for 20,000 km or five years.

- Superior dust protection is available with optional C-Wiper for continuous cleaning in extreme environments.

- Four rows of cylindrical rollers are enclosed in a highly rigid casing.

- Minimal elastic deformation ensures stable and reliable operation under heavy or fluctuating loads, as well as vibration and shock loads.

- Four slide unit lengths available including short, standard, high rigidity long and high rigidity extra long.

- Minimal lubrication requirements make our C-Lube products environmentally friendly.

- Interchangeable outside dimensions between MX and LRX series.

- Five sectional shapes available include: top or bottom mount flange type, top-mount low profile flange type, top-mount block type, top-mount compact block type, and top-mount low profile block type

C-Lube Linear Roller Way Super MX

C-Lube Linear Roller Way Super MX incorporates C-Lube lubrication into the Linear Roller Way Super X. The same high performance can be achieved for applications requiring high load capacity and running accuracies such as machine tools and semiconductor/liquid crystal-related manufacturing equipment, but with C-Lube, long-term, maintenance-free performance can also be realized. This reduces the cost of the whole system by reducing the running costs and the work hours required for lubrication.

- Built-in lubricating element provides long lasting, maintenance-free operation through capillary action. Zero maintenance for 20,000 km or five years.

- Superior dust protection is available with optional C-Wiper for continuous cleaning in extreme environments.

- Four rows of cylindrical rollers are enclosed in a highly rigid casing.

- Minimal elastic deformation ensures stable and reliable operation under heavy or fluctuating loads, as well as vibration and shock loads.

- Four slide unit lengths available including short, standard, high rigidity long and high rigidity extra long.

- Minimal lubrication requirements make our C-Lube products environmentally friendly.

- Interchangeable outside dimensions between MX and LRX series.

- Five sectional shapes available include: top or bottom mount flange type, top-mount low profile flange type, top-mount block type, top-mount compact block type, and top-mount low profile block type

Linear Roller Way Super X LRX

Our Linear Way E rolling guides feature an ultra-compact slide unit that allows continuous linear motion along the track rail. Two rows of steel balls make four-point contact with raceways to ensure high stability and accuracy, even under fluctuating and complex loads.

- A wide variety of interchangeable shapes and sizes for both slide units and track rails meet the needs of different applications.

- Slide units come in three shapes, two flange types for different mounting options and a block style with narrow width.

- Lengths are available in short, standard, and highly rigid long versions.

- Stainless steel versions for use in cleanrooms and other demanding environments.

Linear Roller Motion Guide LRWX…B

A roller-type linear motion rolling guide with cylindrical rollers in four rows. The well-balanced roller arrangement allows it to evenly withstand loads in all directions. Slide unit shapes include a flange type that can be mounted from either the top or bottom and a narrow block type.

- Evenly withstands loads in all directions.

- Cylindrical rollers are enclosed in a rugged case.

- The slide unit has a narrow block-type shape.

- Slide units are equipped with end seals and underseals for dust protection.

- Easy-to-mount bellows provide exceptional dust protection.

Linear Roller Motion Guide LRWXH

Like the LRWX…B, the LRWXH roller-type linear motion guide also provides four rows of cylindrical rollers, well-balanced load handling, and many of the same great features.

- Evenly withstands loads in all directions.

- Cylindrical rollers are enclosed in a rugged case.

- The flange-type slide unit mounts from the bottom.

- Slide units are equipped with end seals and underseals for dust protection.

- Easy-to-mount bellows provide exceptional dust protection.

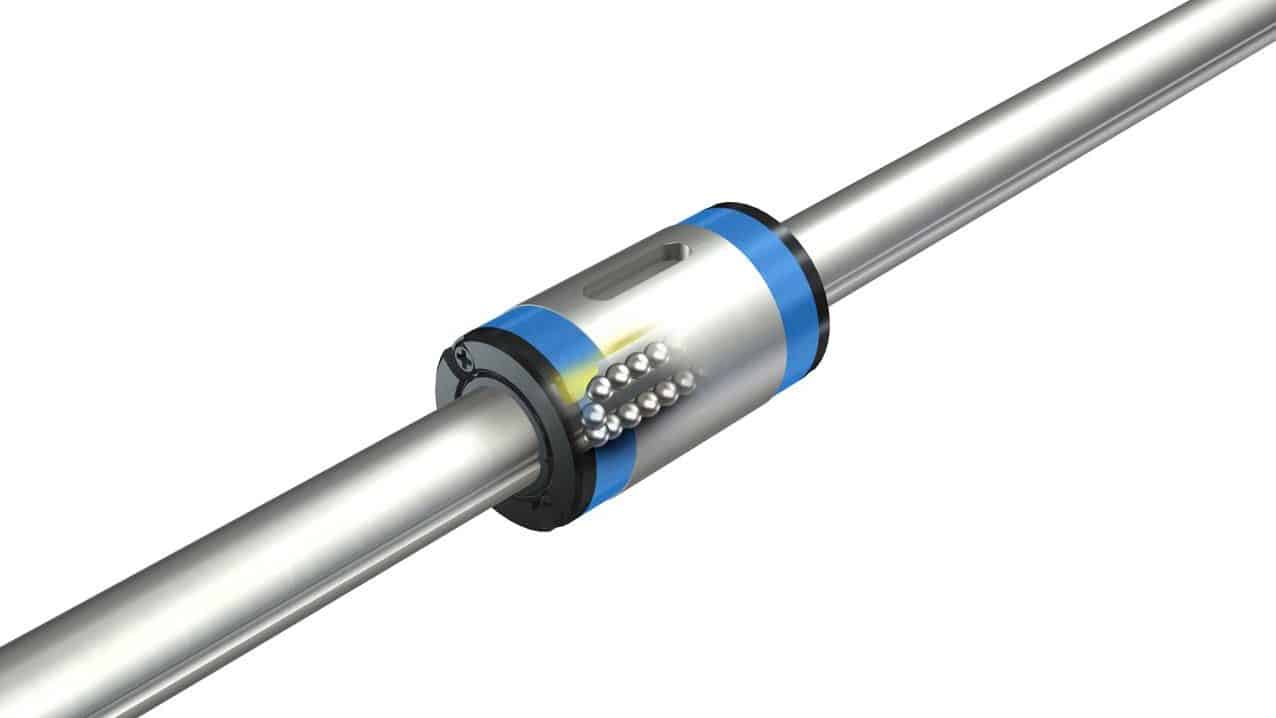

BALL SPLINE LINEAR GUIDES

IKO designs and manufactures a variety of compact ball spline guides to achieve precise linear motion across a diverse range of applications, from medical equipment to semiconductor manufacturing. External cylinders enable smooth linear motion along a spline shaft.

