FSI 50-5K4 R50-5K6 series High precision Linear motion screw in stock

Key attributes

Other attributes

Applicable Industries

Food Shop, Printing Shops, Energy & Mining

Weight (KG)

0.5

Showroom Location

Canada, Germany, Russia, Japan, Malaysia

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Ordinary Product

Warranty of core components

1 Year

Core Components

Bearing

Place of Origin

Taiwan, China

Condition

New

Warranty

1.5 years

Manufacturing Process

Rolled Thread

Material

Imported bearing steel

Length

40mm

Brand Name

HIWIN

Product’s name

Ball Screw

Model NO

50-5K4

Material

Bearing Steel

Precision Rating

P

Market

Global

Package

Standard

Stock

in stocks

Feature

High rigidity;Super smooth;High precision

Sample

Accpet

Application

3D printer; Transmission machinery;CNC machine;Medical instruments

FSI 50-5K4 R50-5K6 series High precision Linear motion screw in stock

Ball screw is also called ball screw, lead screw, etc. It includes screw, nut, circulation system and steel balls. Ball screws are used for machine tools, IT, optoelectronics. The most commonly used transmission element in precision equipment such as semiconductors and medical equipment. Its main function is to convert rotational motion into linear motion or convert torque into axial motion. Repeated force; it also has the characteristics of high precision, reversibility and high efficiency.

Features of HIWIN ball screw: HIWIN precision screws have high smoothness and precise positioning, as well as low torque, high rigidity, ultra-quiet and predictable long life. HIWIN engineered grade screw also has the advantages of high smoothness, long life and low price; it is generally used in situations where accuracy is not required. HIWIN ball screws have many advantages in use, such as high efficiency, reversibility, zero backlash, high rigidity, high lead accuracy and many other advantages. Compared with traditional ACME screws; ball screws Add steel balls between the screw rod and the nut. The sliding friction transmission of the traditional screw is replaced by the rolling motion of steel balls. This greatly reduces friction loss and helps maintain high efficiency and precision. The following details the various characteristics and advantages of HIWIN ball screws.

HIWIN Ball Screw Because the screw shaft and nut of the ball screw are point contact rolling motion, its efficiency can be as high as over 90%. Therefore, its transmission torque is only 1/3 of the traditional guide screw, and the mechanical efficiency of the ball screw is much higher than that of the traditional guide screw. The HIWIN ball screw adopts ultra-precision processing on the tooth surface to reduce the contact friction between the ball groove and the steel ball. The rolling motion between the steel ball and the ball groove is point contact, which has the advantages of low friction and high operating efficiency. Therefore, the motor driving force requirements can be reduced, thereby reducing costs. HIWIN uses high-precision testing instruments and follows standard testing procedures to ensure the efficiency of the ball screw.

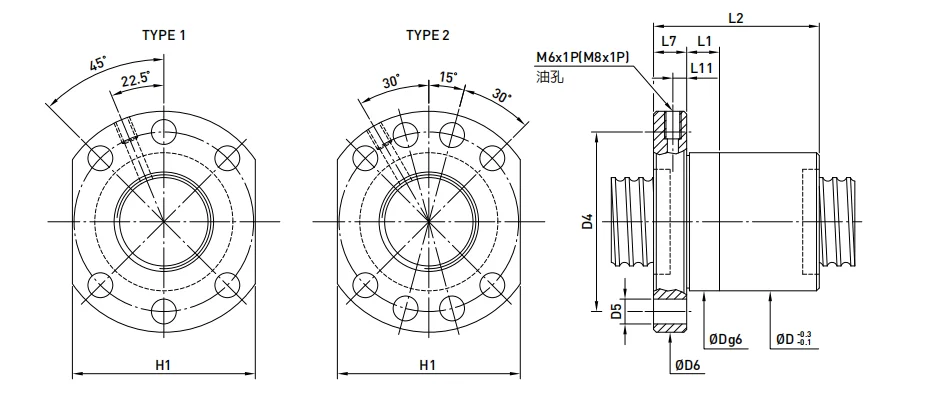

|

Model No

|

Nominal outer diameter

(mm) |

Lead

(mm) |

L2(mm)

|

dynamic load

C(kgf) |

static load

Ca(kgf) |

|

15-5K3

|

15

|

5

|

38

|

990

|

1580

|

|

16-5T3

|

16

|

5

|

40

|

1000

|

2000

|

|

20-5K3

|

20

|

5

|

36

|

1280

|

2410

|

|

20-5K4

|

20

|

5

|

40

|

1670

|

3270

|

|

25-5K3

|

25

|

5

|

38

|

1420

|

3050

|

|

25-5K4

|

25

|

5

|

43

|

1850

|

4150

|

|

25-10K5

|

25

|

10

|

70

|

2260

|

5200

|

|

32-5K4

|

32

|

5

|

38

|

2070

|

5360

|

|

32-5K6

|

32

|

5

|

48

|

2980

|

8190

|

|

32-10T3

|

32

|

10

|

74

|

3650

|

8660

|

|

32-10T4

|

32

|

10

|

85

|

4680

|

11550

|

|

32-10K5

|

32

|

10

|

73

|

3390

|

8160

|

|

32-10K6

|

32

|

10

|

83

|

3990

|

9860

|

|

40-5K4

|

40

|

5

|

40

|

2240

|

6590

|

|

40-5K6

|

40

|

5

|

50

|

3220

|

10060

|

|

38-10K3

|

38

|

10

|

60

|

4350

|

9140

|

|

40-10T3

|

40

|

10

|

74

|

4030

|

10680

|

|

38-10K4

|

38

|

10

|

70

|

5660

|

12410

|

|

40-10T4

|

40

|

10

|

87

|

5170

|

14240

|

|

50-5K4

|

50

|

5

|

40

|

2450

|

8330

|

|

50-5K6

|

50

|

5

|

50

|

3530

|

12720

|

|

50-10K3

|

50

|

10

|

60

|

4960

|

12240

|

|

50-10K4

|

50

|

10

|

70

|

6450

|

16610

|

|

50-10K6

|

50

|

10

|

90

|

9280

|

25350

|

|

63-10K6

|

63

|

10

|

94

|

10180

|

31750

|

|

8-2.5T2

|

8

|

2.5

|

23.5

|

133

|

178

|

|

10-2.5T2

|

10

|

2.5

|

25

|

178

|

263

|

|

10-4T2

|

10

|

4

|

32

|

198

|

282

|

|

12-4B1

|

12

|

4

|

34

|

344

|

574

|