C-Lube Linear Ball Spline MAG Guides

C-Lube Linear Ball Spline MAG incorporates C-Lube in the IKO Ball Spline G. MAG is used primarily in semiconductor/liquid crystal-related manufacturing equipment where harsh operating conditions and high acceleration/deceleration are common. C-Lube provides long-term, maintenance-free operation, and reduces the cost of the whole system by eliminating the oil supply mechanism and reducing the running cost and hours required for lubrication.

- Built-in lubricating element offers long-lasting, maintenance-free operation through capillary action. Zero maintenance for 20,000 km.

- Environmentally friendly due to minimal lubrication requirements.

- Interchangeable specifications allow external cylinders and spline shafts to be mixed and matched easily to meet the needs of specific applications.

- Four-point contact, double-row raceway design ensures high accuracy and rigidity, even under fluctuating and complex loads.

- External cylinder designs include a standard cylindrical shape as well as a flange type.

- Cylinder length options come in both standard and high rigidity long versions for design flexibility.

- Six models offer spline shaft diameters of 4 to 12 mm.

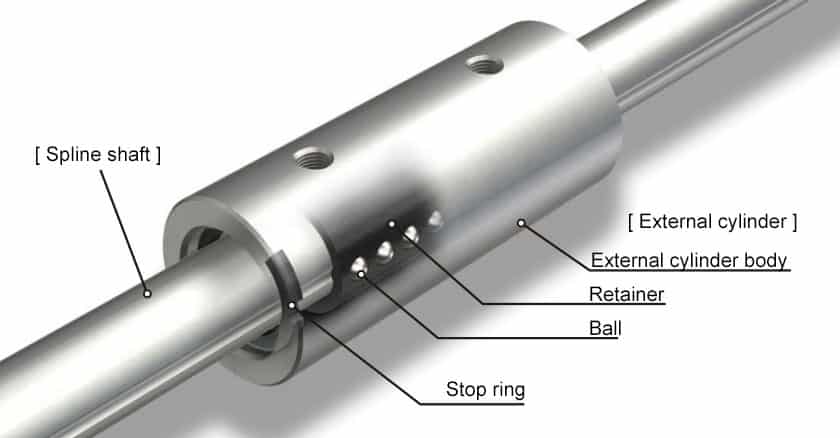

Linear Ball Spline G Guides

The IKO Linear Ball Spline G is a linear motion rolling guide in which an external cylinder performs endless linear motion along a spline shaft. Since two rows of steel balls come in contact with the raceway surface at four points, stable accuracy and rigidity can be achieved, even in applications where load with variable direction and size, or complex load is applied. The linear ball spline is extremely compact, thanks to its simple structure.

- Interchangeable specifications allow external cylinders and spline shafts to be mixed and matched easily to meet the needs of specific applications.

- Four-point contact, double-row raceway design ensures high accuracy and rigidity, even during fluctuating and complex loads.

- External cylinder designs include a standard cylindrical shape as well as a flange type.

- Cylinder length options come in both standard and high rigidity long versions for ultimate flexibility. Cylinders may also be customized to fit a wide variety of applications.

- Solid and hollow shafts are available to suit different needs.

- Eight models offer spline shaft diameters of 2 to 50 mm.

Block Type Linear Ball Spline LSB guides

The IKO Block Type Linear Ball Spline is a linear motion rolling guide in which the slide unit performs endless linear motion along the spline shaft. Since two rows of steel balls come in contact with the raceway surface at four points, stable accuracy and rigidity can be achieved even in applications where load with variable direction and size or complex load is applied.

- Interchangeable specifications allow slide units and spline shafts to be mixed and matched easily to meet the needs of specific applications.

- Four-point contact, double-row raceway design ensures high accuracy and rigidity, even under fluctuating and complex loads.

- Easy installation due to slide units featuring threaded mounting holes.

- Stainless steel version offers excellent corrosion resistance for use in clean environments such as semiconductor manufacturing.

- Solid and hollow shafts available to suit different application needs.

- Three models offer spline shaft diameters of 6 to 25 mm.

Stroke Ball Splines

Achieved Extremely Smooth Motion

By building the high accuracy cage into the limited stroke type with small recirculation resistance of the balls, a light and smooth motion with extremely small fluctuation of frictional resistance even in vertical shaft use has been achieved.

High Rigidity and Precision at a Compact Size

By adopting a structure in which large-diameter steel balls are arranged in two rows in contact with the raceway at four points, it has achieved a compact external cylinder diameter with respect to the shaft diameter and high rigidity in all directions. Since an appropriate preload is provided, there is no clearance in the rotational direction and accurate positioning is possible.

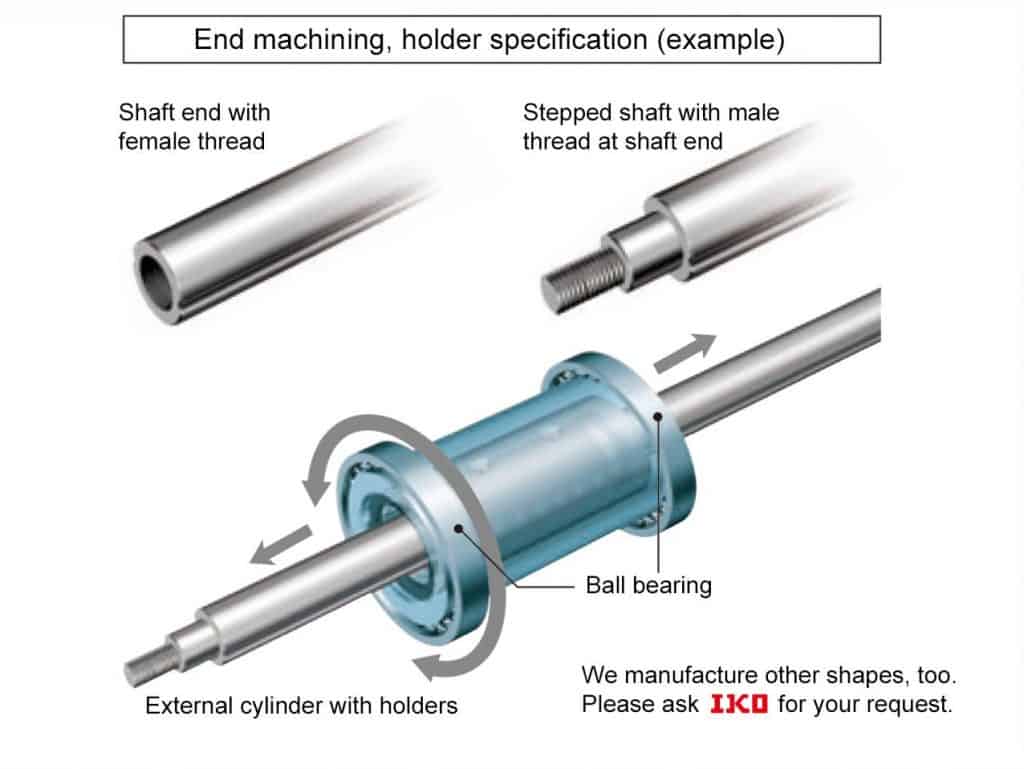

Supports Special Shapes

We manufacture special shapes to meet the customer’s uses, such as end machining and external cylinders with holders.

- Four-point contact, double-row raceway design ensures high accuracy and rigidity, even during high speeds and high acceleration/deceleration.

- Regularly specified in semiconductor and liquid crystal manufacturing equipment.

- Two models offer spline shaft diameters of 4 to 6 mm.

OTHER LINEAR MOTION ROLLING GUDES

IKO designs and manufactures a variety of heavy-duty, functional guides to achieve high precision linear machine motion across a diverse range of applications such as medical equipment and semiconductor manufacturing. A wide range of specialty designs is available, from crossed roller ways that prevent cage creeping to precision slide units for cleanroom operation.

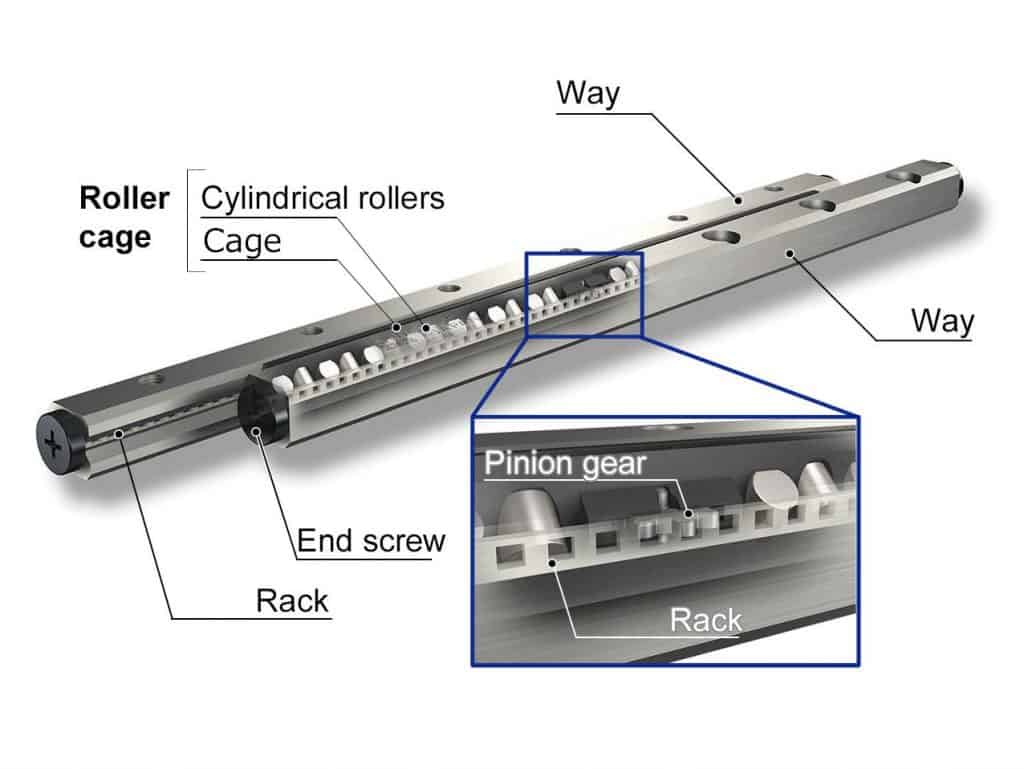

Crossed Roller Way Guides (CRW, CRWM)

Crossed Roller Way Guides (CRW, CRWM) features a unique design that incorporates a roller cage between two linear ways with V-shaped surfaces that act as track grooves. Because the cylindrical rollers are alternately crossed, this specialized structure can handle loads in any direction while facilitating highly accurate and smooth linear motion.

- The standard model (CRW) features four ways and two roller cages.

- The module version (CRWM) combines two inner ways into a single component.

- Stainless steel versions of the CRW type are available in multiple sizes for superior corrosion resistance.

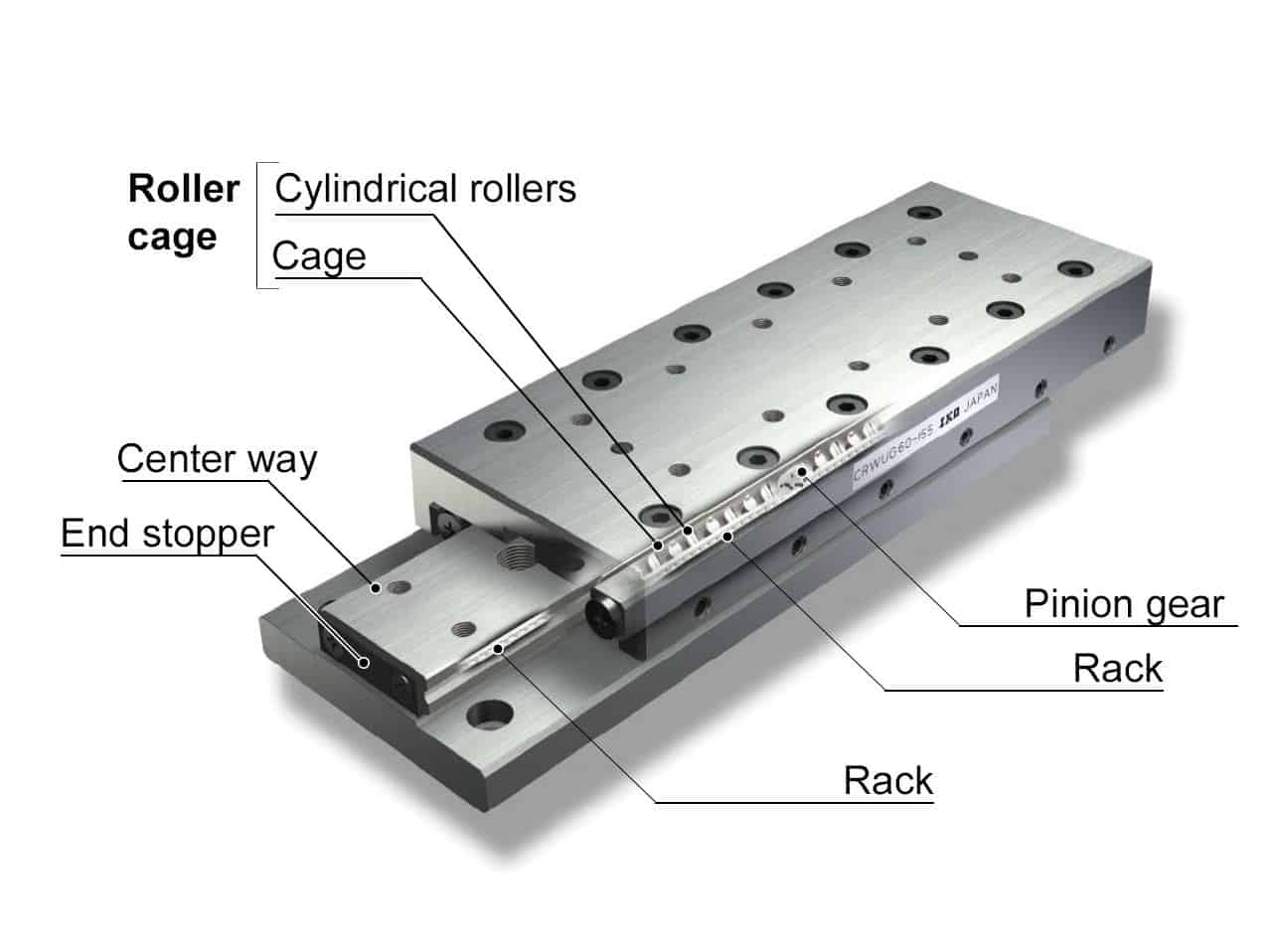

Crossed Roller Way Units (CRWU) and Anti-Creep Crossed Roller Way Units (CRWUG)

The IKO Crossed Roller Way Unit consists of a Crossed Roller Way (CRW) mounted to a highly rigid table and bed. It performs smooth, limited linear motion with low elastic deformation and high rigidity. It can handle loads in every direction and is available in various sizes that can be selected according to the application.

- Three sectional shapes and multiple sizes are available.

- The anti-creep version includes:

- A rack and pinion mechanism that eliminates cage creep

- Highly accurate and stable linear motion

- Suitable for use on a vertical axis.

High Rigidity Precision Linear Slide Units (BWU)

High Rigidity Precision Linear Slide Units (BWU) are compact slides for limited stroke lengths. Slides incorporate two rows of steel balls in four point contact with raceways for stable and highly rigid linear motion, even under complex loads.

- All components are made of stainless steel for excellent corrosion and heat resistance.

- They are suitable for use in cleanrooms.

- Multiple sizes are available.

Miniature Linear Bushings (LMS)

The IKO Miniature Linear Bushing is an extremely small linear motion rolling guide with a shaft diameter of 3 to 5 mm that performs endless linear motion in the axial direction while making rolling contact with the shaft. Cage, steel balls, and stop ring are compactly built in the external cylinder, allowing high feed accuracy to be obtained.

- Both standard and high-rigidity long versions are available.

- Stainless steel models for excellent corrosion resistance.

Stroke Rotary Cages (BG)

The IKO Stroke Rotary Bushing is a linear motion rolling guide with a small diameter and sectional height. It can provide rotary and linear motion in the axial direction simultaneously with rotational motion. It is extremely compact, has high accuracy, and smooth motion with low frictional resistance, making it suitable for various measuring instruments, IC manufacturing devices, precision machines, or other small and highly accurate parts.

- Highly rigid, lightweight retainers have low inertia and are suitable for abrupt operation.

- Large load ratings and high rigidity keep elastic deformation to a minimum, even under fluctuating and offset loads.

Stroke Rotary Bushings (ST)

Stroke Rotary Bushings (ST) enables simultaneous rotary and linear motion with a specialized design that combines an external cylinder with a cylindrical raceway and balls incorporated in the retainer. The high rigid, lightweight retainer experiences minimal inertia and is well-suited for both rolling and reciprocal motion during high-speed operation.

- Standard and heavy load models are available, each offered with or without seals.

- Miniature stroke rotary bushings (STSI) are also available and feature tiny balls incorporated in a retainer and an external cylinder.

- Choose models with or without shafts.

ROTARY MOTION

IKO designs and develops needle roller bearings to enable reliable and smooth rotational motion in numerous applications. This unique design incorporates a thin, needle-shaped roller into the moving element to achieve high load capacity in a small footprint.

Rotary Motion Products

- Lower cross-section height and higher load capacity than traditional ball bearings.

- Small and compact for reduced overall machine size in lightweighting efforts.

- Widely used in automobiles, motorcycles, printing presses, industrial robots, construction equipment and other demanding applications.

- Many styles to choose from including: radial, thrust and combined models, cam followers and roller followers.

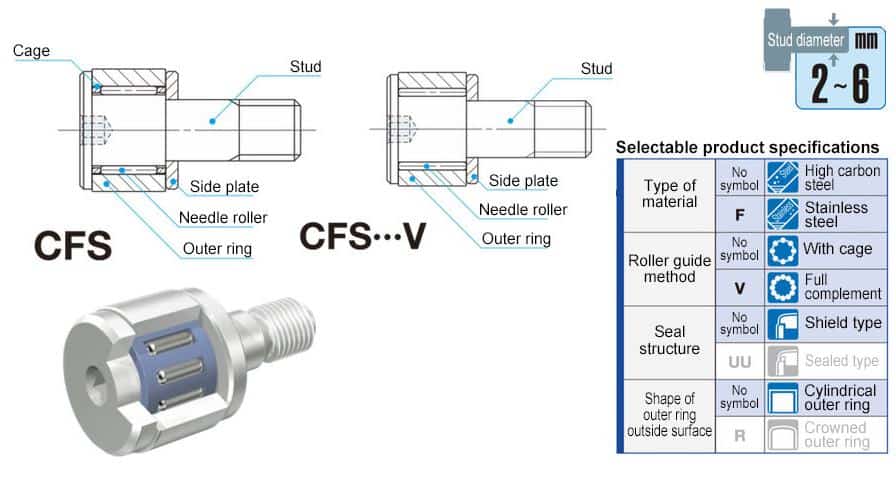

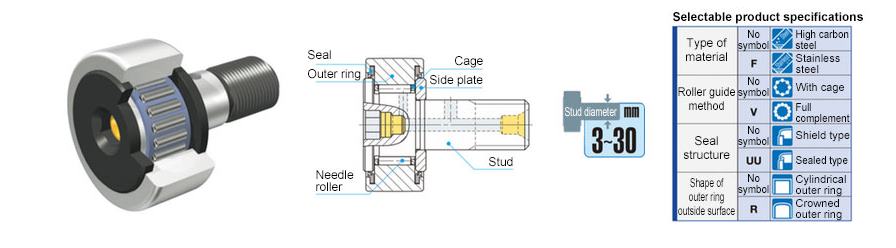

IKO CAM FOLLOWERS

IKO designs and manufactures a broad selection of cam followers to meet the diverse needs of applications including machine tools, industrial robots, electronic parts production, and office automation equipment. A cam follower is a bearing that incorporates needle style rollers between a stud and a thick outer ring.

- Small coefficient of friction.

- Excellent rotational performance designed for outer ring revolution.

- High load capacity by design—radial gap is smaller than within the general needle roller bearings, alleviating impact load and increasing lifetime.

- Easy attachment with either hexagon sockets or screw driver slots.

- Multiple shapes and styles are available to fit a variety of applications. Followers are available with a cage or full complement design, shield or sealed versions, and either spherical or cylindrical outer rings.

- Sizes, materials and design options abound; ranging from miniature and standard models to eccentric styles and those with thrust disks. Stainless steel versions resist corrosion and are suitable for clean room applications.

CR…VBS Cam Followers

CR…VBS Series cam followers feature our proprietary ThrustDisk™ sealing technology along with a radial gap to alleviate impact loading.

Handles axial loads, preventing wear and friction caused by mounting errors.

Resists heat and contamination for an improved lifetime.

Stud diameters range from 4.8 to 9.5 mm.

Standard Cam Followers

Standard cam followers are the basic style and suit a wide range of applications.

- Easy lubrication with oil supplied from the stud head with a hexagon socket design.

- Stud diameters range from 3 to 30 mm.

.

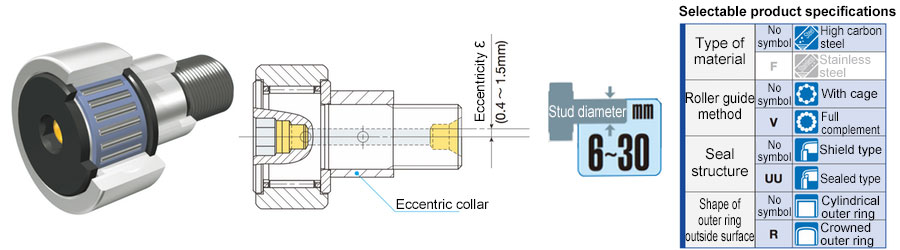

Eccentric Type Cam Followers CFE

In these bearings, an eccentric collar is assembled with the stud, enabling the outer ring to be positioned easily in the radial direction against the mating track surface. The eccentricity is 0.4 mm to 1.5 mm.

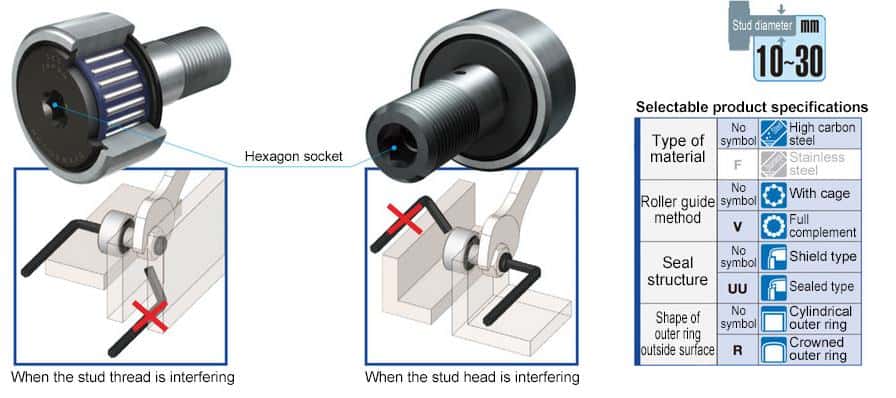

Standard Type Cam Followers CFKR (Double Hex Hole)

Cam Followers are bearings with a stud incorporating needle rollers in a thick-walled outer ring. These bearings are designed for outer ring rotation with superior rotational performance, a low coefficient of friction, and high load capacity. Double Hex Hole Cam Followers have a structure with hexagon sockets at each end of the stud, allowing for use in any mounting location.

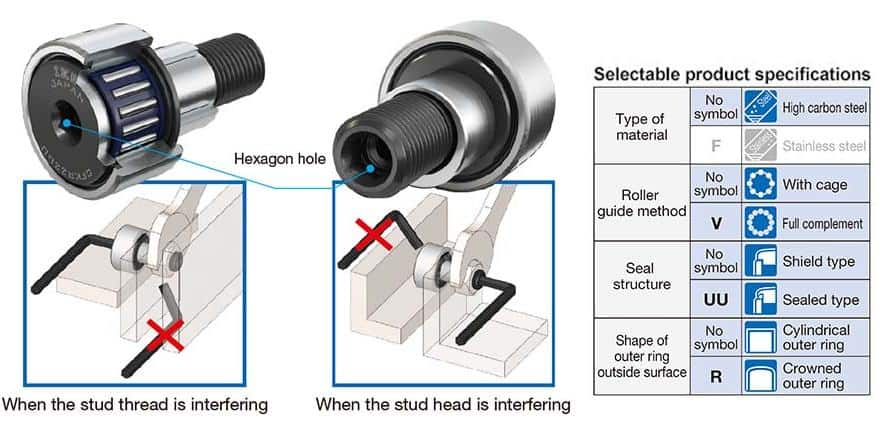

Eccentric Type Cam Followers CFKRE (Double Hex Hole)

Cam Followers are bearings with a stud incorporating needle rollers in a thick-walled outer ring. These bearings are designed for outer ring rotation with superior rotational performance, a low friction coefficient, and high load capacity. CFKRE has a structure with hexagon holes at the end of each stud, making it possible to mount from any location. With an eccentric collar, it also enables easy height positioning adjustment by rotating the stud.

Miniature Type Cam Follower Series

These bearings are compactly designed, incorporating very thin needle rollers in an outer ring with a small outside diameter relative to the stud diameter. They are used in electronic devices, OA equipment, and small index devices, etc.

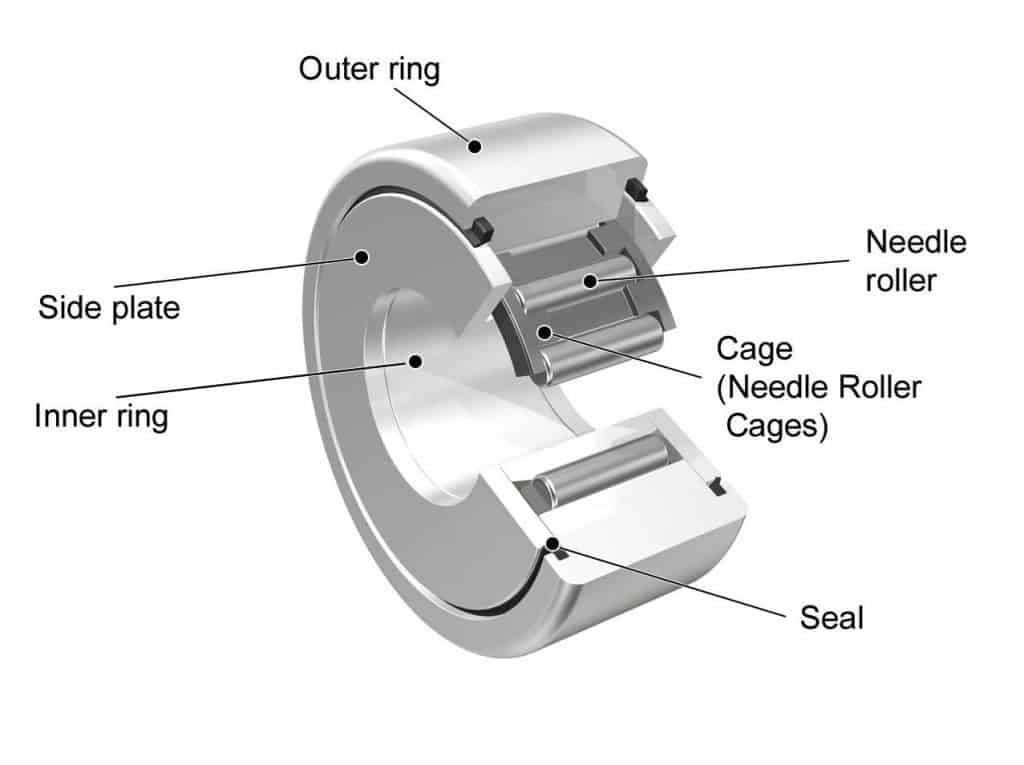

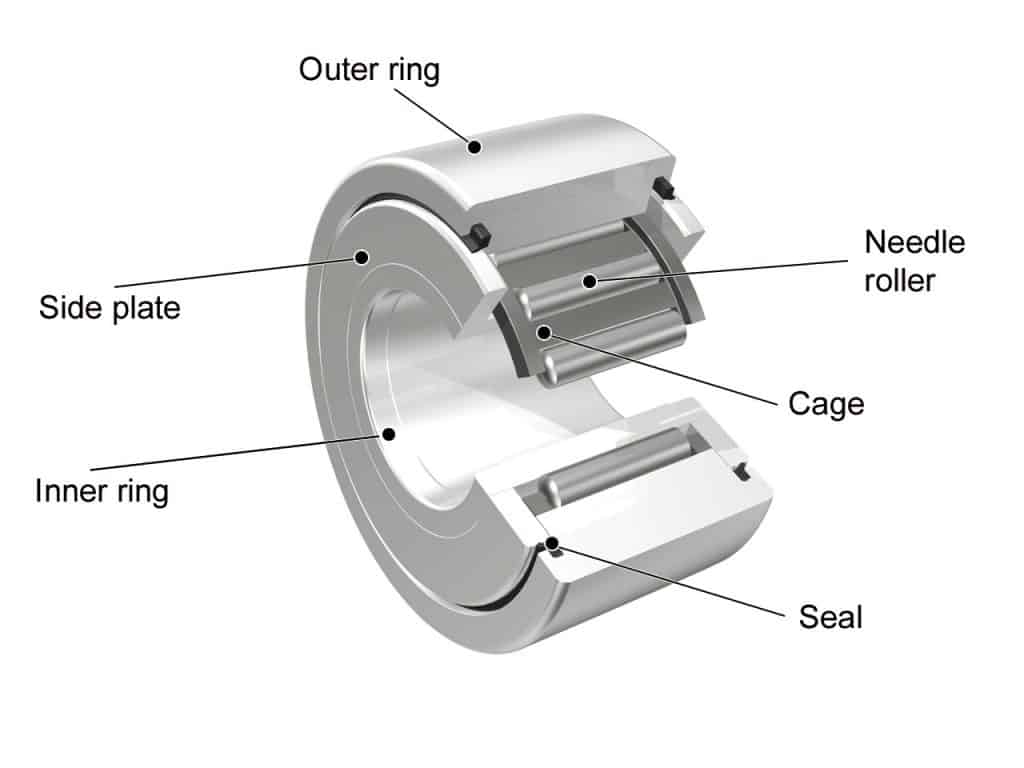

IKO ROLLER FOLLOWERS

IKO Roller Followers are bearings with needle rollers in the thick outer ring that are designed for outer ring rotation. There are separable and non-separable models, double row cylindrical, and other models available. Roller Followers are widely used as follower bearings for various cam mechanisms and as guide rollers for linear motion in conveying equipment.

Separable Roller Followers

C-Lube Linear Roller Way Super MX incorporates C-Lube lubrication into the Linear Roller Way Super X. The same high performance can be achieved for applications requiring high load capacity and running accuracies such as machine tools and semiconductor/liquid crystal-related manufacturing equipment, but with C-Lube, long-term, maintenance-free performance can also be realized. This reduces the cost of the whole system by reducing the running costs and the work hours required for lubrication.

Non-Separable Roller Followers

These non-separable type bearings have side plates press-fitted on both sides of the inner ring. Types include caged and full complement, as well as shield and sealed types. These bearings are also available in a high corrosion-resistant stainless steel specification, suitable for applications where rust prevention oil cannot be used, such as in cleanroom environments. Inch series non-separable roller followers are full complement type bearings with a black oxide surface treatment.

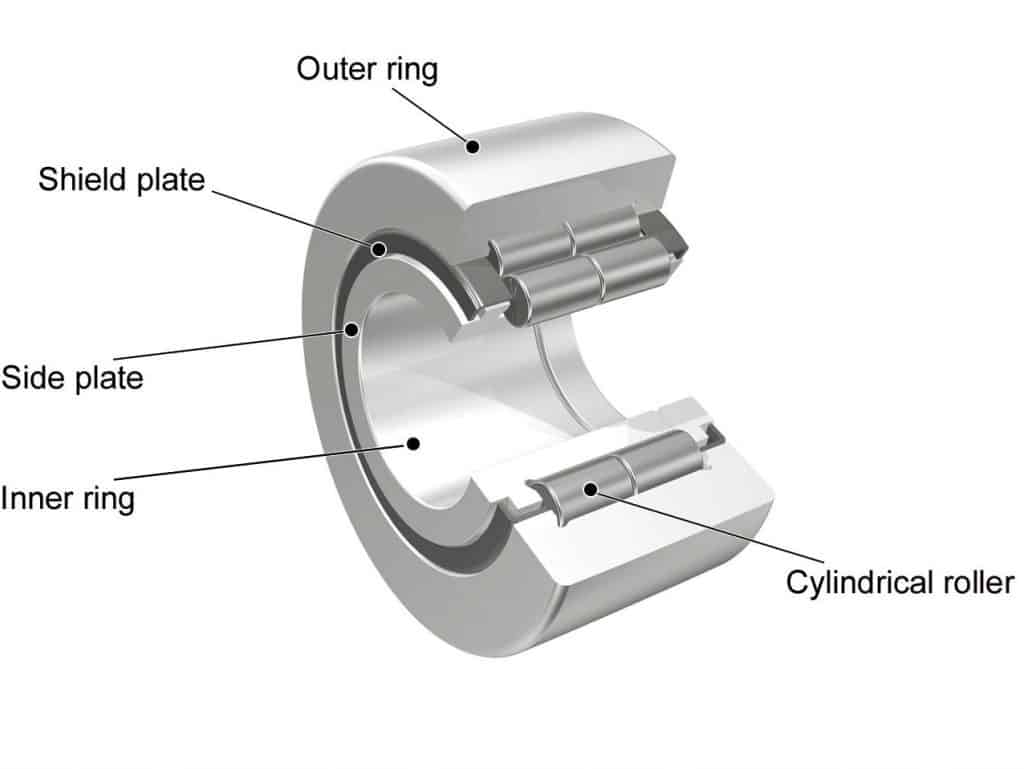

Cylindrical Roller Followers

These bearings are full complement type bearings incorporating double rows of full complement cylindrical rollers in the outer ring. They can withstand large radial loads. Additionally, the outer ring is guided by the outer ring shoulder and the end face of the cylindrical rollers to the axial direction.

C-Lube Roller Followers

These Roller Followers are lubricated with C-Lube, a thermosetting solid-type lubricant which fills the inner space of the bearing. C-Lube is lubricant made of a lot of lubrication oil and fine particles of super-high molecular polyolefin that are solidified by heat treatment. As the bearing rotates, the lubricating oil oozes out onto the raceway surface in proper quantities, maintaining the lubrication performance for a long period of time.

IKO CROSSED ROLLER

BEARINGS

IKO designs and manufactures a variety of crossed roller bearings that can handle radial, thrust and moment loads at the same time. These compact bearings feature rollers crossed at right angles between inner and outer rings.

- Widely used in machine tools, industrial robots and medical equipment because of their high rotational accuracy.

- Roller guide options include a cage or separator as well as a full complement design. Both the cage and separator styles offer a small coefficient of friction for high-speed rotation. Full complement bearings handle heavy loads at low speeds.

- Sealed and open designs are available. Sealed bearings incorporate synthetic rubber seals to protect against dust, dirt and grease.

High Rigidity Type Crossed Roller Bearing V

High Rigidity Type Crossed Roller Bearing V has a solid one-piece construction for both inner and outer rings. Therefore, high accuracy and high rigidity are achieved, and mounting errors can be minimized. As separators are incorporated between the cylindrical rollers for smooth rotation, these bearings are suitable for applications where rotation speed is comparatively high. These bearings are widely used in the rotating parts of industrial robots, machine tools, medical equipment, etc., which require compactness, high rigidity and high rotational accuracy. In addition, bearings made of stainless steel and those with inner and outer rings provided with mounting holes are also available on request. Please contact IKO.

Features

Rollers are arranged by intersecting orthogonally between inner ring and outer ring of the single structure. A separator, which can smoothly rotate rollers, is incorporated between rollers.

Mounting Holed Type High Rigidity Crossed Roller Bearing V

The Mounting Holed Type High Rigidity Crossed Roller Bearing has an integral structure (non-split) for both the inner and outer rings, with mounting holes that allows it to be easily attached to equipment. Further it is less subject to peripheral structures such as housing or pressure plate and realizes high rigidity and high-accuracy guidance.

Features

Rollers are arranged by intersecting orthogonally between inner ring and outer ring of the single structure. A separator, which can smoothly rotate rollers, is incorporated between rollers.

The mounting holes in both inner and outer rings facilitate installation to your equipment.

An open type and a sealed type are available. The sealed type incorporates special synthetic rubber sealing.

Standard Type Crossed Roller Bearings

These bearings are full complement type bearings incorporating double rows of full complement cylindrical rollers in the outer ring. They can withstand large radial loads. Additionally, the outer ring is guided by the outer ring shoulder and the end face of the cylindrical rollers to the axial direction.

Super Slim Type Crossed Roller Bearings

Super Slim Type Crossed Roller Bearings are extremely compact bearings with 5.5 mm sectional height and 5 mm width. Separators are incorporated between cylindrical rollers for smooth rotation. Contributes to making machines or equipment more compact and lightweight.

Features

The cross sectional height is reduced by 69% in comparison with the Slim Type Crossed Roller Bearing CRBS, previously the slimmest. The width is also as small as 5 mm and the cross sectional area is reduced by 43% in comparison with conventional products. Also, the mass ratio is 0.38, realizing significant weight saving in comparison with CRBS. (compared with a product with bearing bore diameter of 50 mm)

Mounting Holed Type Super Slim Crossed Roller Bearings

Mounting Holed Type Super Slim Crossed Roller Bearings CRBTF is a compact and light weight bearings which mounting holes are prepared on both inner and outer ring of Super Slim Type Crossed Roller Bearings with the ultra-slim 5mm bearing width to make mounting to equipment easier.

Features

1.We achived the ultra-slim 5mm bearing width by IKO technology of miniature bearings production, and this bearing contributes to make equipments more compact.

2. Complicated mounting structures are not neccesary thanks to the mounting holes provided to both innner and outer rings which make it possible to mount directly to the mounting surface without a housing or a pressure plate.

Slim Type Crossed Roller Bearings

CRBS

Slim Type Crossed Roller Bearings are slim bearings having a small outside diameter against the bore diameter and a narrow width. In addition, types with cage, types with separator, and full complement types are available, which can be selected according to the intended use.

IKO THRUST BEARINGS

IKO designs and manufactures thrust bearings with precisely machined cages and rollers to handle high axial loads in confined spaces. Two styles are available—thrust needle roller bearings and thrust roller bearings.

Thrust Needle Roller Bearings

IKO Thrust Bearings consist of precisely machined cages and rollers. They have high rigidity and high load capacity and can be used in small spaces. Thrust Needle Roller Bearings use needle rollers, while Thrust Roller Bearings use cylindrical rollers. Various types of raceway rings are available, and can be selected according to the operating conditions. When the bearing mounting surface of a machine is heat-treated and finished by grinding, Thrust Bearings can be used without raceway rings, making the machine more compact. They are best suited for applications where high accuracy is required at high speeds and under fluctuating heavy loads, such as the drive mechanisms for automobiles, machine tools, and high-pressure pumps.

NTB WS GS

These bearings consist of a cage made from a steel plate, which is precisely press formed and surface-hardened, and needle rollers with a diameter variation within 2μm. They have a rigid structure and a high lubricant-retaining capacity. As they have the lowest sectional height compared with other thrust bearings, they can be used instead of conventional thrust washers and can withstand high-speed rotations with a low coefficient of friction.

AZK AZ

In this series, the caged cylindrical rollers, AZK, and the complete bearings, AZ, in which AZK are combined with an inner ring (WS) and an outer ring (GS) are available. The cage has a special precise structure which is highly rigid. The cylindrical rollers are outwardly arranged and guided by the cage with exact precision to enable them to withstand heavy loads, even at high rotation speeds.

IKO COMBINED NEEDLE ROLLER BEARINGS

IKO manufactures an economical series of combined needle roller bearings, comprised of both radial and thrust bearings. Caged needle roller bearings act as radial bearings, while thrust ball or roller bearings serve as thrust bearings. This series is available in four styles, including designs that incorporate thrust ball bearings, thrust roller bearings, angular contact ball bearings or three-point contact ball bearings. Applications include machine tools, textile equipment and industrial machinery.

Combined Type Needle Roller Bearings

NAX NBX NATA NATB

IKO Combined Type Needle Roller Bearings are combinations of a radial bearing and a thrust bearing. Caged Needle Roller Bearings are used as radial bearings and thrust ball bearings or thrust roller bearings are used as thrust bearings. They are compact and very economical, and can be subjected to radial loads and axial loads simultaneously. They are widely used for machine tools, textile machinery, and industrial machinery.

PLAIN BEARINGS

Our plain bearings ensure articulating systems perform their best and support heavy and complex loads. Our lineup includes many styles of spherical bushings, as well as rod ends to address misalignment and other angular motion challenges. These units are ideal for a wide range of machines and equipment in industries like general industrial, automotive, construction, agriculture and packaging.

Spherical Bushings

SB SBB GE

IKO Spherical Bushings are compact self-aligning spherical bushings with inner and outer rings in contact with the sphere, which can support a large radial load and a bi-directional axial load at the same time. There are many models of Spherical Bushings, but they are basically divided into steel-on-steel types and maintenance-free types according to the kind of sliding surfaces. Steel-on-steel Spherical Bushings have inner and outer rings of high-carbon chromium bearing steel, of which sliding surfaces are phosphate-treated and then dry-coated with molybdenum disulfide (MoS2). They can, therefore, operate with low torque, and have excellent wear resistance and large load capacity. They are especially suitable for applications where there are alternate loads and shock loads. They have wide applications mainly in industrial and construction machinery. Maintenance-free Spherical Bushings consist of an outer ring which has a special PTFE liner reinforced with copper alloy meshes on the sliding surface, and a spherical inner ring of which sliding surface has a hard chromium plating. Creep deformation due to compressive load is small, and wear resistance is superior. Thus, they are maintenance-free and can be used for extended periods of time without re-lubrication. They are especially suitable in cases where fixed directional loads are applied and are used mainly in food processing machines and construction machinery and in other applications in which the use of oil is undesirable or lubrication is not possible.

PILLOBALLS

PB PHS PHSA POS

IKO PILLOBALLs are compact self-aligning spherical bushings which can support a large radial load and a bi-directional axial load at the same time. These bearings are available in insert type, die-cast type and lubrication-free type depending on the type of sliding surface. In the insert type, a spherical inner ring makes contact with a special copper alloy bushing with superior run-in properties. In the die-cast type, a spherical inner ring makes direct contact with the bore surface of the body of special zinc die-cast alloy. In the maintenance-free type, a spherical inner ring makes contact with a special self-lubricating PTFE liner. Thus, a smooth rotational and oscillatory motion can be achieved with superior anti-wear and load properties in each type. PILLOBALL Rod Ends have either a female thread in the body or a male thread on the body, so they can be easily assembled onto machines. They are used in control and link mechanisms in machine tools, textile machines, packaging machines, etc. The maintenance-free type is especially suitable for loading in one direction and is the best choice for machines in which oil must be avoided such as food processing machines, or machines which cannot be re-lubricated.

L-Balls

LHS LHSA

IKO L-Balls are self-aligning Spherical Bushings consisting of a special zinc die-cast alloy body and a studded ball which has its axis at right angles to the body. They can perform tilting movement, oscillating movement and rotation with low torque, and transmit power smoothly due to uniform clearance between the sliding surfaces. Their superior wear resistance assures stable accuracy for long periods of time, and maintenance is simple. They are very economical bearings. For these reasons, they are widely used in link mechanisms in automobiles, constructio

Super Flexible Nozzles

SNA SNM SNPT

The IKO Super Flexible Nozzle is a compact nozzle used on machine tools to supply and spray cutting oil exactly at a specified location. Since the angle of the nozzle can be easily changed, the oil supply can be concentrated on the working area, and cooling and lubrication can be performed effectively. As a result, cutting resistance is reduced and superior finish is obtained, achieving high machining accuracy. The tool life can also be extended, which can result in cost savings. The Super Flexible Nozzle can be used at the spindle end of machining centers and at the tool holder of an NC lathe.

TFL Bearings can provide most of the bearing products in the IKO BEARINGS catalog. If you need our help, we are happy for you, you can fill out our online form and bearing engineers exchange.

Category

Find more products in China.

You can contact us any convenient way. We are available 24/7 via fax or email.

You can also use the quick contact form below or visit our office personally. Please email us with any questions or inquires or use our contact data. We would be happy to answer your questions.